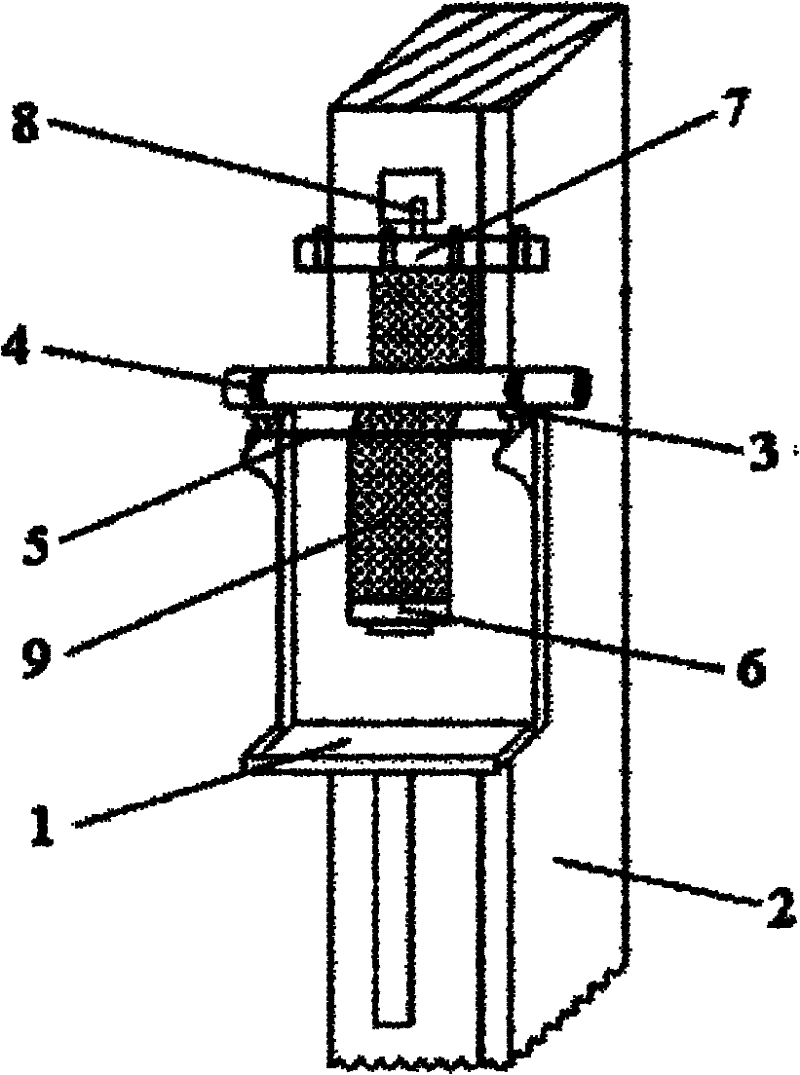

Device and method for detecting frictional performance between fabric and skin

A friction performance and friction device technology, applied in the field of friction performance testing of textile fabrics, can solve the problems of no clothes and skin wearing conditions, difficulty in imitating wearing conditions, small sample size, etc. effect of breadth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

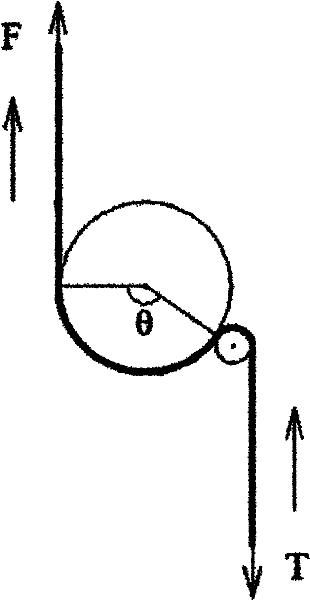

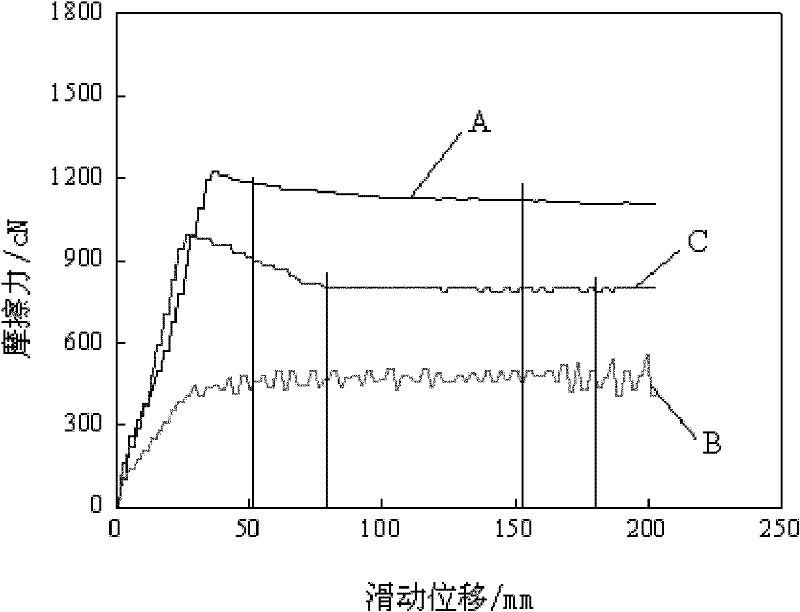

Embodiment 1

[0067] The wrapping angle between the fabric and the skin in the test device is θ=5π / 6, the descending speed of the rest is 600mm / min, and the pre-tension T=200cN applied by the tension clamp. The volunteer who participated in the experiment was a 23-year-old male with a height of 1.70m and a weight of 70kg. The skin was in good health. The test site was the inner skin of the middle part of the forearm of the volunteer. The sample size is 80 S ×80 S / 898×800, 98g / m 2 The pure cotton elastic Zhigong is used for the friction test along the warp direction, and the length and width of the sample are 500mm×100mm.

[0068] First measure the complete drying time t of the fabric m , Weigh the samples that have been dried or conditioned in a constant temperature room for 24 hours, soaked in water at 25°C, and lightly kneaded at the initial stage of infiltration to facilitate rapid infiltration, and taken out after 30 minutes in a windless laboratory (Temperature 20°C±3°C, relative ...

Embodiment 2

[0074] The wrapping angle between the fabric and the skin in the test device is θ=π, the descending speed of the rest is 600mm / min, and the pre-tension T=140cN applied by the tension clamp. The volunteer who participated in the experiment was a 25-year-old female, 1.68m in height, 60kg in weight, with good skin health, and the test site was the inner skin of the middle part of the forearm of the volunteer. The sample specification is 90D×120D / 460×270, 80g / m 2 The polyester chiffon fabric is subjected to the friction test along the warp direction, and the length × width of the sample is 500mm × 80mm.

[0075] First measure the complete drying time t of the fabric m 30min, the test method is the same as in Example 1, and 30min is divided into 5 time zones and 6 time nodes, which are respectively 0min, 6min, 12min, 18min, 24min and 30min, that is, the relative open time T is successively 0, 0.2, 0.4, 0.6, 0.8 and 1.

[0076] Soak 6 samples of the same variety and size (numbere...

Embodiment 3

[0081] The wrapping angle between the fabric and the skin in the test device is θ=2π / 3, the descending speed of the rest is 400mm / min, and the pre-tension T=280cN applied by the tension clamp. The volunteer who participated in the experiment was a 22-year-old female with a height of 1.65m and a weight of 56kg. The skin was in good health. The test site was the inner skin of the middle part of the forearm of the volunteer. The sample specification is JC80 S ×JC80 S / 670×412, 73g / m 2 The poplin fabric is subjected to the friction test along the warp direction, and the length and width of the sample are 500mm×120mm.

[0082] First measure the complete drying time t of the fabric m 115min, the test method is the same as in Example 1, and 115min is divided into 5 time zones and 6 time nodes, which are respectively 0min, 23min, 46min, 69min, 92min and 115min, that is, the relative open time T is successively 0, 0.2, 0.4, 0.6, 0.8 and 1.

[0083] Soak 6 samples of the same varie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com