Laser cladding method for titanium alloy

A technology of laser cladding and titanium alloy, which is applied in the coating process and coating of metal materials, can solve the problems of reducing the cracking sensitivity of the coating and not having universality, so as to eliminate the cracking sensitivity and reduce the residual stress , The effect of less pores and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

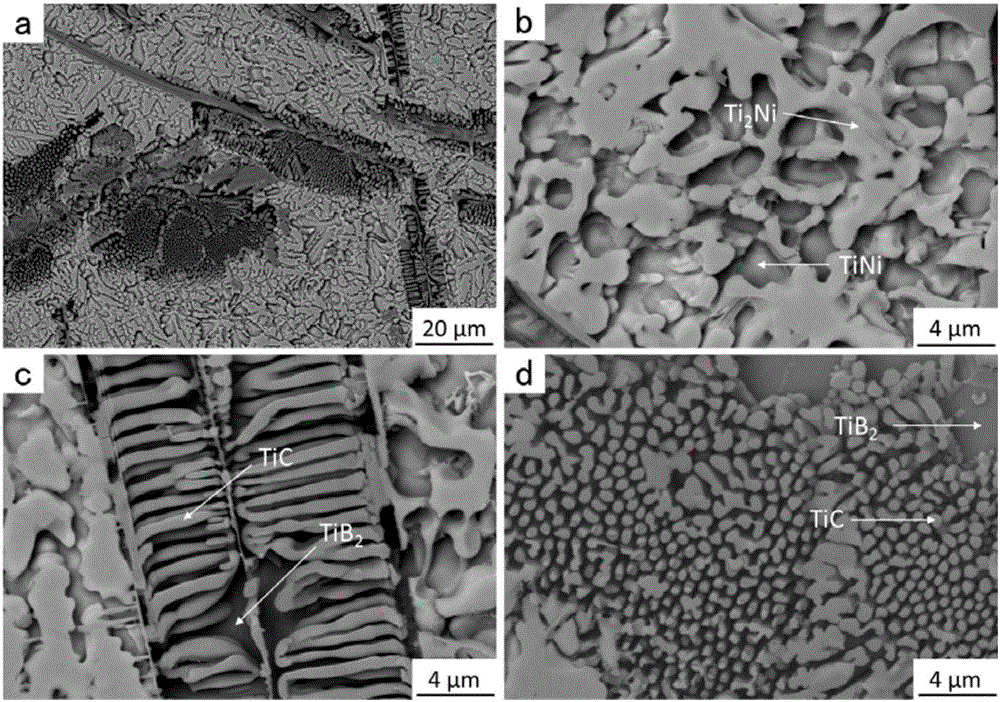

[0044] a) The composition of the cladding material is selected, and the nickel-based alloy powder and carbide ceramic composition are designed as shown in Table 1:

[0045] Table 1 Nickel-based alloy powder and carbide ceramic components

[0046] NiCCrBSi(wt.%)

B 4 C(wt.%)

90

10

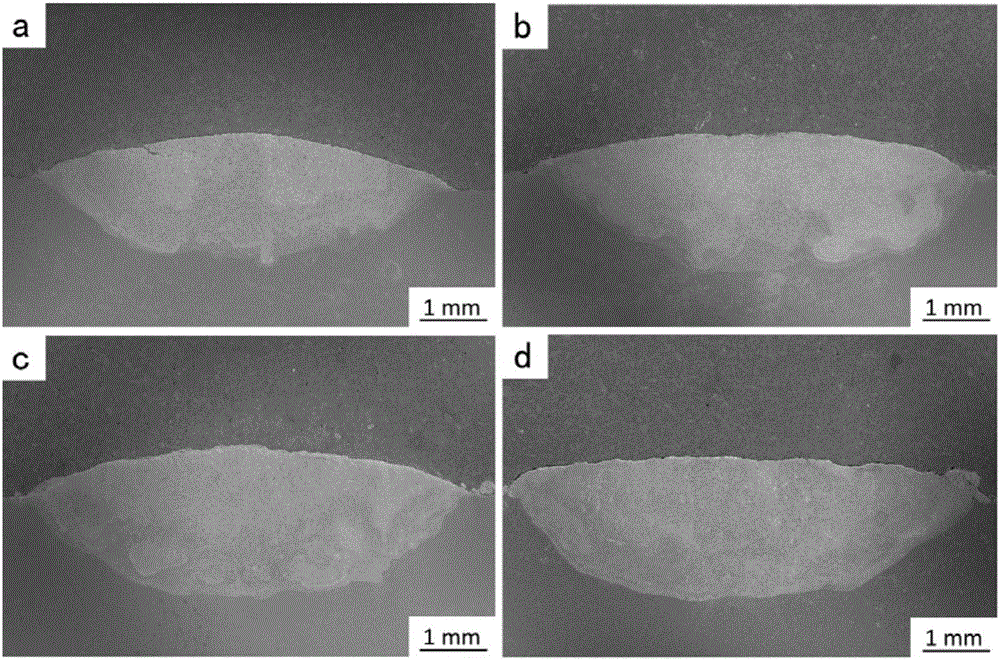

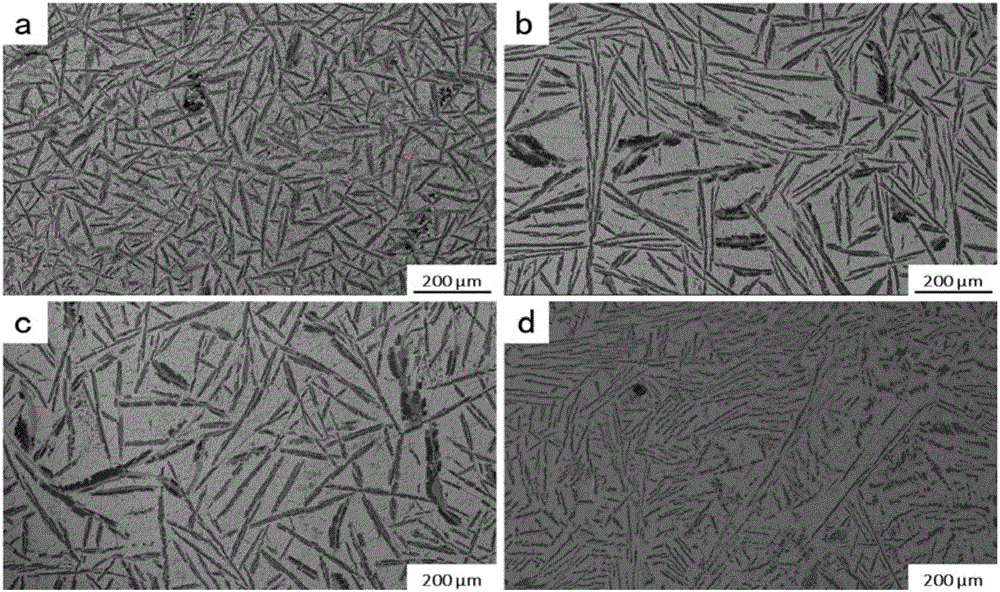

[0047] b) The design of preheating and holding time, four different preheating processes are designed, as shown in Table 2:

[0048] Table 2 Different preheating processes

[0049] Group design

Preheating temperature (℃)

Holding time (min)

I

25

30

II

400

30

III

600

30

IV

800

30

[0050] c) The preparation process of the composite coating composed of this component and different preheating processes includes the following steps:

[0051] (1) Weigh the nickel-based alloy powder and the carbide ceramic powder in the above-mentioned mass ratio, stir and grind the powder fully to form a uniform mixed powder;

[0052] (2) Using an improved pre-coating method on the titanium alloy Ti6Al4V substrate, through ...

Embodiment 2

[0064] A laser cladding method for titanium alloy, including the following steps:

[0065] (1) Grind the nickel-based alloy and carbide ceramics into powders and stir and mix to obtain the mixed powder, ready for use; wherein the nickel-based alloy contains the following elements by weight, Ni 70%, C 5%, Cr 20%, B 4%, Si 1%; carbide ceramic is B 4 C, the mass ratio of nickel-based alloy to carbide ceramic is 3:7;

[0066] (2) Brush a layer of polyvinyl alcohol with a mass fraction of 3% on the titanium alloy Ti6Al4V substrate, and then add the mixed powder obtained in step (1), and press the tablet under the tablet machine to form a pre-coating, wherein the tablet machine The applied pressure is 40MPa, the holding time is 1min, and the thickness of the formed pre-coating is 0.5mm;

[0067] (3) Put the titanium alloy Ti6Al4V substrate containing the pre-coated layer in a well-type resistance furnace and heat it to 100°C. After keeping it for 30 minutes, perform laser cladding at 100°...

Embodiment 3

[0070] A laser cladding method for titanium alloy, including the following steps:

[0071] (1) Grind the nickel-based alloy and carbide ceramics into powders and stir and mix to obtain the mixed powder, ready for use; wherein the nickel-based alloy contains the following elements by weight, Ni 80%, C 0.1%, Cr 10%, B 5%, Si 4.9%; carbide ceramic is B 4 C, the mass ratio of nickel-based alloy to carbide ceramic is 95:5;

[0072] (2) Brush a layer of polyvinyl alcohol with a mass fraction of 10% on the titanium alloy Ti6Al4V substrate, and then add the mixed powder obtained in step (1), press the tablet under the tablet machine to form a pre-coating, wherein the tablet machine The applied pressure is 20MPa, the holding time is 5min, and the thickness of the formed pre-coating is 1mm;

[0073] (3) Put the titanium alloy Ti6Al4V substrate containing the pre-coated layer in a well-type resistance furnace and heat it to 800°C. After holding for 10 minutes, perform laser cladding at 800°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com