Measuring method and measuring device of elastohydrodynamic lubrication line contact pressure based on photoelasticity

An elastohydrodynamic lubrication line and contact pressure technology, which is applied in the application of optical methods to fluid pressure measurement, etc., to achieve high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of this law will be further described below in conjunction with the accompanying drawings and examples, but the specific implementation and protection scope of the present invention are not limited thereto.

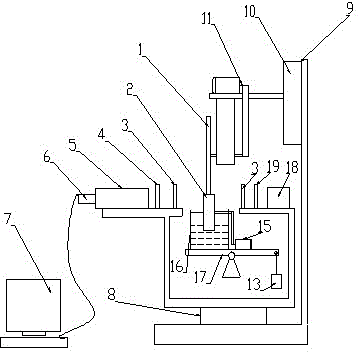

[0020] Such as figure 1 , the photoelastic elastohydrodynamic lubrication line contact pressure measurement device consists of a stereo microscope 5, an imaging recording device 6 (such as a video camera), a polarizer 19, an analyzer 4, a 1 / 4 wave plate 3, a collimated light source 18, and an upper test Sample 1, lower sample 2, loading mechanism 17, longitudinal sliding table 10, X-Y direction sliding table 8, bench 9 and so on. The upper sample 1 is a thin disc made of transparent photoelastic material, and the lower sample 2 is a stepped shaft made of photoelastic material or metal material. The upper sample 1 can be driven and rotated by the first motor 11 through the synchronous belt. The upper sample 1 and the motor 11 are installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com