Intelligent assembly testing production line of hydraulic plunger pump

A technology of hydraulic plunger pump and assembly detection, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inappropriate structure and steps, inconvenient stoppage and assembly, and difficult maintenance, and reduce labor costs. , to achieve the effect of automatic handling and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

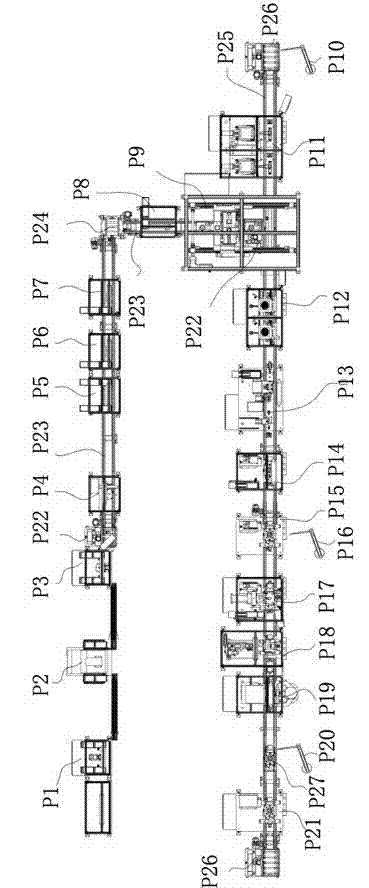

[0036] see figure 1 , The intelligent assembly and detection production line of the hydraulic plunger pump according to the embodiment of the present invention includes a branch line assembly line and a main line assembly line.

[0037] The branch line assembly line includes the branch line conveying line and the assembly tables set on the branch line in sequence: A dimension inspection table P1, bearing press P2, BC size inspection station P3, glue dispenser P4, plunger auxiliary assembly station P5, and return board Assembly table P6, cylinder body assembly table P7, shield assembly table P8, movement assembly manipulator P9, the feeder conveyor line reciprocatingly conveys a number of feeder trays P24, and the assembly table on the feeder conveyor line is equipped with stoppers and feeder trays Positioning mechanism, branch line conveying line includes slideway and branch line conveying chain P23, between A dimension inspection table P1 and bearing press P2, and between bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com