Waste metal treatment equipment

A technology for processing equipment and scrap metal, which is applied in the removal of solid waste, presses, manufacturing tools, etc., can solve the problems of affecting operation, position offset, large volume, etc., and achieve the effect of improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

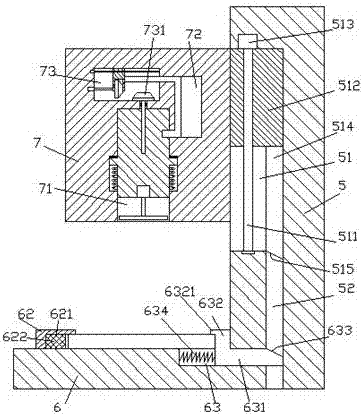

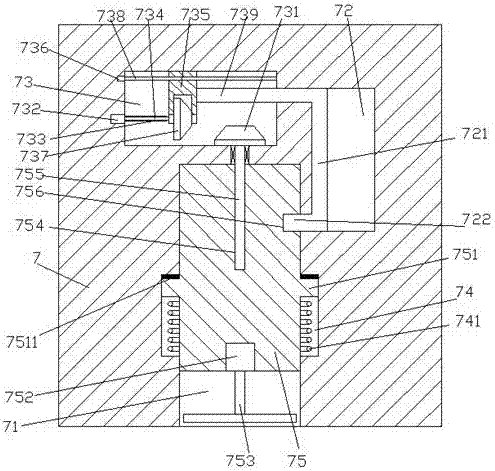

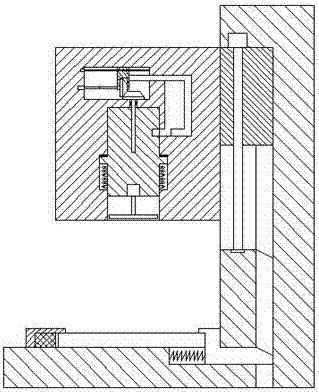

[0025] Such as Figure 1-Figure 7 As shown, a scrap metal processing equipment of the present invention includes a frame body composed of a working table 6 and a column body 5 and a compression device 7 arranged in the frame body, and a compression slide is arranged in the bottom end surface of the compression device Transport chute 71, the compression device 7 above the compression chute 71 is provided with a transfer chamber 73, and the compression device 7 on the top right side of the compression chute 71 is provided with an upwardly elongated Locking cavity 72, the elongated section at the top of the locking cavity 72 is located on the right side of the transfer cavity 73, the inner side wall of the compression sliding groove 71 is provided with a guide groove 74, the compression sliding groove The inner slide of 71 is connected with a compression slide block 75, and the top end surface of the compression slide block 75 is provided with a screw-shaped hole 754, and the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com