Low-melting-point high-latent-heat phase change and energy storage material as well as preparation method thereof

A phase change energy storage material with a low melting point technology, applied in the field of phase change energy storage, can solve the problems of reducing the latent heat of phase change of materials, low latent heat, and reducing the recycling performance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

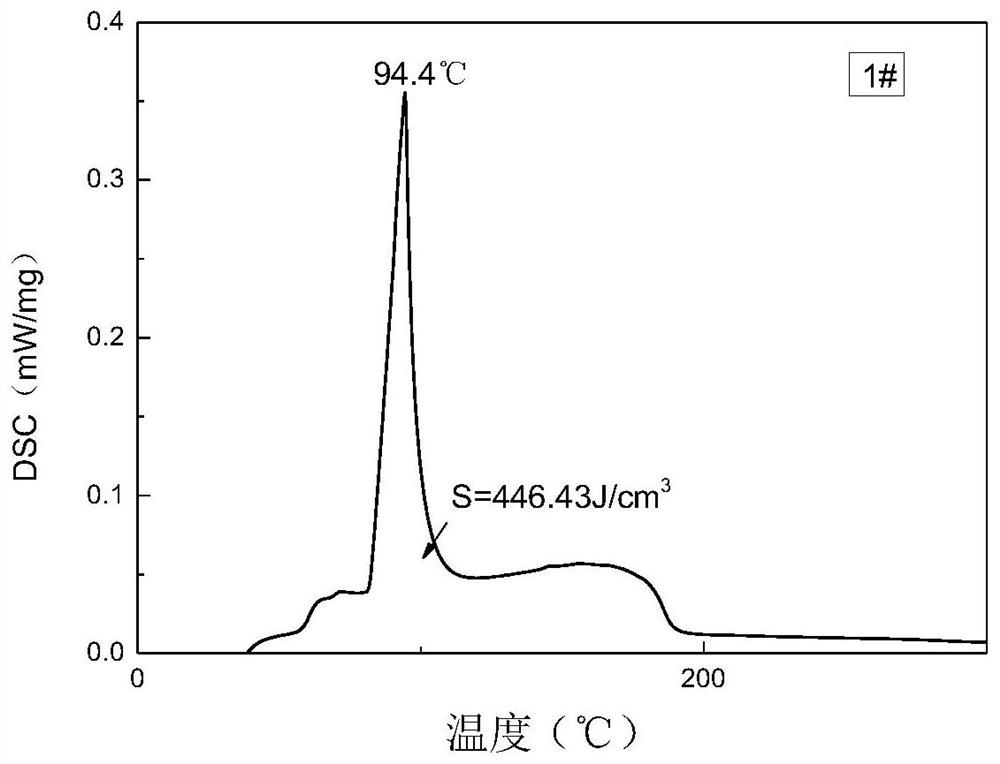

Embodiment 1

[0027] A method for a high latent heat phase change energy storage material, comprising the following steps:

[0028] (1) In this embodiment, the alloy composition and weight ratio of eutectic melting characteristic with low melting point and high latent heat are as follows: Sn 10%, In 10%, Bi 80%.

[0029] (2) According to the above proportions, take Sn, In and Bi elemental metal blocks with a corresponding mass of 99.995% purity, ultrasonically clean them in 95% alcohol solution for 5 minutes, and put them into a drying oven for drying. Put the dried metal element into the vacuum melting furnace, close the vacuum melting furnace and carry out vacuum treatment to make the vacuum pressure in the vacuum melting furnace reach -0.1MPa, and then fill the vacuum melting furnace with argon to normal pressure.

[0030] (3) Put the simple metal into the crucible, and heat it to 400°C with a heating furnace at a heating rate of 20°C / min in an environment isolated from water and oxygen,...

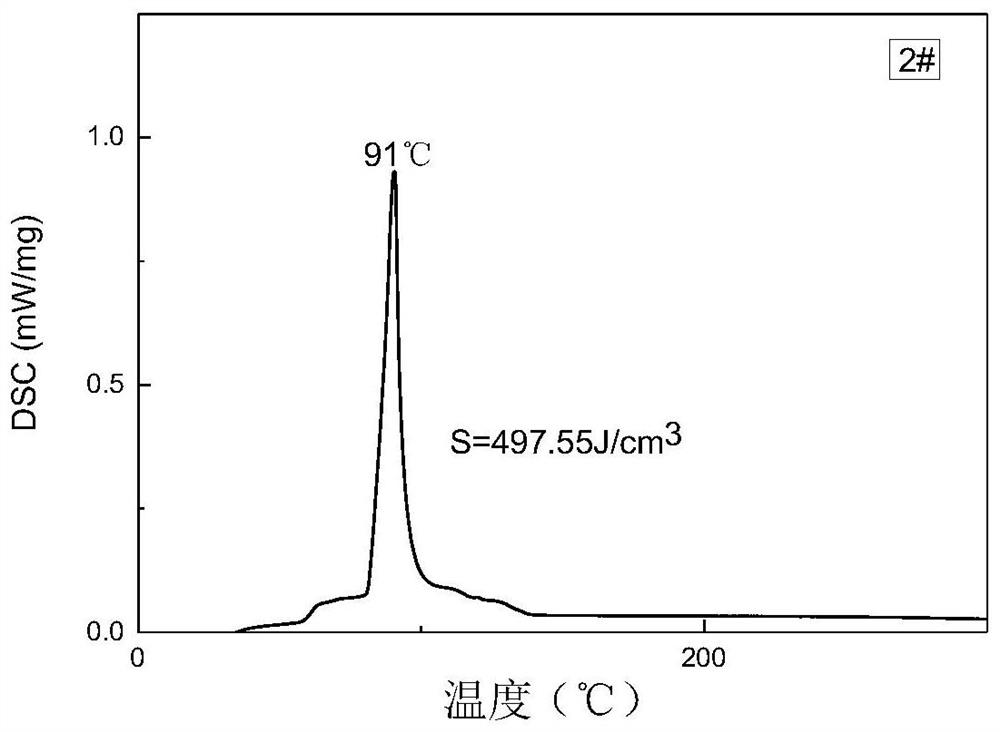

Embodiment 2

[0033]A method for a high latent heat phase change energy storage material, comprising the following steps:

[0034] (1) In this embodiment, the alloy composition and weight ratio of eutectic melting characteristic with low melting point and high latent heat are as follows: Sn 20%, In 20%, Bi 60%.

[0035] (2) According to the above proportions, take Sn, In and Bi elemental metal blocks with a corresponding mass of 99.995% purity, ultrasonically clean them in 95% alcohol solution for 5 minutes, and put them into a drying oven for drying. Put the dried metal element into the vacuum melting furnace, close the vacuum melting furnace and carry out vacuum treatment to make the vacuum pressure in the vacuum melting furnace reach -0.1MPa, and then fill the vacuum melting furnace with argon to normal pressure.

[0036] (3) Put the simple metal into the crucible, and heat it to 400°C with a heating furnace at a heating rate of 20°C / min in an environment isolated from water and oxygen, ...

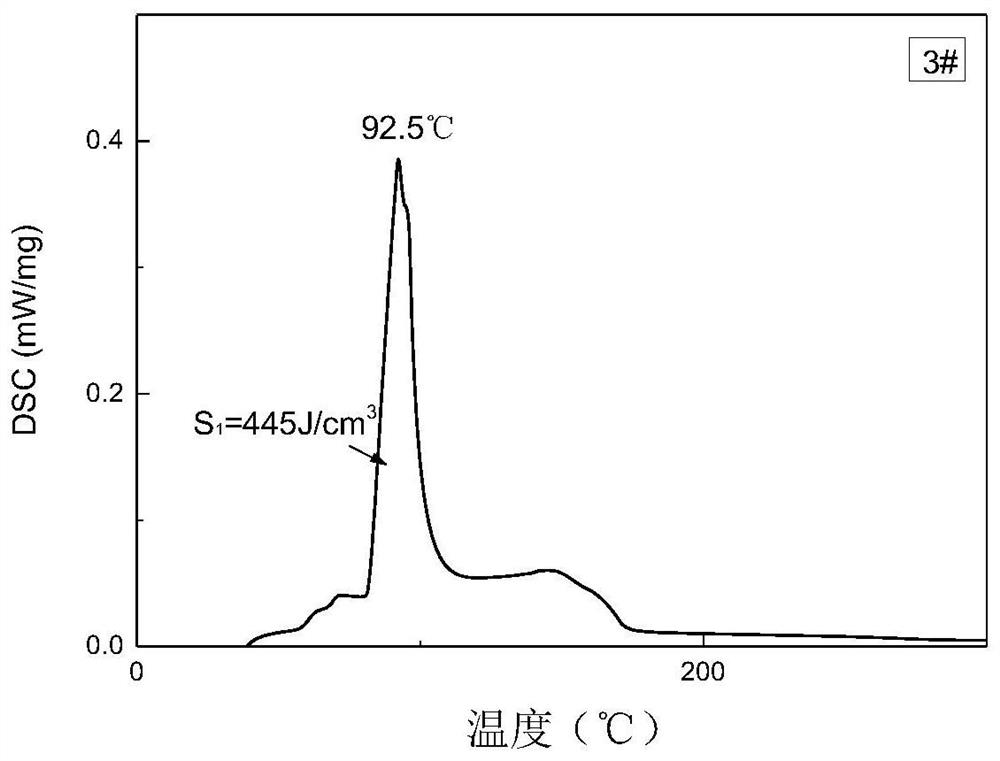

Embodiment 3

[0039] A method for a high latent heat phase change energy storage material, comprising the following steps:

[0040] (1) In this embodiment, the alloy composition and weight ratio of eutectic melting characteristic with low melting point and high latent heat are as follows: Sn 20%, In 10%, Bi 70%.

[0041] (2) According to the above proportions, take Sn, In and Bi elemental metal blocks with a corresponding mass of 99.995% purity, ultrasonically clean them in 95% alcohol solution for 5 minutes, and put them into a drying oven for drying. Put the dried metal element into the vacuum melting furnace, close the vacuum melting furnace and carry out vacuum treatment to make the vacuum pressure in the vacuum melting furnace reach -0.1MPa, and then fill the vacuum melting furnace with argon to normal pressure.

[0042] (3) Put the simple metal into the crucible, and heat it to 400°C with a heating furnace at a heating rate of 20°C / min in an environment isolated from water and oxygen,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com