Carbon segregation control method for continuous casting round billet for vehicle wheel

A continuous casting round billet and control method technology, applied in the field of train wheel steel production, can solve the problems of unsteady control of wheel homogenization, unstable quality, etc., to improve solidification structure, improve composition uniformity, and reduce smelting costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

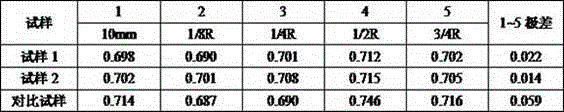

Embodiment 1

[0028] R14m arc round billet continuous casting machine in a steel factory produces wheel steel CL60Φ380mm continuous casting round billet, production process parameters: superheat 25°C, casting speed 0.50m / min, stirring parameters of M-EMS electromagnetic stirrer: 250A / 2.5 Hz, the stirring parameter of S-EMS electromagnetic stirrer is: 350A / 9Hz (alternate), the stirring parameter of F-EMS electromagnetic stirrer is: 400A / 7Hz, the parameter of high-frequency pulse oscillator is 300A / 200Hz. Use a Φ8mm alloy drill bit to sample cuttings at 5 points from the surface, 10mm, 1 / 8R, 1 / 4R, 1 / 2R, and 3 / 4R, on the low-magnification sample in the transverse direction of the round billet, and use an infrared carbon and sulfur analyzer to measure the carbon content. . After analysis, from the surface 10mm to 3 / 4R, the carbon range is within 0.025%, see Table 1. The carbon segregation of the round billet is obviously better than that of the traditional mold casting billet, and the continuo...

Embodiment 2

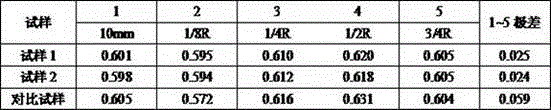

[0033]R14m curved round billet continuous casting machine in a steel factory produces wheel steel AAR-C Φ380mm continuous casting round billet. Production process parameters: superheat degree 22°C, casting speed 0.50m / min, stirring parameters of M-EMS electromagnetic stirrer are: 280A / 2.5Hz, the stirring parameter of S-EMS electromagnetic stirrer is: 350A / 9Hz (alternate), the stirring parameter of F-EMS electromagnetic stirrer is: 400A / 7Hz, the parameter of high frequency pulse oscillator is 300A / 200Hz. Use a Φ8mm alloy drill bit to sample cuttings at 5 points from the surface, 10mm, 1 / 8R, 1 / 4R, 1 / 2R, and 3 / 4R, on the low-magnification sample in the transverse direction of the round billet, and use an infrared carbon and sulfur analyzer to measure the carbon content. . After analysis, from the surface 10mm to 3 / 4R, the carbon range is within 0.022%, see Table 2.

[0034] Table 2

[0035]

[0036] Note: R is the radius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com