Winding machine for spinning

A winding machine and winding roller technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of low winding efficiency and achieve the goal of improving processing efficiency, ensuring quality and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

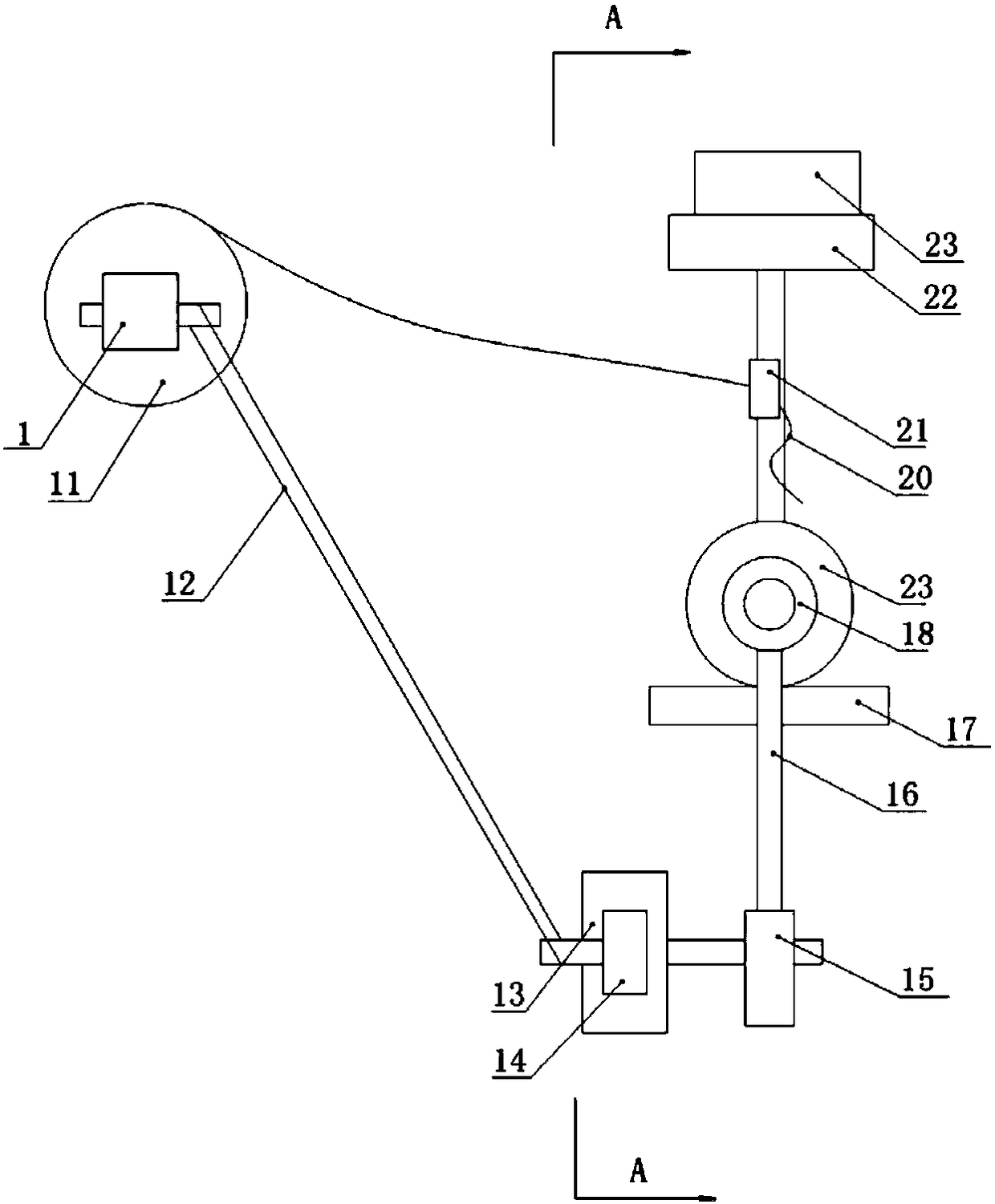

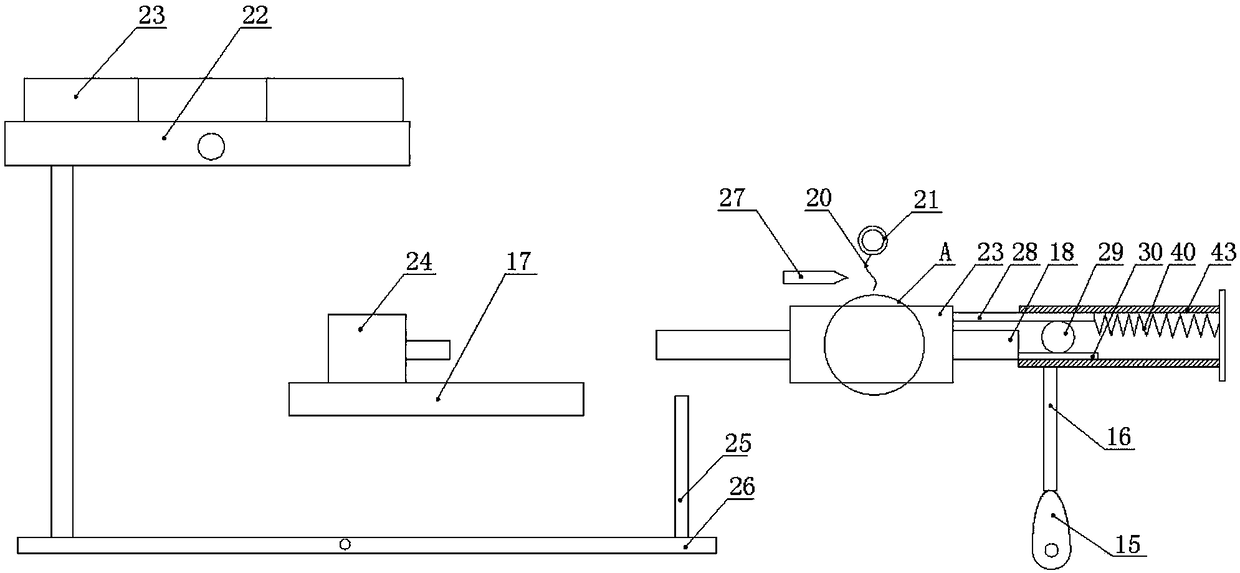

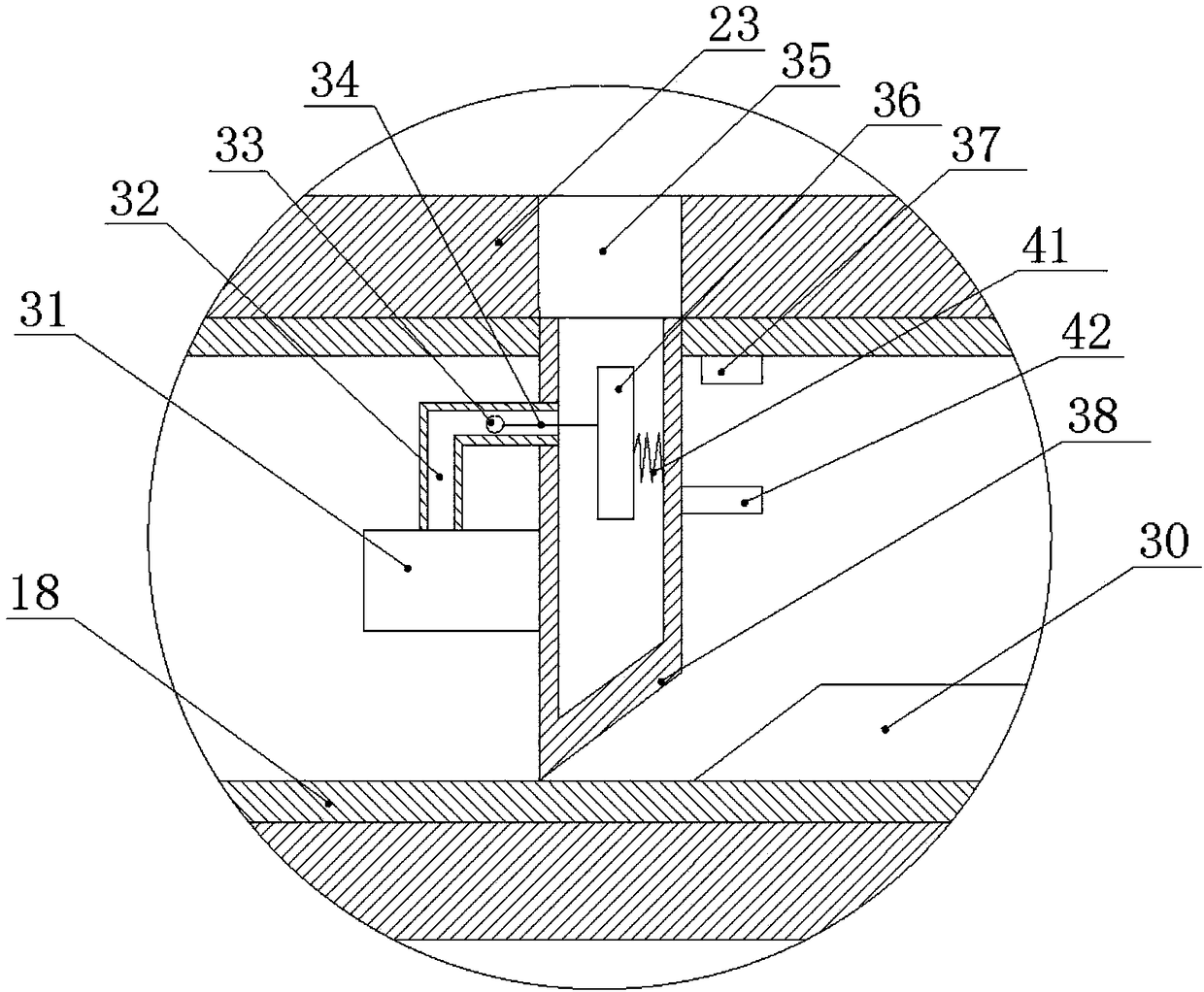

[0023] The reference signs in the accompanying drawings of the specification include: the second cam 1, the feed roller 11, the belt 12, the large gear 13, the pinion 14, the first cam 15, the connecting rod 16, the loading table 17, the spline shaft 18, the yarn Line 20, line ring 21, placing table 22, winding roller 23, cylinder 24, push rod 25, lever 26, cutter 27, rack 28, gear 29, the second wedge bar 30, air pump 31, air pipe 32, Ball 33, stay cord 34, through hole 35, pressing plate 36, switch 37, first wedge bar 38, second spring 40, first spring 41, pole 42, sleeve 43.

[0024] Such as figure 1 As shown, a winding machine for textile use in the present invention includes a frame on which a feeding mechanism, a feeding mechanism and a hollow spline shaft 18 are arranged. A feed roller 11 parallel to the spline shaft 18 is installed above the left side. One end of the feed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com