Patents

Literature

116 results about "Loop start" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Loop start is a telecommunications supervisory protocol between a central office or private branch exchange (PBX) and a subscriber telephone or other terminal for the purpose of starting and terminating a telephone call. It is the simplest of the telephone signaling systems, and uses the presence or absence of loop current to indicate the off-hook and on-hook loop states, respectively. It is used primarily for subscriber line signaling. An extension of the protocol that adds disconnect supervision is often called kewlstart.

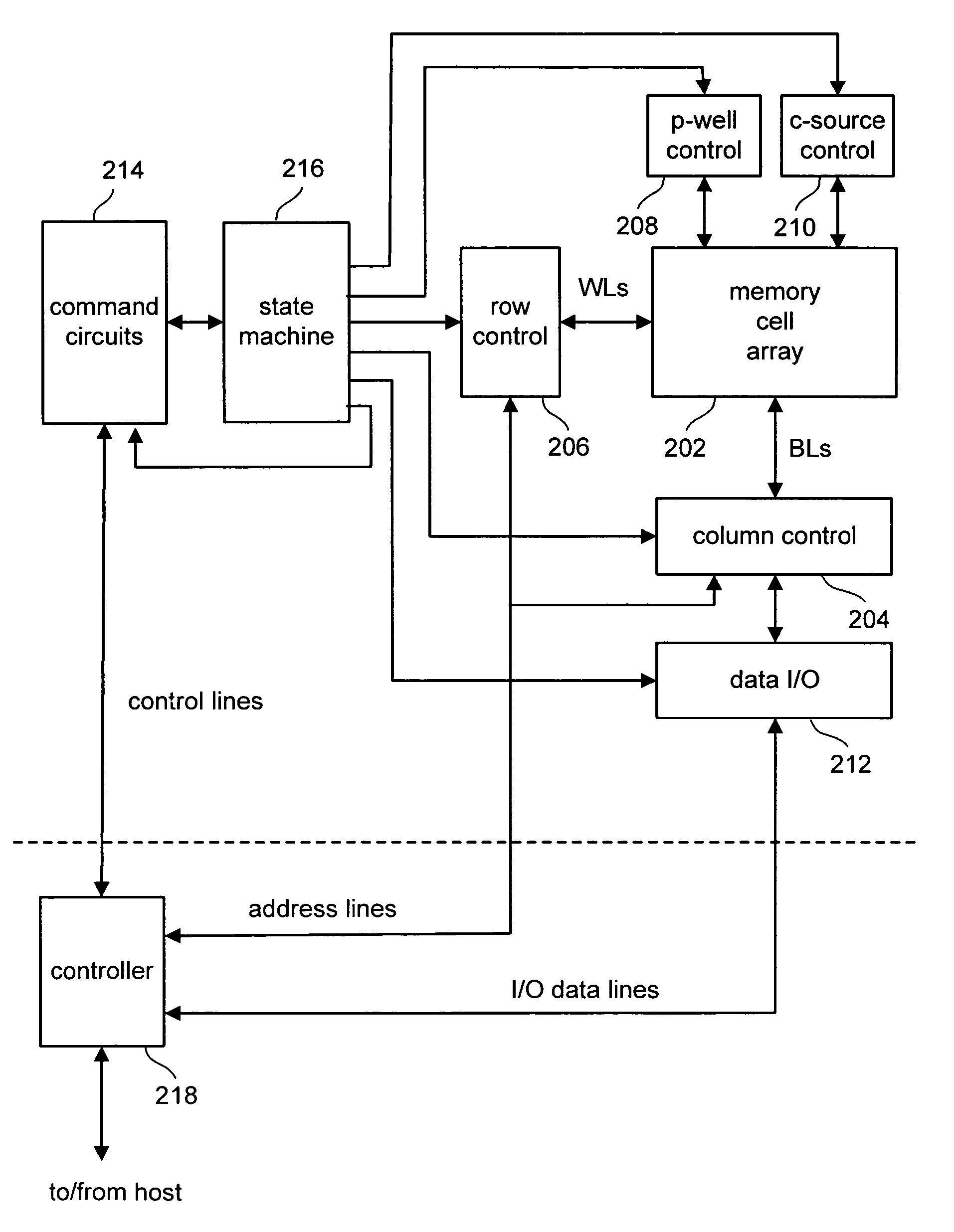

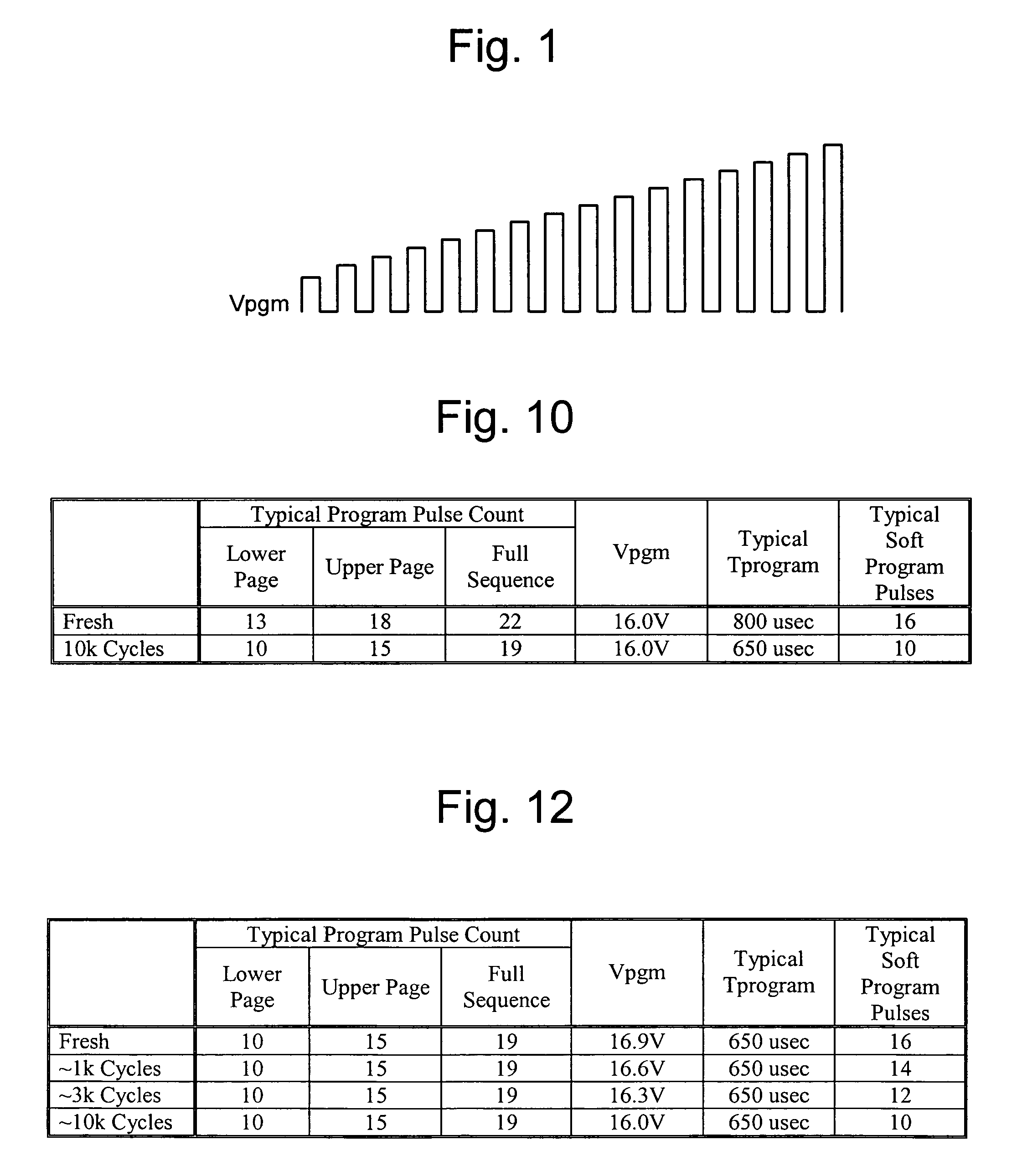

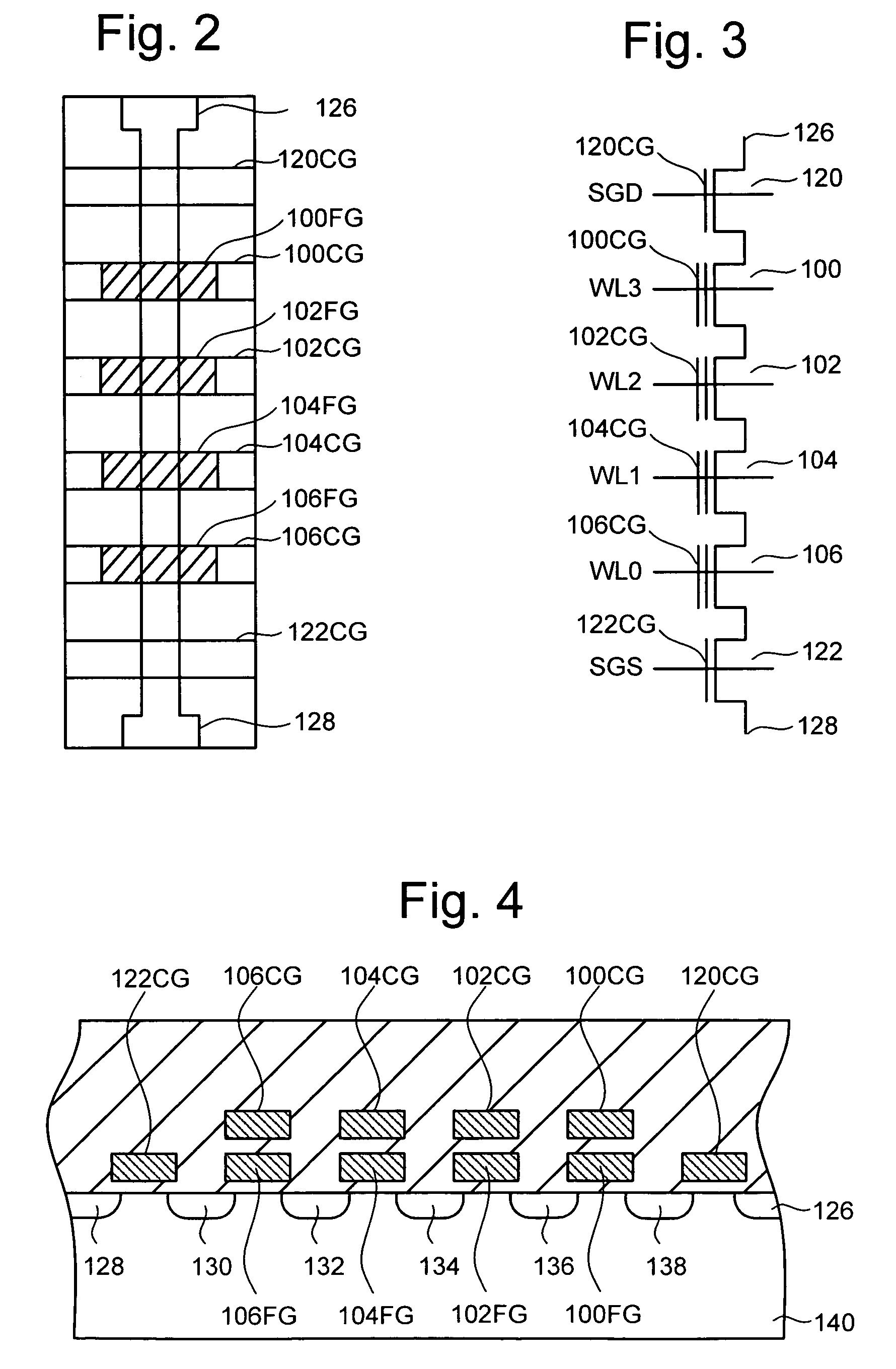

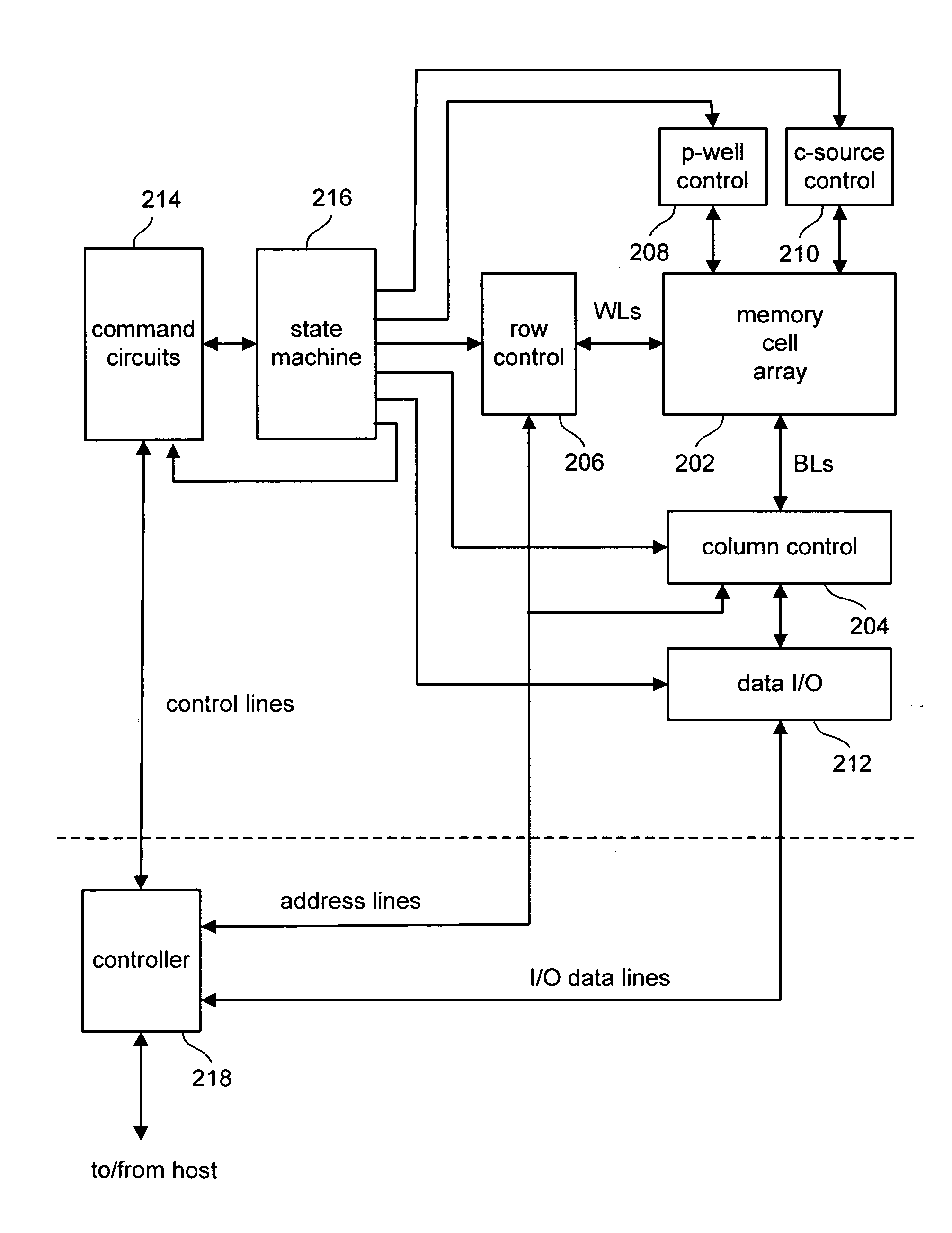

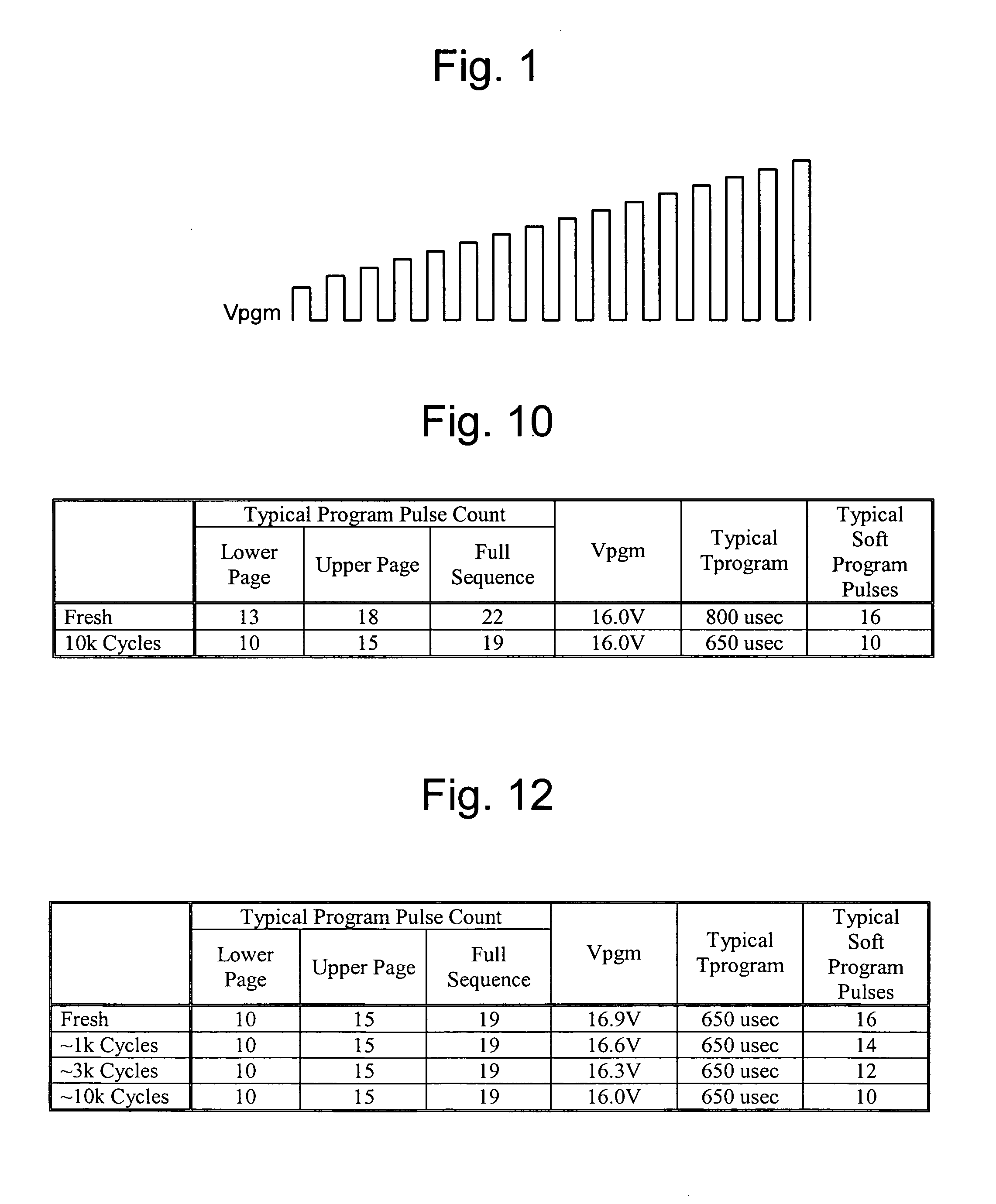

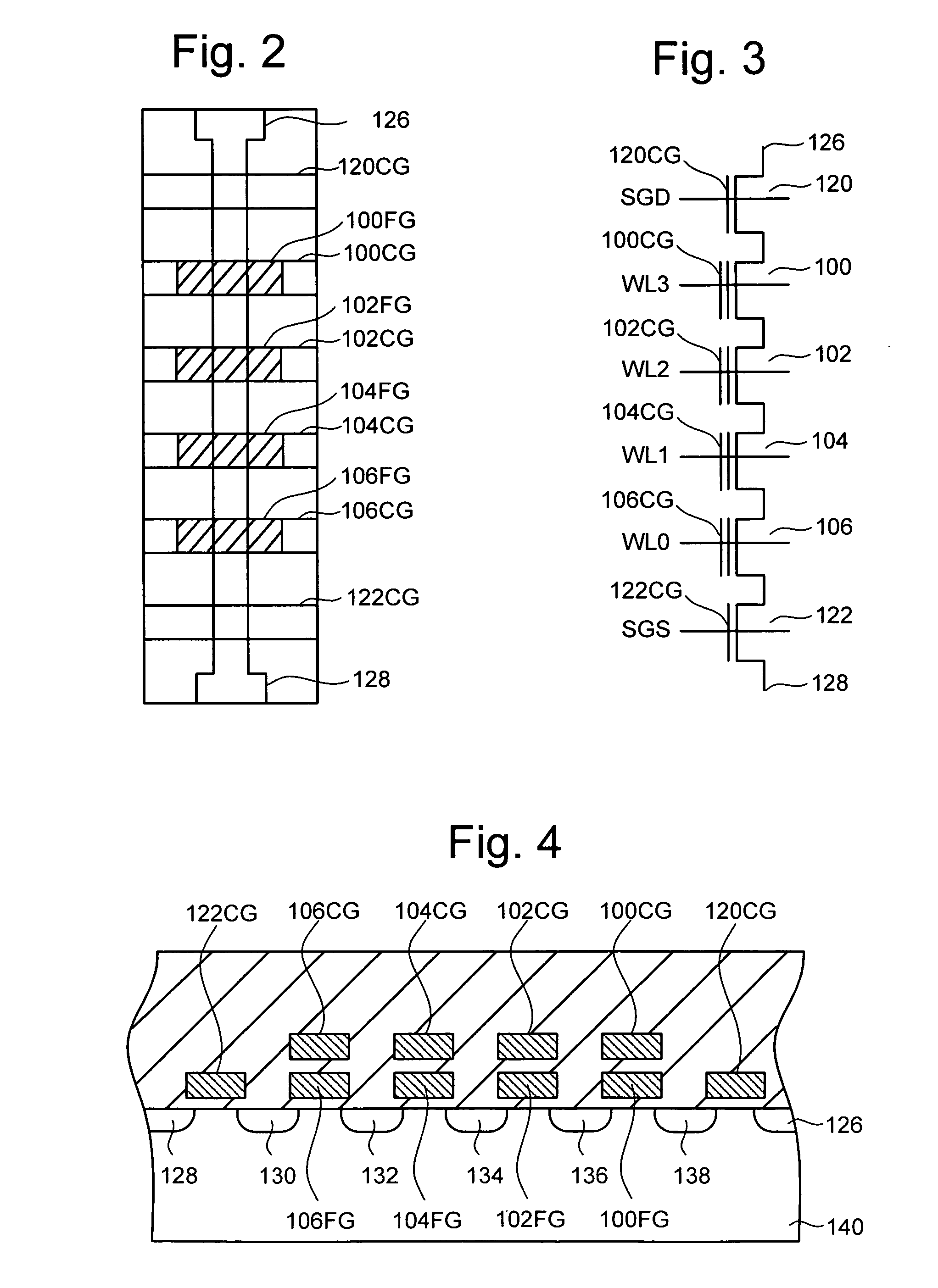

Starting program voltage shift with cycling of non-volatile memory

A system is disclosed for programming non-volatile storage that improves performance by setting the starting programming voltage to a first level for fresh parts and adjusting the starting programming voltage as the memory is cycled. For example, the system programs a set of non-volatile storage elements during a first period using an increasing program signal with a first initial value and subsequently programs the set of non-volatile storage elements during a second period using an increasing program signal with a second initial value, where the second period is subsequent to the first period and the second initial value is different than the first initial value.

Owner:SANDISK TECH LLC

Starting program voltage shift with cycling of non-volatile memory

ActiveUS20060274583A1Reduce riskProgramming data fasterRead-only memoriesDigital storageVoltage shiftComputer science

A system is disclosed for programming non-volatile storage that improves performance by setting the starting programming voltage to a first level for fresh parts and adjusting the starting programming voltage as the memory is cycled. For example, the system programs a set of non-volatile storage elements during a first period using an increasing program signal with a first initial value and subsequently programs the set of non-volatile storage elements during a second period using an increasing program signal with a second initial value, where the second period is subsequent to the first period and the second initial value is different than the first initial value.

Owner:SANDISK TECH LLC

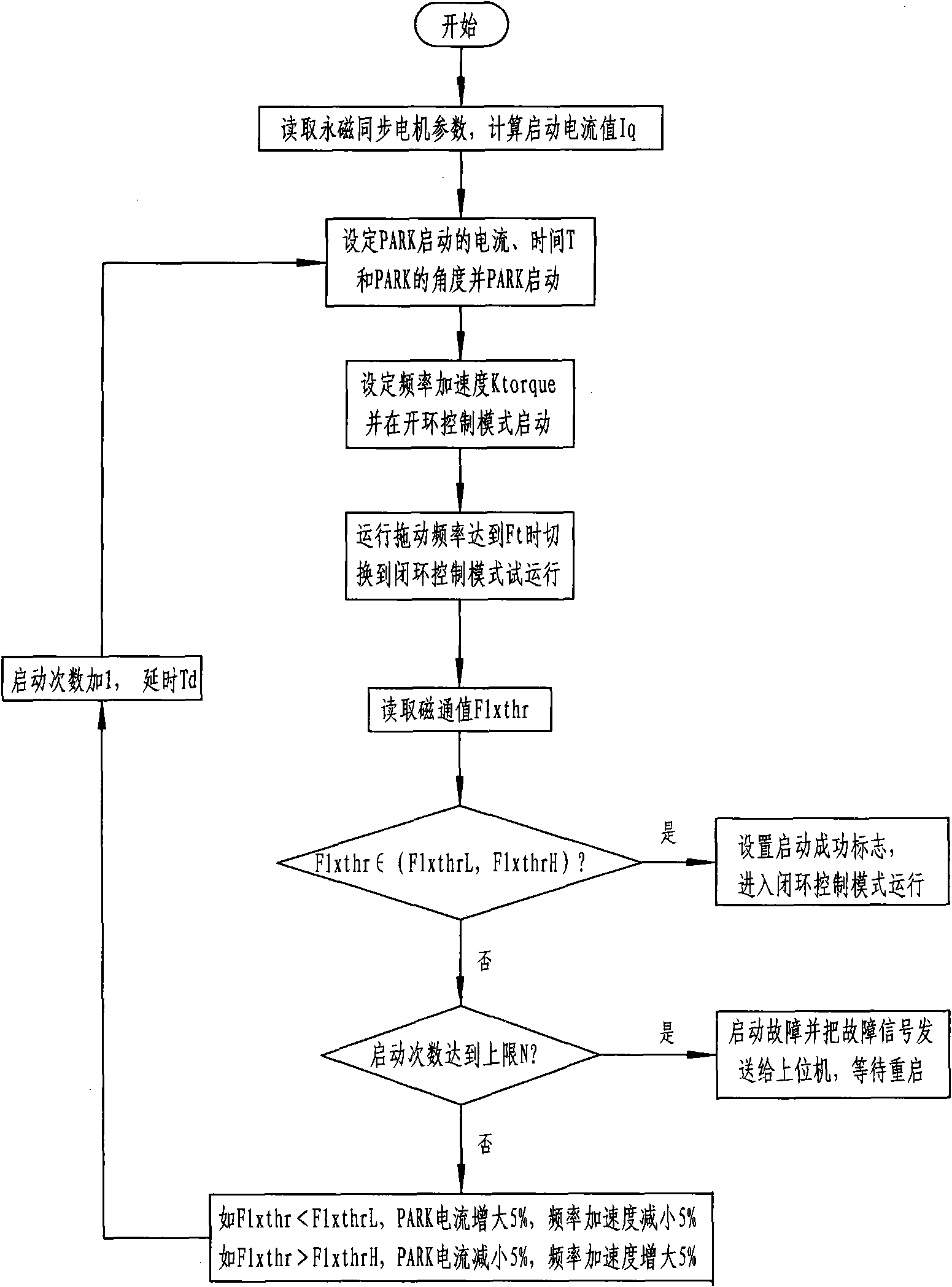

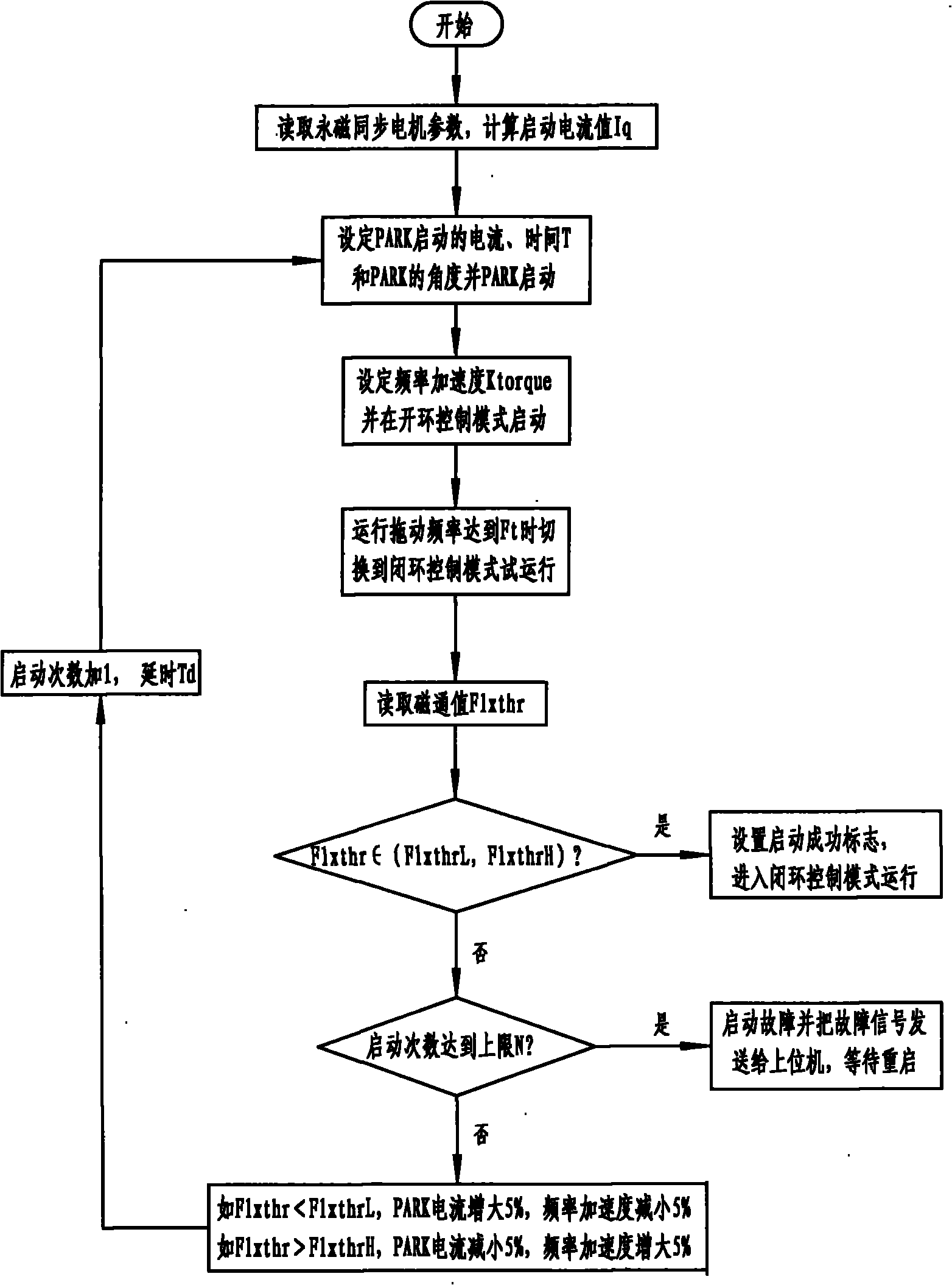

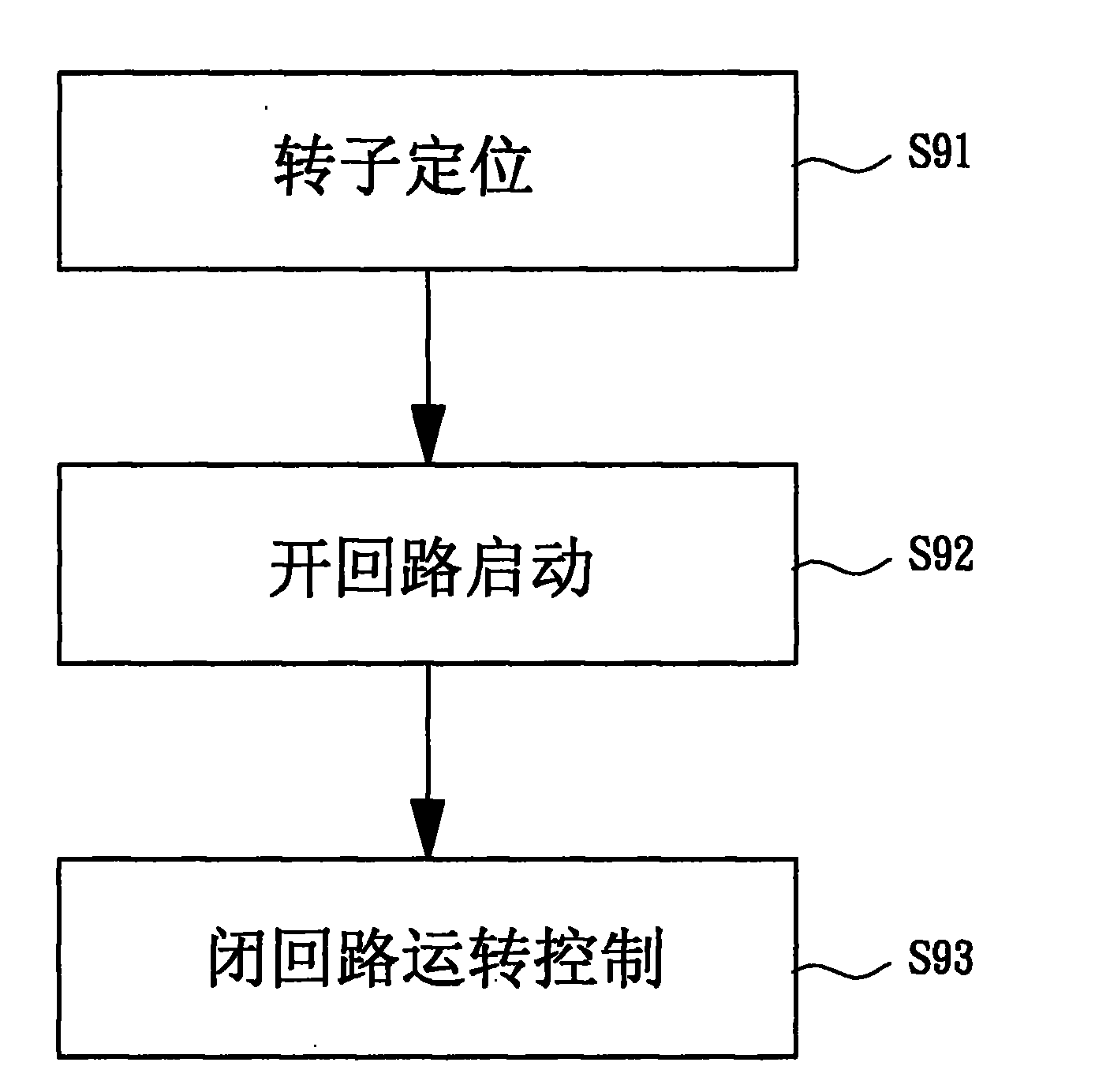

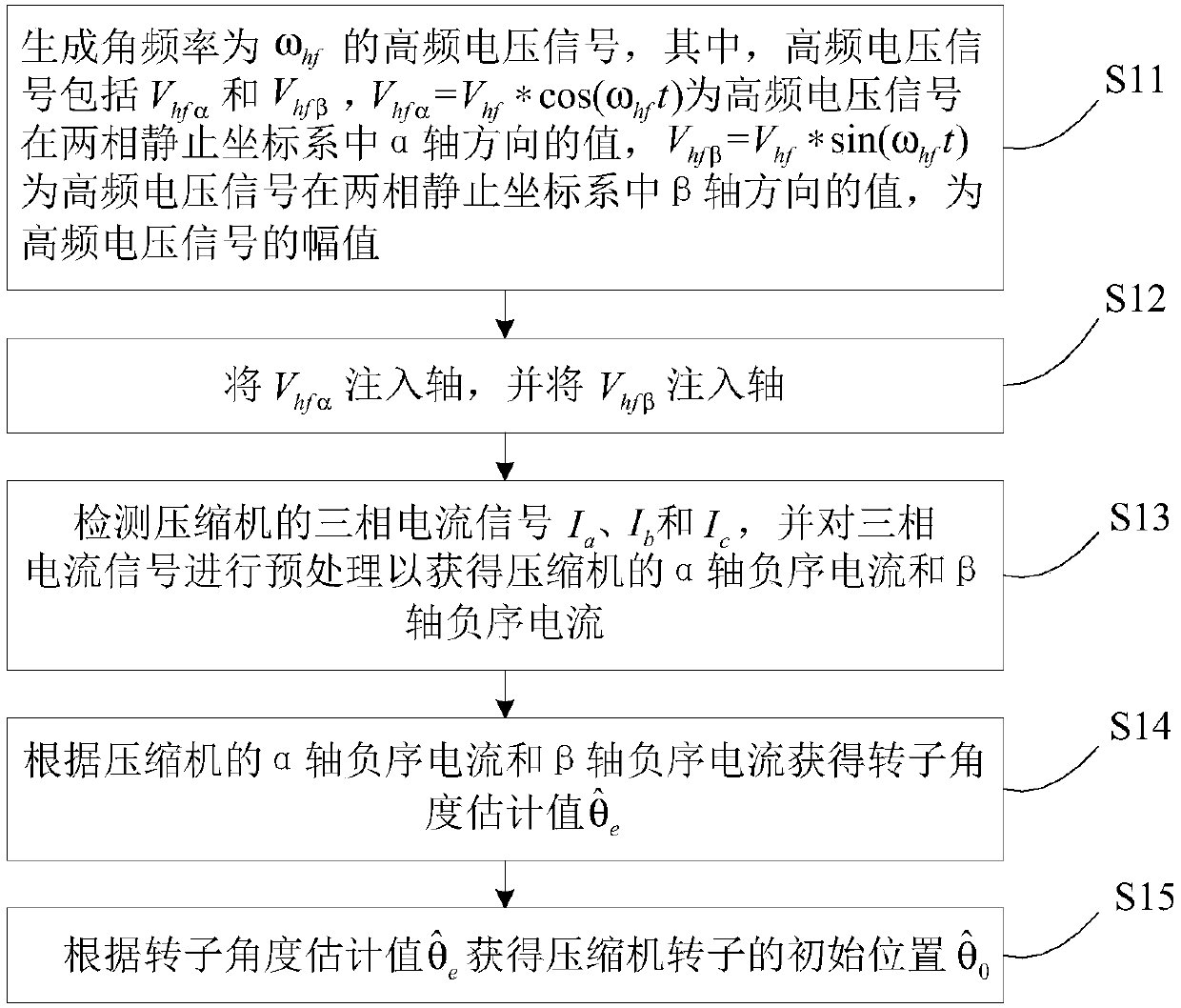

Starting method of permanent-magnet synchronous compressor for variable-frequency air conditioner

ActiveCN101917152AAvoid damageAvoid startup instability issuesStarter arrangementsPermanent magnet synchronous motorClosed loop

The invention discloses a starting method of a permanent-magnet synchronous compressor for a variable-frequency air conditioner, which comprises the following steps of: firstly locking the initial position of a rotor through a PARK process, then carrying out open-loop starting, switching to a closed-loop control mode for trial operation when the dragging frequency of a permanent-magnet synchronous motor reaches the lowest frequency Ft of switching an open loop to a closed loop when in open-loop starting, reading a magnetic flux valve to judge whether the closed-loop control mode is successfully switched for operation or not, and if the closed-loop control mode is not successfully switched, adjusting the PARK current and the frequency acceleration of the open-loop starting process for restarting according to the magnitude of the magnetic flux valve; and setting the limitation of starting times, reporting a fault signal to an upper computer after unsuccessful starting for many times, and giving a restarting signal by the upper computer. The invention can guarantee the reliable starting of the permanent-magnet synchronous compressor under the condition of heavier or lighter loads.

Owner:NINGBO AUX ELECTRIC

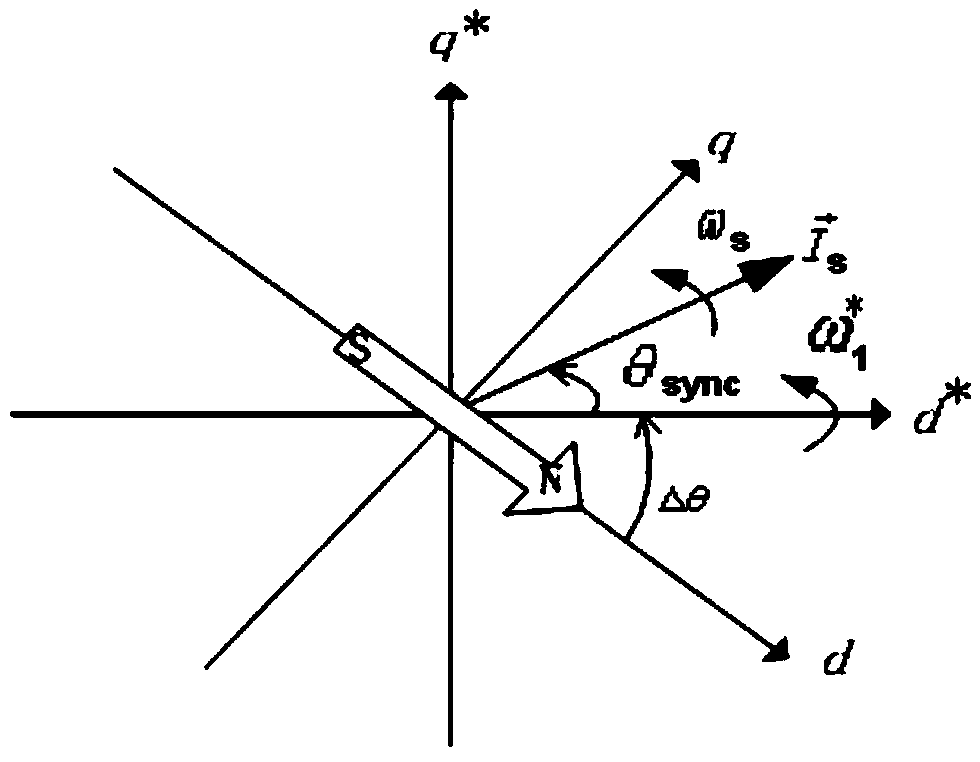

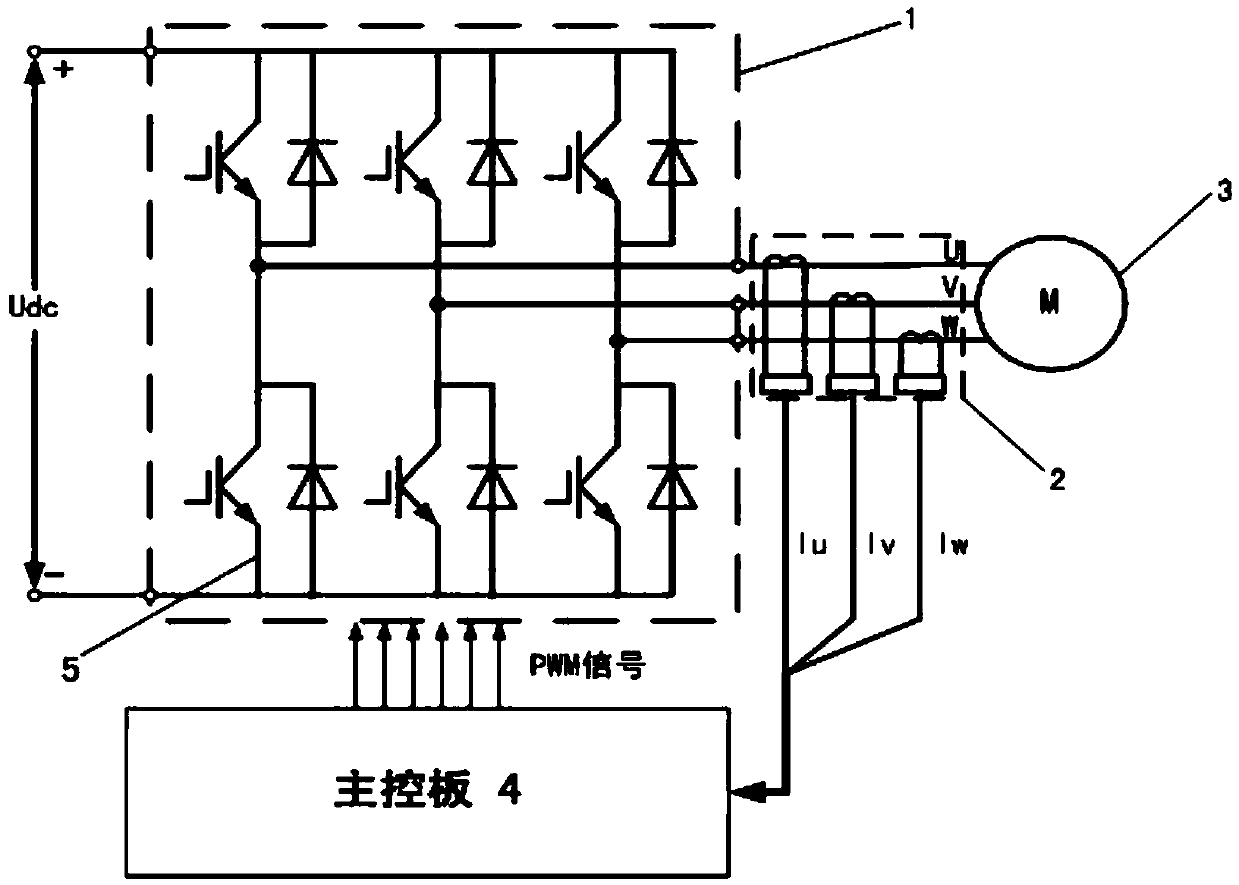

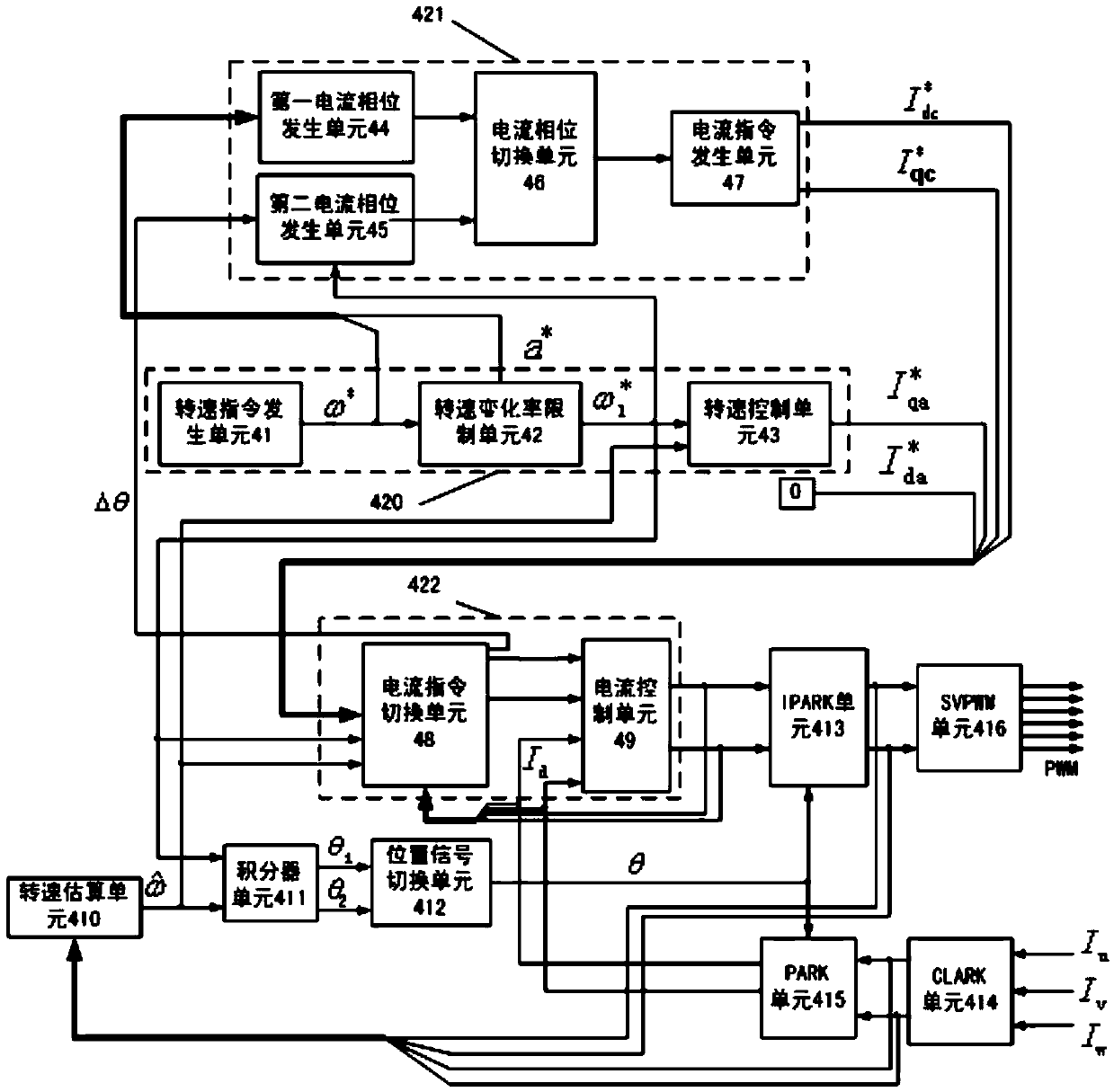

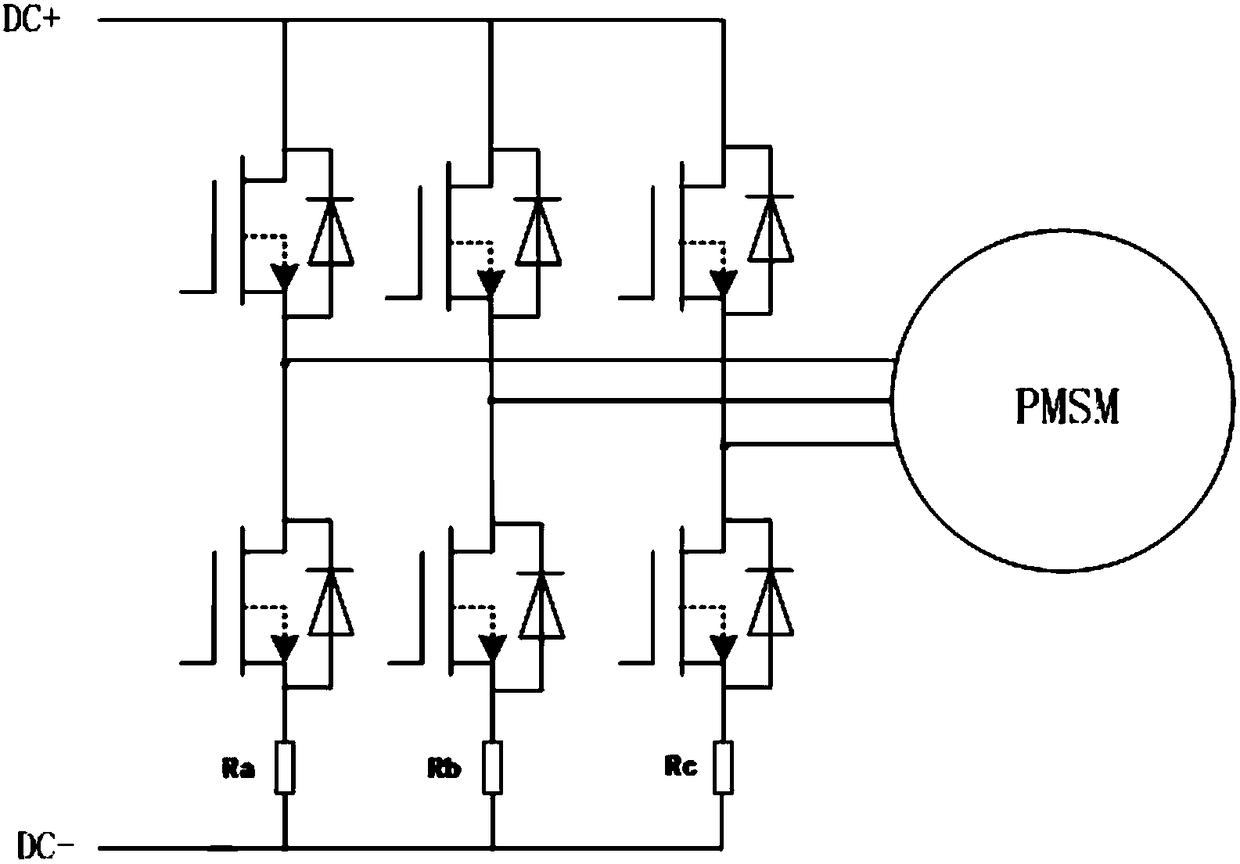

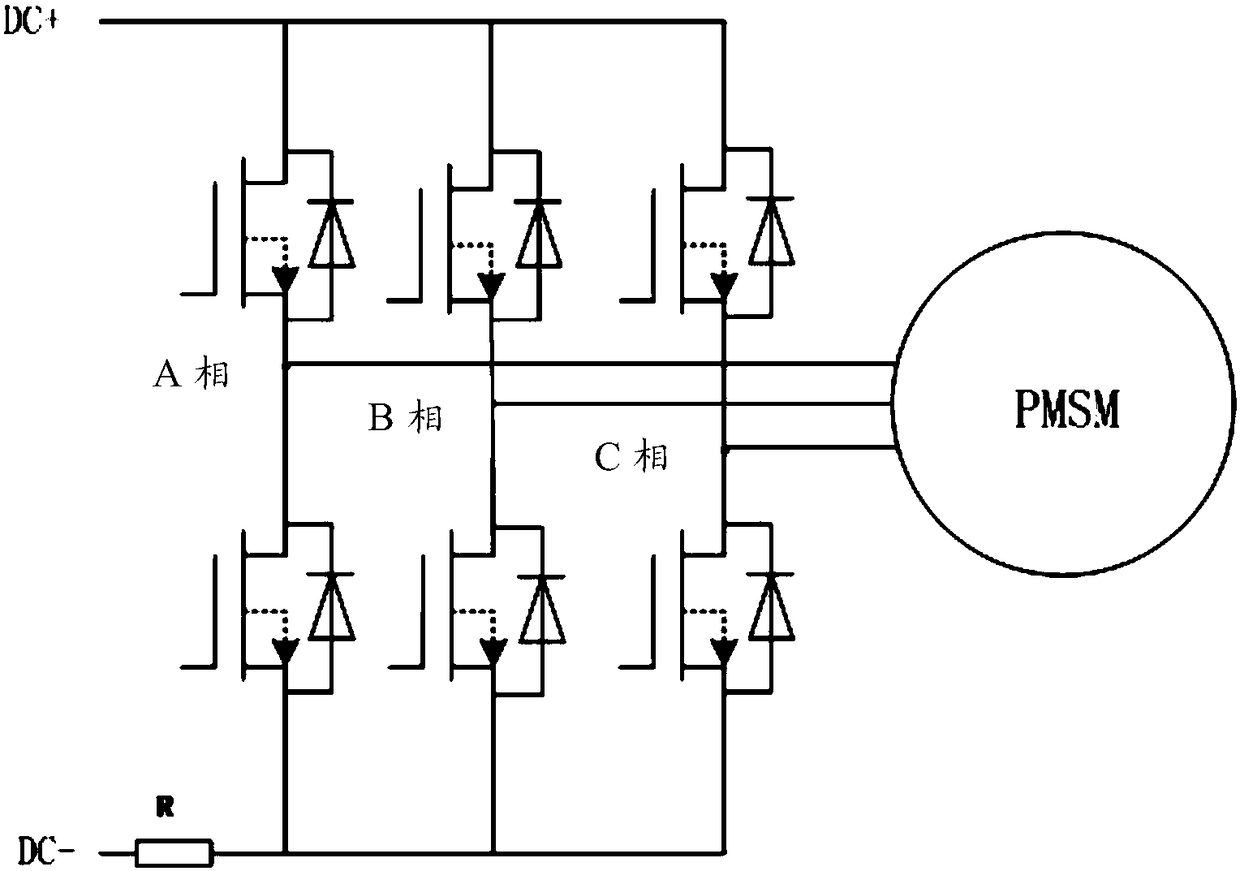

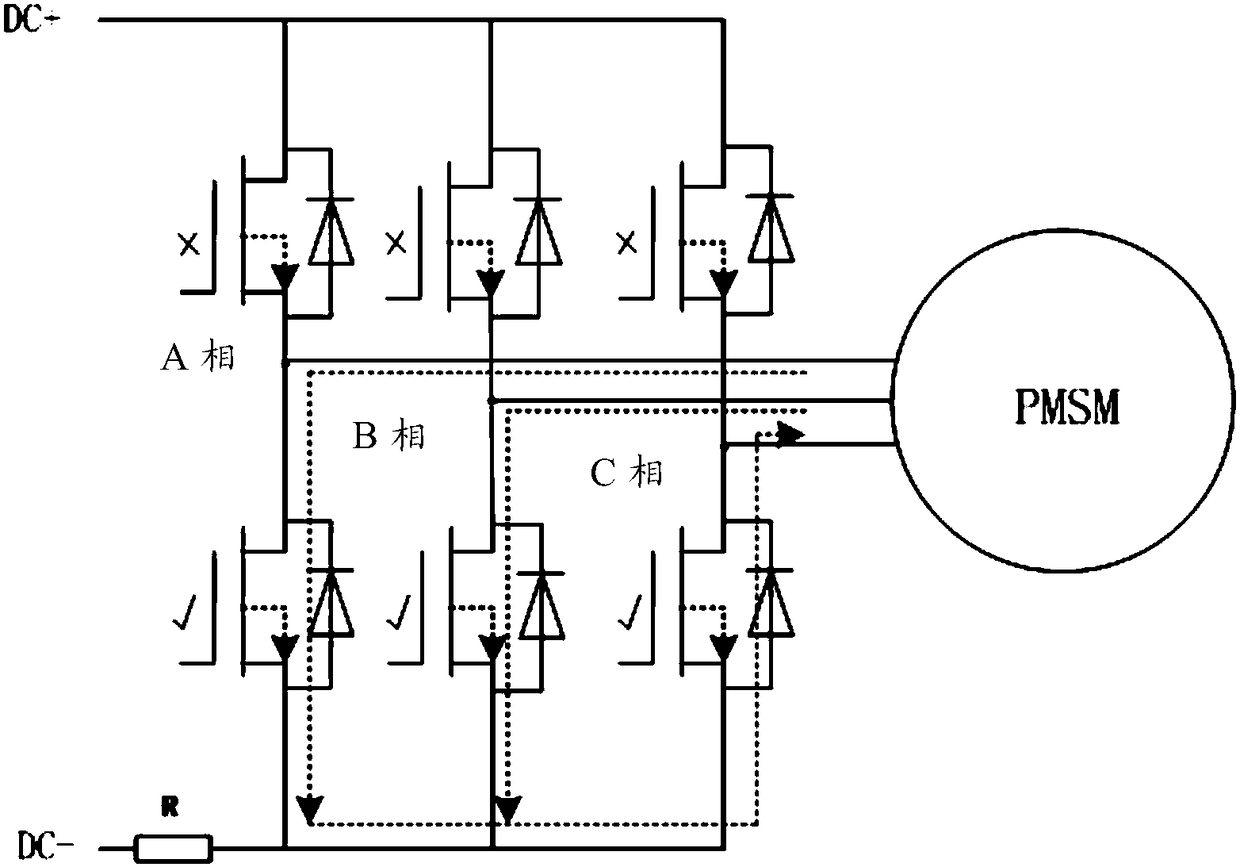

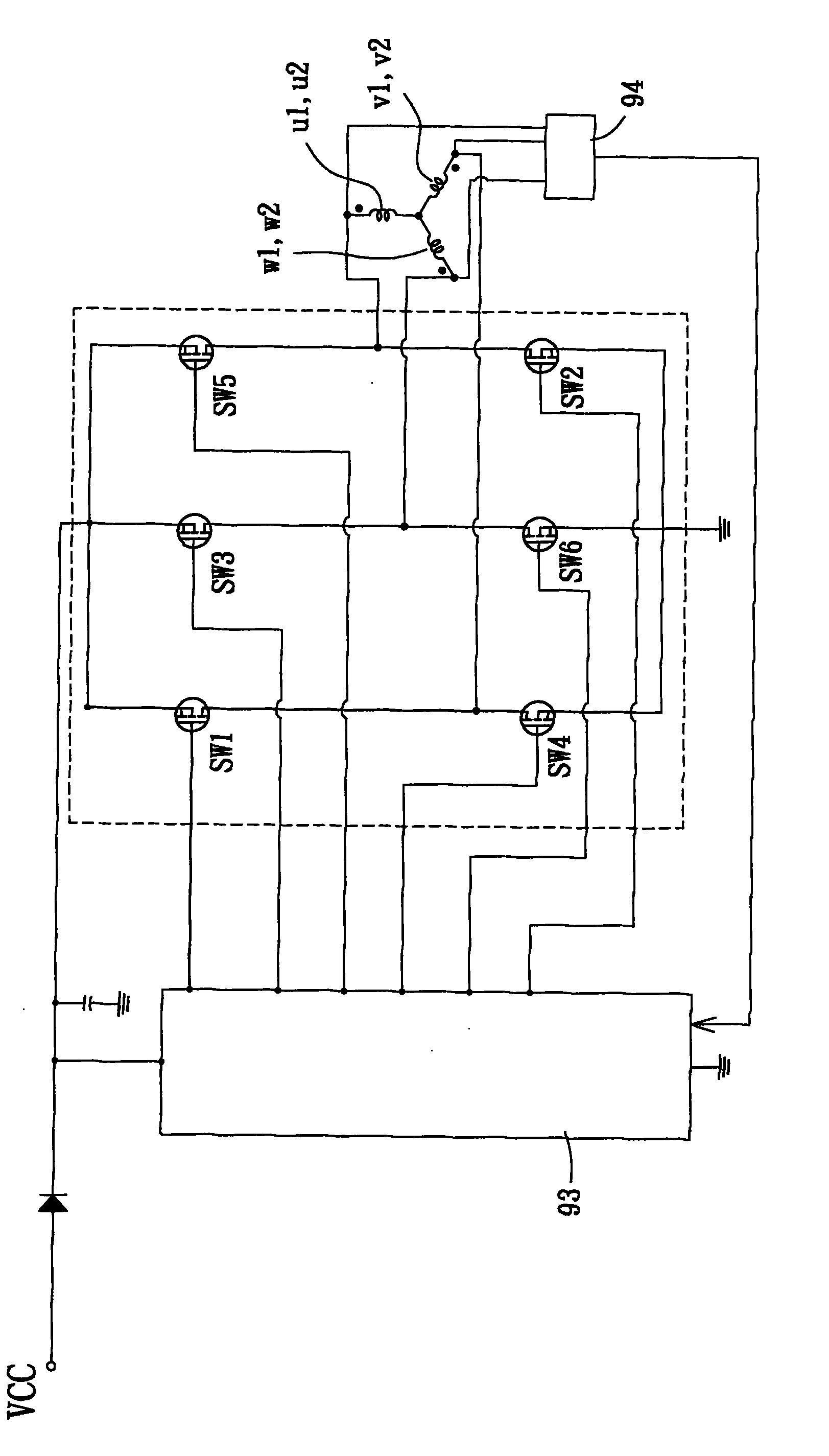

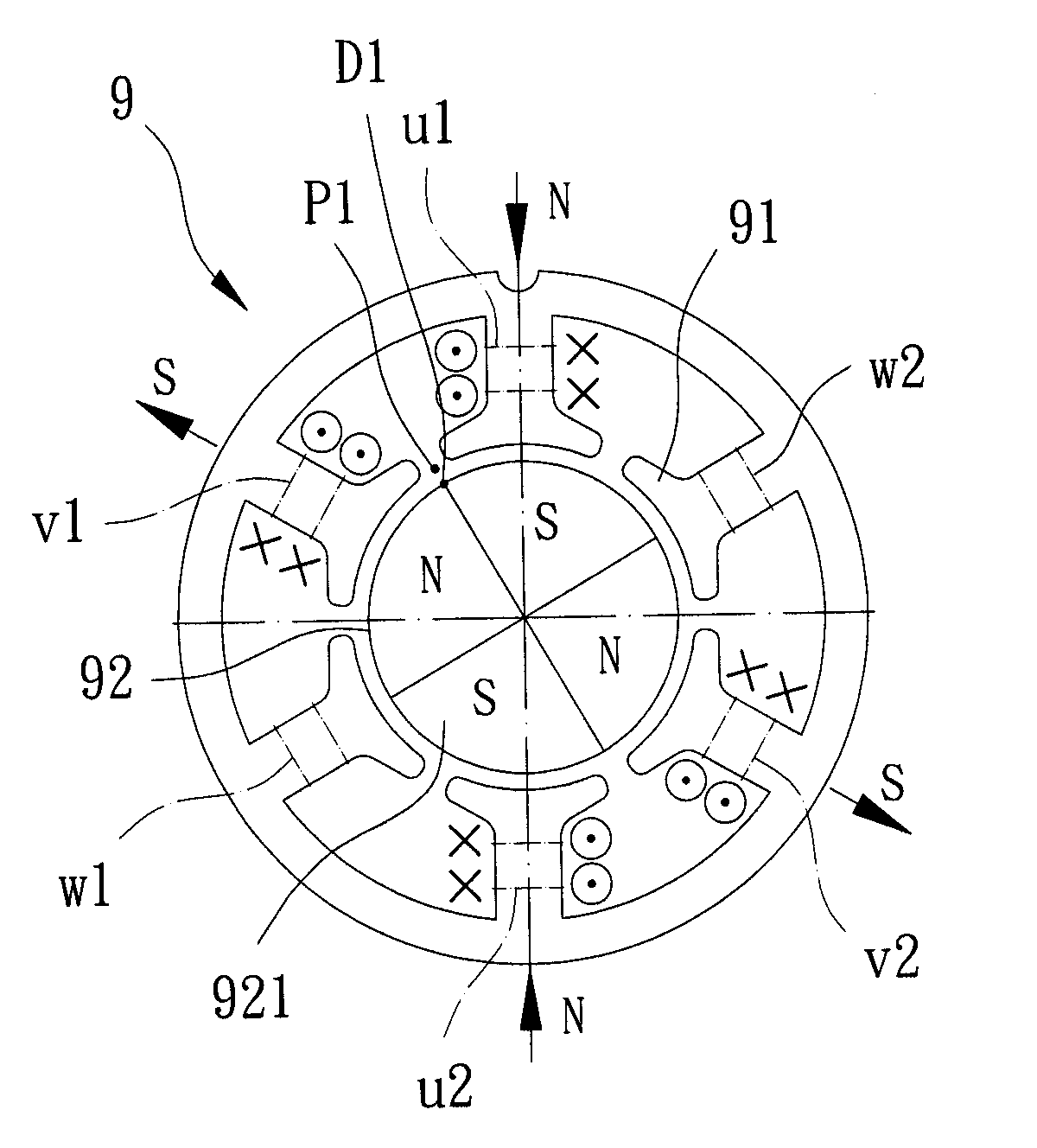

Starting circuit and starting method of permanent magnet synchronous motor

ActiveCN105356812ASpeed up the sync startup processEasy to judgeElectronic commutation motor controlAC motor controlControl vectorIntegrator

The invention discloses a starting circuit and a starting method of a permanent magnet synchronous motor. The starting circuit of the permanent magnet synchronous motor comprises an inverter circuit, three current sensors, a motor and a master control panel, wherein the inverter circuit comprises three groups of IGBT modules; the three groups of IGBT modules are electrically connected with the motor through three leads respectively; the three current sensors are respectively located on the three leads; and the master control panel comprises a rotating speed control module, a starting current instruction generation module, a current control module, a rotating speed estimation unit, an integrator unit, a position signal switching unit, an IPARK unit, a CLARK unit, a PARK unit and an SVPWM unit. The starting circuit and the starting method have the characteristics that the starting process can be quickened; the angle difference between a given rotating coordinate system and an actual rotating coordinate system is reduced; and smooth switching from rotating speed open loop starting to double closed-loop sensorless vector control operation of rotating speed current is ensured.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

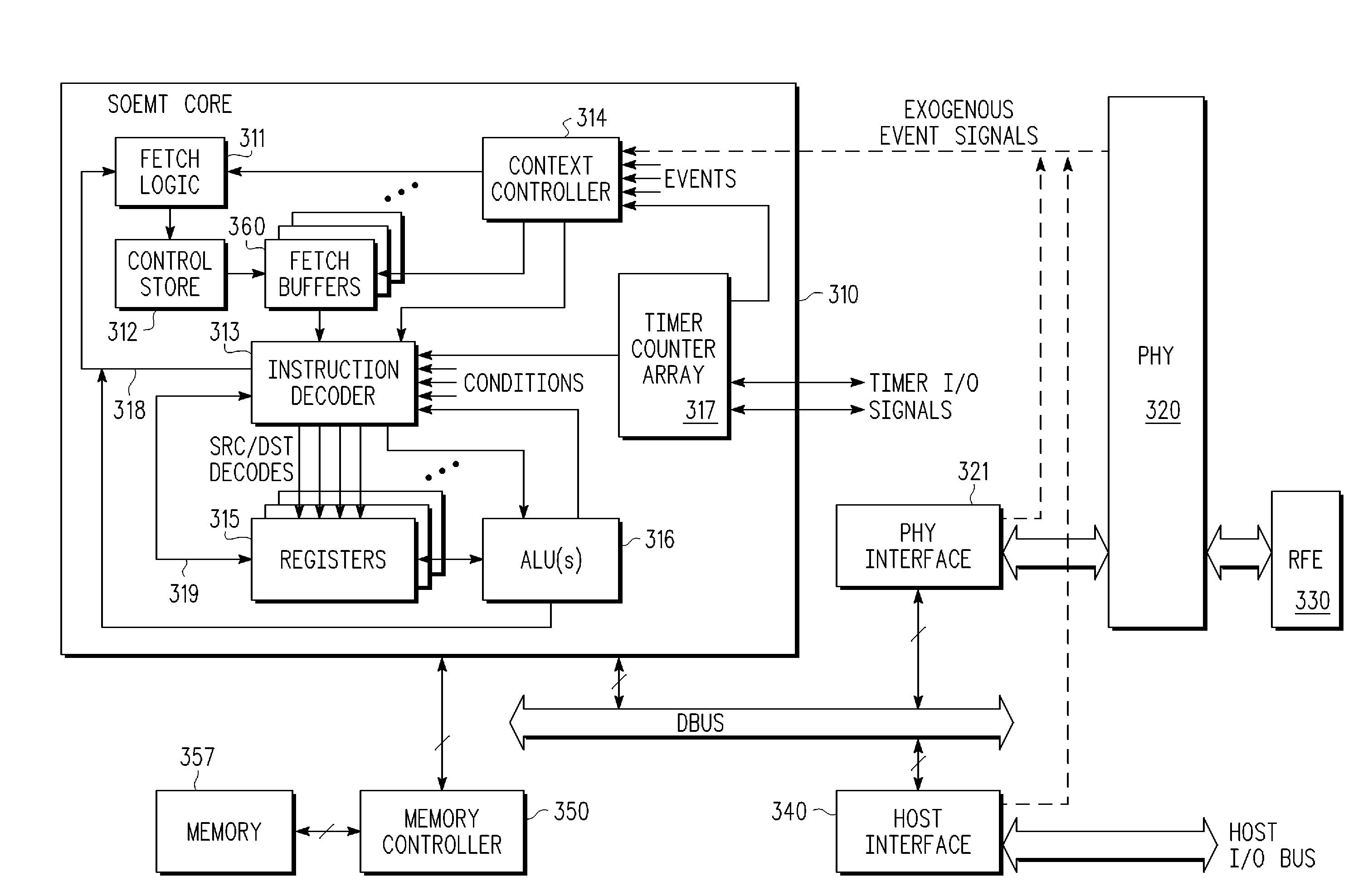

Instruction method for facilitating efficient coding and instruction fetch of loop construct

InactiveUS20100122066A1Digital computer detailsConcurrent instruction executionMachine instructionConditional loop

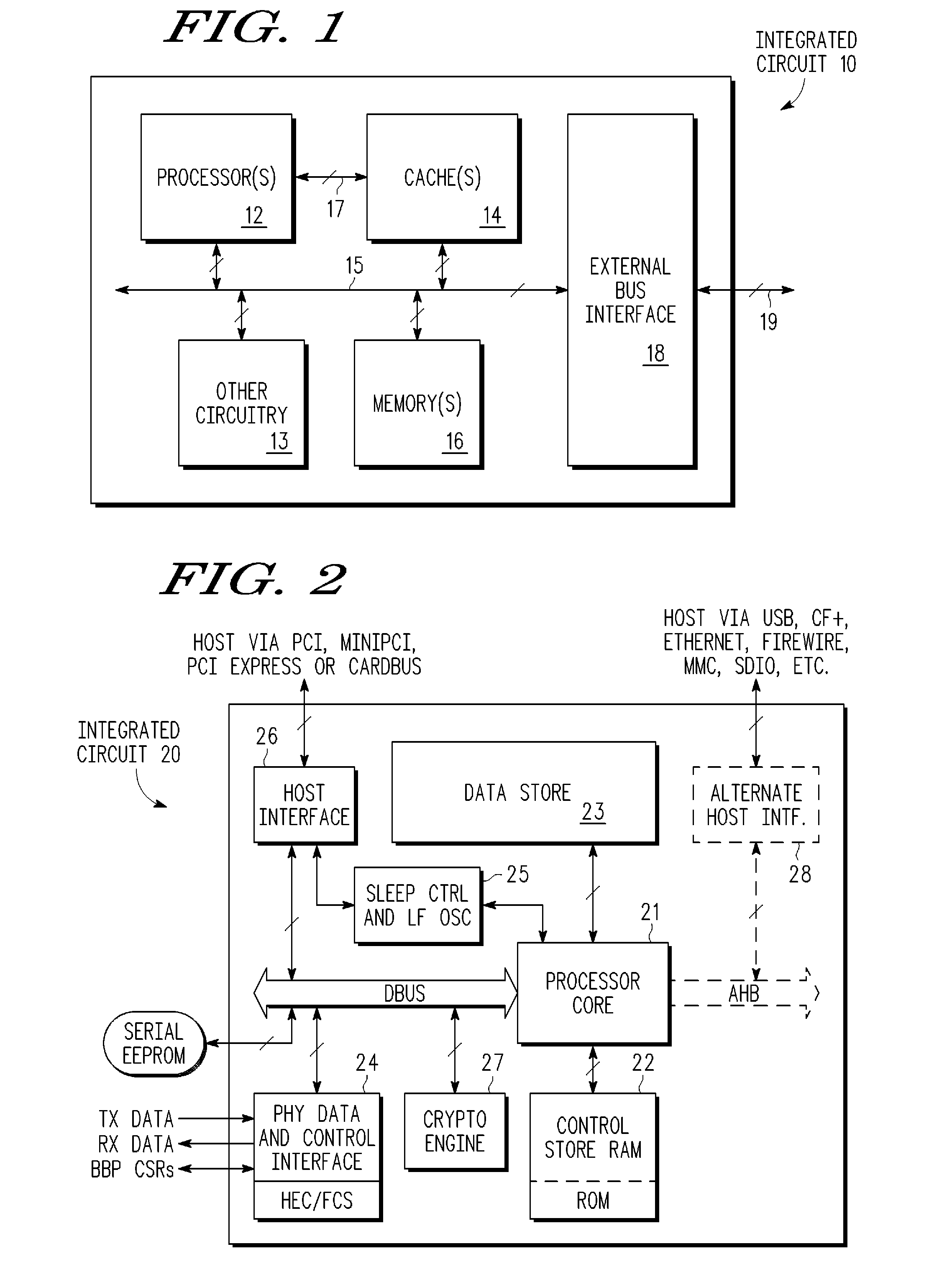

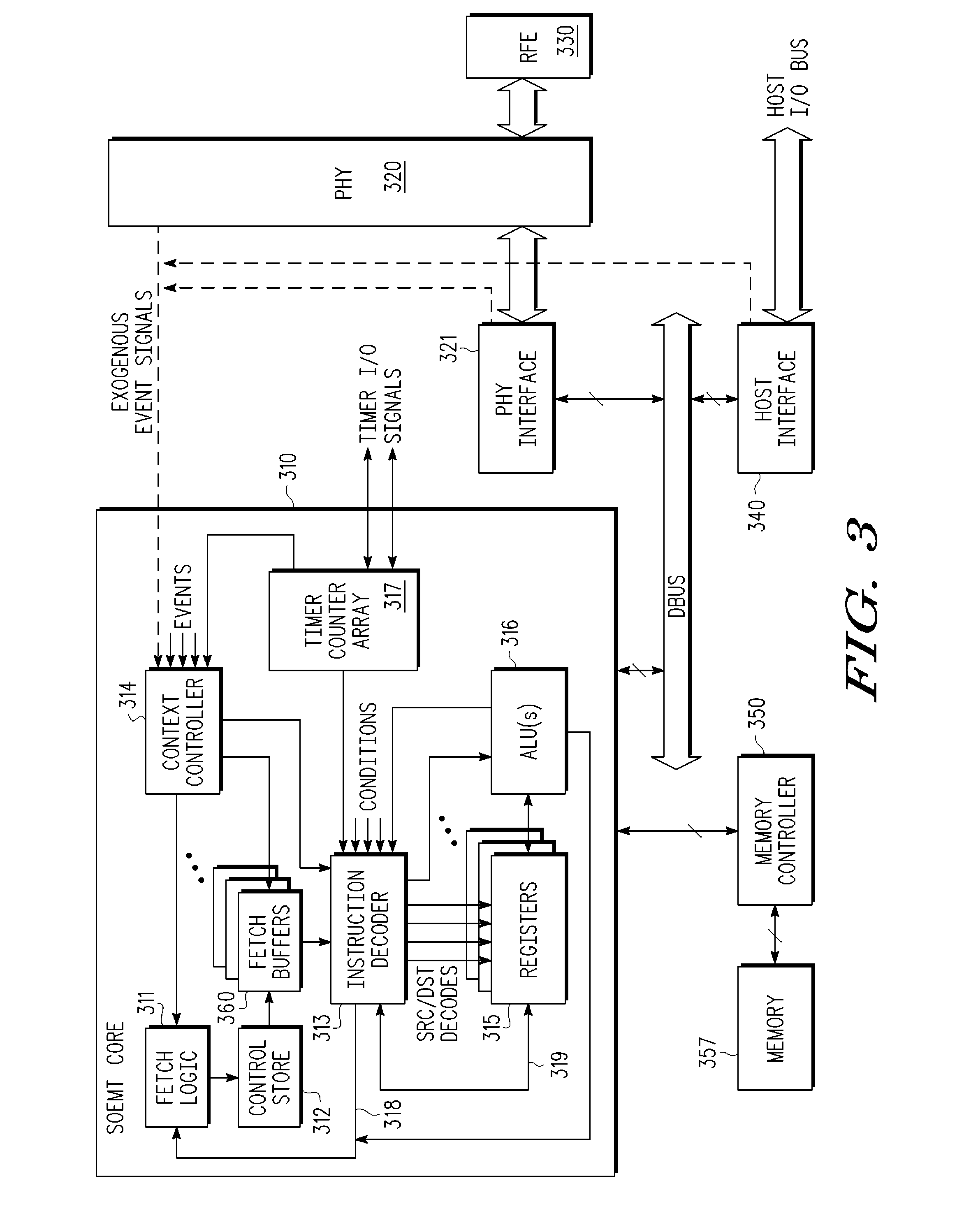

Instruction set techniques have been developed to identify explicitly the beginning of a loop body and to code a conditional loop-end in ways that allow a processor implementation to efficiently manage an instruction fetch buffer and / or entries in an instruction cache. In particular, for some computations and processor implementations, a machine instruction is defined that identifies a loop start, stores a corresponding loop start address on a return stack (or in other suitable storage) and directs fetch logic to take advantage of the identification by retaining in a fetch buffer or instruction cache the instruction(s) beginning at the loop start address, thereby avoiding usual branch delays on subsequent iterations of the loop. A conditional loop-end instruction can be used in conjunction with the loop start instruction to discard (or simply mark as no longer needed) the loop start address and the loop body instructions retained in the fetch buffer or instruction cache.

Owner:FREESCALE SEMICON INC

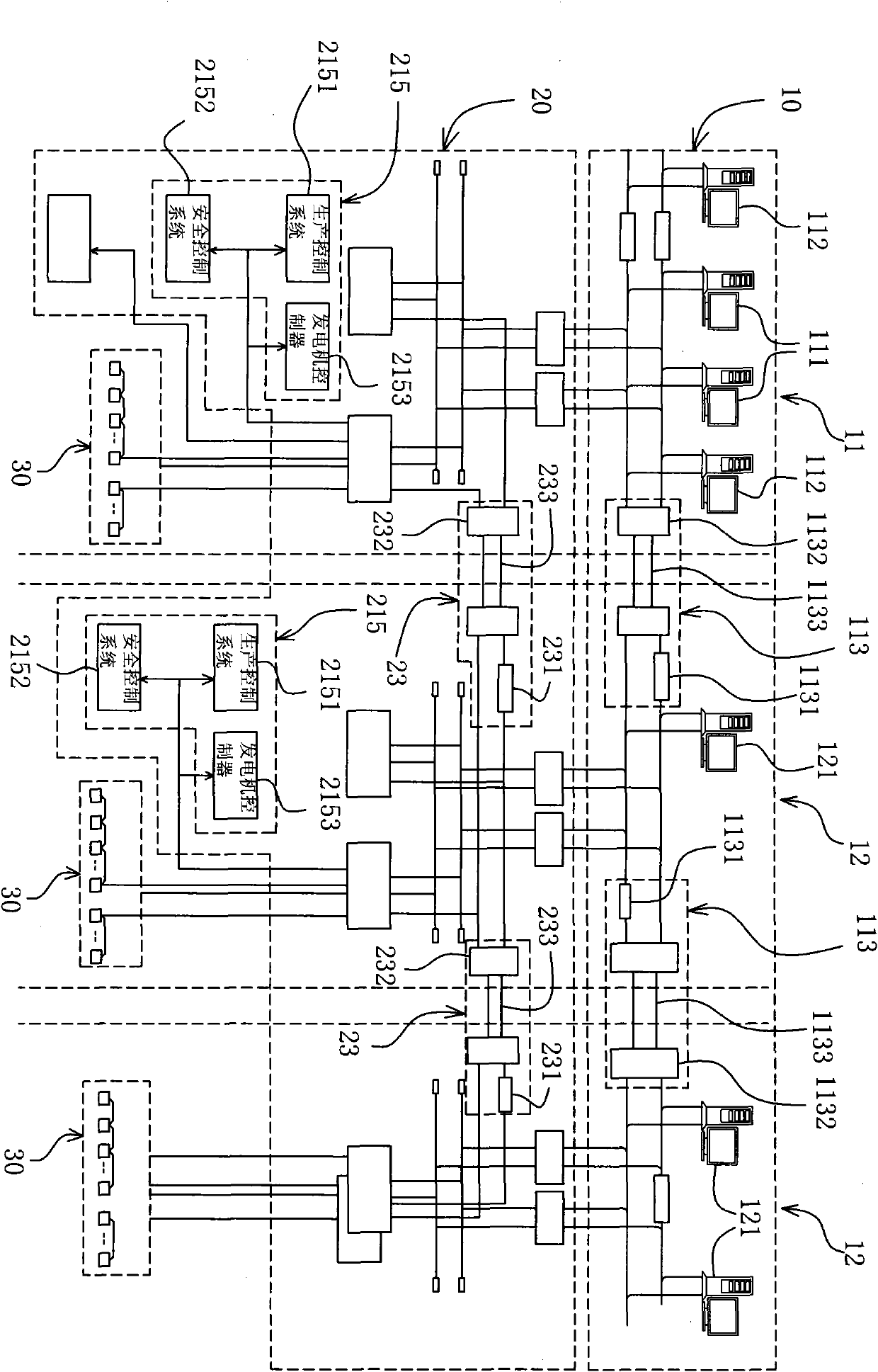

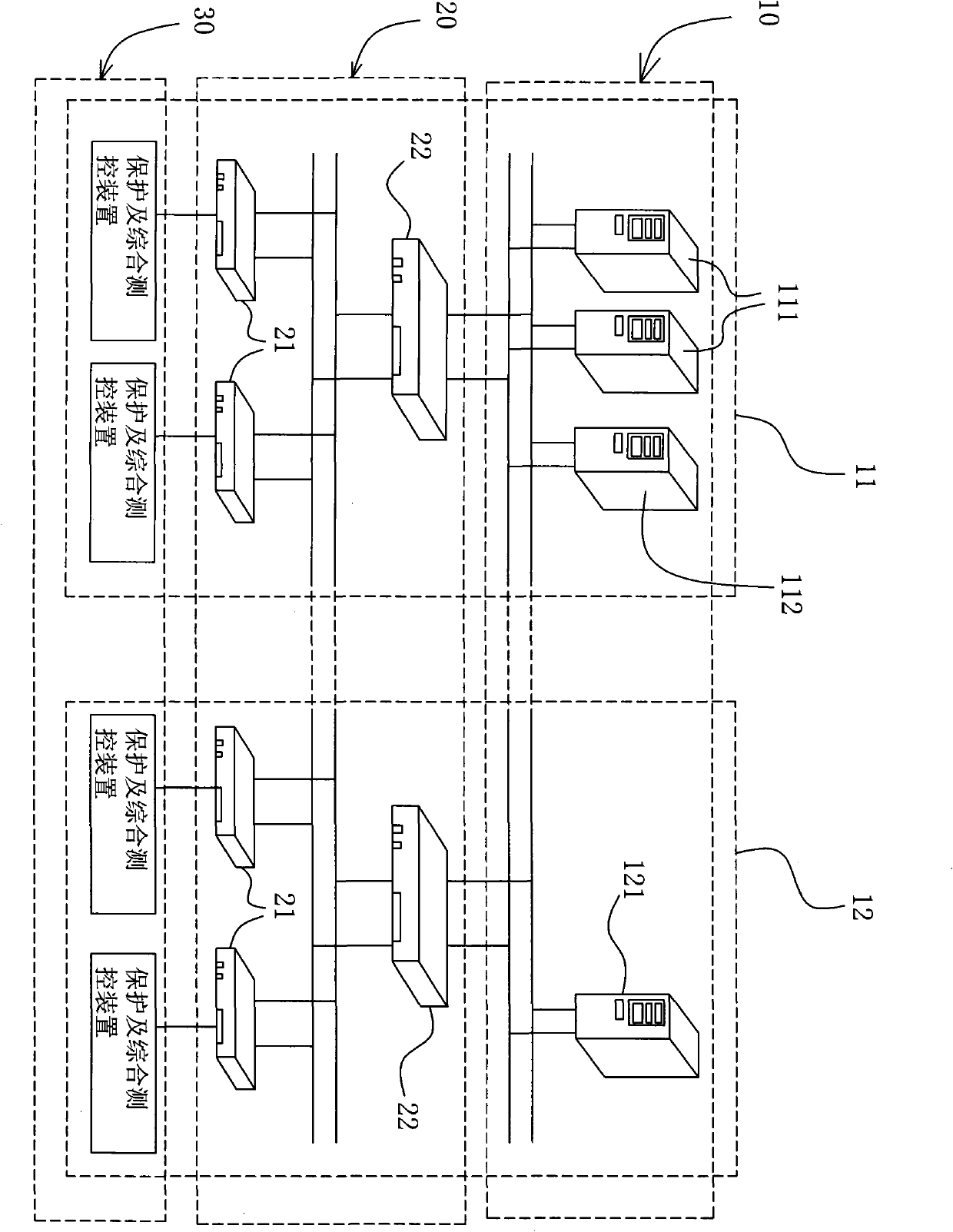

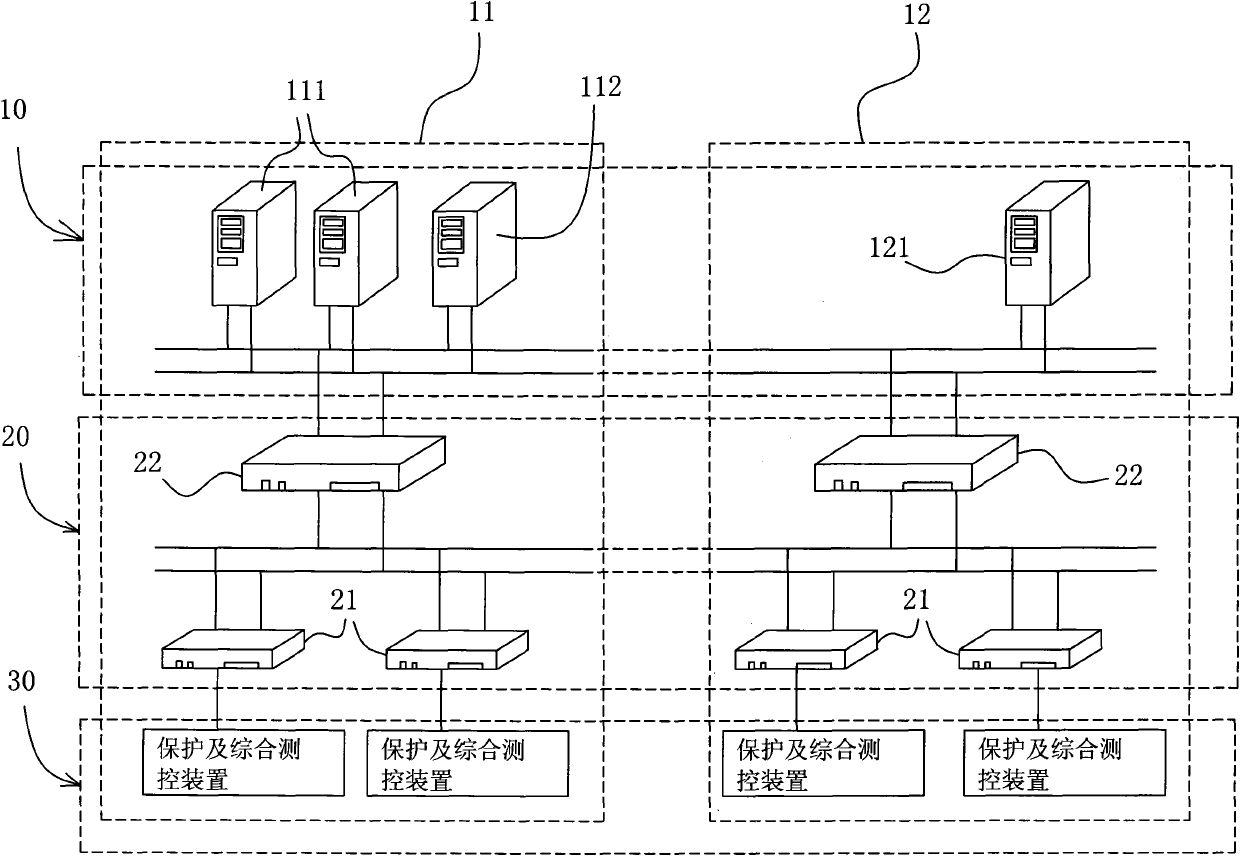

Energy management system of offshore grid

ActiveCN101951025ARealize monitoringEasy to controlCircuit arrangementsInformation layerControl layer

The invention discloses an energy management system of offshore grid, comprising an information layer, a station control layer and a spacing layer, wherein the information layer, the station control layer and the spacing layer are respectively arranged in a central control station and the platform workstations of a plurality of offshore platform power stations distributed in a sea area; the station control layer is connected and communicated with the information layer and the spacing layer through a communication network; the system carries out the monitoring and control of each generator set, the monitoring and control of each breaker, the distribution, adjustment and control of the reactive power and reactive power contribution, the control of the preferential trip, the management and control of the loop start of a motor, and the cooperative control of the black start of the grid and a platform shutdown system through the information layer, the station control layer and the spacing layer. The invention has the characteristics of high channel speed and degree of automation, highly integrated function, safe and reliable work, easy maintenance, and flexible configuration.

Owner:CHINA NAT OFFSHORE OIL CORP +2

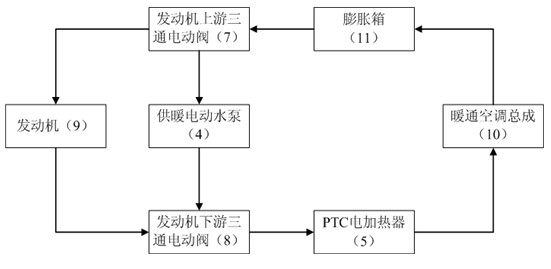

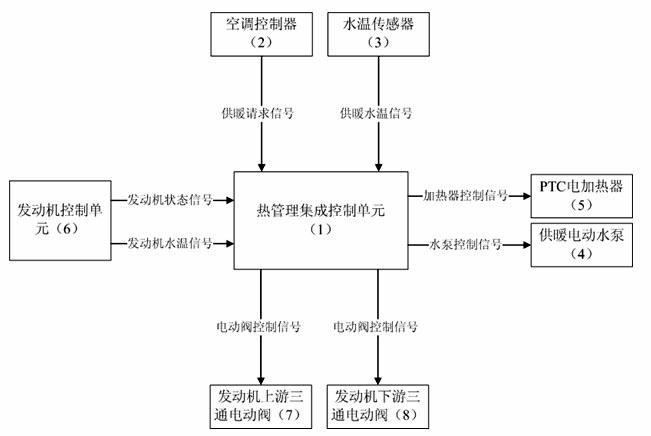

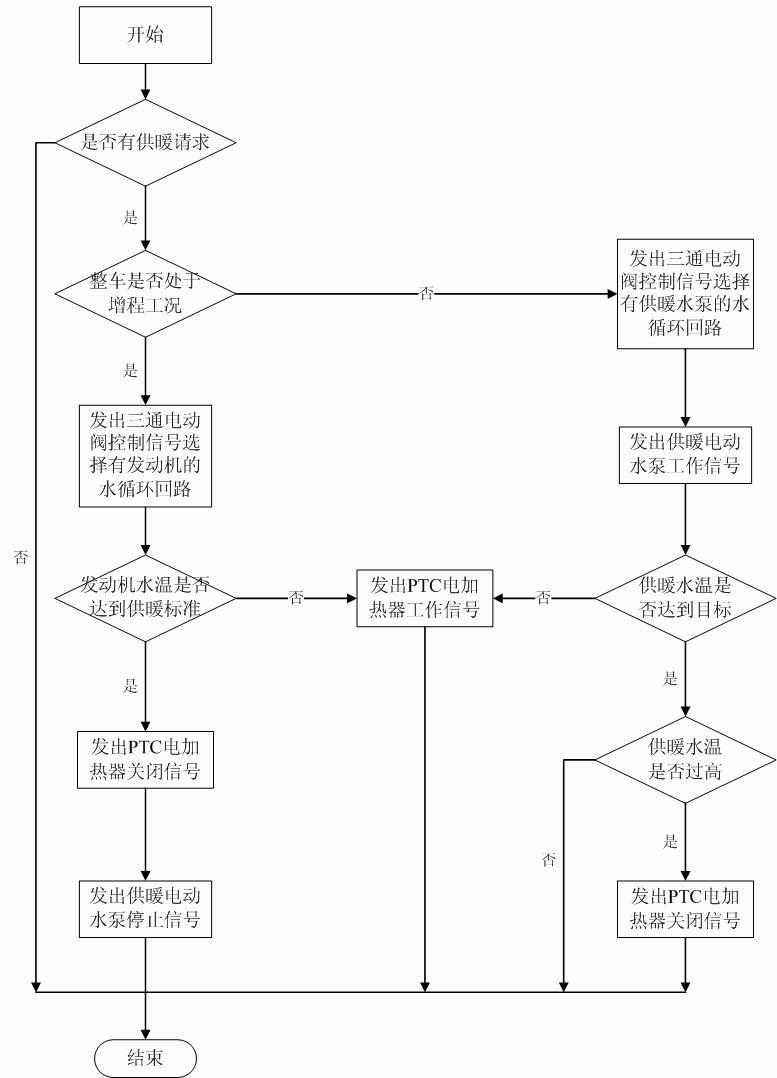

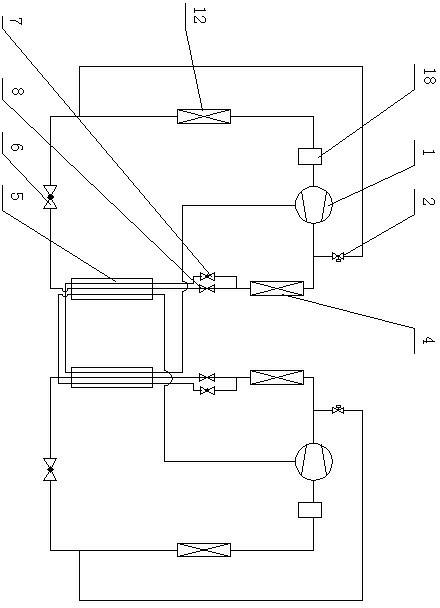

Air-conditioner heating system for extended range electric vehicle and control method of air-conditioner heating system

ActiveCN102529642AImprove battery lifeSave time at workAir-treating devicesVehicle heating/cooling devicesExpansion tankHeat management

The invention discloses an air-conditioner heating system for an extended range electric vehicle, which comprises a control circuit and two heating circulating water loops. The control circuit comprises a heat management integrated control unit, an air-conditioner controller, a water temperature sensor, a heating electric water pump, a PTC (positive temperature coefficient) electric heater and an engine control unit. The first heating circulating water loop starts from the heating electric water pump to sequentially pass through an engine lower three-way electric valve, the PTC electric heater, a heating ventilation air-conditioner assembly, an expansion tank and an engine upper three-way electric valve and returns to the heating electric water pump through water pipes. The second heating circulating water loop starts from an engine to sequentially pass through the engine lower three-way electric valve, the PTC electric heater, the heating ventilation air-conditioner assembly, the expansion tank and the engine upper three-way electric valve and returns to engine through water pipes. The invention further discloses a control method of the air-conditioner heating system for the extended range electric vehicle. Usable heat and power source in operation of the engine are effectively used by the air-conditioner heating system and the method, and electric quantity of batteries is saved while endurance mileage of the vehicle is increased.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

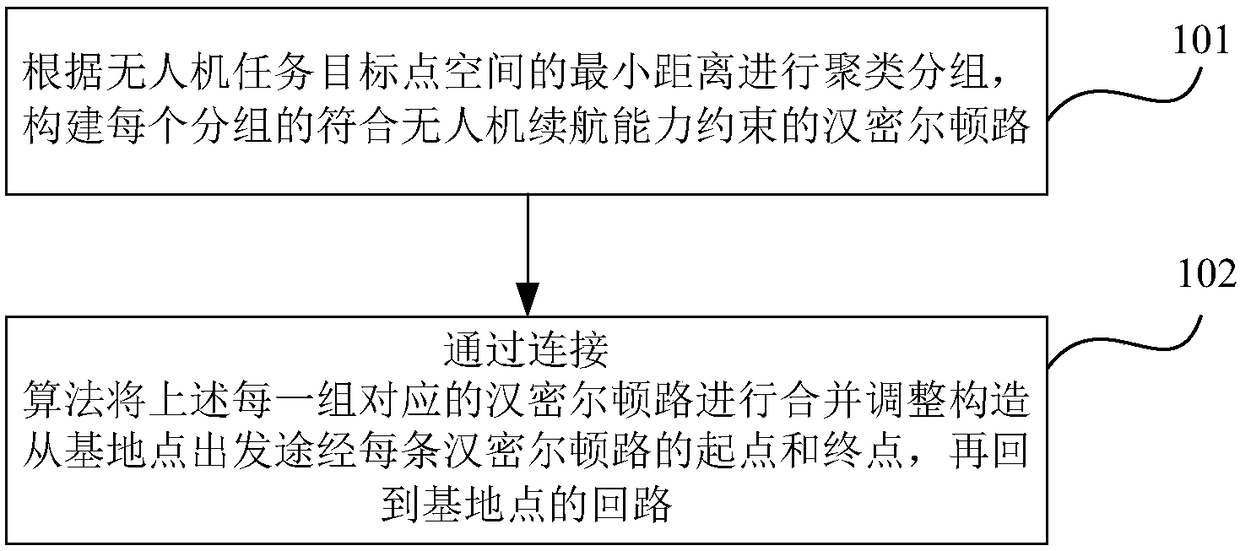

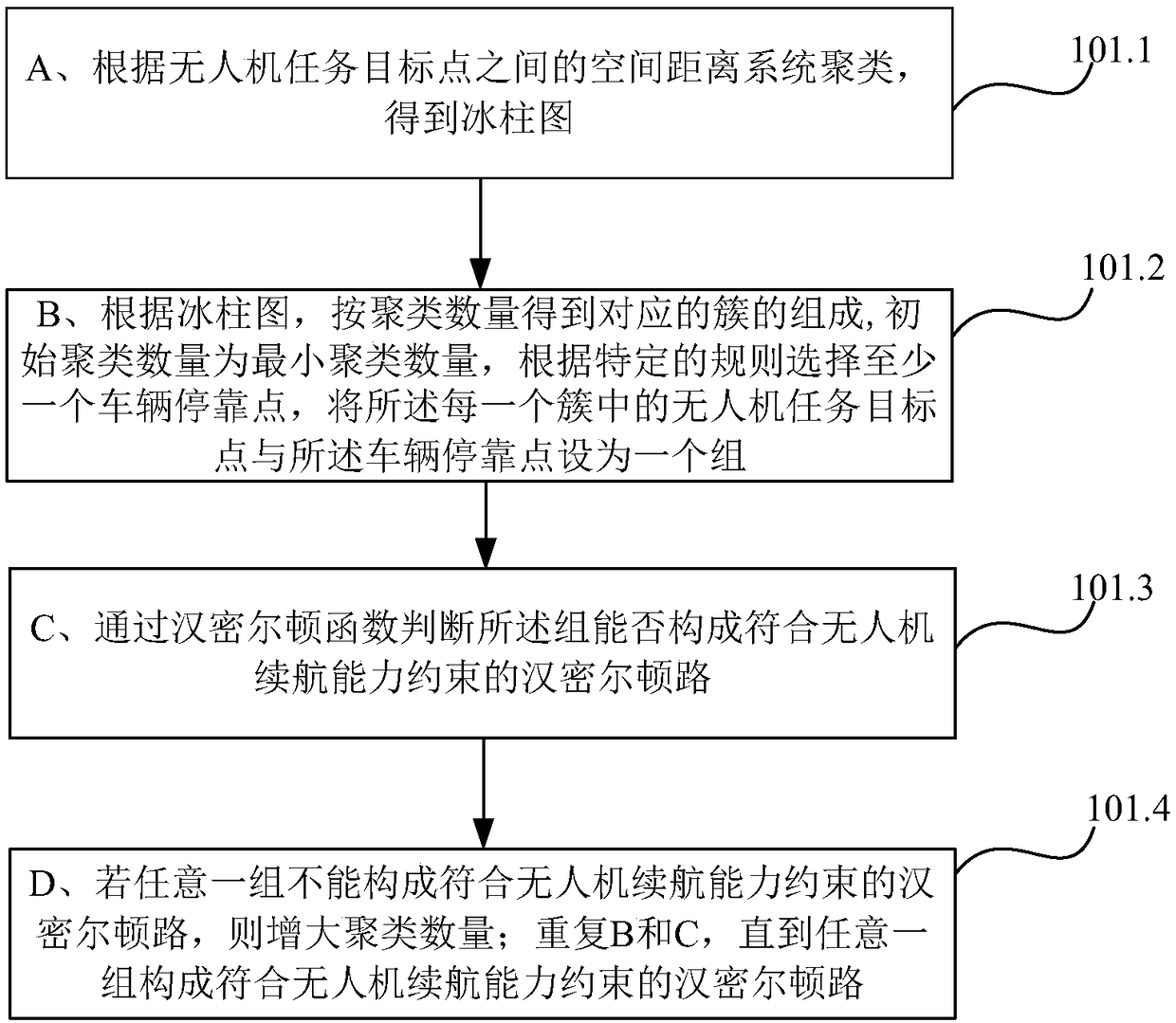

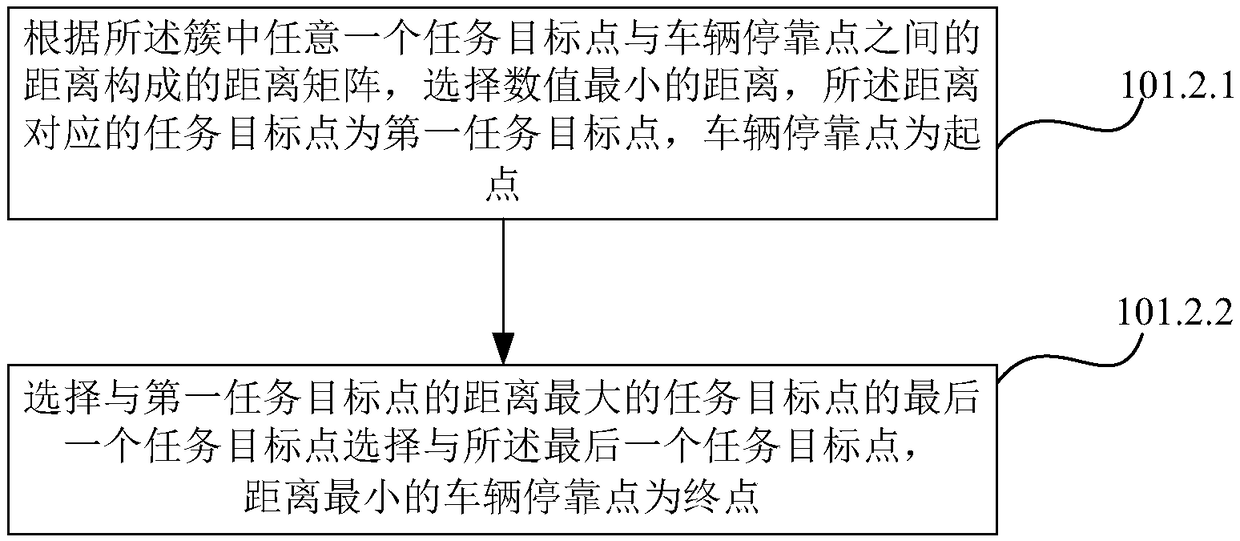

Construction method and device for double-layer path of vehicle-mounted unmanned aerial vehicle

ActiveCN108256553AShorten the timeNavigational calculation instrumentsForecastingPath networkCluster group

Owner:NAT UNIV OF DEFENSE TECH

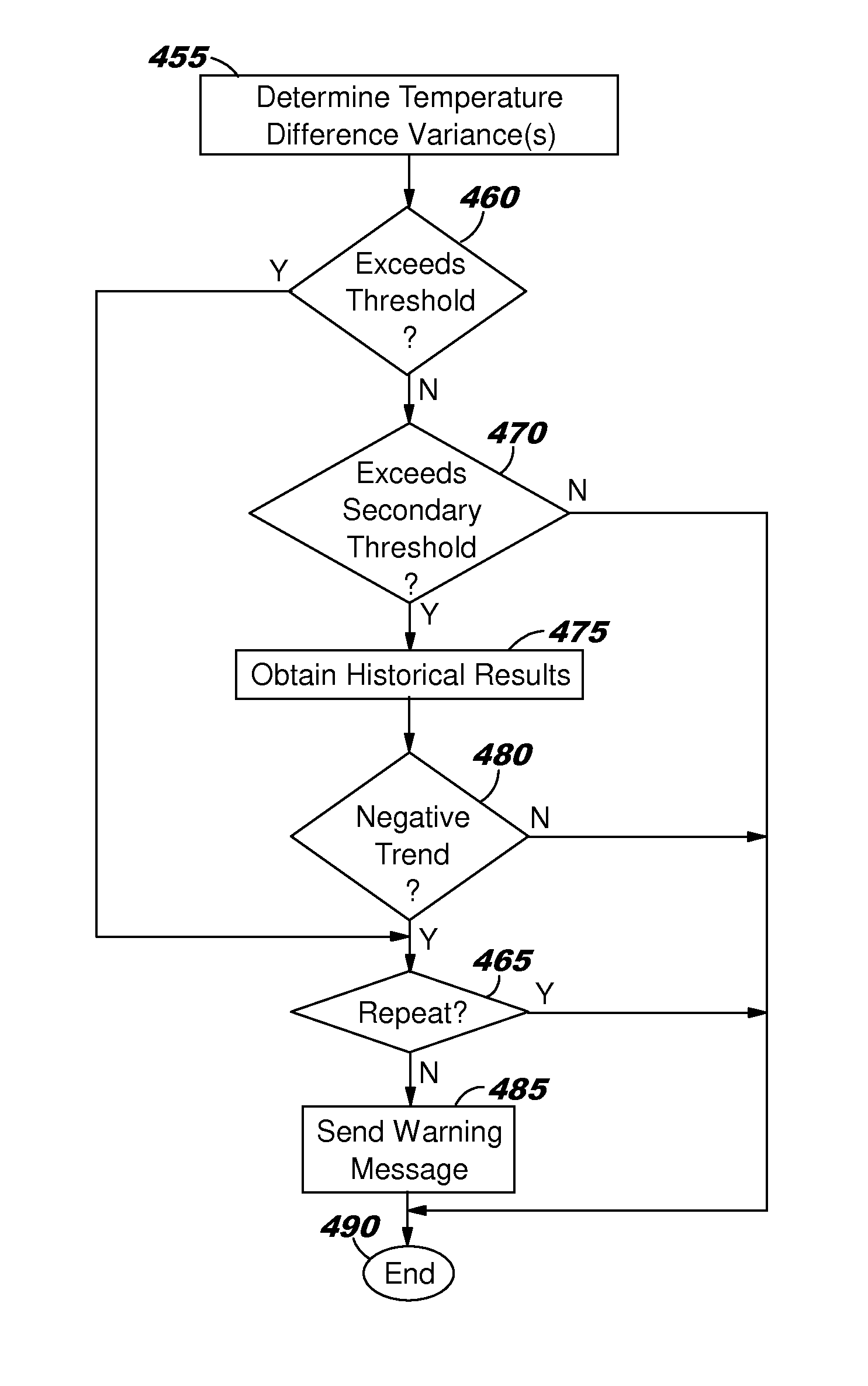

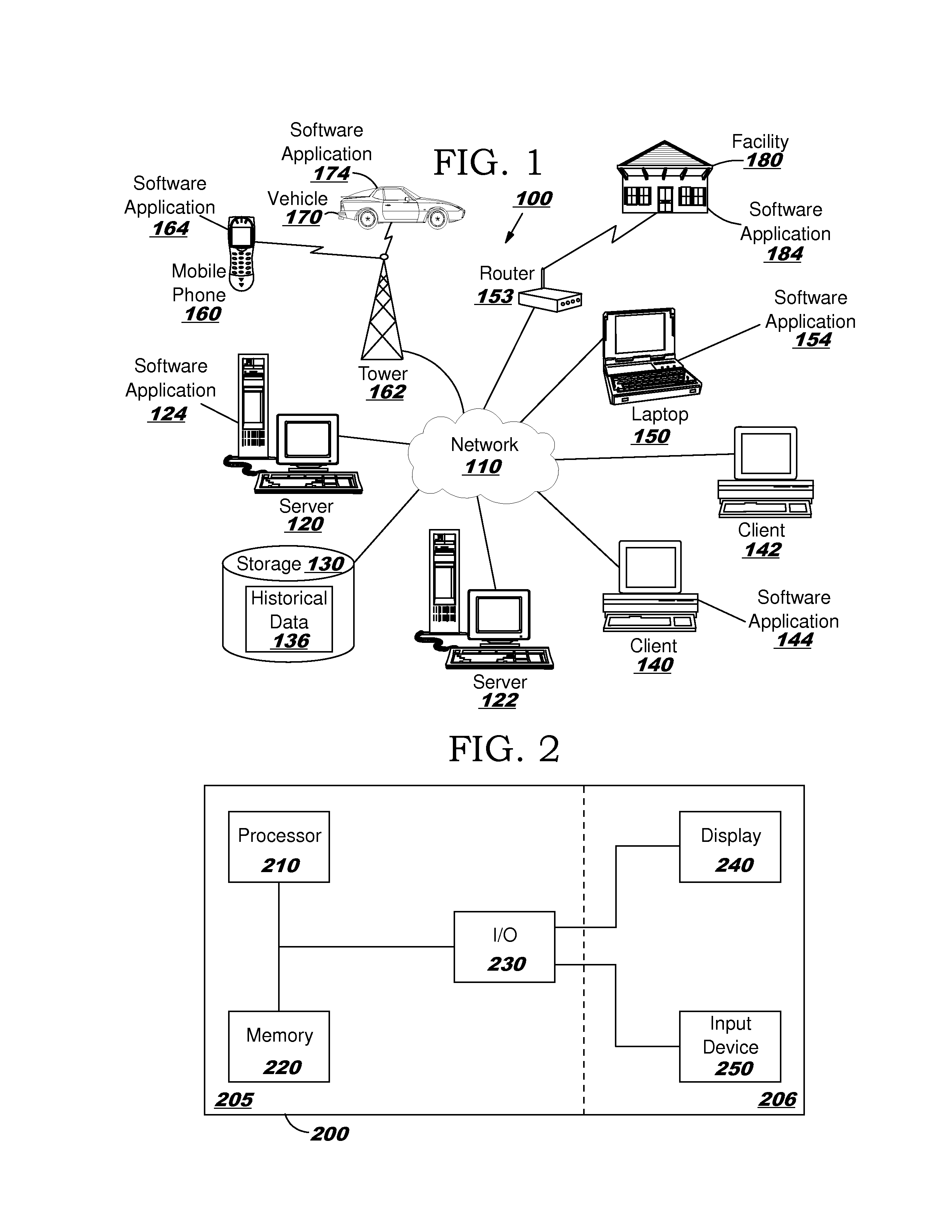

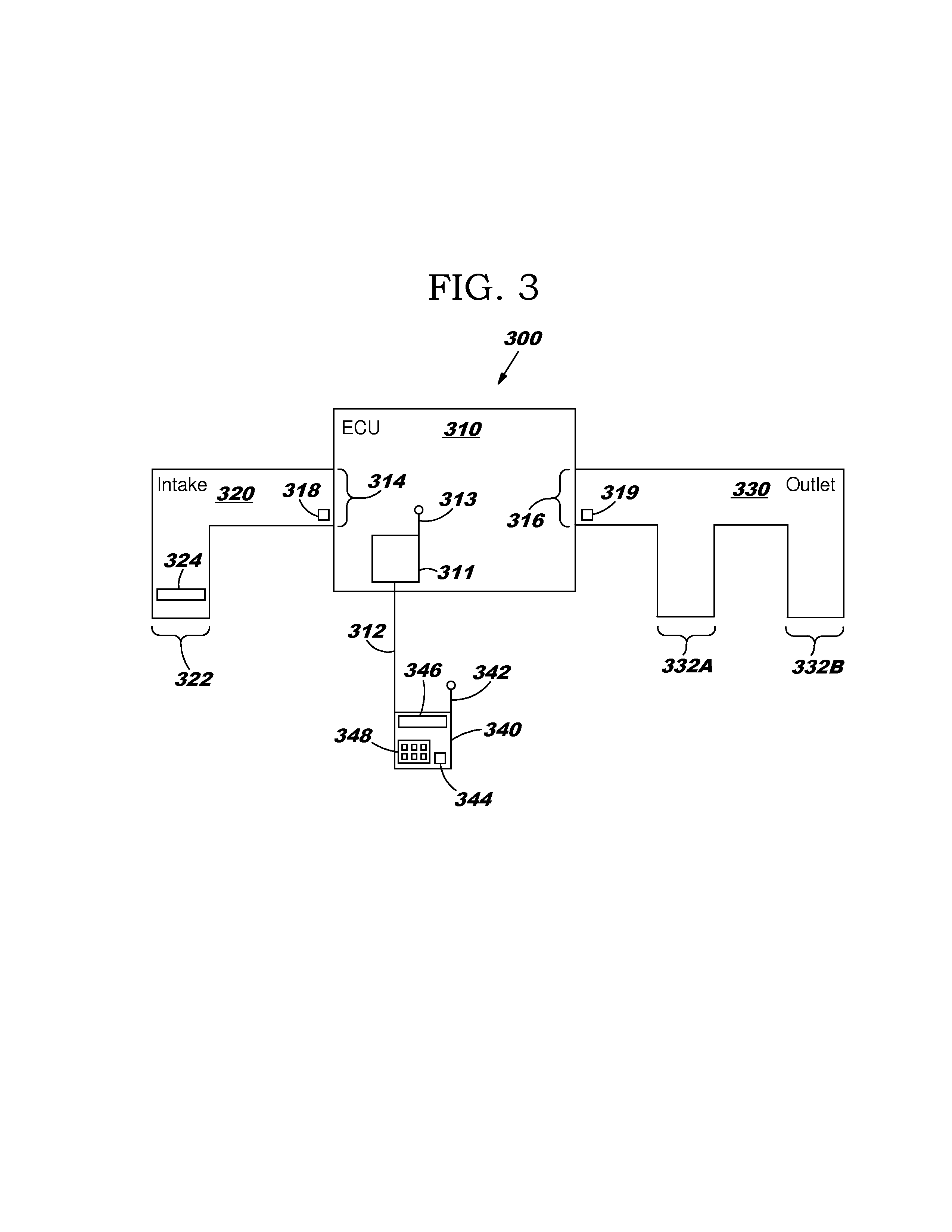

Managing environmental control system efficiency

A method, system or computer usable program product for providing alerts of inefficiency of an environmental conditioning system including, responsive to a cycle initiation by the environmental conditioning system, measuring a difference between an intake temperature and an outlet temperature after a predetermined period of time, and responsive to the difference being below a minimum level, generating an alert.

Owner:GENERAC POWER SYSTEMS

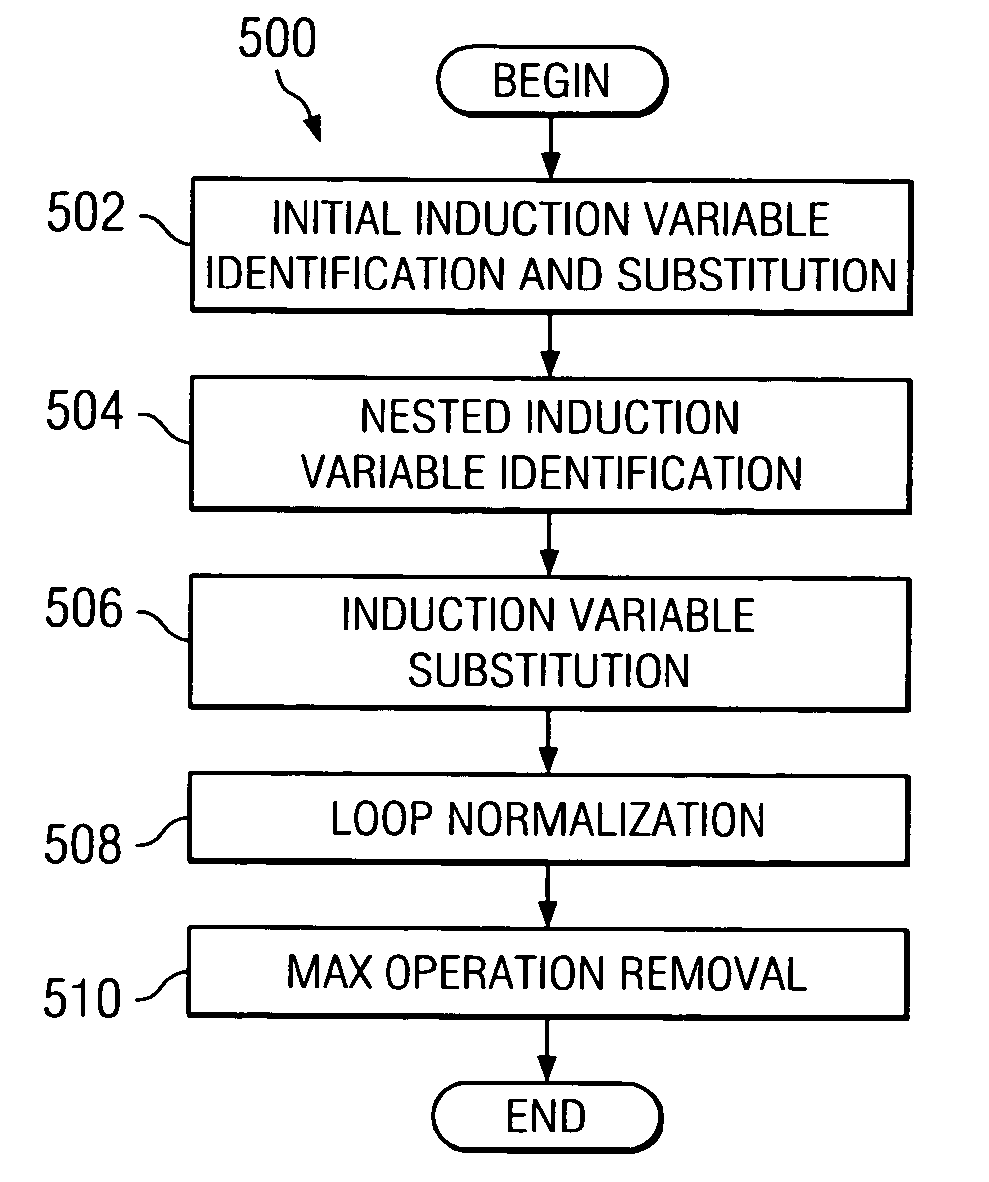

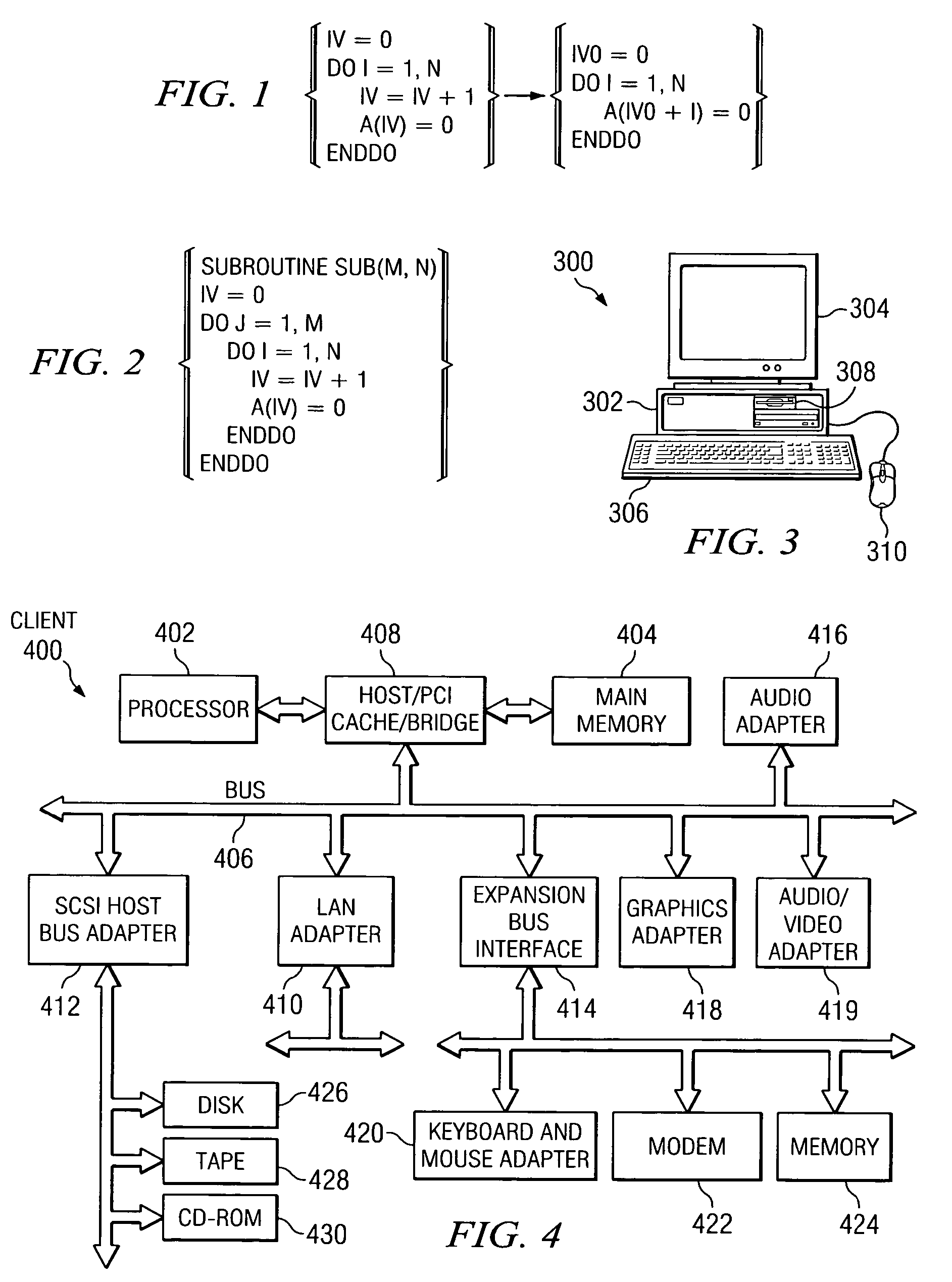

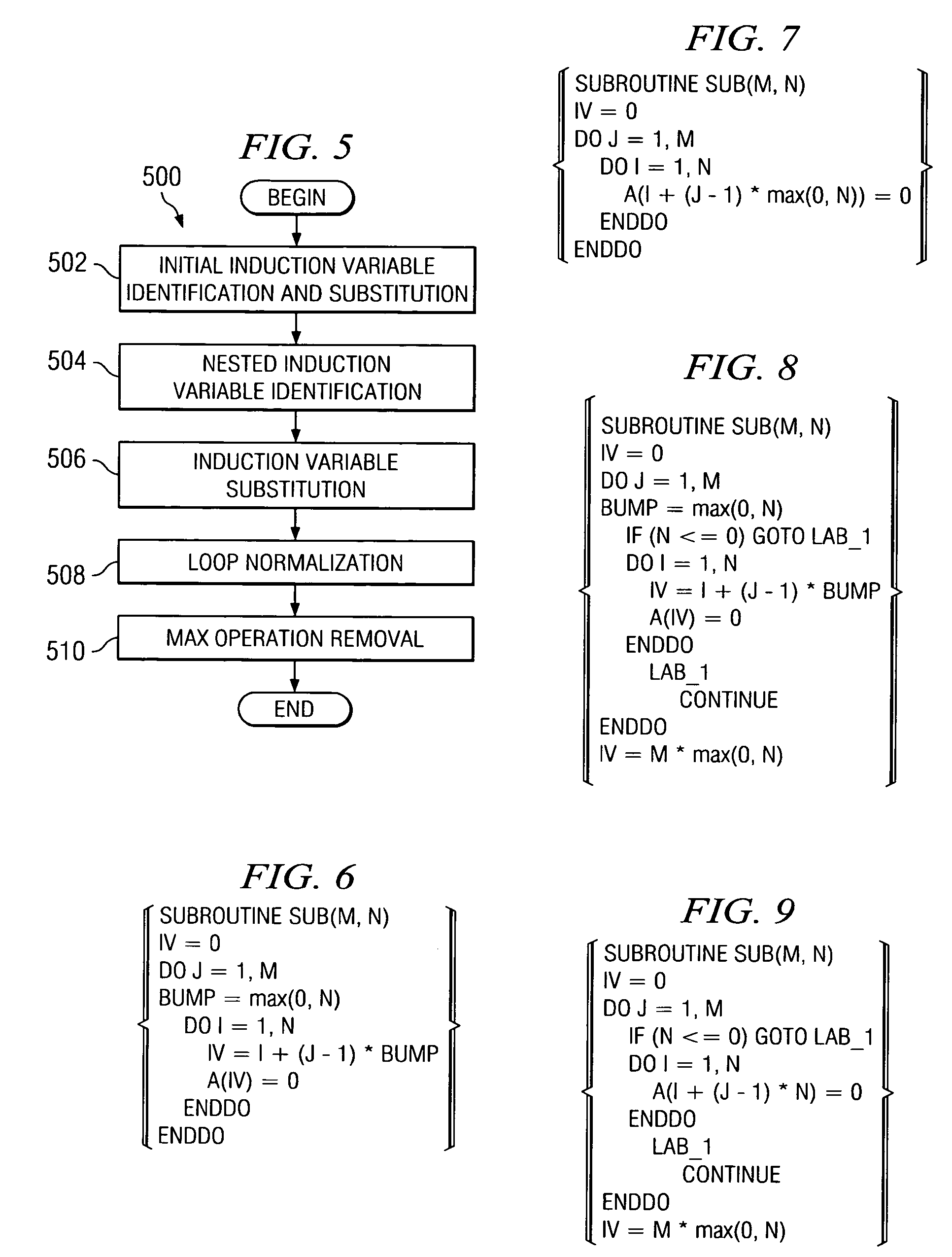

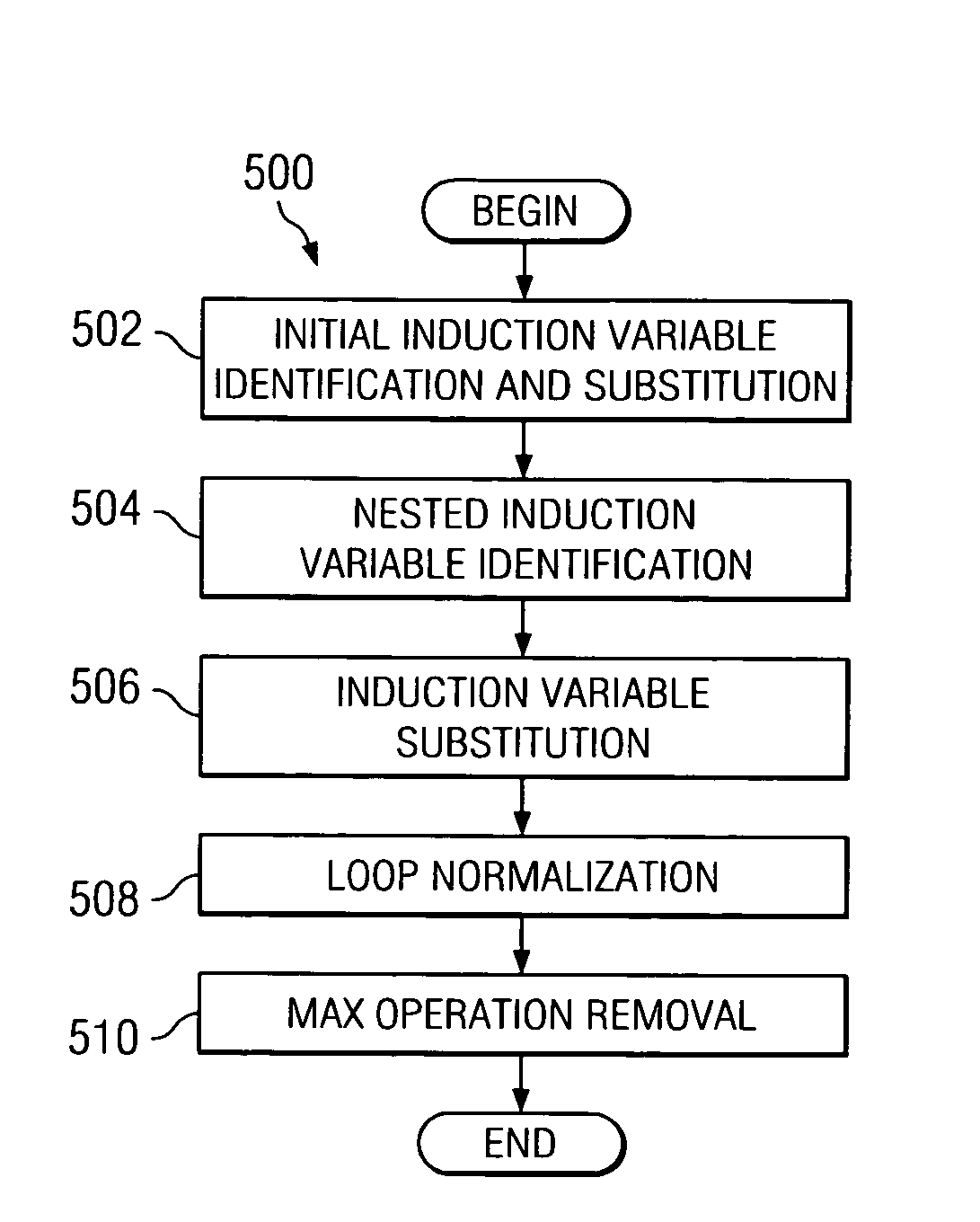

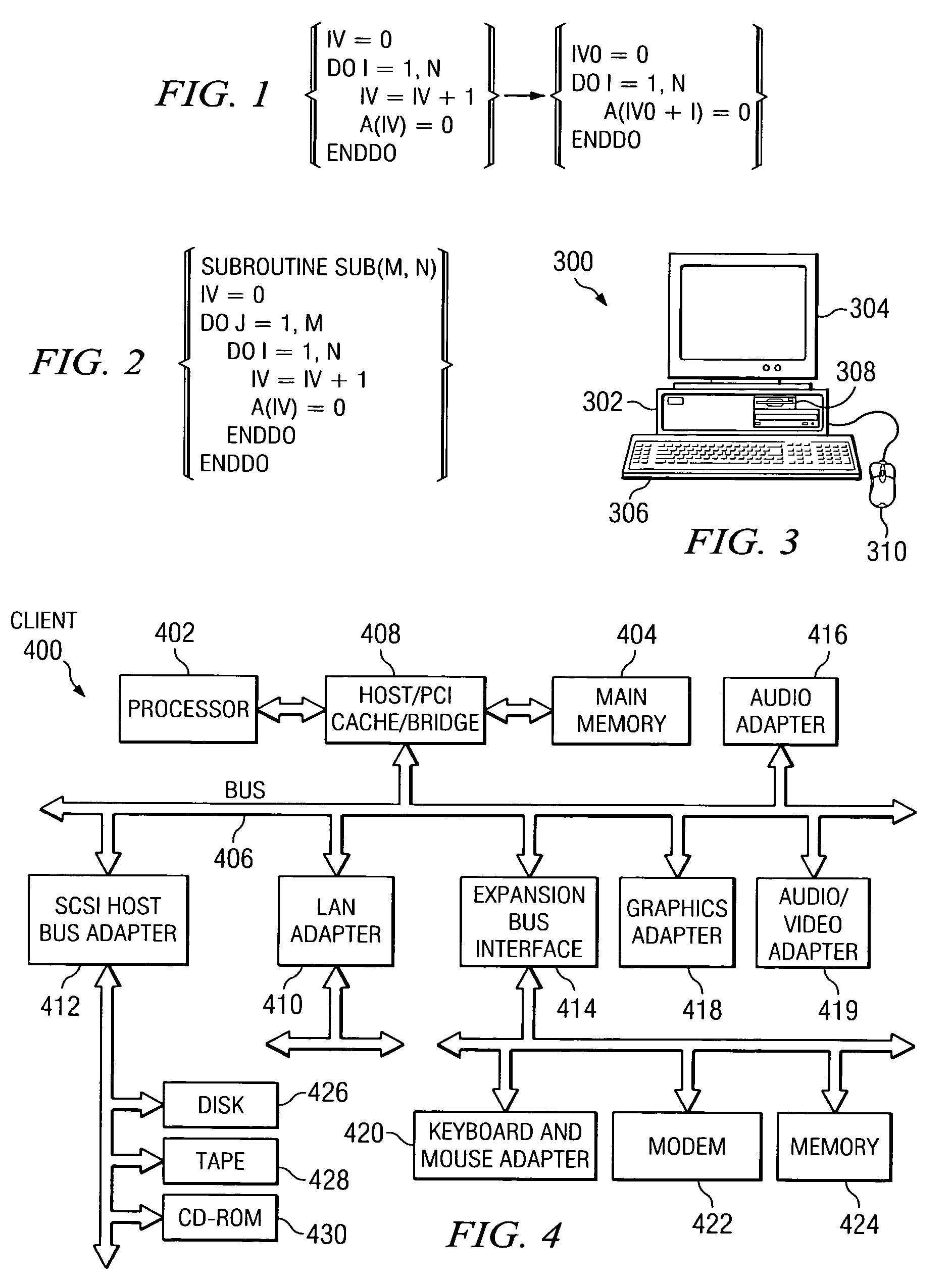

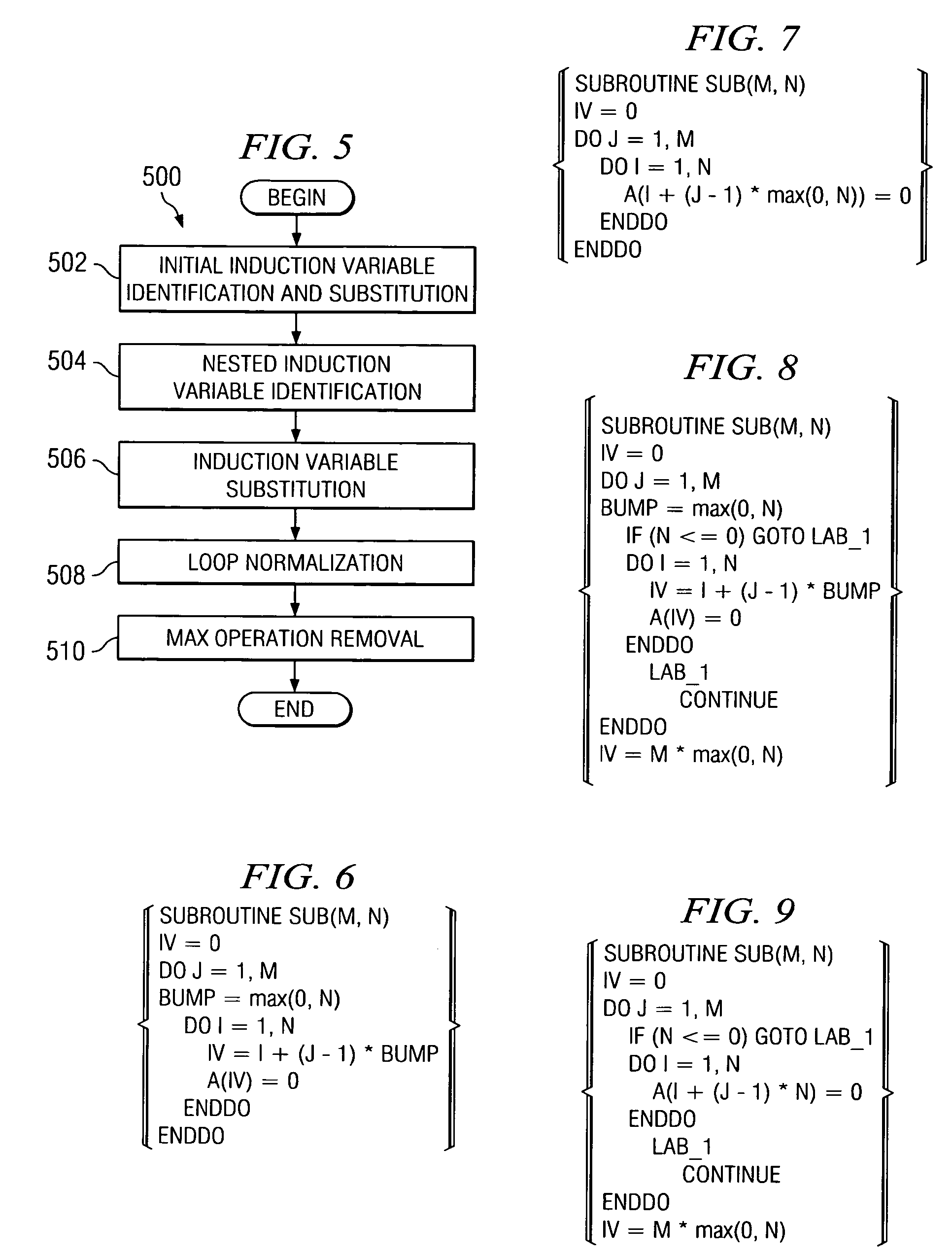

Method and system for auto parallelization of zero-trip loops through induction variable substitution

InactiveUS20060048119A1Eliminates loop dependency on the induction variableSoftware engineeringProgram controlCopy propagationEngineering

A method and system of auto parallelization of zero-trip loops that substitutes a nested basic linear induction variable by exploiting a parallelizing compiler is provided. Provided is a use of a max{0,N} variable for loop iterations in case of no information is known about the value of N, for a typical loop iterating from 1 to N, in which N is the loop invariant. For the nested basic induction variables, an induction variable substitution process is applied to the nested loops starting from the innermost loop to the outermost one. Then a removal of the max operator afterwards through a copy propagation pass of the IBM compiler is provided. In doing so, the loop dependency on the induction variable is eliminated and an opportunity for a parallelizing compiler to parallel the outermost loop is provided.

Owner:IBM CORP

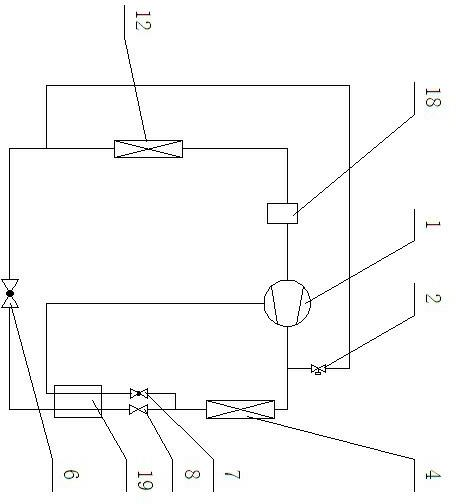

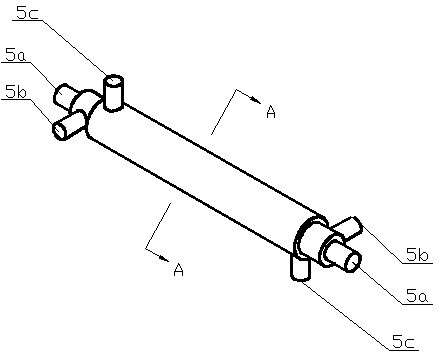

Coupling injection enthalpy-increasing air source heat pump system

InactiveCN102563974AStrong complementarityContinuous heatingHeat pumpsCorrosion preventionVapor–liquid separatorEngineering

The invention relates to an air source heat pump system, which comprises two injection enthalpy-increasing air source heat pump subsystems and two triple-sleeve heat exchangers. A refrigerating loop starts from an outlet of an indoor heat exchanger of each subsystem, runs through a flow regulating valve and enters a suction opening of a compressor via the triple-sleeve heat exchanger, a first throttling valve, an outdoor heat exchanger and a first gas and liquid separator of the subsystem; and an air supplementing loop is branched at the outlet of the indoor heat exchanger of each subsystem and enters an air supplementing opening of the compressor of the subsystem via a second throttling valve, the triple-sleeve heat exchanger and a coupling subsystem triple-sleeve heat exchanger of the subsystem. By the aid of the coupling injection enthalpy-increasing air source heat pump system, problems that heat cannot be supplied continuously during defrosting in a low-temperature environment and defrosting time is long are solved, energy is reasonably utilized, heat required by defrosting is increased, and problems that the quantity of accumulated liquid refrigerating working media generated by an outdoor heat exchanger of a defrosting subsystem is increased, a compressor is impacted by liquid and the like are solved.

Owner:CHONGQING UNIV

Starting method of senseless permanent magnet synchronous motor

ActiveCN108418480AStarts smooth and smoothReduce start-up energy consumptionAC motor controlVector control systemsStart timeControl vector

The invention discloses a starting method of a senseless permanent magnet synchronous motor, comprising the following steps: S10), after short-circuiting a motor winding, detecting a motor induced current by driving a sampling module of a controller; S20), determining whether the motor induced current is less than a predetermined value of induced current, if so, proceeding to step S30), or if not,proceeding to step S40); S30), performing open-loop start control; S40), determining whether the motor is in a forward or reverse rotation state, if in the forward rotation state, proceeding to stepS50), if not, proceeding to step S60); S50), performing forward rotation closed-loop vector start control; and S60), performing reverse rotation closed-loop vector start control. The starting method ensures the fast and low-current high-efficiency start when the permanent magnet synchronous motor is stationary or tends to be stationary, realizes fast closed-loop vector control under strong downwind or upwind conditions, reduces energy consumption, shortens start time, and makes motor start smooth.

Owner:苏州半唐电子有限公司

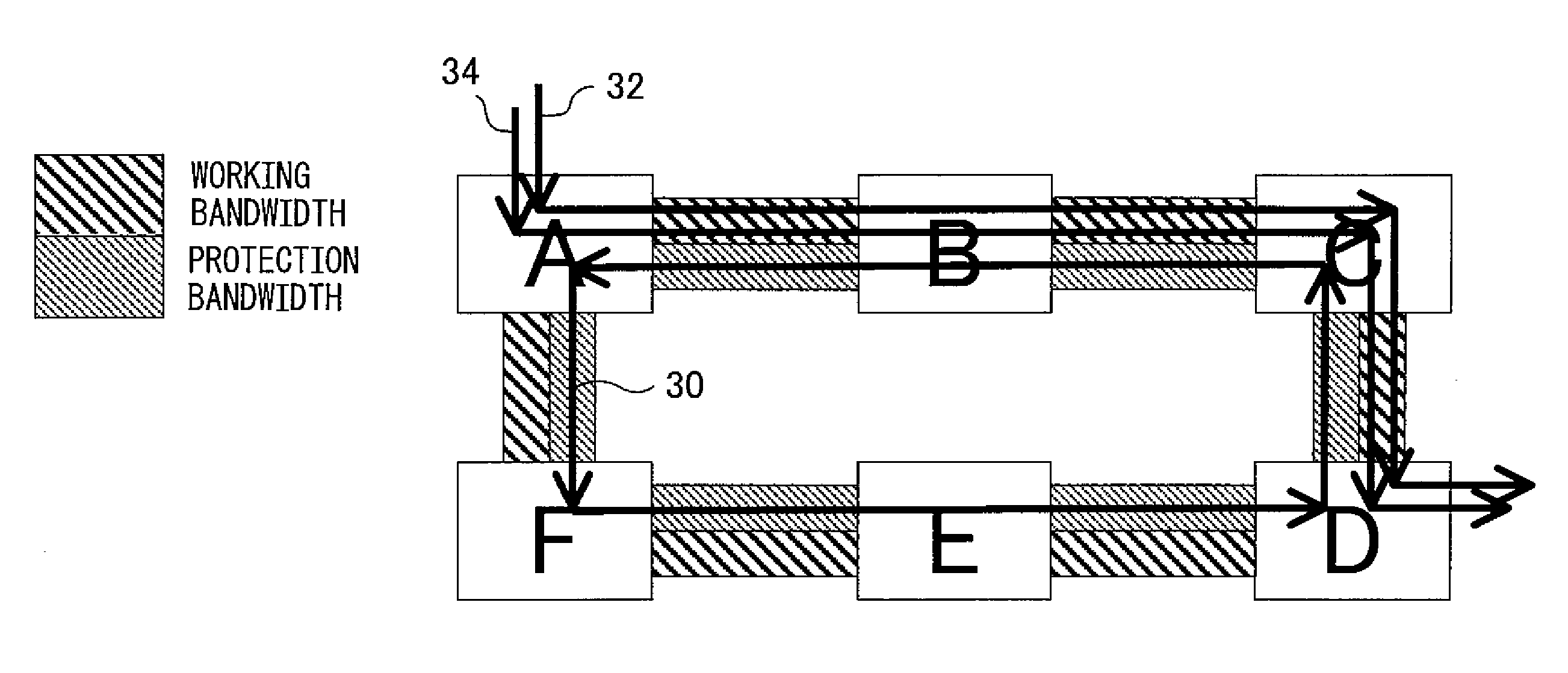

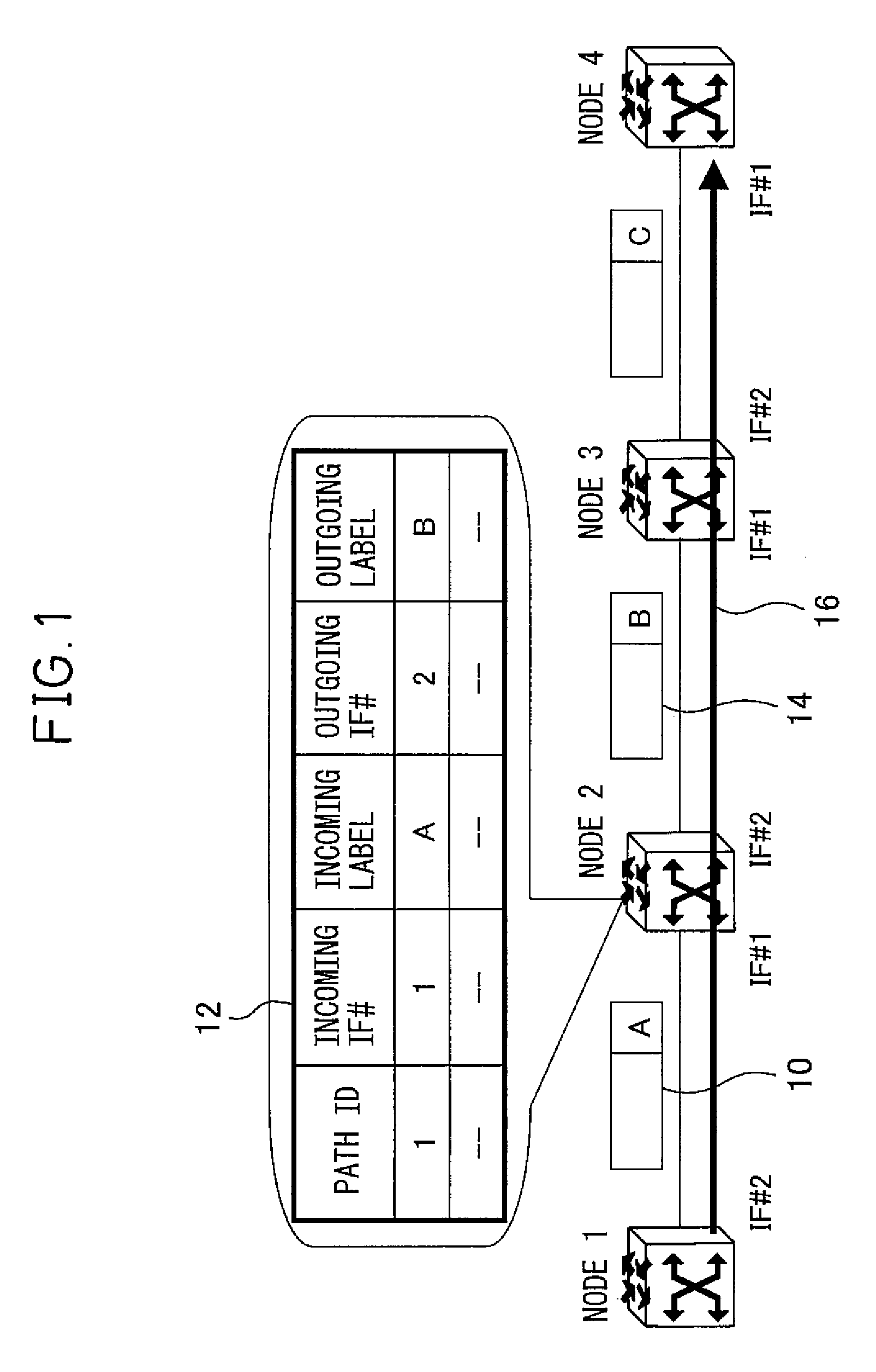

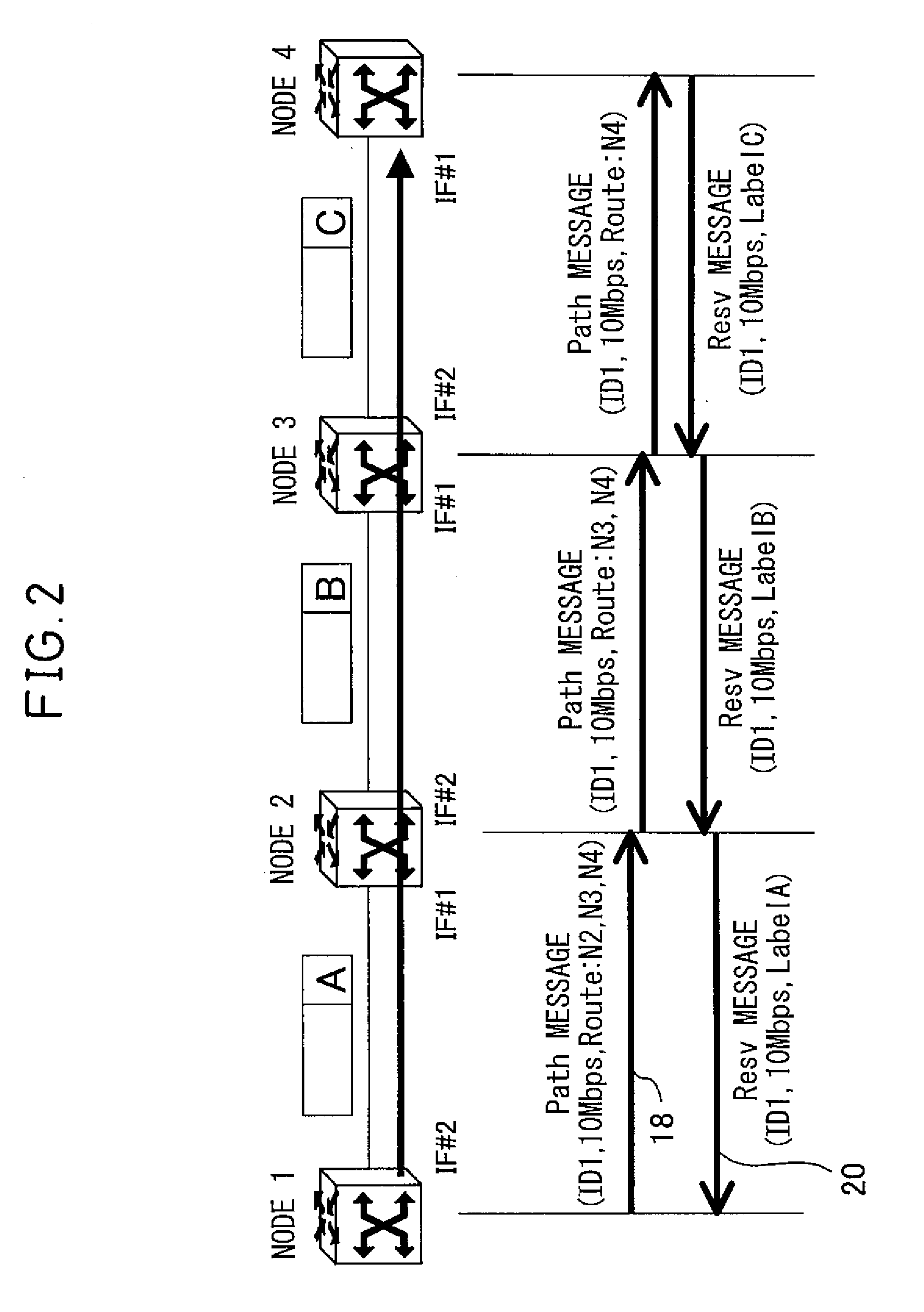

Management of protection path bandwidth and changing of path bandwidth

InactiveUS20080170496A1Easy to useError preventionTransmission systemsBandwidth managementChange request

A highly efficient protection path bandwidth management method is provided. When a protection path is set up in a loop with a node A as the starting point and endpoint in order to protect a working path, the bandwidth of the protection path is changed by transferring a bandwidth change request message, containing the identifier of the protection path as well as the value of the bandwidth after the change, so as to cycle once around the protection path set up in a loop starting from a node B that first received a PATH message for a working path.

Owner:FUJITSU LTD

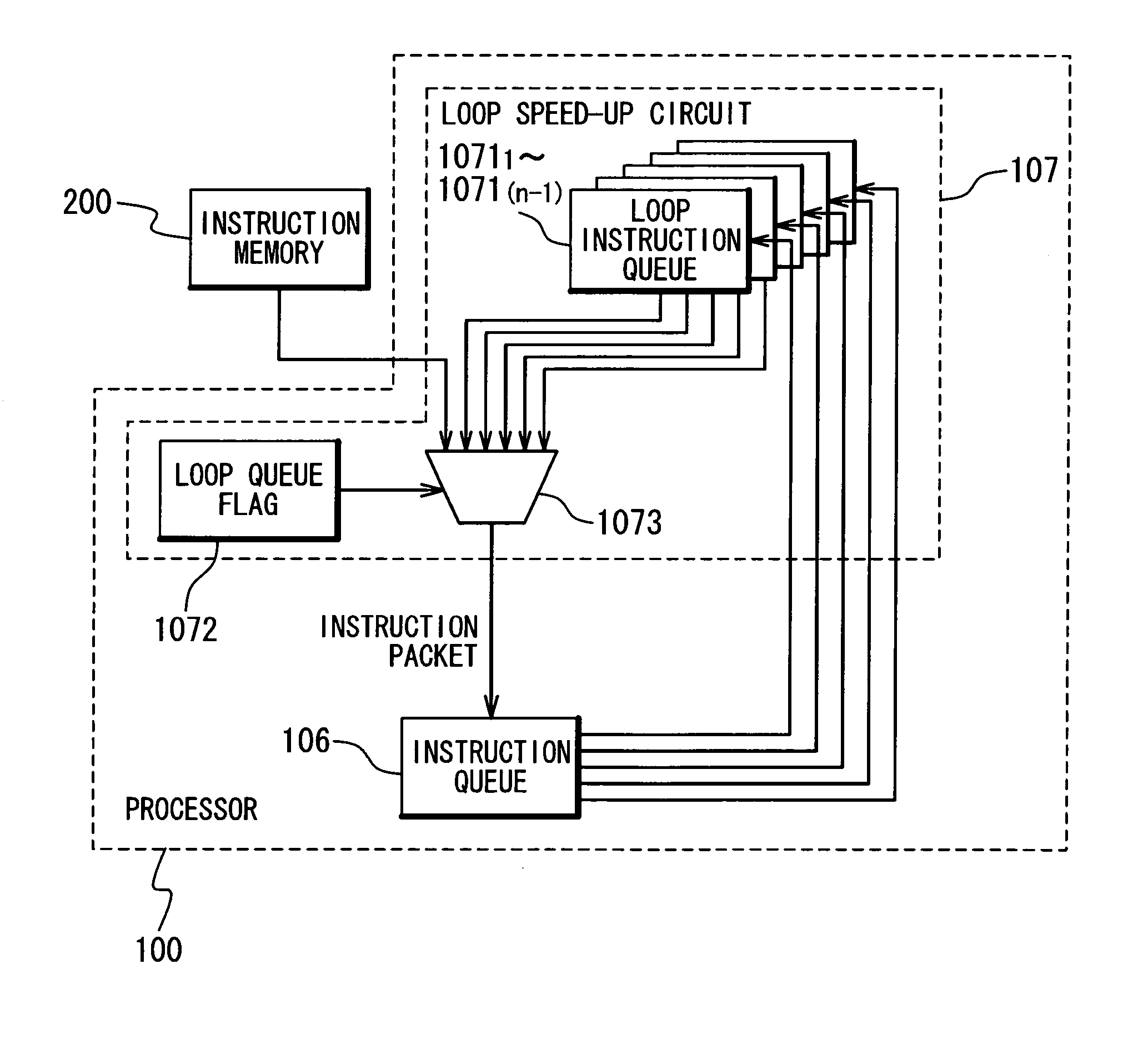

Data processing apparatus adopting pipeline processing system and data processing method used in the same

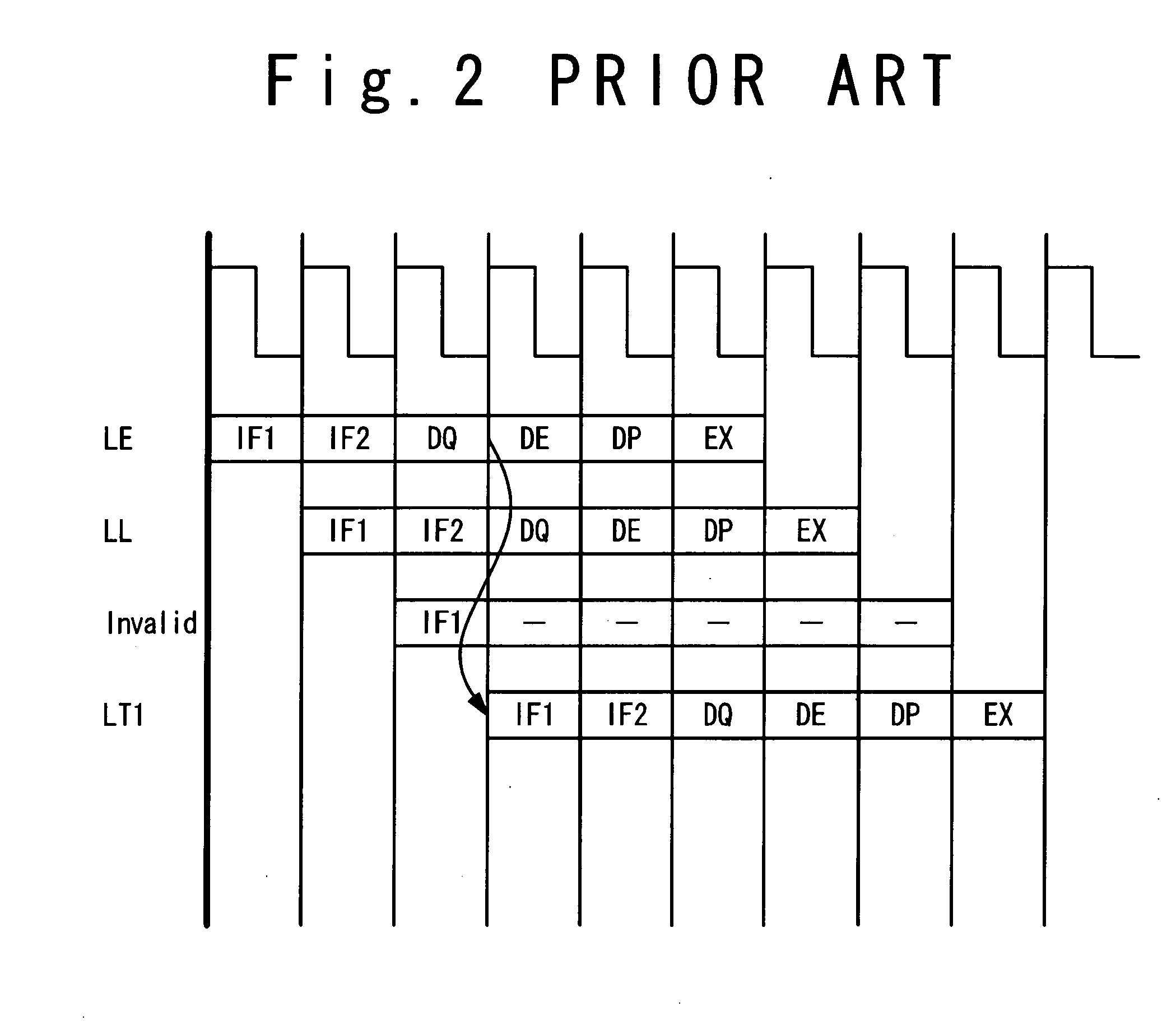

InactiveUS20050223204A1Digital computer detailsNext instruction address formationInstruction memoryCyclic process

A data processing apparatus adopting a pipeline processing system, includes an instruction memory which store instruction packets; and a processing unit configured to execute the instruction packets sequentially in a pipeline manner. The processing unit includes an instruction queue and a loop speed-up circuit. The instruction packets stored in the instruction queue are executed sequentially by the processing unit. The loop speed-up circuit stores the instruction packets read out from the instruction memory into the instruction queue sequentially, holds the instruction packet containing a loop start address for a loop process, and outputs the held instruction packet to the instruction queue, when a loop process end is detected and the loop process is not circulated for a predetermined number of times.

Owner:NEC ELECTRONICS CORP

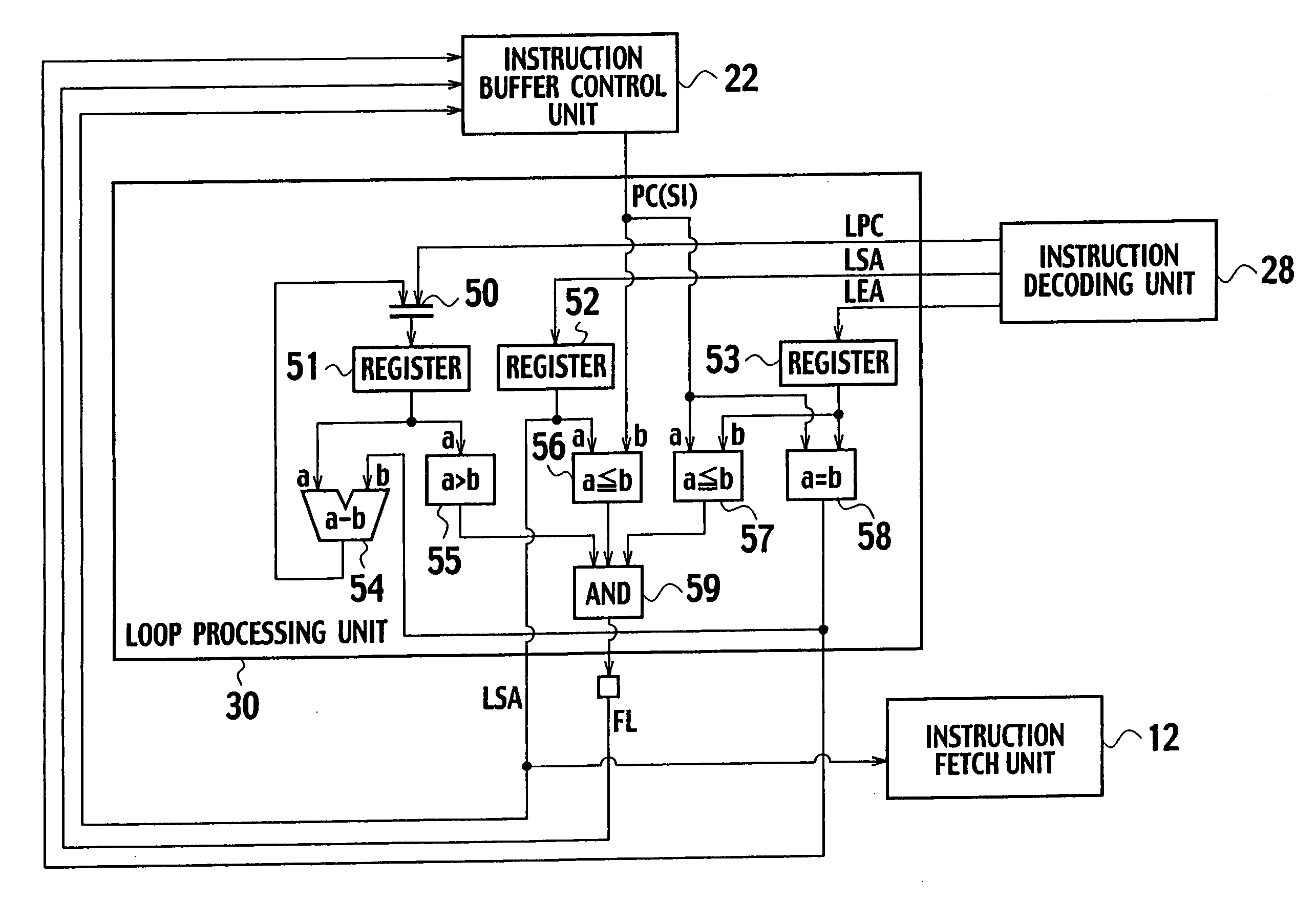

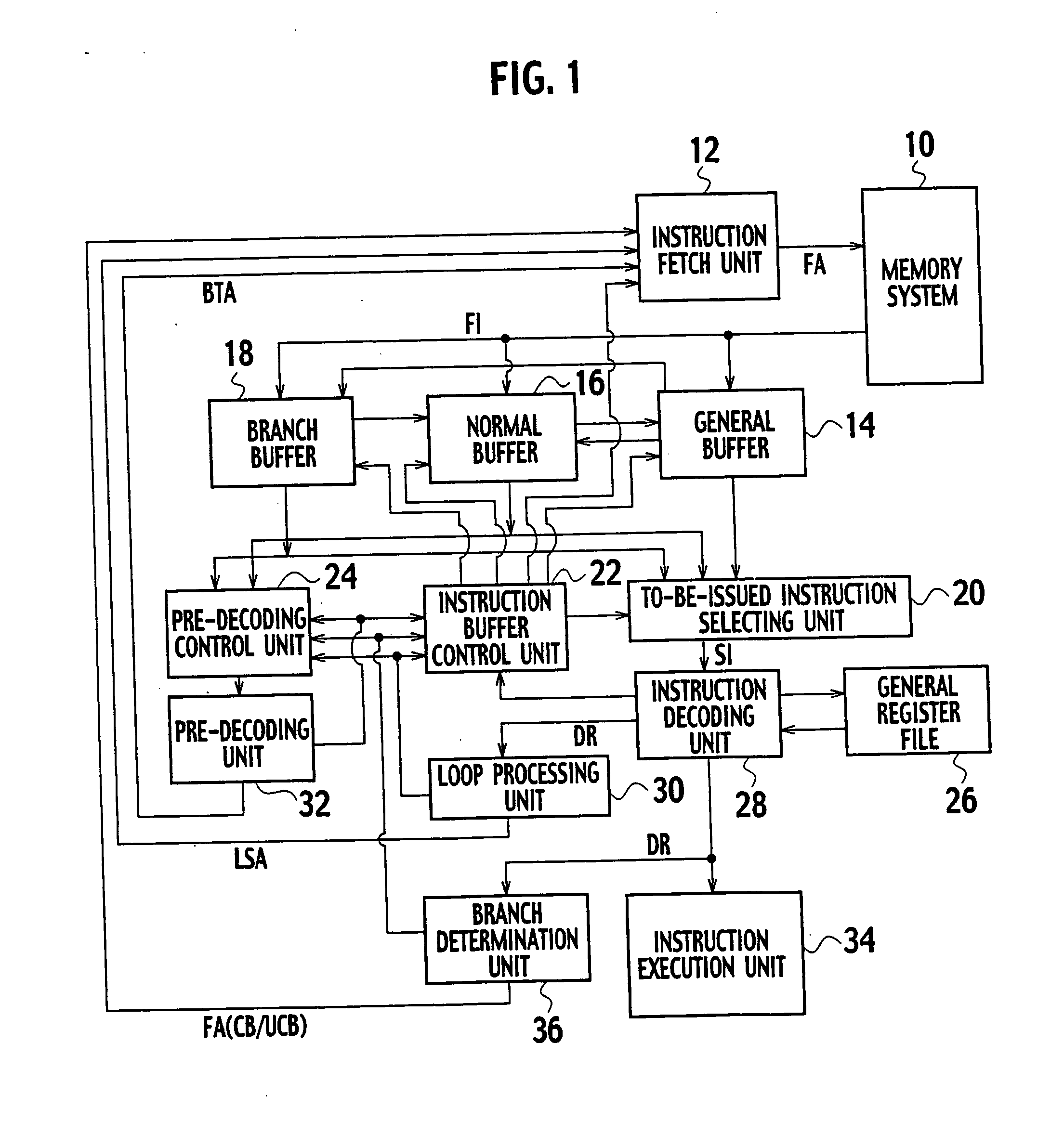

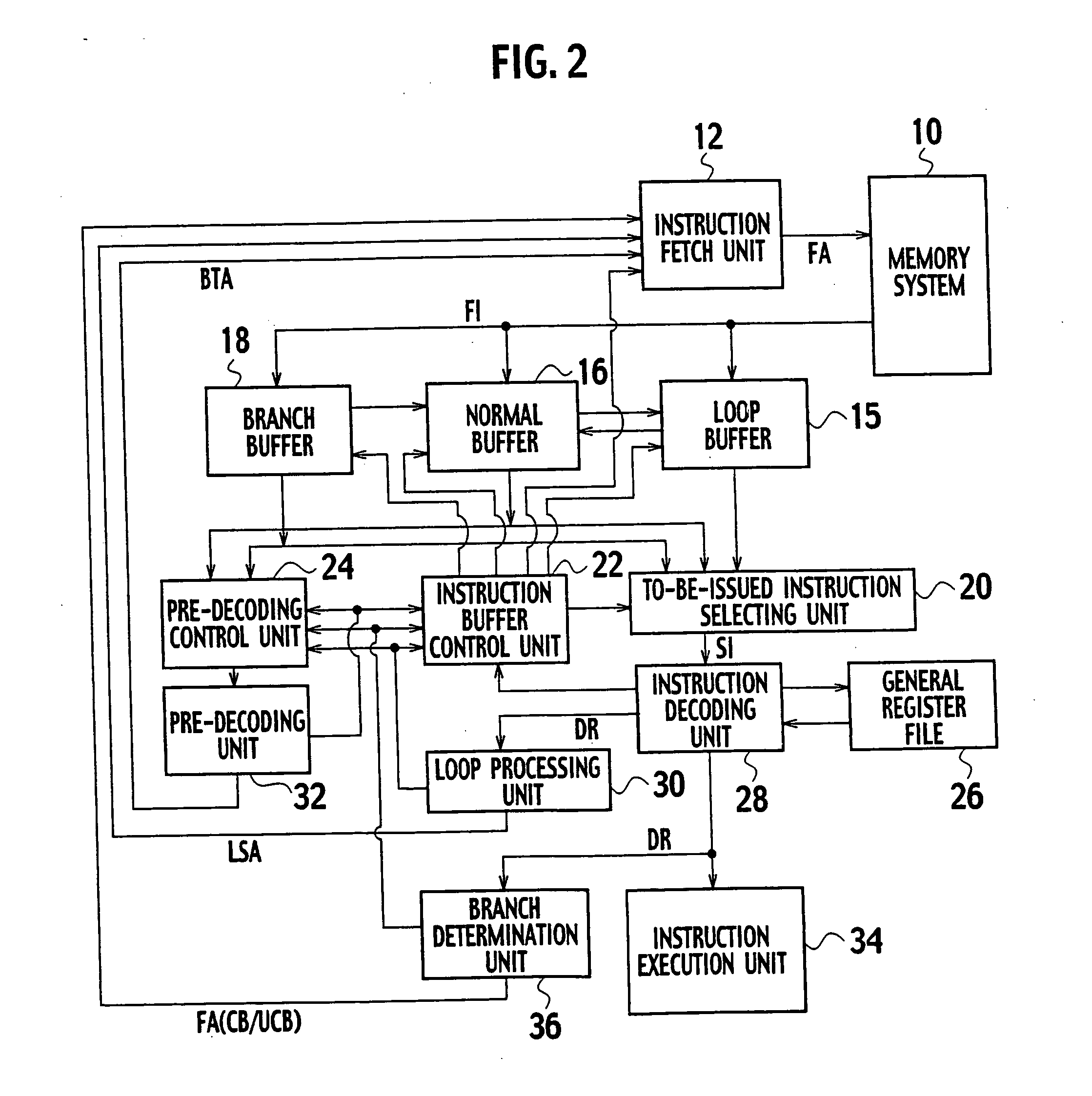

Processor and processor instruction buffer operating method

InactiveUS20060242394A1Instruction analysisDigital computer detailsProcessing elementInstruction buffer

A processor includes an instruction fetch unit providing a fetch address to the memory system; a branch buffer, a normal buffer, and a general buffer, which receive fetch instructions, respectively; a to-be-issued instruction selecting unit, which selects an instruction from the normal buffer, the branch buffer, and the general buffer and issues the instruction in conformity with an instruction from the instruction buffer control unit; an instruction decoding unit, which receives the instruction issued from the to-be-issued instruction selecting unit, decodes the issued instruction, and transmits decoded results to the instruction buffer control unit; a loop processing unit, which receives the decoded results from the instruction decoding unit and transmits a loop start address to the instruction fetch unit; and a branch determination unit, which transmits a fetch address to the instruction fetch unit established when a branching condition is satisfied or not satisfied.

Owner:KK TOSHIBA

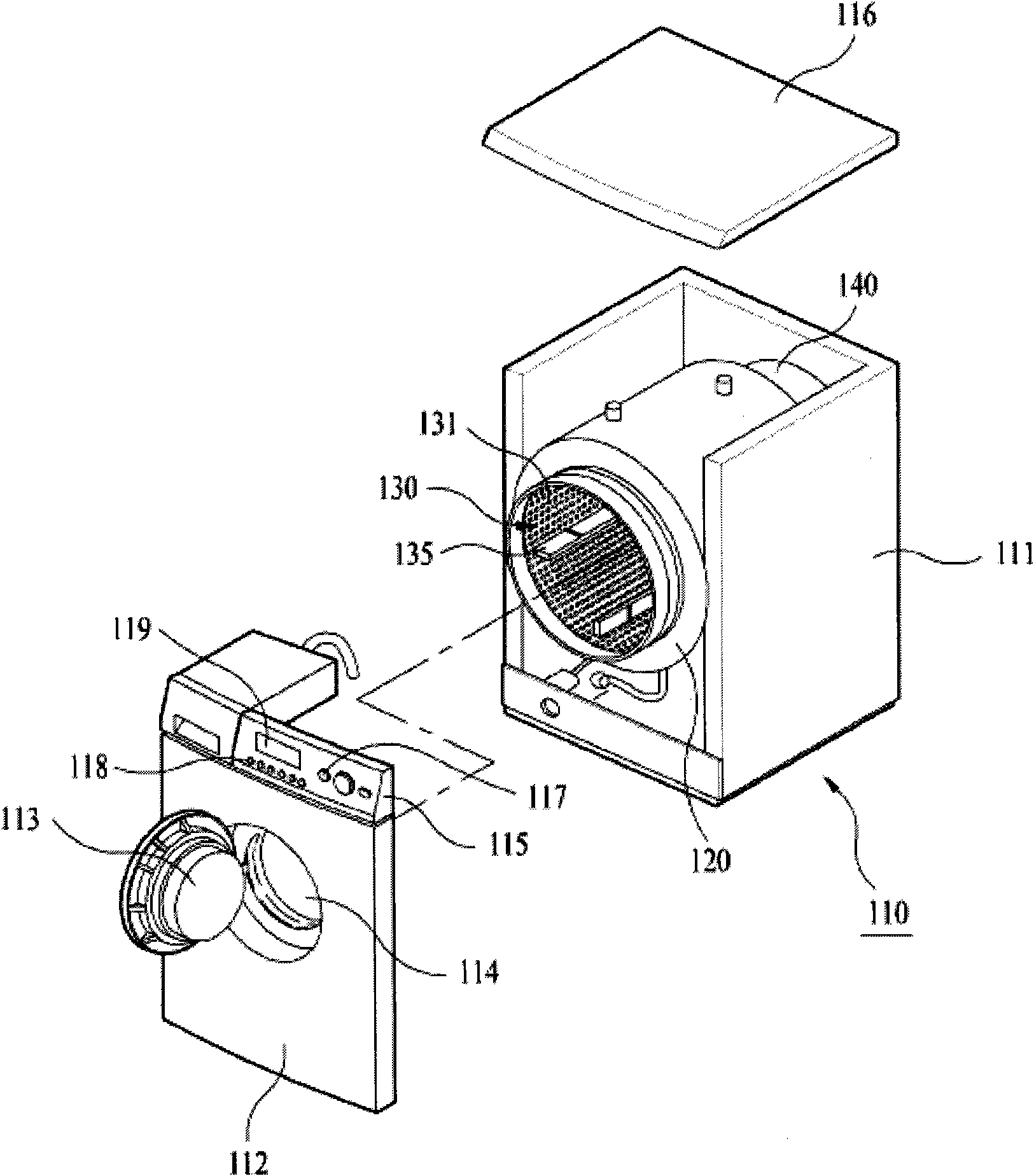

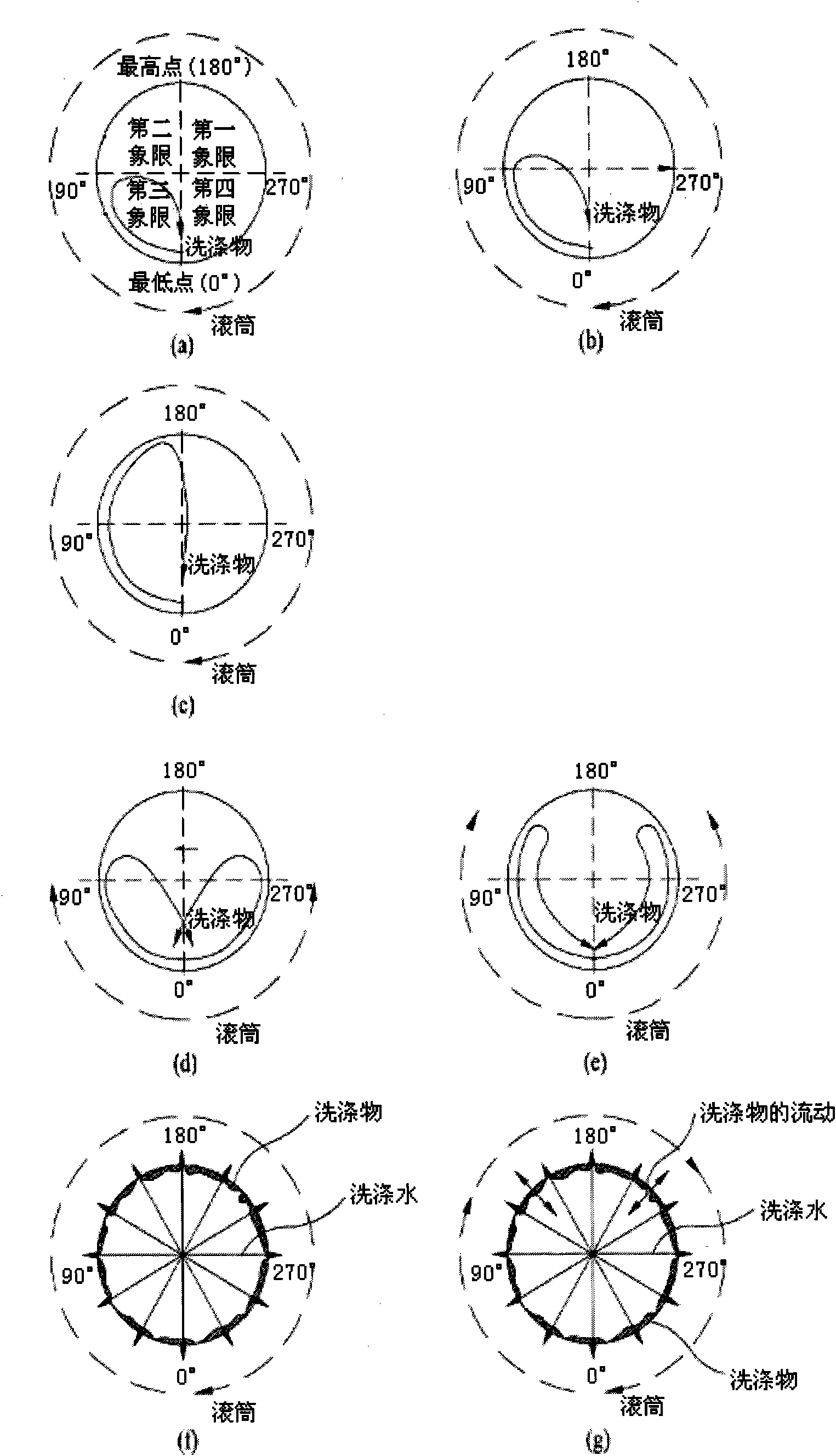

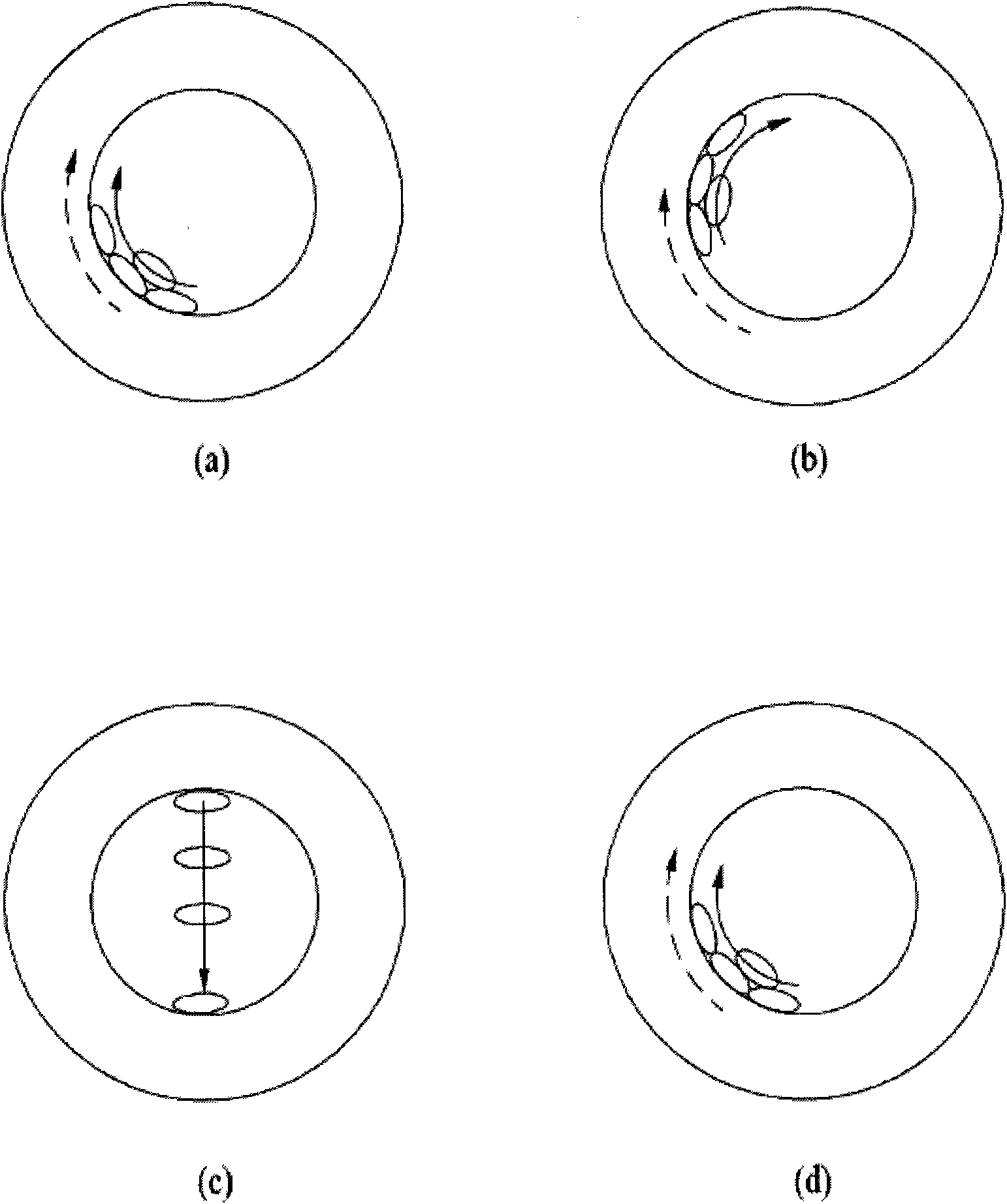

Control method of laundry device

InactiveCN101818434ACurrent peak minimizationOther washing machinesControl devices for washing apparatusPower flowLaundry

Owner:NANJING LG PANDA APPLIANCES

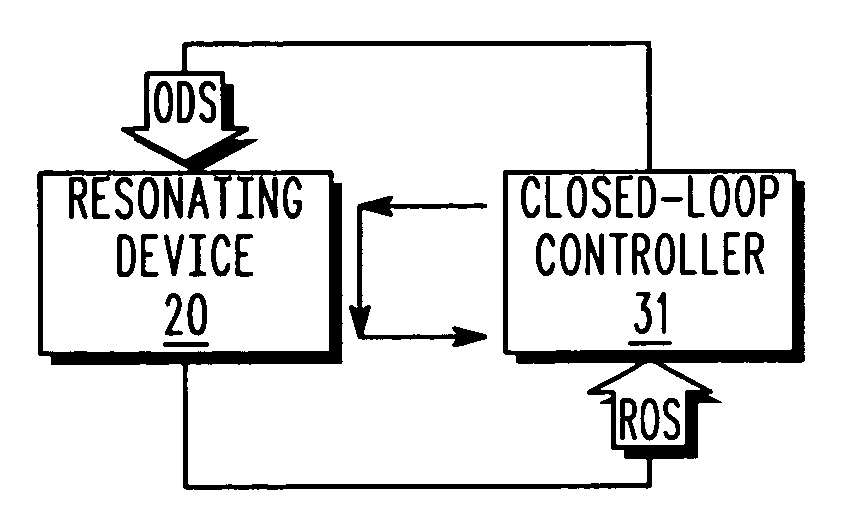

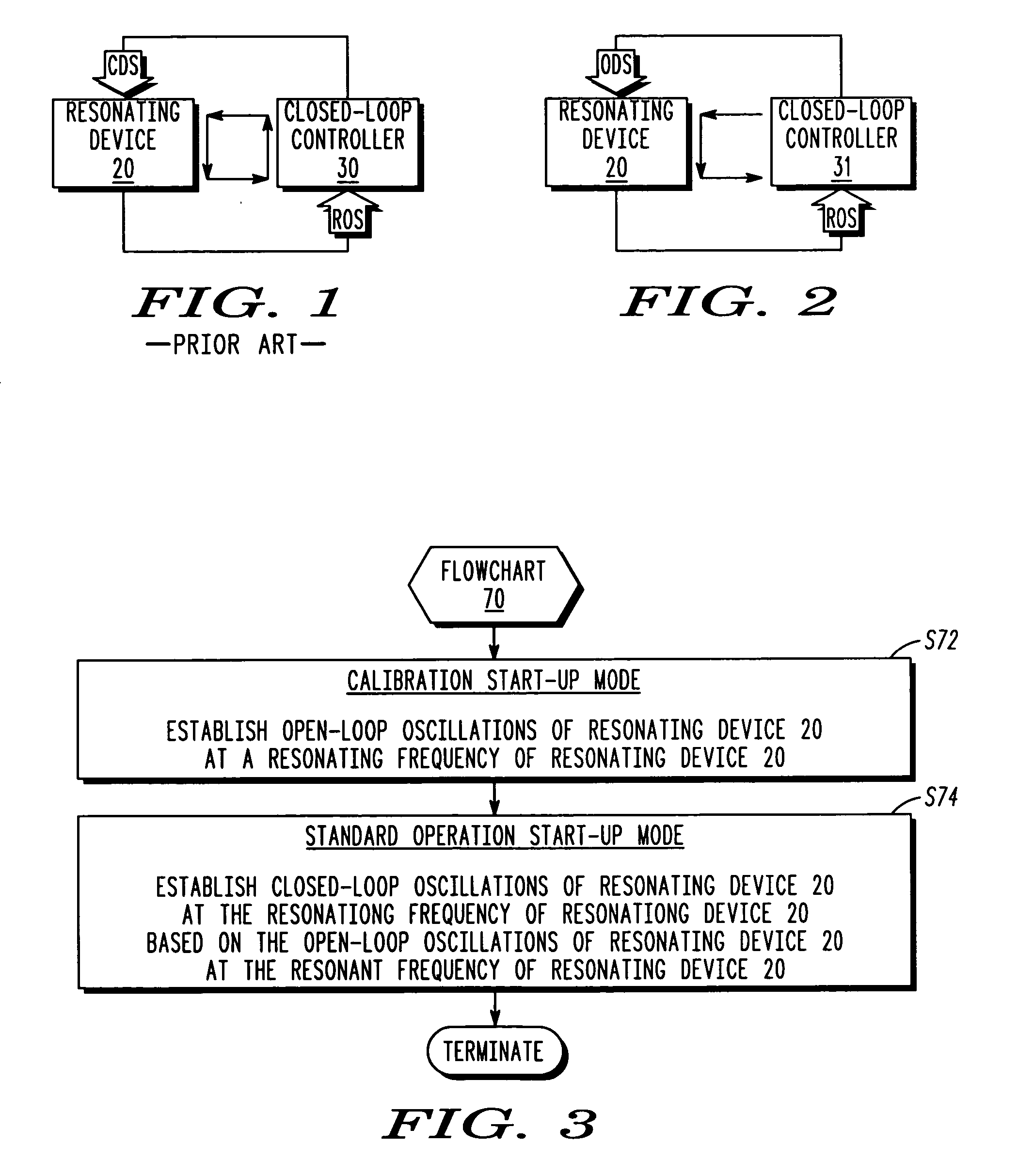

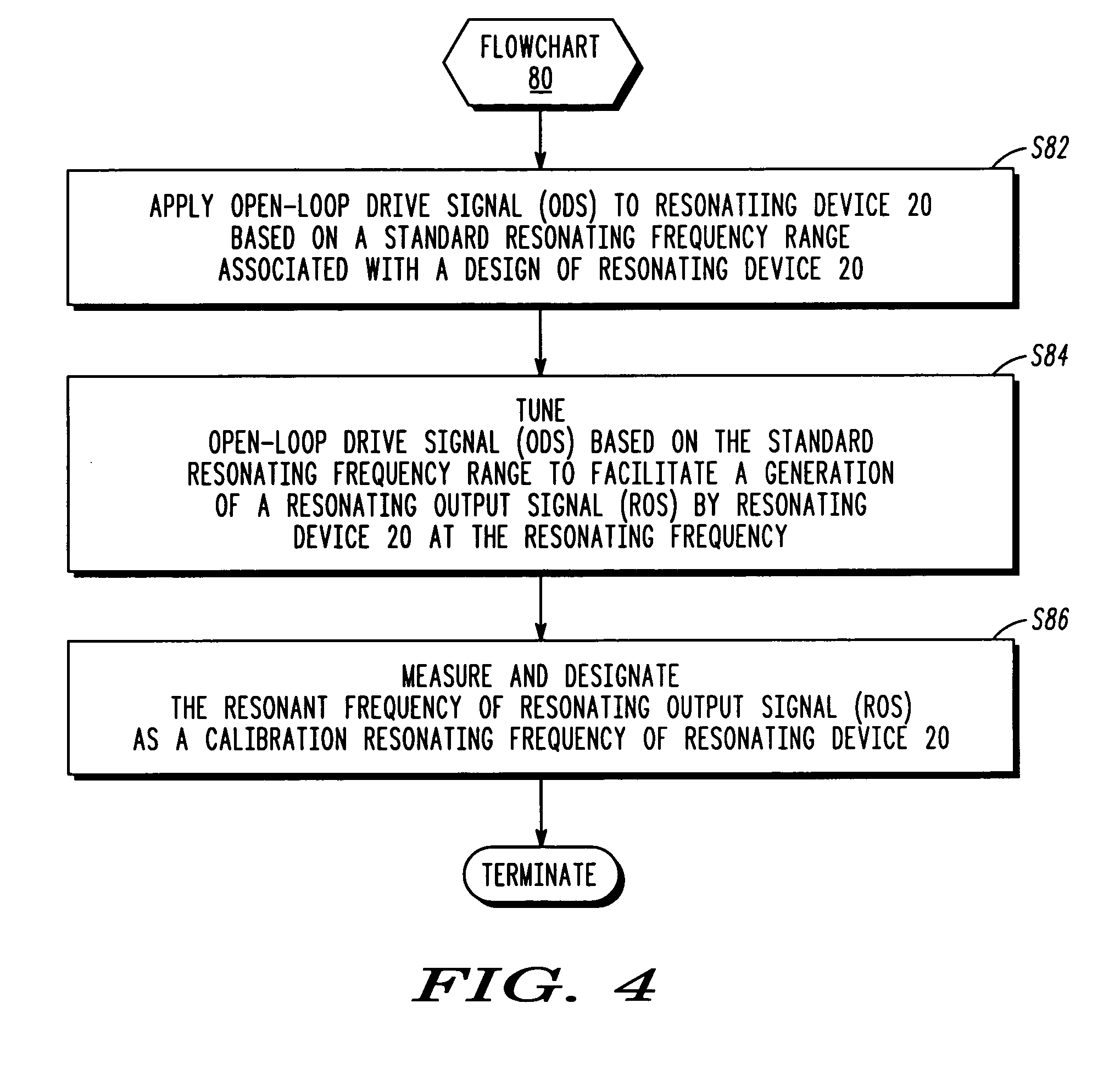

Open-loop start-up method for a resonating device

InactiveUS20050264366A1Promote generationPulse automatic controlSpeed measurement using gyroscopic effectsClosed loopLoop start

A system employing a resonating device and a controller implements a method involving an establishment by the controller of open-loop oscillations of the resonating device at a resonating frequency of the resonating device, and an establishment by the controller of closed-loop oscillations of the resonating device based on the open-loop oscillations of the resonating device at the resonating frequency. To this end, the controller controls an application and a tuning of a first open-loop drive signal to the resonating device based on a design-drive standard resonating frequency range whereby the controller can measure and designate a frequency of a resonating output signal from the resonating device as a calibration resonant frequency, and controls an application and a tuning of a second open-loop drive signal to the resonating device based on the calibration resonant frequency whereby the controller can subsequently apply a closed-loop drive signal to the resonating device.

Owner:TEMIC AUTOMOTIVE OF NORTH AMERICA

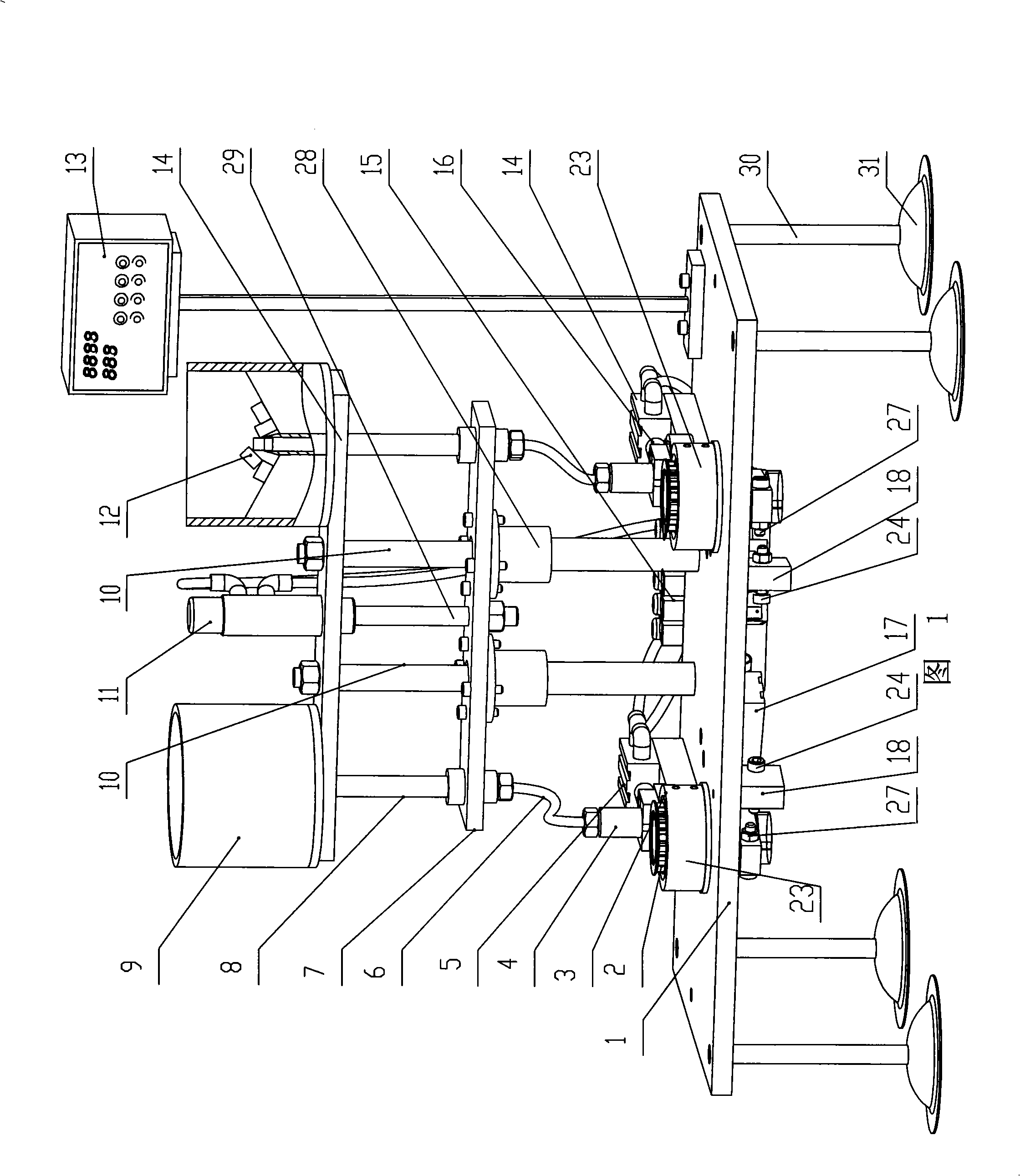

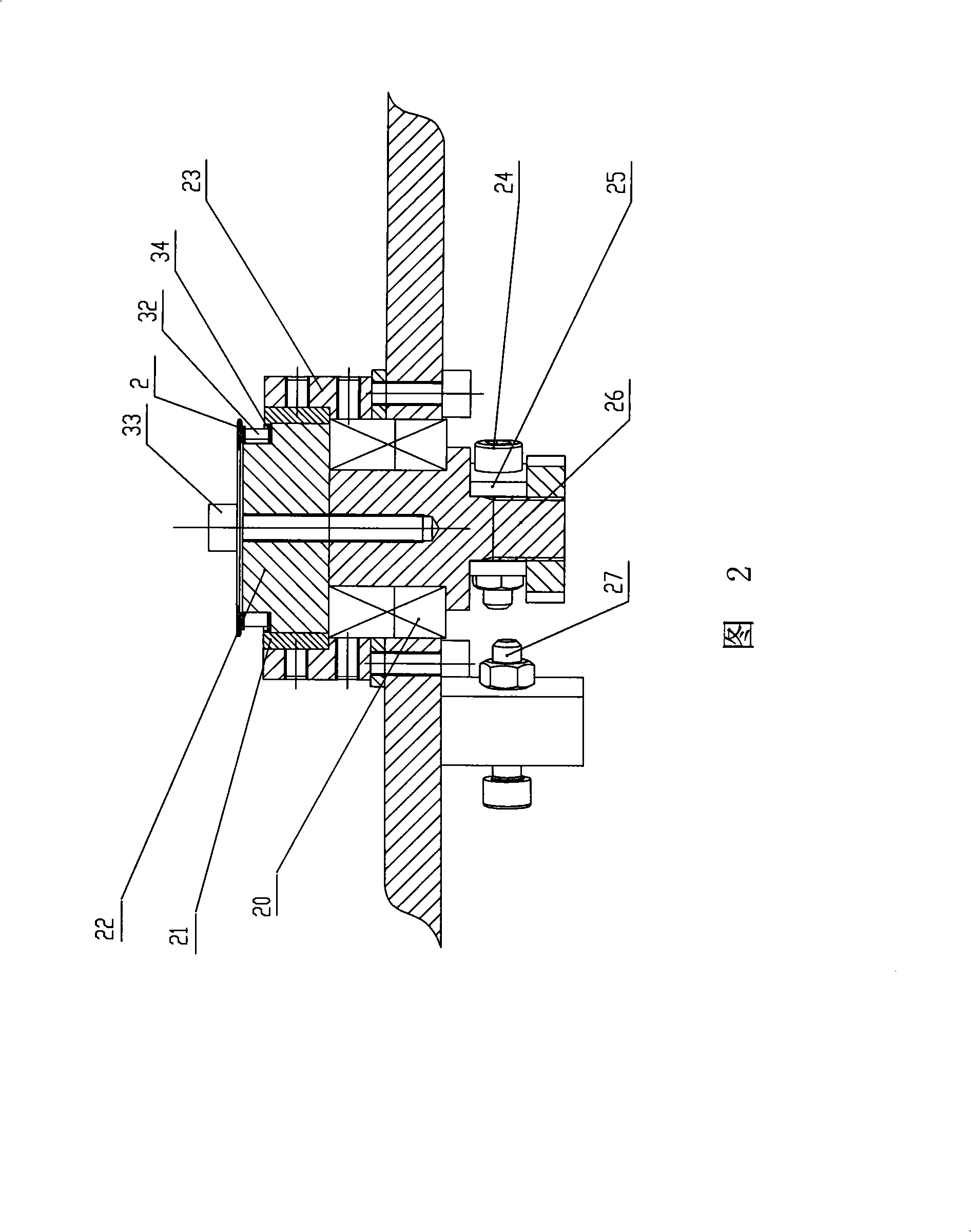

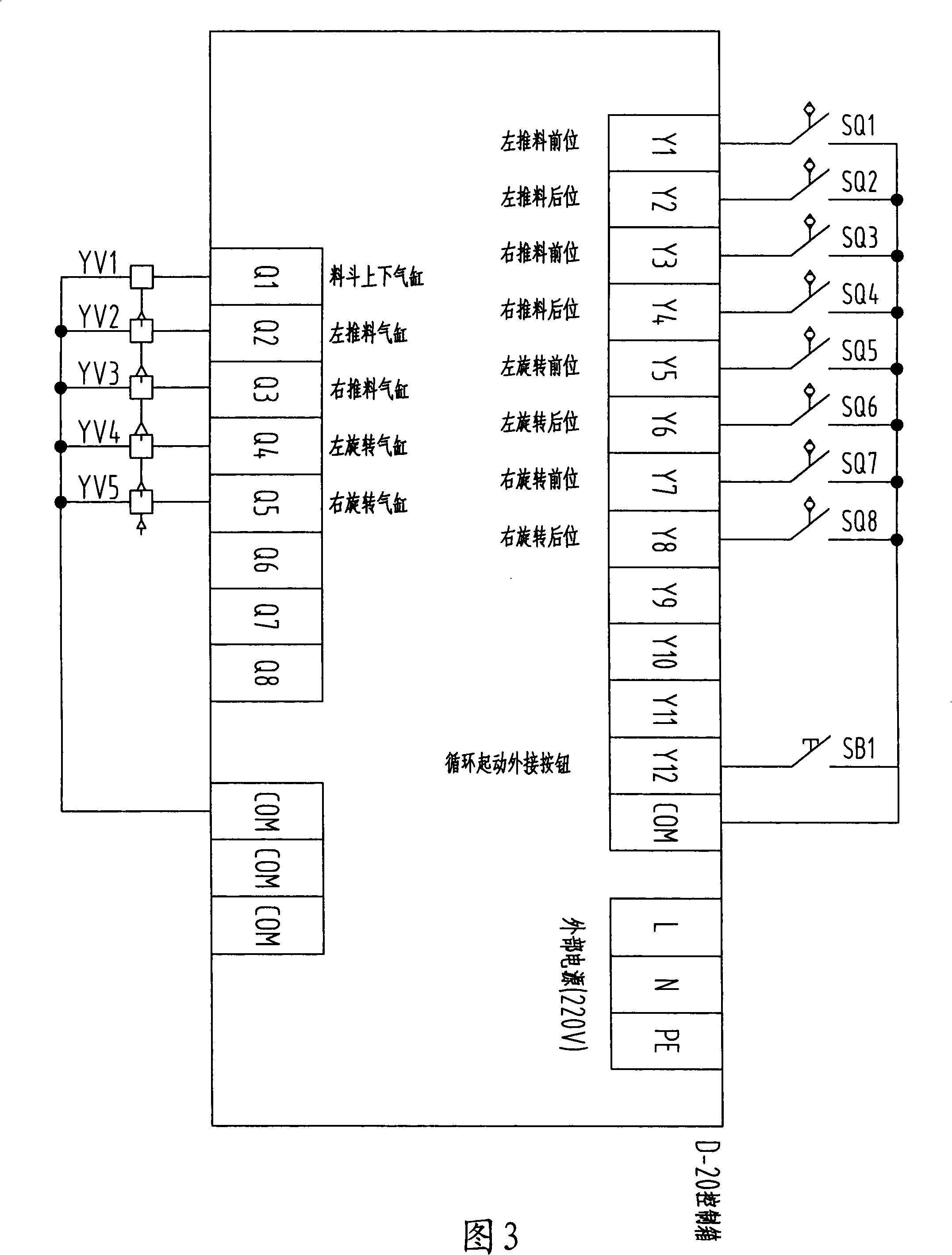

Semi-automatic roller loading machine of one-way bearing

InactiveCN101315103AAutomate assemblyImprove assembly efficiencyBearing componentsBearingsSolenoid valveSemi automatic

The invention relates to the assembly of a unidirectional bearing, which comprises a unidirectional bearing semiautomatic roller loading machine capable of automatically conducting suction, delivery, feeding, discharging and loading of rollers and rotation of a holder at an angle. Two round pneumatic roller storage disks capable of automatically orienting and delivering rollers are arranged inside a workpiece basket positioned on one side of a rectangular workbench, a rectangular vertical controller is arranged on the other side of the rectangular workbench, a PLC chip is equipped inside the controller for controlling the operation of the unidirectional bearing semiautomatic roller loading machine by programming the PLC chip, two completely same holder mechanisms are arranged at the front end of the rectangular workbench for manually placing a holder into a serrated holder seat; two completely same transposition mechanisms are arranged below the holder mechanisms for controlling the powering on sequence of five solenoid valves via the PLC in the controller, so as to press the rollers in the roller storage disks into a material guide pipe and wait for the action of a rolling pushing machine; and when the rolling pushing machine pushes a first roller into a pocket hole of the holder, the transposition mechanisms start to operate by the steps of rotating an angle in accordance with a predetermined angle, waiting for the pushing of a second roller, and repeating and stopping until the pocket hole of the holder is full of rollers, and then the holder is removed and a holder not filled with rollers is loaded to start the next round roller loading operation by pressing a loop start button on a controller panel. The inventive assembly has the advantages of easy assembly of the unidirectional bearing and high assembly efficiency.

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

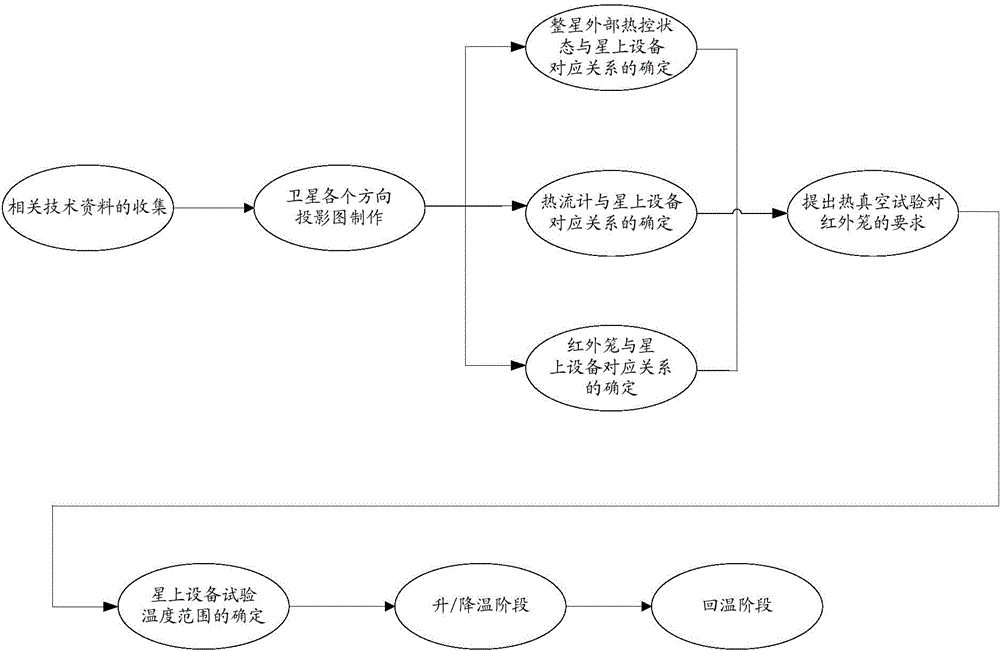

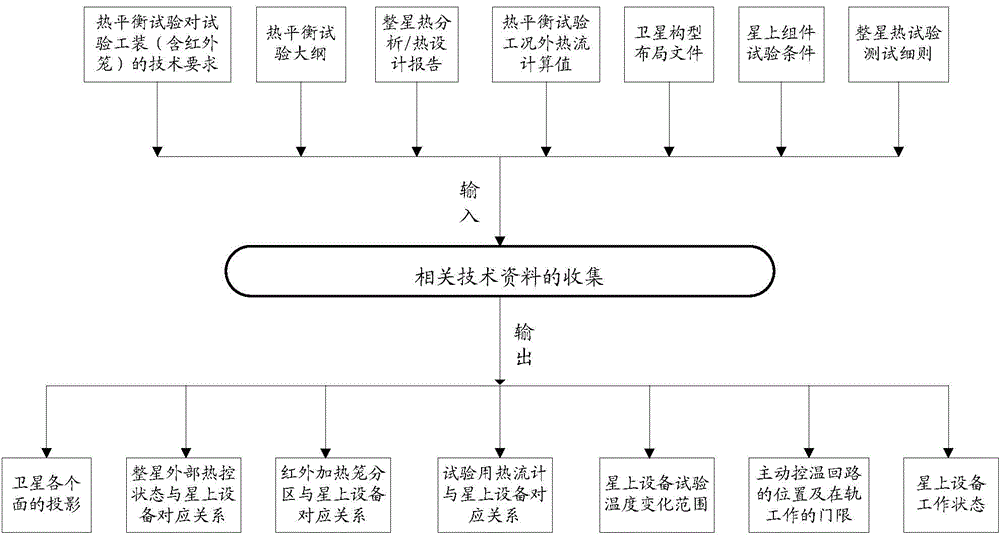

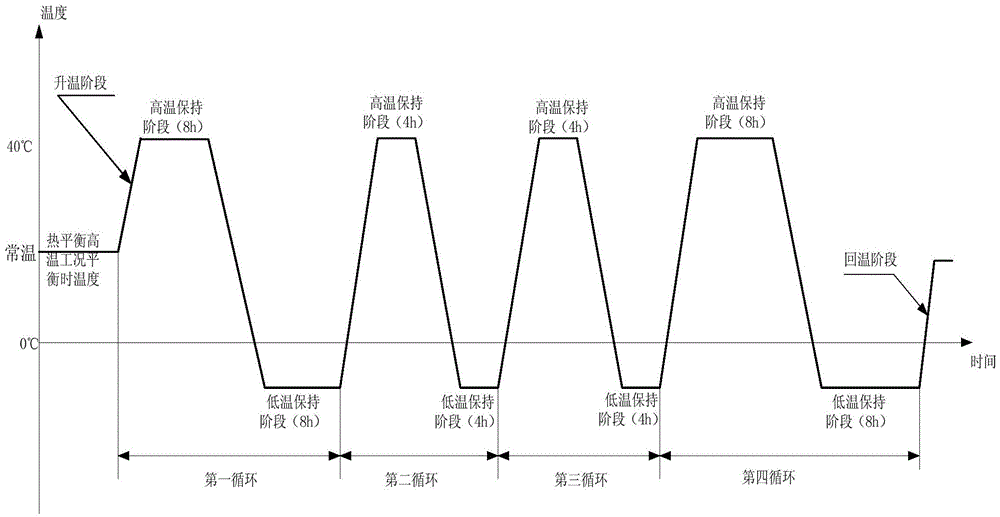

Temperature control method for equipment on satellite in system level thermal vacuum test

ActiveCN103914092ATo achieve the purpose of screeningEnsure safetyTemperature control using electric meansTemperature controlSimulation based

The invention relates to a temperature control method for equipment on a satellite in a system level thermal vacuum test. The method mainly includes a temperature range determining method for the equipment on the satellite, a high temperature determining method for the equipment on the satellite, an infrared heating cage manufacturing method before the test, a method for modifying the on-off state and the working state of the equipment on the satellite in the test process and an active temperature control heating loop starting / stopping threshold on the satellite, and a loop controlling method. According to the method, when the infrared heating cage is used for simulation based on external heat stream, temperature control of the equipment on the satellite is reasonable and effective, the temperature changing rate of the equipment on the satellite is increased, it is guaranteed that the temperature of the equipment does not exceed the checking and accepting level temperature range, and not only is the safety of the equipment on the satellite guaranteed, but also the purpose of eliminating potential early-stage defects of the satellite is effectively achieved.

Owner:AEROSPACE DONGFANGHONG SATELLITE

Method and system for auto parallelization of zero-trip loops through induction variable substitution

InactiveUS7487497B2Eliminates loop dependency on the induction variableSoftware engineeringProgram controlCopy propagationEngineering

A method and system of auto parallelization of zero-trip loops that substitutes a nested basic linear induction variable by exploiting a parallelizing compiler is provided. Provided is a use of a max{0,N} variable for loop iterations in case of no information is known about the value of N, for a typical loop iterating from 1 to N, in which N is the loop invariant. For the nested basic induction variables, an induction variable substitution process is applied to the nested loops starting from the innermost loop to the outermost one. Then a removal of the max operator afterwards through a copy propagation pass of the IBM compiler is provided. In doing so, the loop dependency on the induction variable is eliminated and an opportunity for a parallelizing compiler to parallel the outermost loop is provided.

Owner:INT BUSINESS MASCH CORP

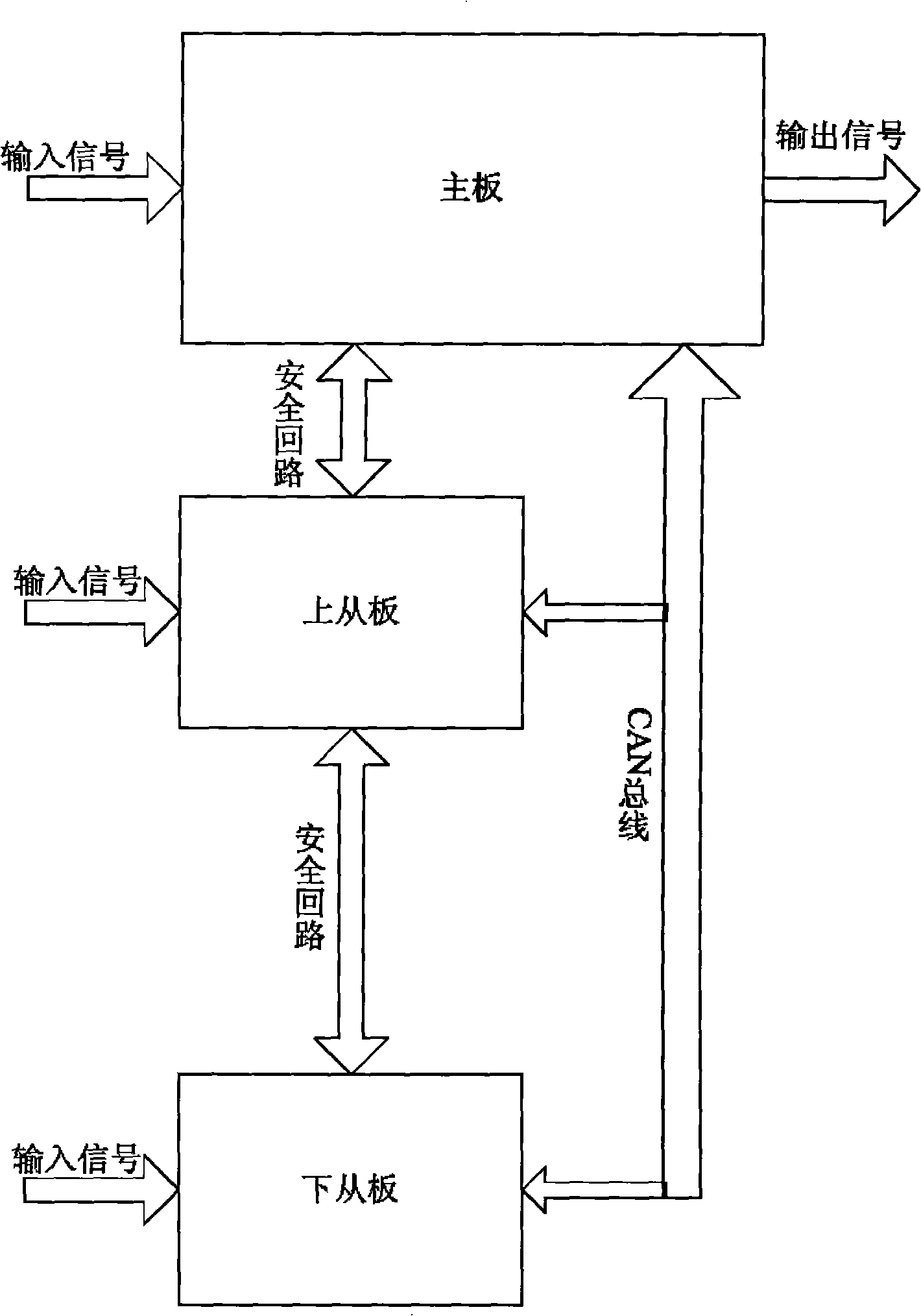

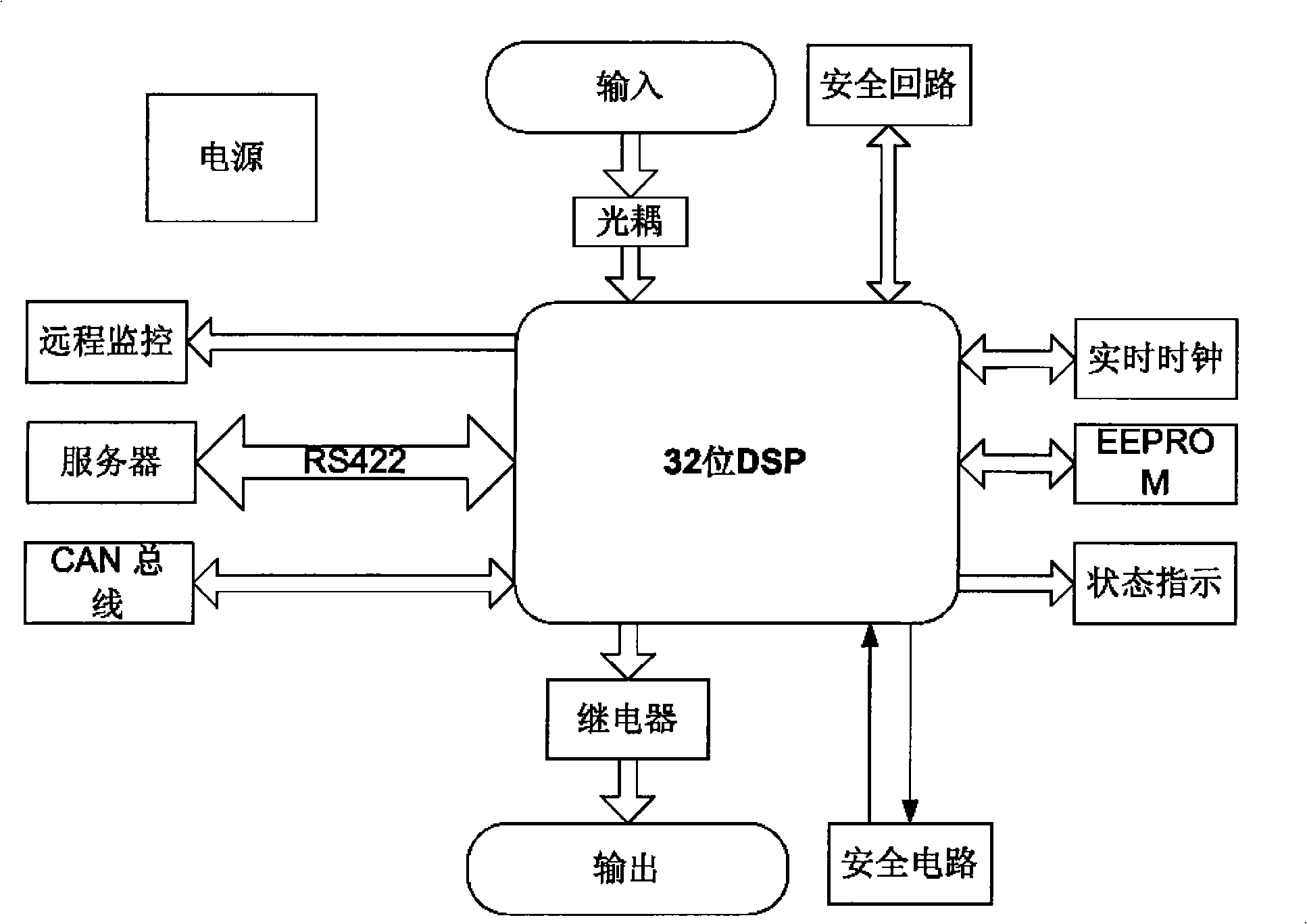

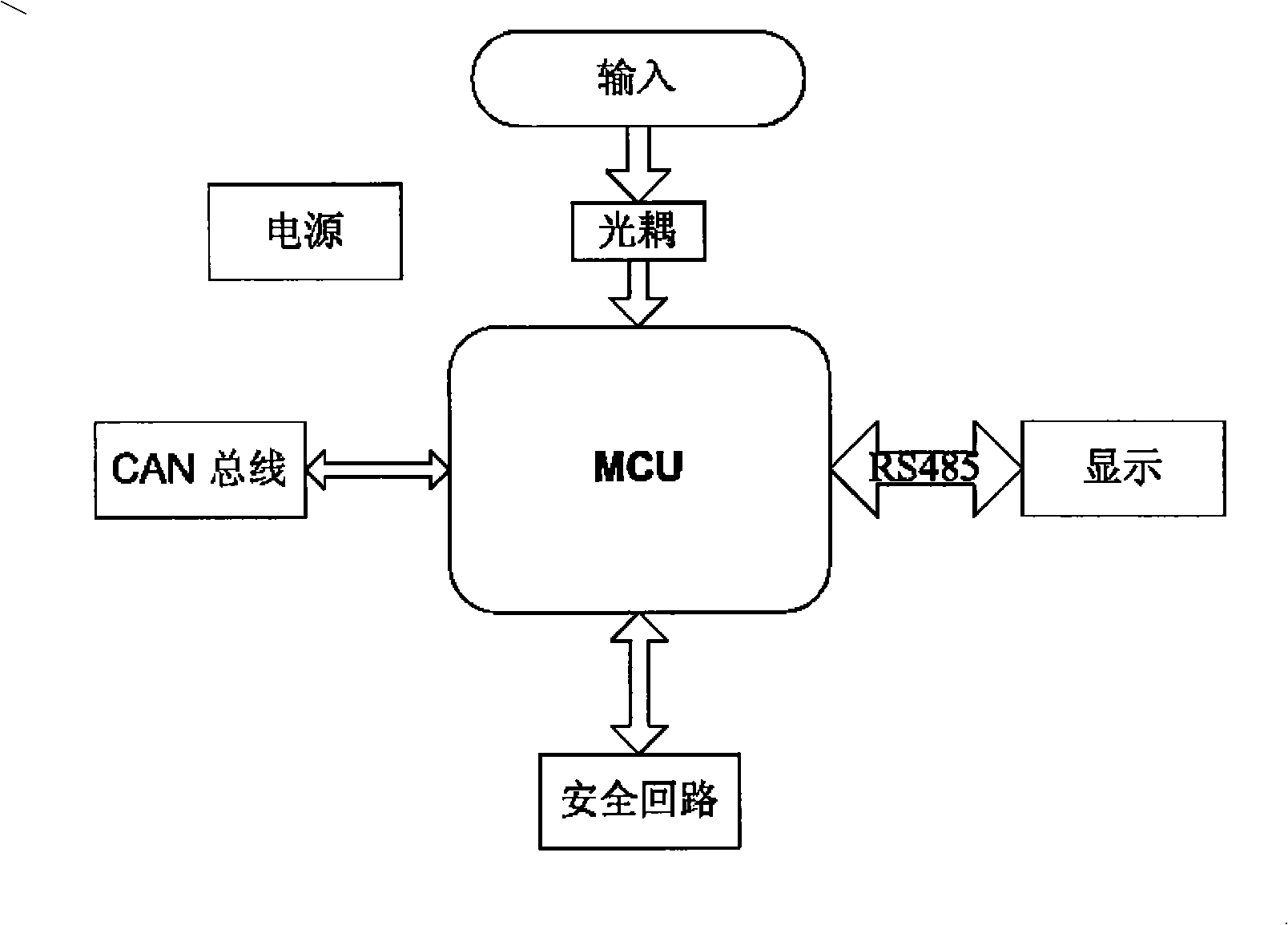

Control system for escalator

The invention relates to an escalator control system, in which communication is realized by a pair of twisted-pair lines between a principal board and subordinate boards and by setting the principal board and the subordinate boards, wherein, the subordinate boards receive the nearby input signal and send the signal to the principal board through a CAN bus; an upper subordinate board and a lower subordinate board send the display information transmitted from the principal board to a key switch box to display; the principal board inspects the input signal, determines the output signal through logical operation, records the fault of the error signal and alarms; a starting point of a safety loop starts from the principal board, goes through a series of safety switches, connects the upper subordinate board and the lower subordinate boards nearby, goes through an end point of the principal board and returns to the principal board, the principal board checks the state of the safety loop and realizes control and detection of multiple functions of the escalator. The escalator control system, as an ideal substitute of the prior art, avoids laying transmission lines in large quantity and has the advantages of simple structure, reasonable layout, safe and reliable system operation and braking and effectively reduced production cost.

Owner:HANGZHOU OPTIMAX TECH

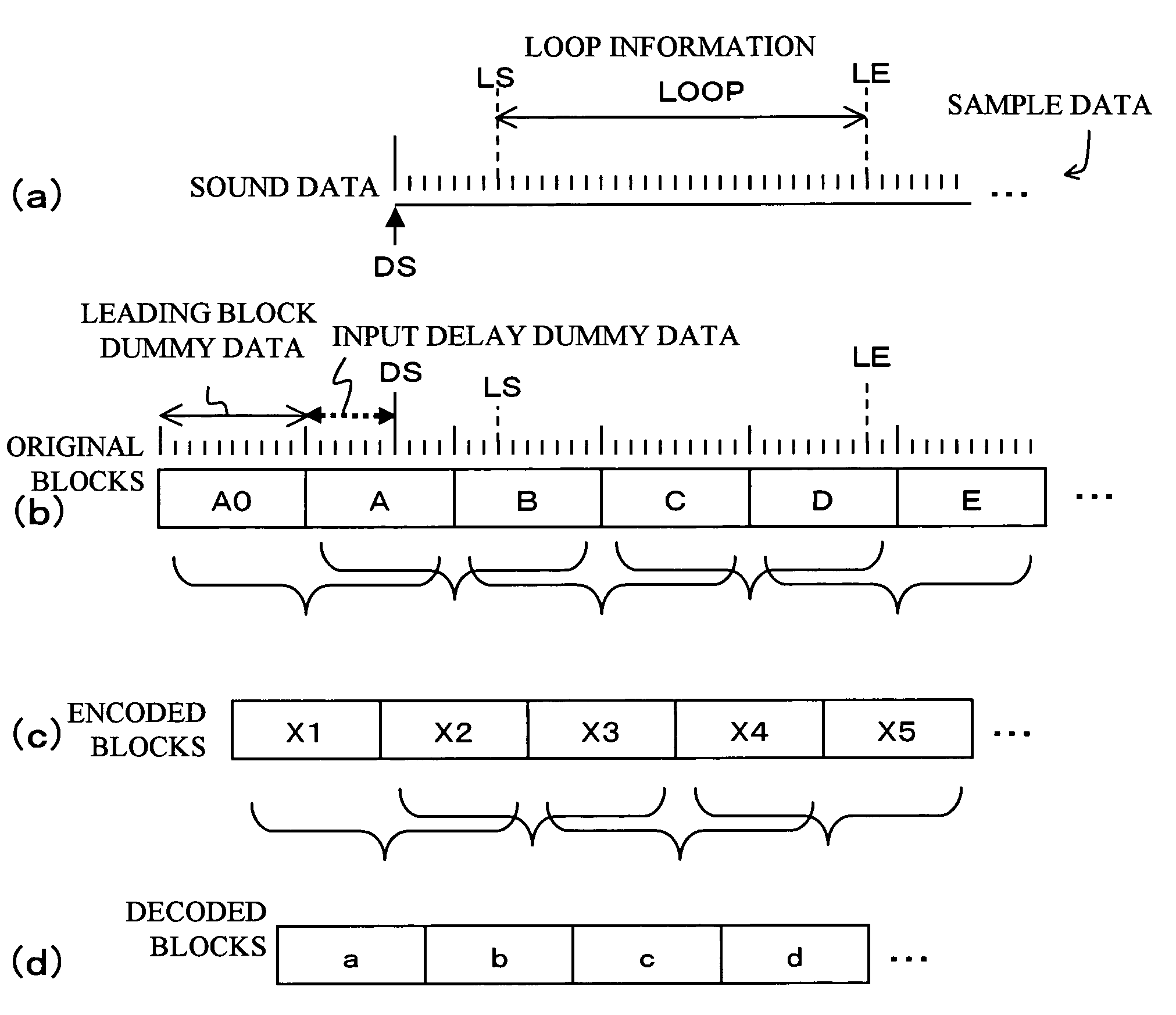

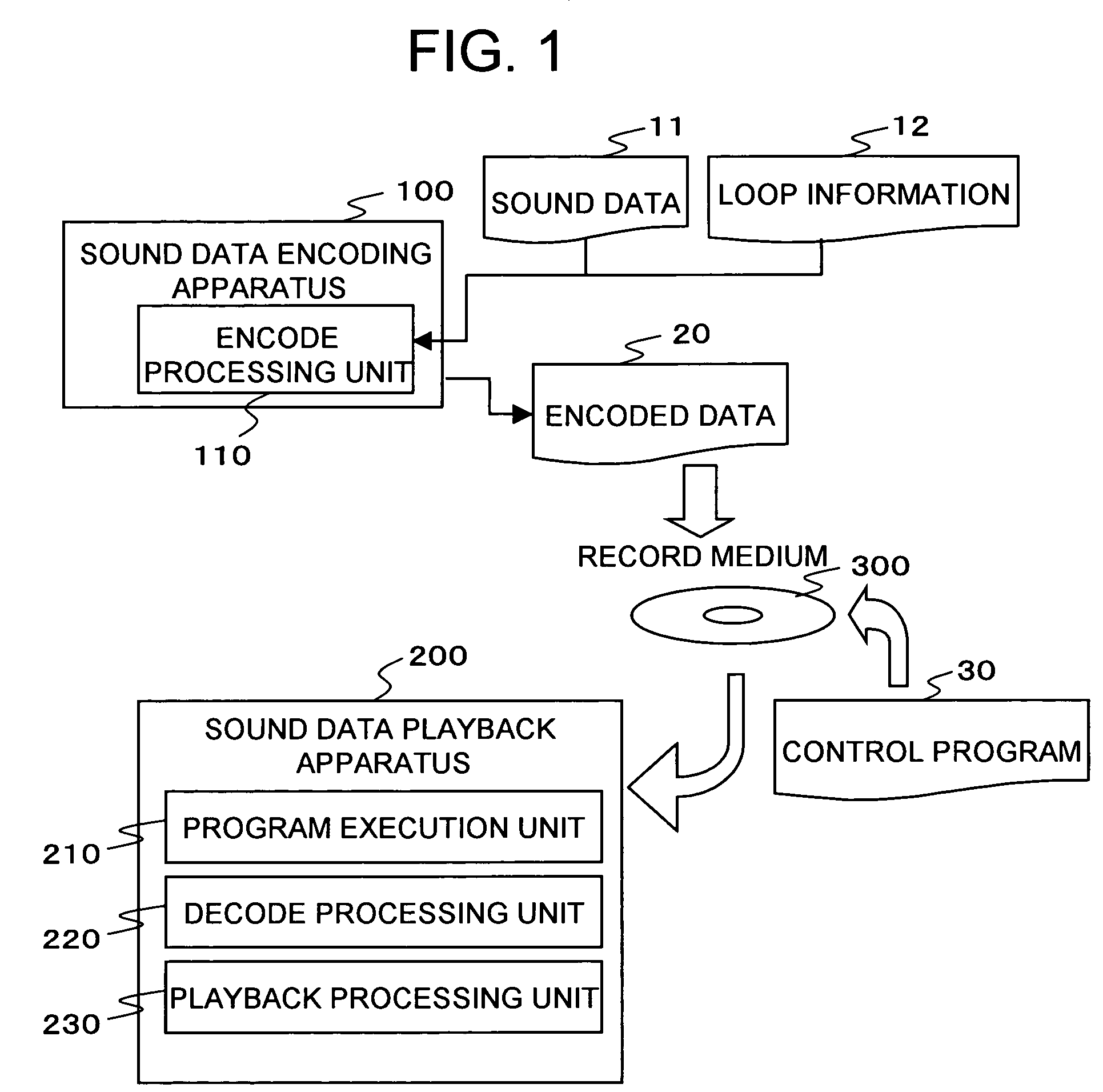

Sound data encoding apparatus and sound data decoding apparatus

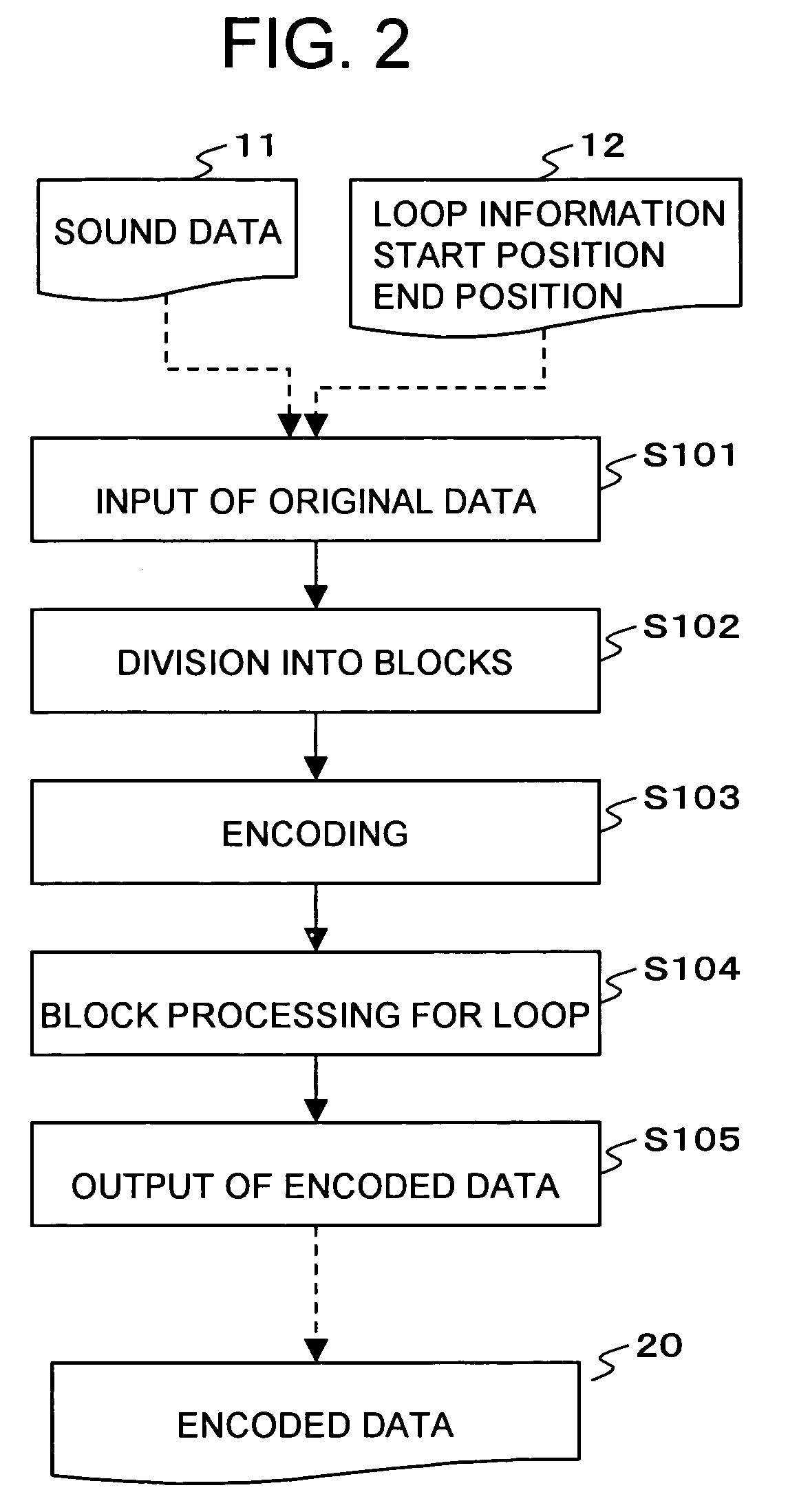

A processing load at the time of playing back sound data having a loop part is reduced.A sound data encoding apparatus comprises a block dividing means that divides the sound data into blocks according to predetermined rules, and an encoding means that encodes the blocks in groups of a plurality of consecutive blocks. The block dividing means divides the sound data such that, when encoded blocks encoded by the encoding means are decoded to output decoded blocks, then the loop end position in a block that includes the loop end position in the decoded blocks is nearer to an end of the block than a predetermined position. In detail, input delay dummy data are added ahead of the sound data before dividing the sound data. At the time of outputting the encoded data, loop information is outputted also. The loop information includes the number of samples of the added input delay dummy data, the number of samples corresponding to the encoding delay, the number of samples corresponding to the decoding delay, the start and end positions of the sound data, and the loop start and end positions.

Owner:SONY COMPUTER ENTERTAINMENT INC

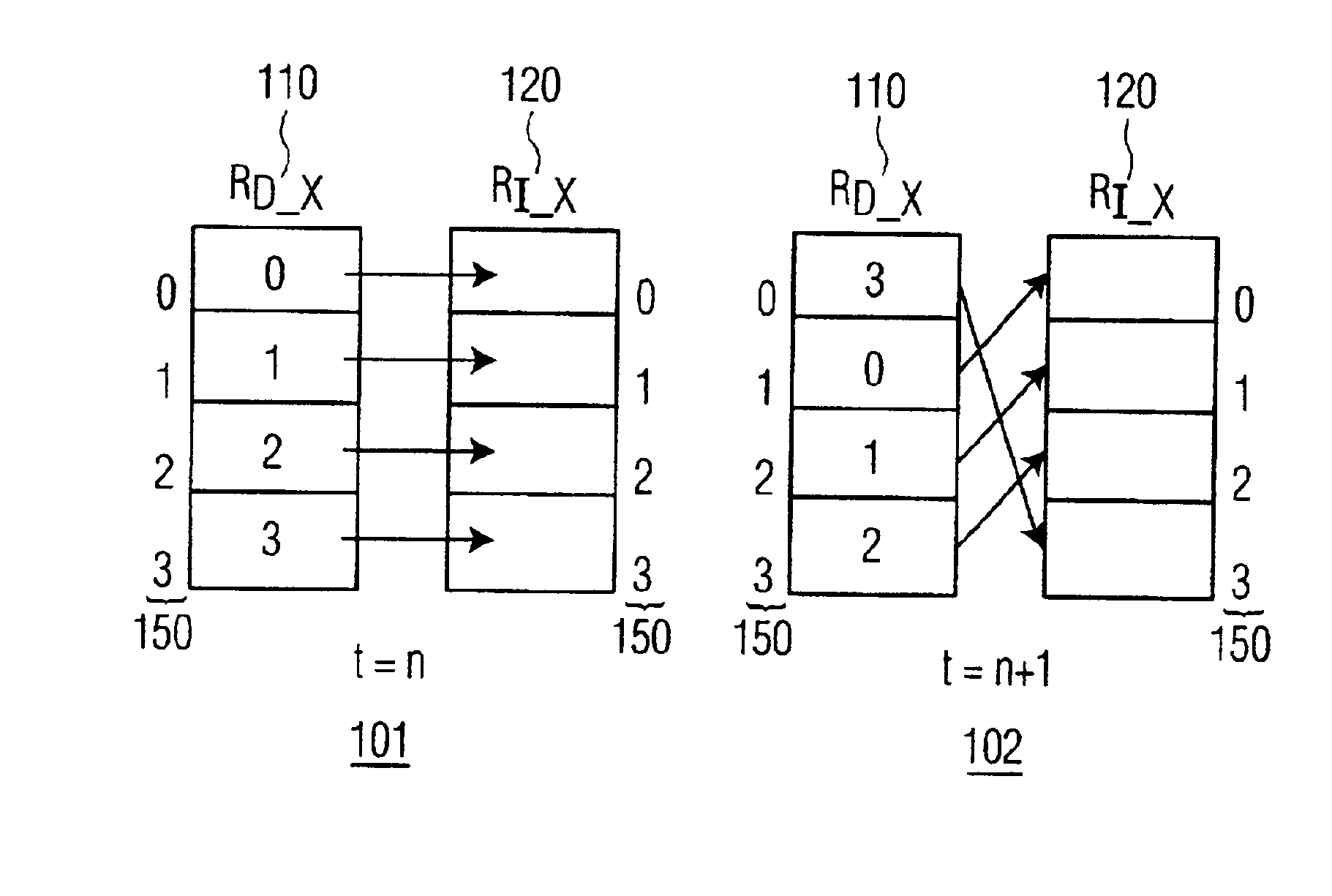

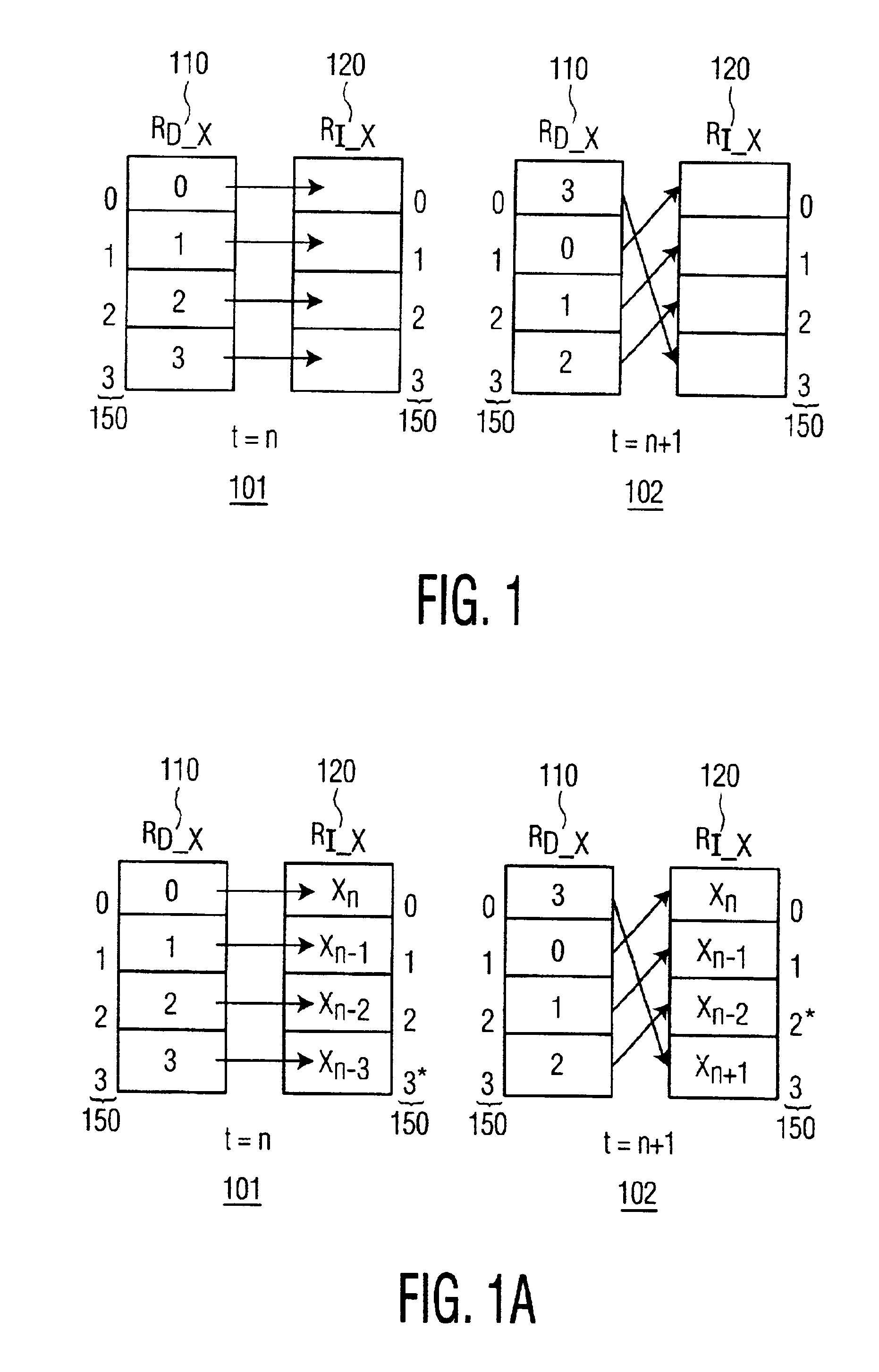

Programmable delay indexed data path register file for array processing

InactiveUS6970895B2Reduce in quantityComponent separationRegister arrangementsAdaptive filterDatapath

A delay addressed data path register file is designed for use in a programmable processor making up a cell in a multi-processor or array signal processing system. The delay addressable register file is particularly useful in, inter alia, adaptive filters where the filter update latency is variable, interpolation filters where the interpolation factor needs to be programmable, and decimation filters where the decimation factor needs to be programmable. The programmability is achieved in an efficient manner, reducing the number of cycles required to perform this task. A single parameter, the “delay limit” value, is programmed at start-up, setting up an internal delay-line within the register file of the processor. Thus, any of the delayed registers can be addressed by specifying the delay index during run-time. The delay line advances one location, modulo “delay-limit”, when the processing loop starts a new iteration.

Owner:FUNAI ELECTRIC CO LTD

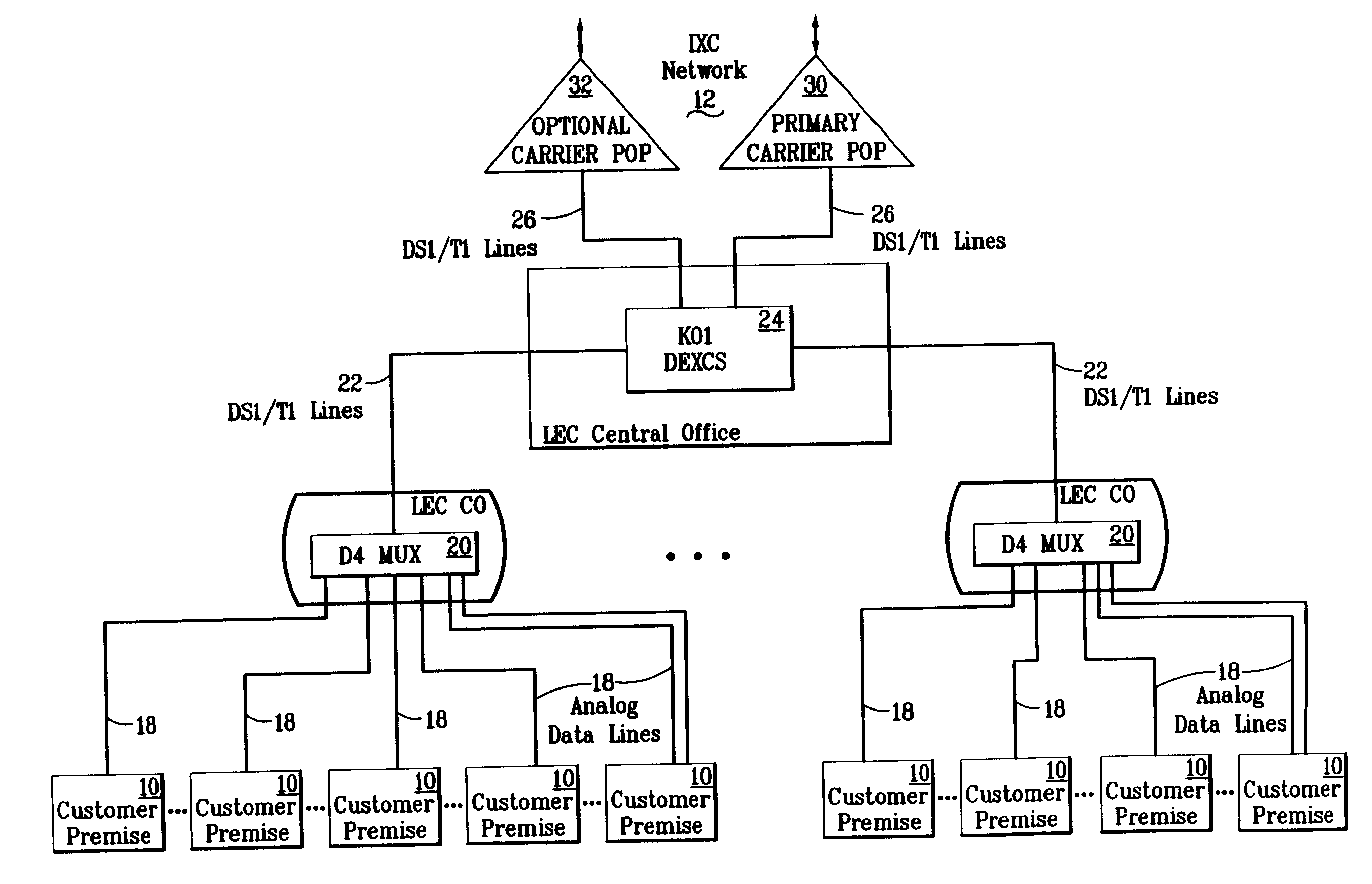

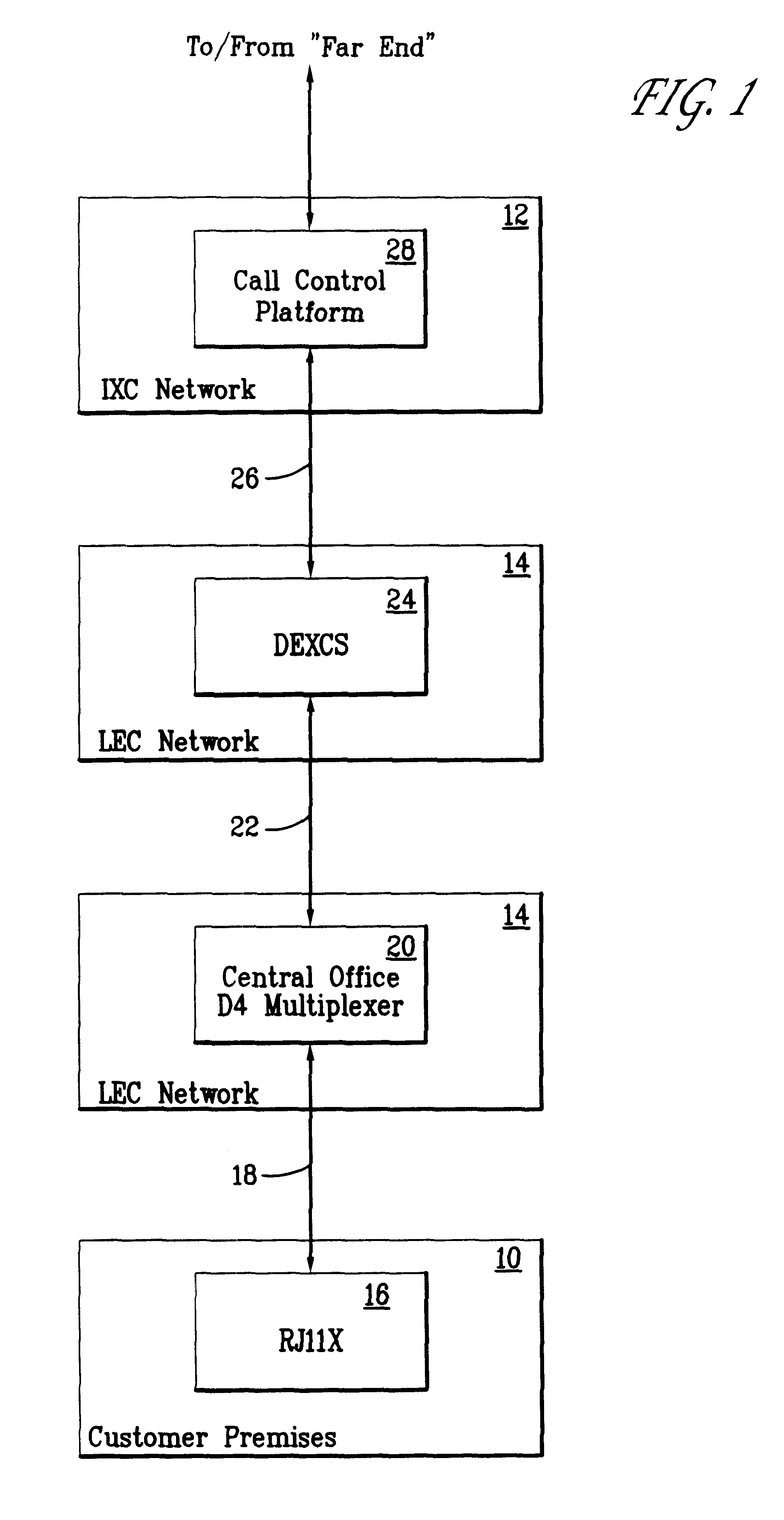

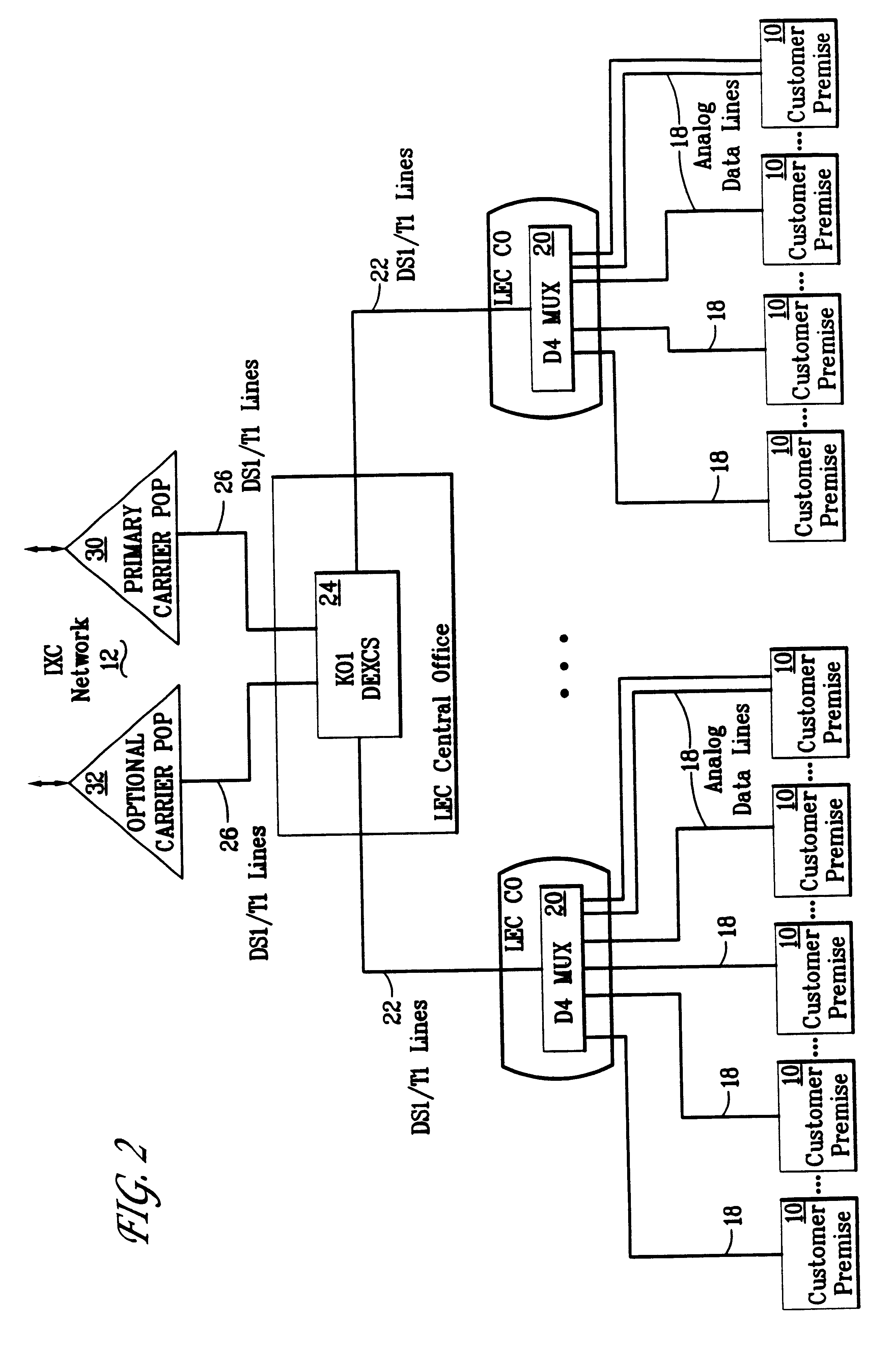

Method and apparatus for bypassing a local exchange carrier using analog in-band signaling

InactiveUS6363080B1Multiplex system selection arrangementsSpecial service for subscribersMultiplexerCarrier signal

A technique for reducing or eliminating the access charges typically payable by an IXC to a LEC, and, in turn, payable by the subscriber to the IXC, for originating long distance calls by providing a hardwire connection between the IXC and the customer premises. The hardwire connection is created by purchasing analog facilities from the LEC which originate at the Central Office and connecting these facilities directly to a Central Office D4 multiplexer. The terminating end of the analog facilities are installed at the subscriber premises and terminated on a standard RJ11X four wire jack. The voice interface modules typically used in the D4 multiplexer are replaced by Foreign Exchange Subscriber (FXS) modules which perform A / D conversion of the analog voice data provided over the analog facilities from the customer premises. A T1 or higher capacity digital facility is also ordered from the LEC to terminate to the Central Office D4 multiplexer, and the T1 or higher capacity digital facility is D4 / AMI configured for 56 kbps DS0 channels. The terminating end of the T1 or higher capacity digital facility is directed to a tandem "toll" Central Office and is terminated on a K01 digital electronic cross-connect system (DEXCS) frame which is ordered from the LEC. Each of the channels of the T1 or higher capacity digital facility is then configured by the customer using a network reconfiguration service at the end pointing towards the Central Office D4 multiplexer with Foreign Exchange Office (FXO) Loop Start signaling. A T1 is also ordered from the LEC to connect the DEXCS to the IXC and is also D4 / AMI configured for 56 kbps DS0 channels. Each of the channels of this T1 is also configured by the customer using the reconfiguration service at the end pointing towards the IXC with FXS Loop Start signaling. The IXC terminates the T1 from the DEXCS within its own Call Control Platform.

Owner:MOUNT HAMILTON PARTNERS

Sensor-free start control method for brushless DC motor

ActiveCN102136820AHigh positioning accuracyReduce power consumptionStarter arrangementsClosed loopEngineering

The invention discloses a sensor-free start control method for a brushless DC motor, which comprises: a primary rotor positioning step, a secondary rotor positioning step, an open loop starting step and a closed loop operation control step. In the method, by the starting step, when a starting dead angle is generated in the primary rotor positioning step, a rotor still can be positioned by the secondary rotor positioning step to further improve positioning accuracy in the starting of the brushless DC motor, reduce power consumption and improve the starting smoothness.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

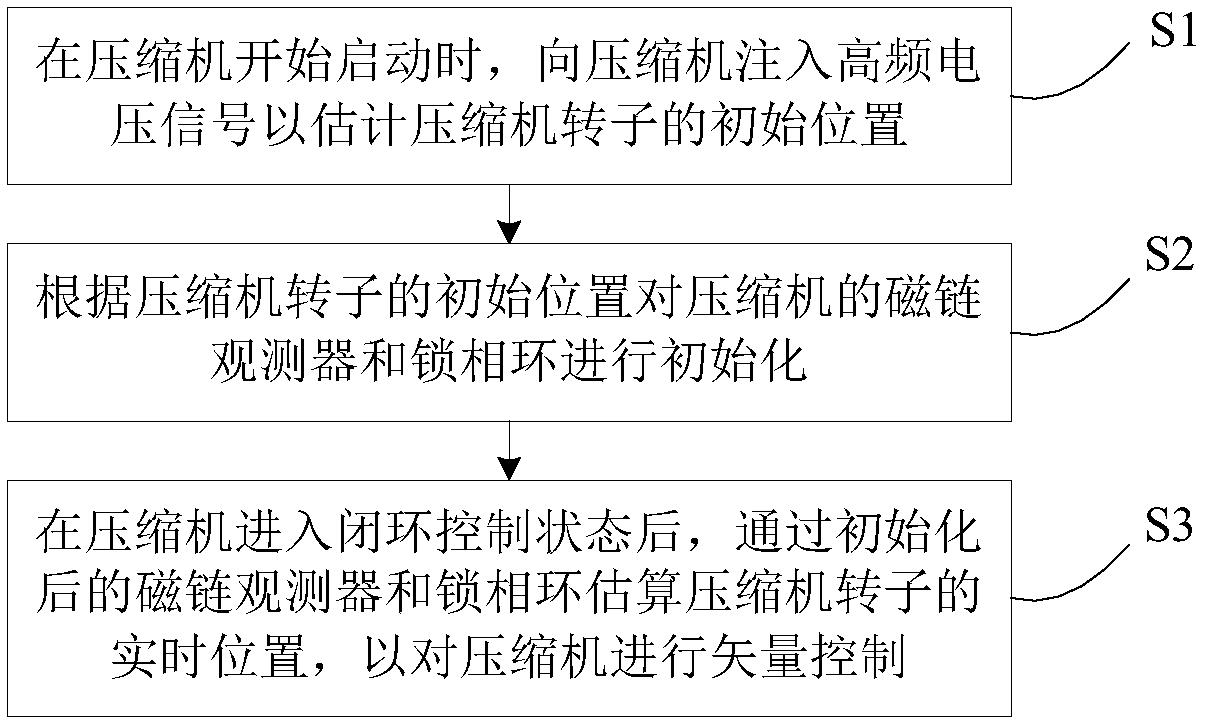

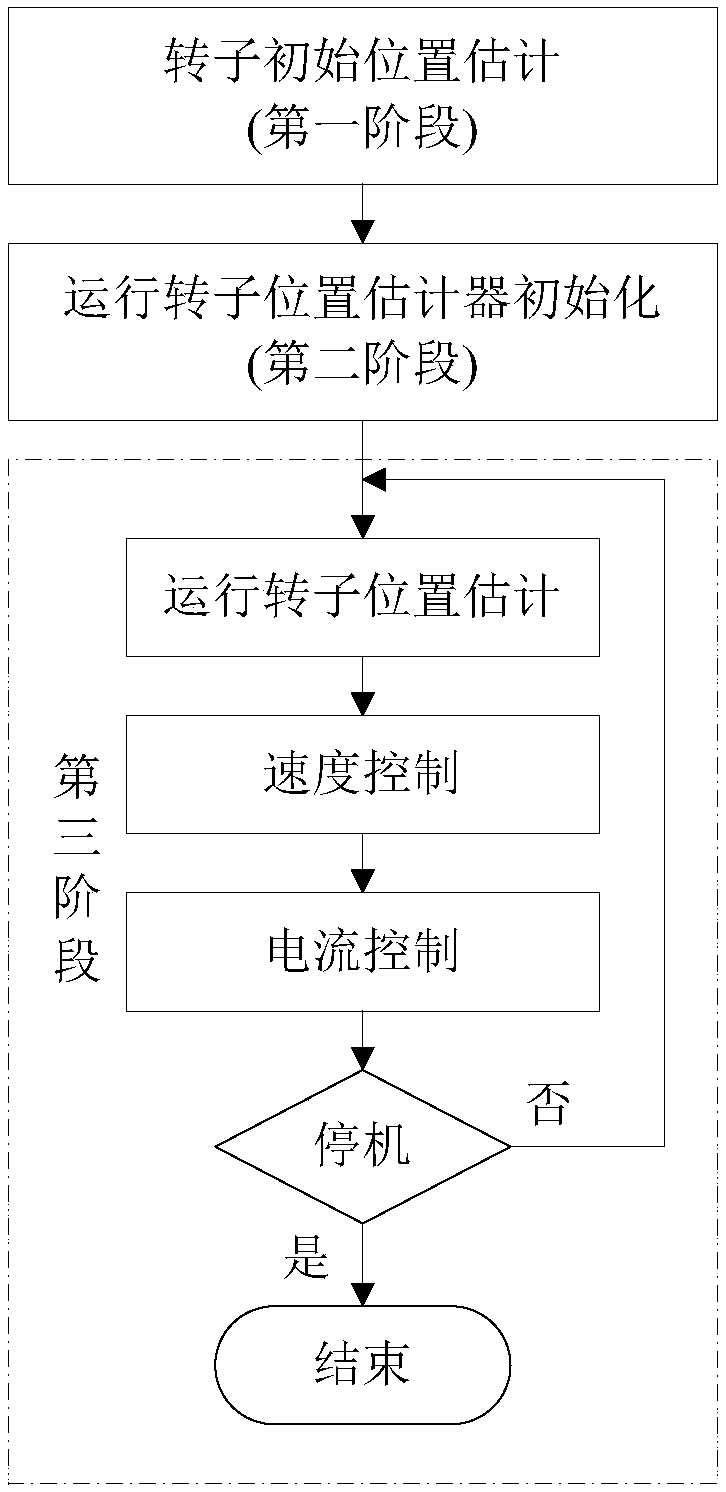

Air conditioner, compressor, and closed-loop zero-speed start method and system for compressor

InactiveCN107070348AReduce the starting current amplitudeReduce startup power consumptionElectric motor controlVector control systemsControl vectorGas compressor

The invention discloses an air conditioner, a compressor, and a closed-loop zero-speed start method and system for the compressor. The method comprises the following steps: injecting a high-frequency voltage signal to the compressor when the compressor is started, so as to estimate the initial position of a compressor rotor; carrying out the initialization of a magnetic flux observer and a phase locking ring of the compressor according to the initial position of the compressor rotor; estimating the real-time position of the compressor rotor through the initialized magnetic flux observer and phase locking ring after the compressor enters a closed-loop control state, so as to carry out the vector control of the compressor. The method can achieve the full-process position closed-loop start of the compressor, can reduce the amplitude of the start current of the compressor, and achieves an effect of energy consumption reduction.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

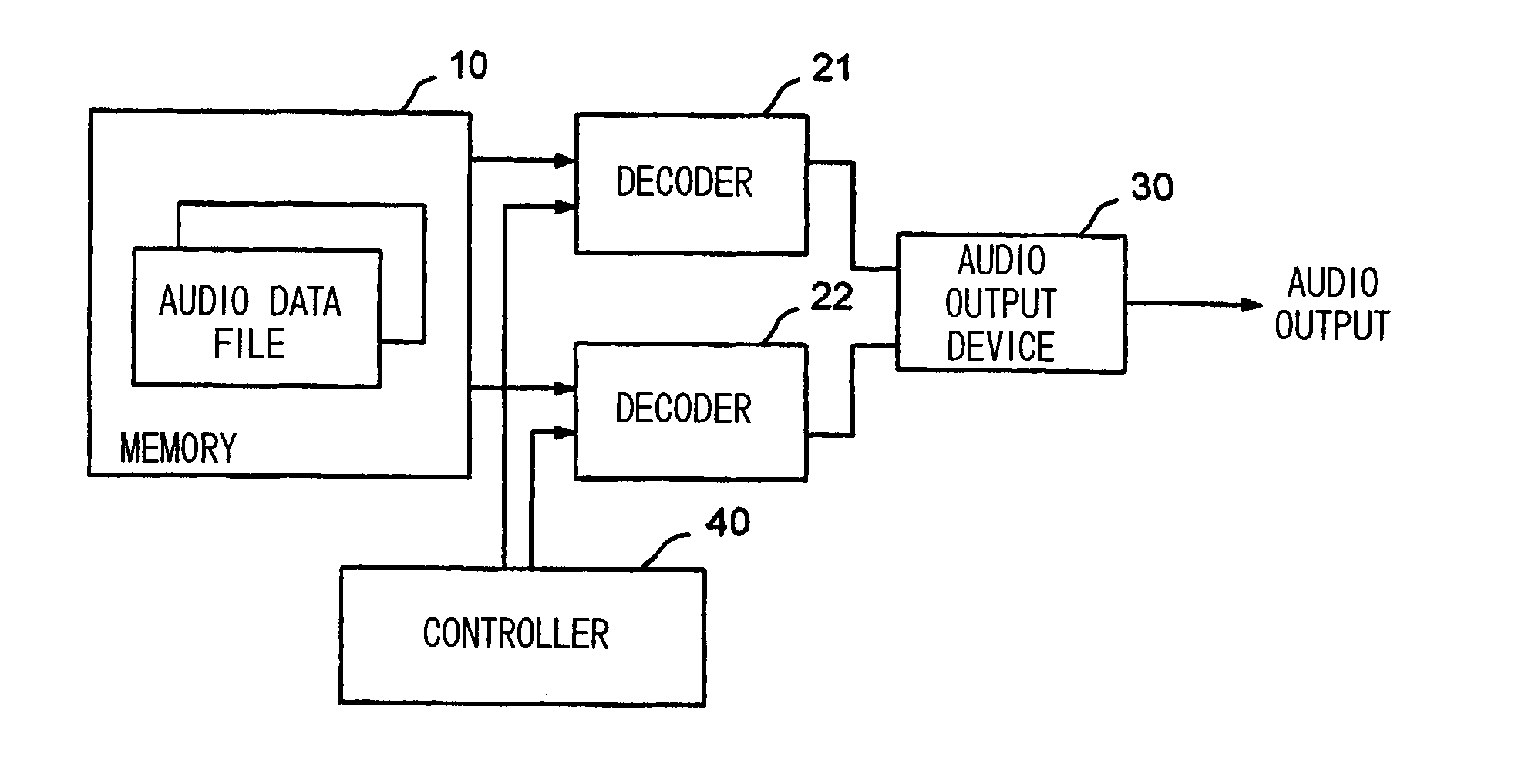

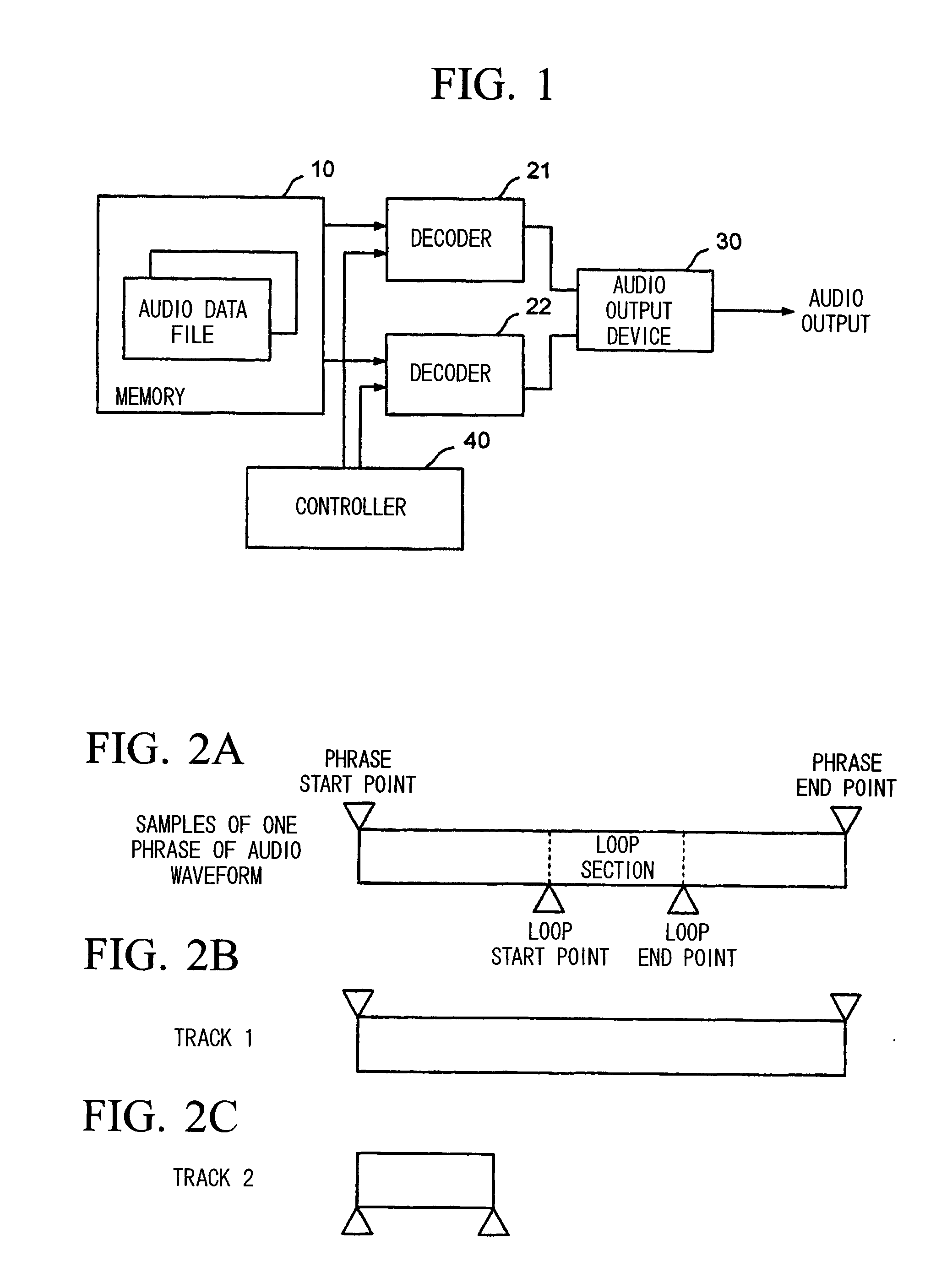

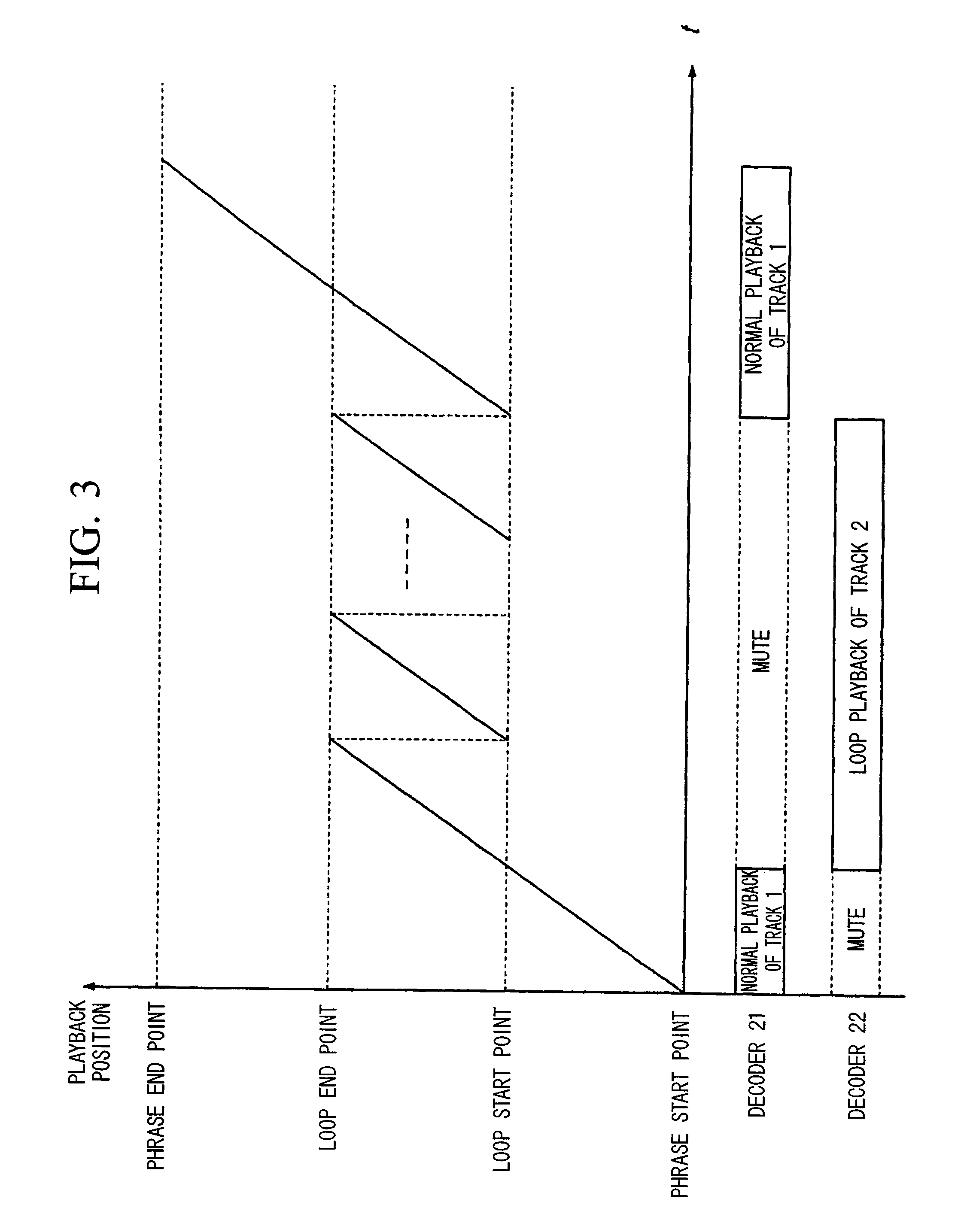

Audio playback apparatus

InactiveUS20070116301A1Reliable reproductionReliable outputElectrophonic musical instrumentsSpeech analysisComputer architectureAudio frequency

An audio playback apparatus realizes both of normal playback and loop playback with respect to compressive coded data forming an audio waveform of one phrase, which is constituted by a string of samples and which includes a loop section. In the normal playback, a decoder sequentially reproduces the samples. In the loop playback, the decoder sequentially reproduces the samples until a sample preceding a loop start point, then, the decoder repeatedly reproduces the samples belonging to the loop section, then, the decoder sequentially reproduces the samples started from the loop start point. Alternatively, two decoders are alternately controlled to perform decoding in the loop playback. Thus, it is possible to reliably output all the samples including the samples of the loop section without causing breaks.

Owner:YAMAHA CORP

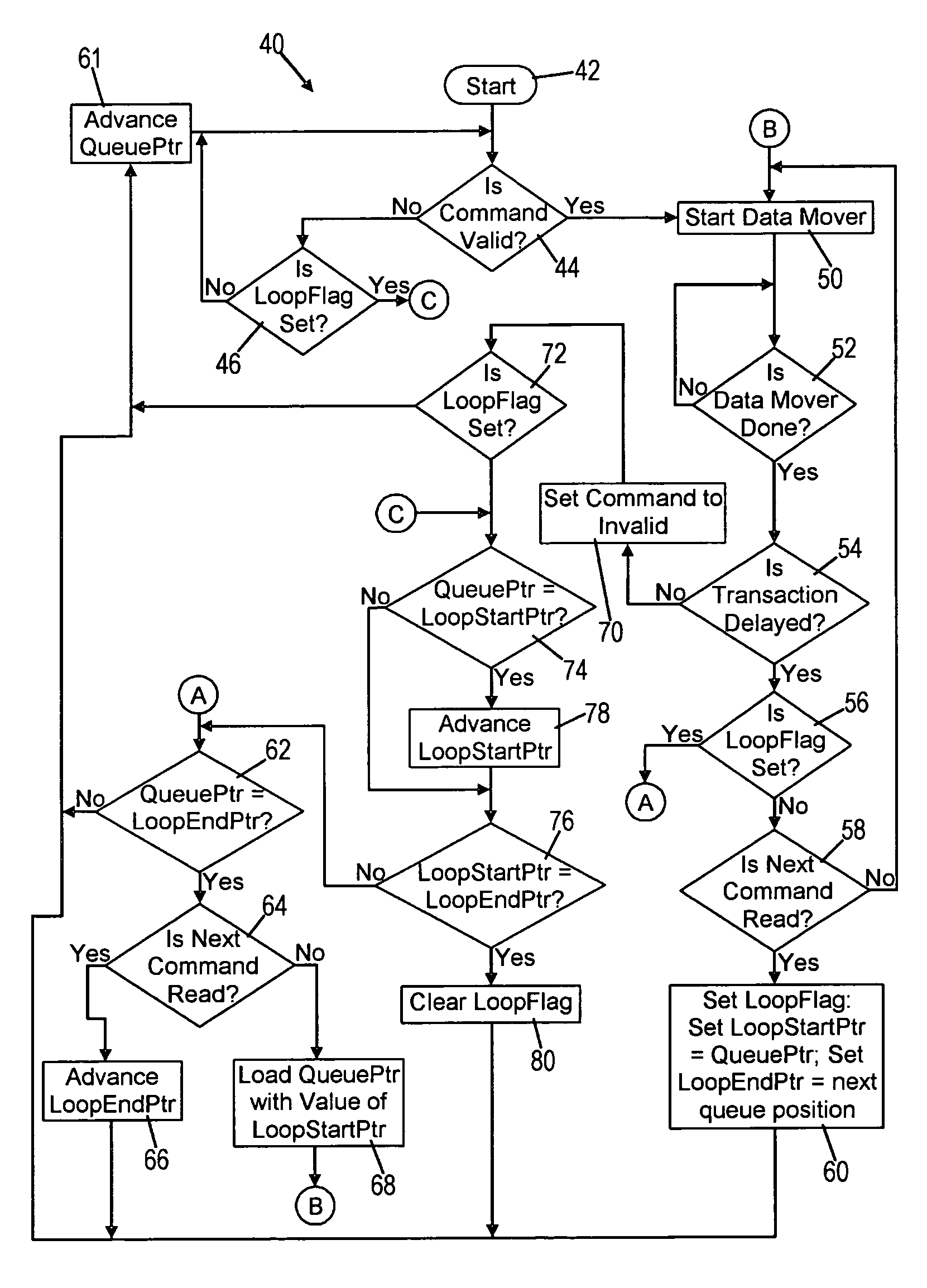

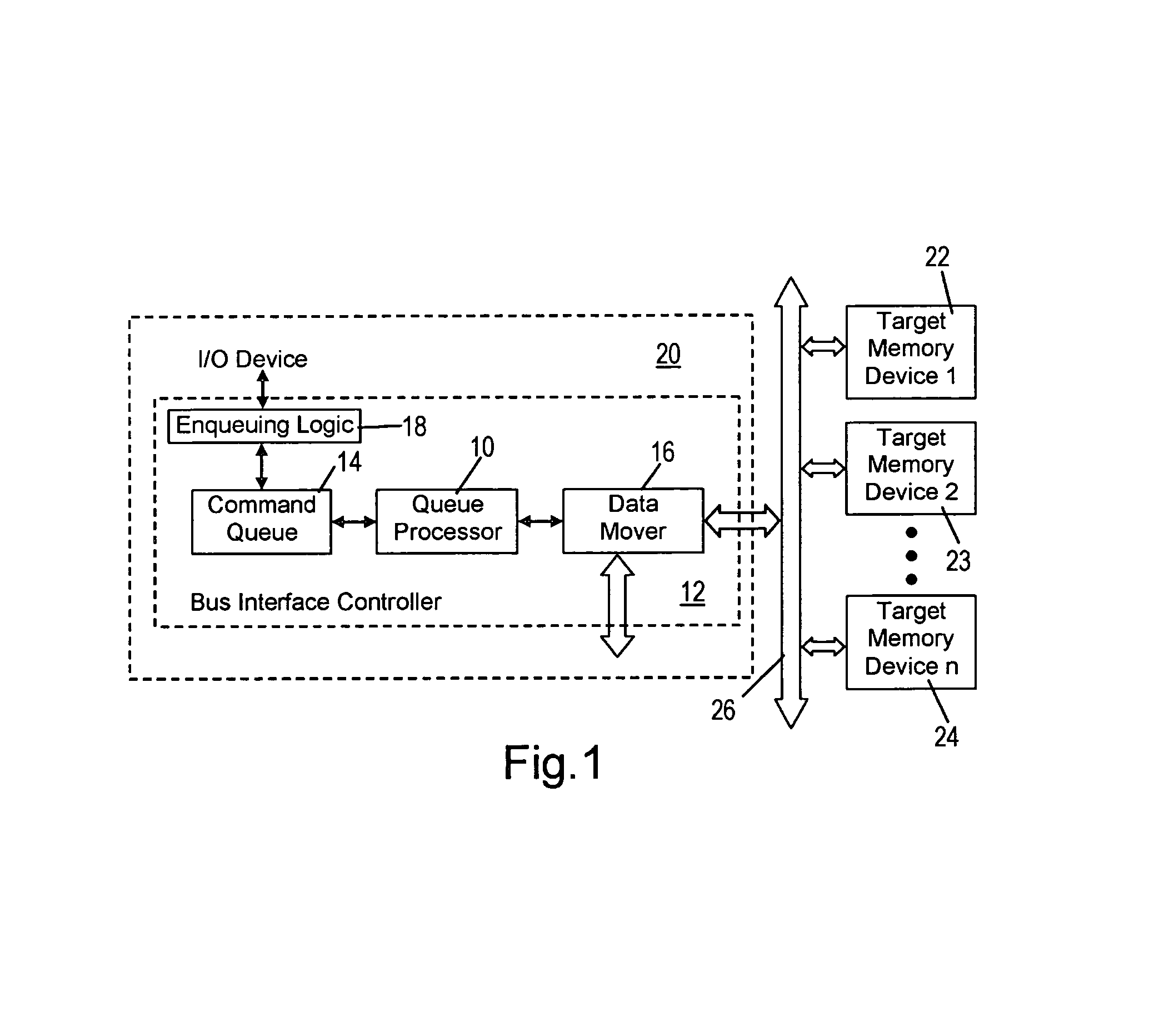

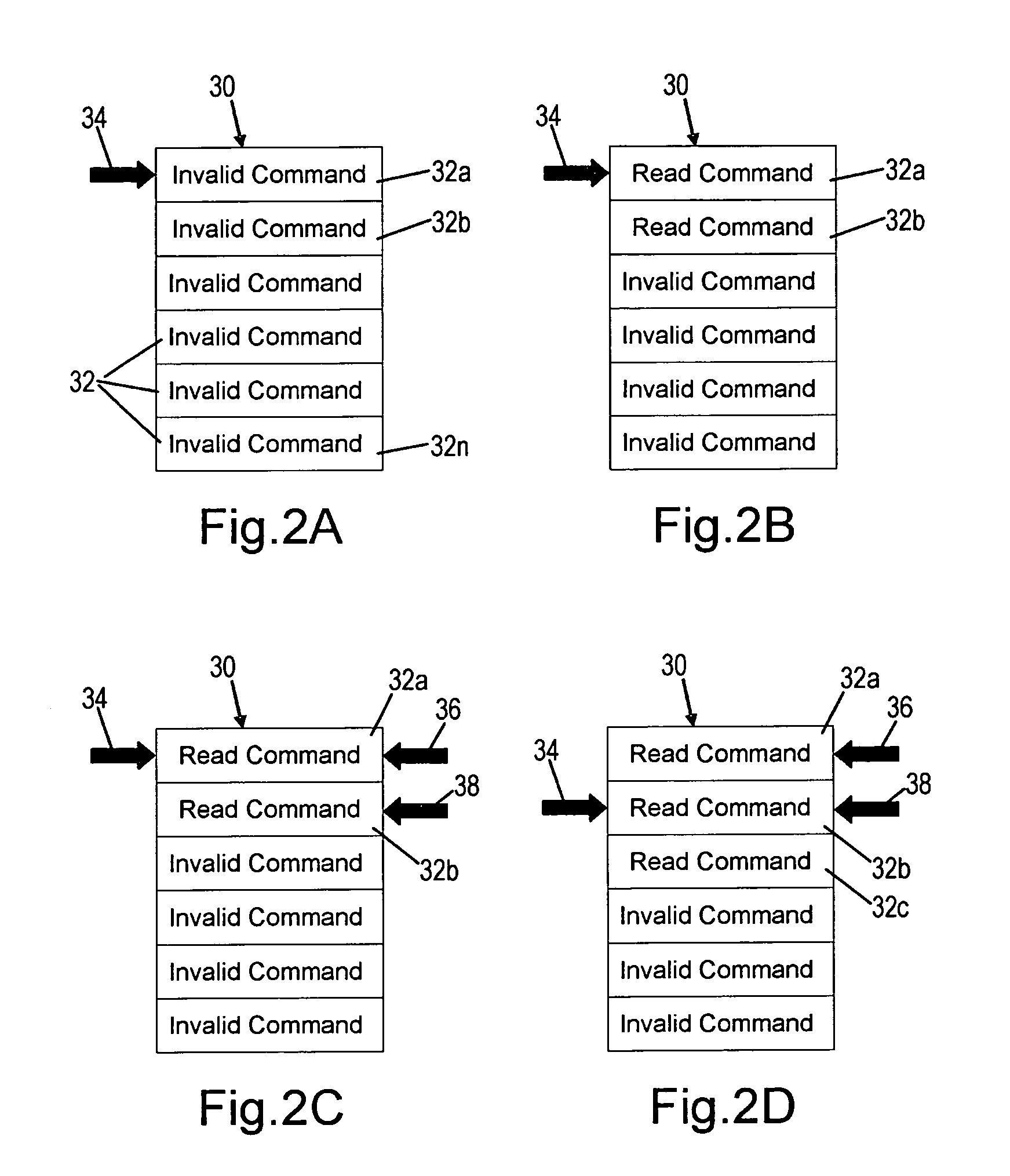

Method and apparatus of establishing a dynamically adjustable loop of delayed read commands for completion in a queue buffer

InactiveUS6968409B1Lower latencyImprove data throughputMemory systemsInput/output processes for data processingParallel computingLoop start

A loop of delayed read commands is established from a larger set of queued commands. Upon recognizing a delay in completing a first read command which is followed by a second read command, the loop is established by setting loop start pointer to identify the first delayed read command and setting a loop end pointer to identify the second read command. Upon recognizing a delay in completing the second read command which is followed by a third read command, the loop end pointer is advanced to identify the third read command. All of the read commands in the loop at and between the loop start pointer and the loop end pointer are completed before attempting to complete other commands in the queue not within the loop.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

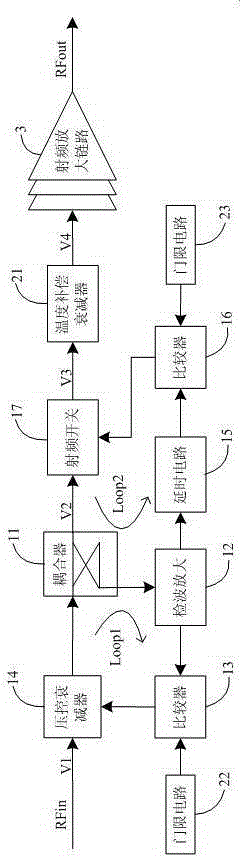

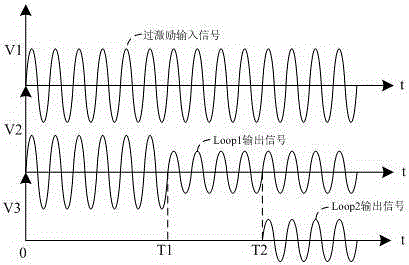

Over excitation protection circuit of solid state power amplifier and implementation method thereof

ActiveCN105227144AImprove linearityReduce output powerAmplifier modifications to reduce temperature/voltage variationAmplifier protection circuit arrangementsAudio power amplifierTime delays

The invention relates to the technical field of solid state power amplifiers, and discloses an over excitation protection circuit of a solid state power amplifier. The over excitation protection circuit specifically comprises an automatic level control loop and a switch control loop. A threshold of the automatic level control loop is set to stabilize over excitation input power at a certain rated power level; and a time delay or a threshold of the switch control loop is set to turn on a radio frequency switch after the automatic level control loop starts to control, so as to prevent an over excitation signal prior to control from entering a radio frequency amplification link. By means of the cooperative use of the two circuits, when an over excitation signal is input, subsequent equipment is protected, and meanwhile, the amplitude of the input over excitation signal is controlled instead of simply preventing over excitation by the on-off of a time delay switch used in the prior art. A universal over excitation protection device limiter is not used in the over excitation protection circuit disclosed by the invention, thereby avoiding the deterioration of such indexes as transmission system harmonics, third-order cross modulation, noise coefficient and the like. The invention further discloses an implementation method of over excitation protection circuit of the solid state power amplifier.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

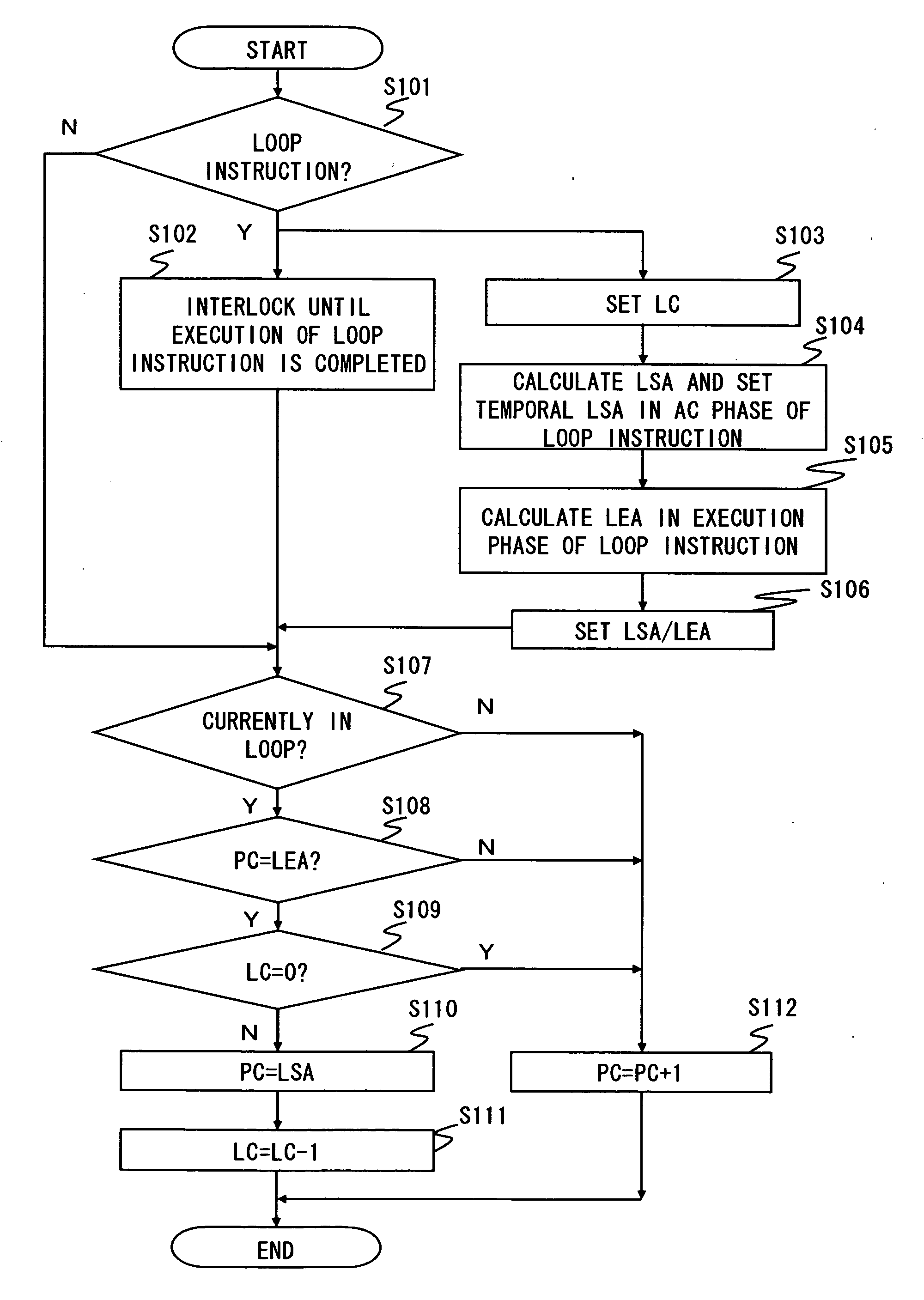

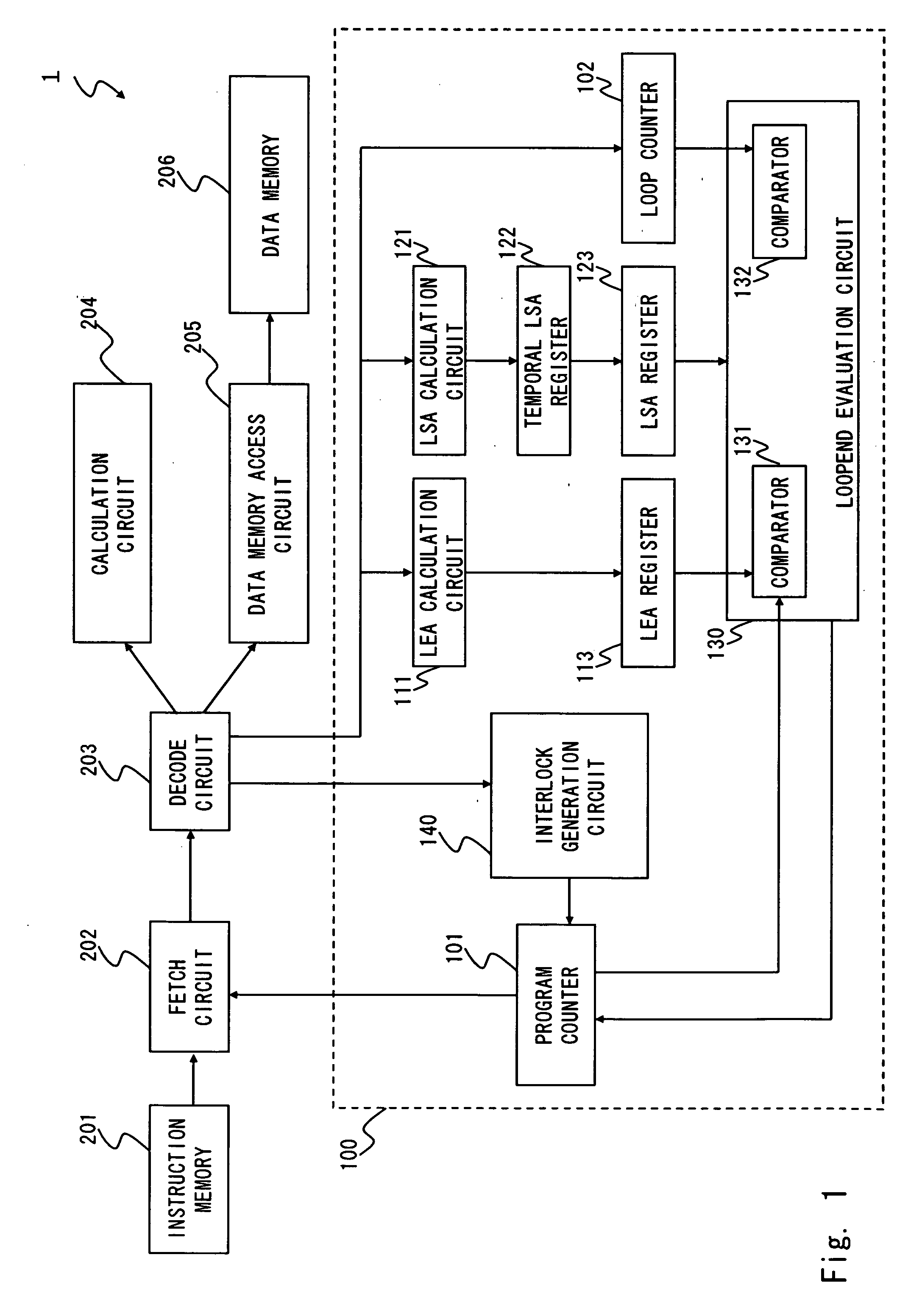

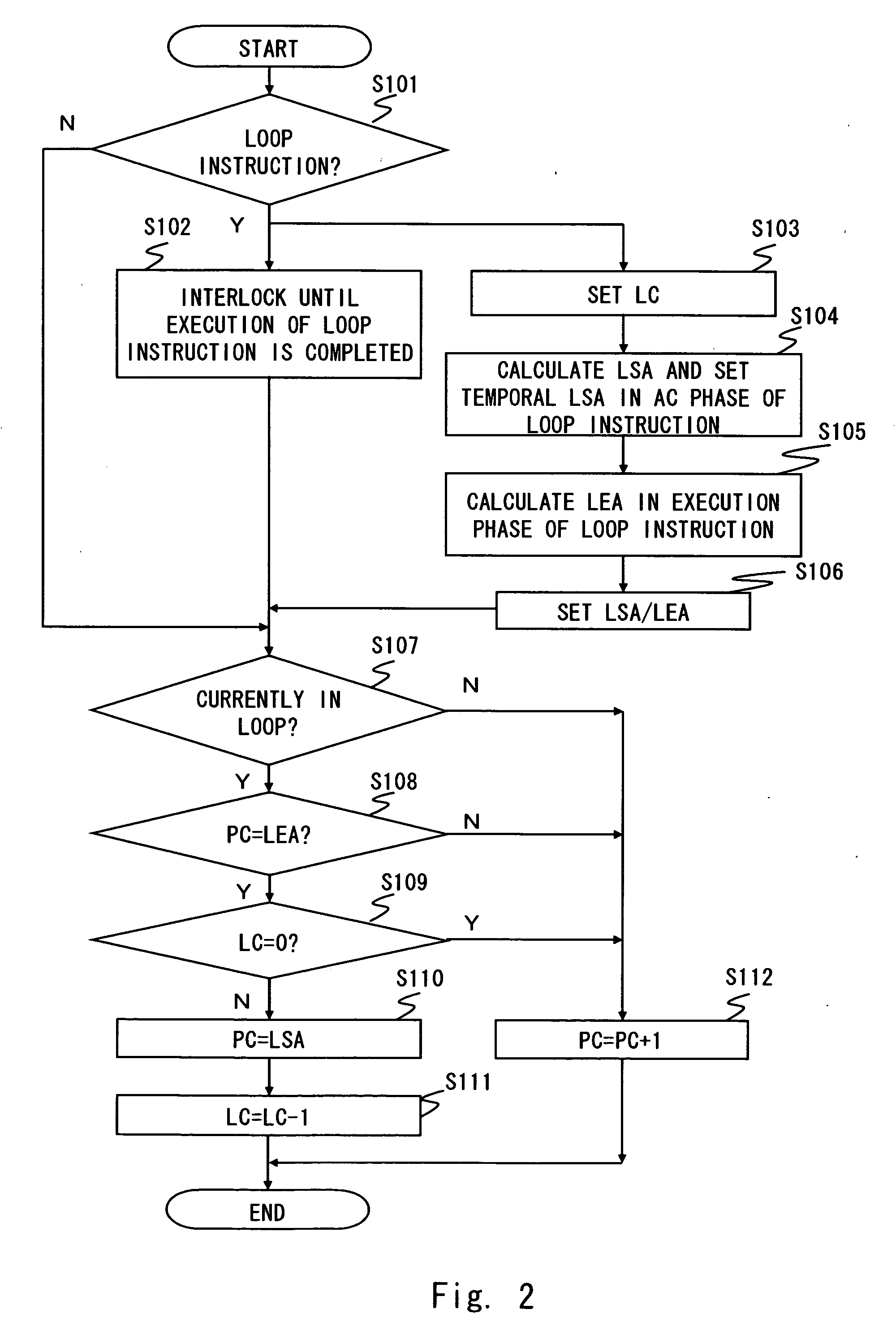

Circuit and method for loop control

InactiveUS20070186084A1Ensure correct executionAccurate assessmentDigital computer detailsSpecific program execution arrangementsLoop controlParallel computing

A loop control circuit of the present invention includes a program counter for sequentially indicating an address of an instruction, a LSA calculation circuit for calculating a loop start address of a loop start instruction, a LEA calculation circuit for calculating a loop end address of a loop end instruction, an interlock generation circuit for generating an interlock until a pipeline of a loop instruction is completed so as to suspend a pipeline process of the loop end instruction, and a loop end evaluation circuit for setting the program counter to the loop start address according to a result of a comparison between the program counter and the loop end address after the pipeline process of the loop instruction is completed.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com