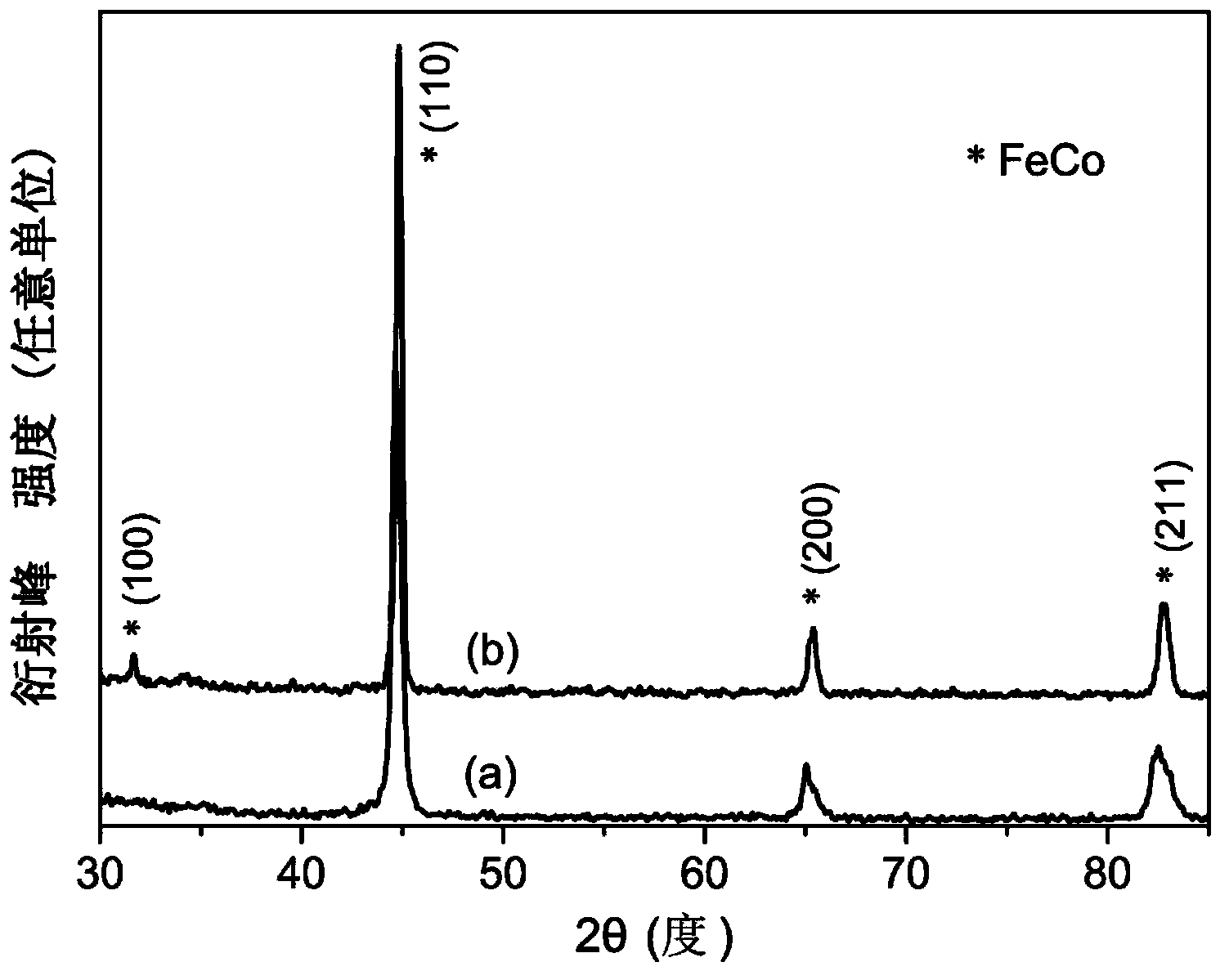

Preparation method for micrometer-particle-diameter FeCo particles

A technology of micron particles and particles, which is applied in the field of magnetic material preparation, can solve the problems of large specific surface area, high pressure, and difficulty in preparing dense blocks of nanoparticles, and achieve high purity, simple process, and uniform composition and structure. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

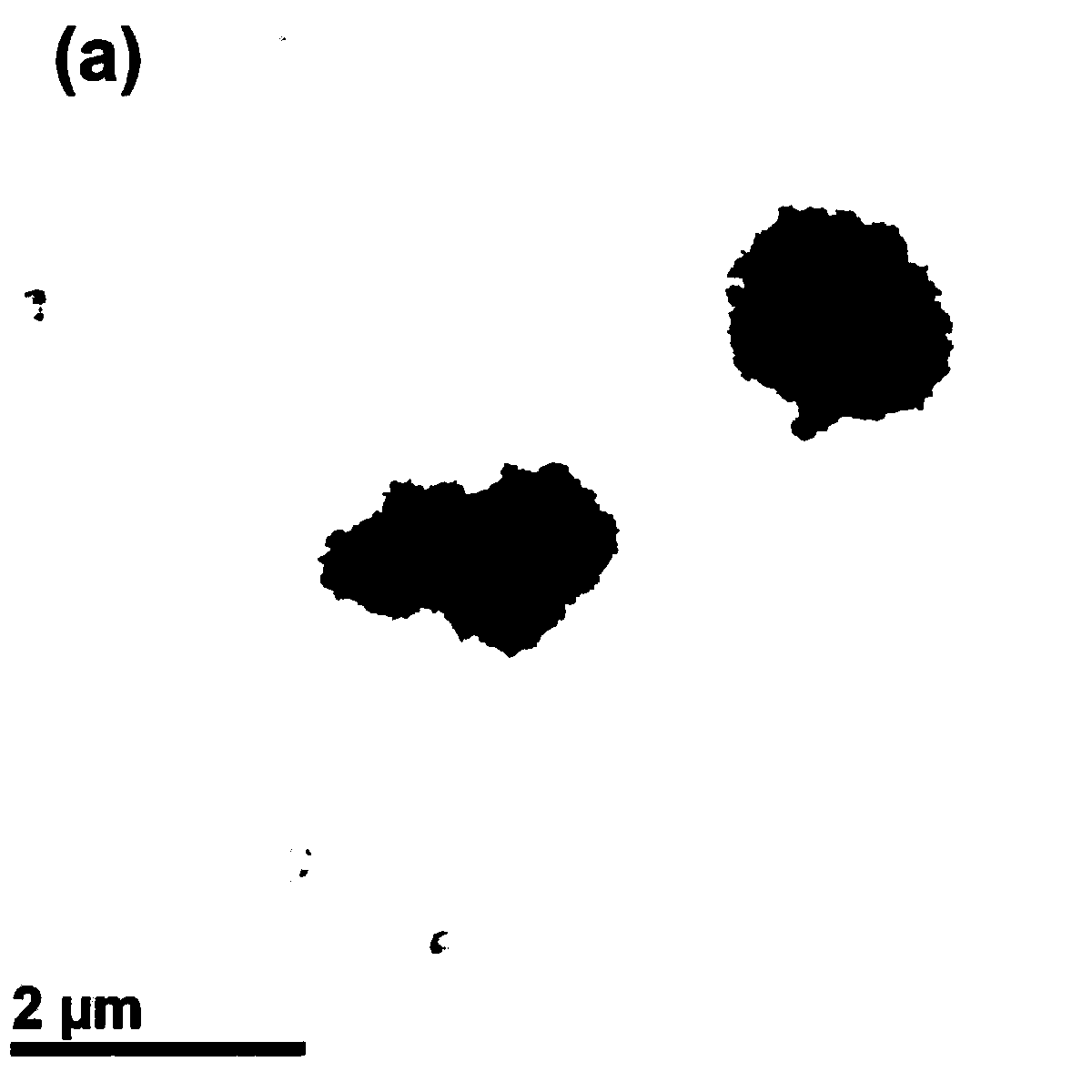

Embodiment 1

[0033]According to the preparation method of the present invention, FeCo particles with a particle size of 1.5 microns are prepared. Specific steps are as follows:

[0034] i) 0.2380g CoCl with a molar ratio of 1:1 2 ·6H 2 O and 0.2780 g FeSO 4 ·7H 2 O is placed in a container A with a volume of 50 mL, and 1 mL of distilled water is added to the container A, and stirred with a glass rod until fully dissolved;

[0035] ii) Weigh 10mL (42 times CoCl 2 ·6H 2 The mass of O) n-hexane, placed in a suitable size container B; measure 2.5mL n-butanol into container B, stir with a glass rod for 10 minutes; then add 2.5g hexadecyl trimethyl to container B ammonium bromide (CTAB), add 1mL distilled water at the same time, stir for 10 minutes;

[0036] iii) Place container B treated in step ii) on a heating stirrer, heat to 30°C, and stir for 10 minutes;

[0037] iv) Slowly pour the solution in container A treated in step i) into container B in step iii), and stir for 10 minutes; ...

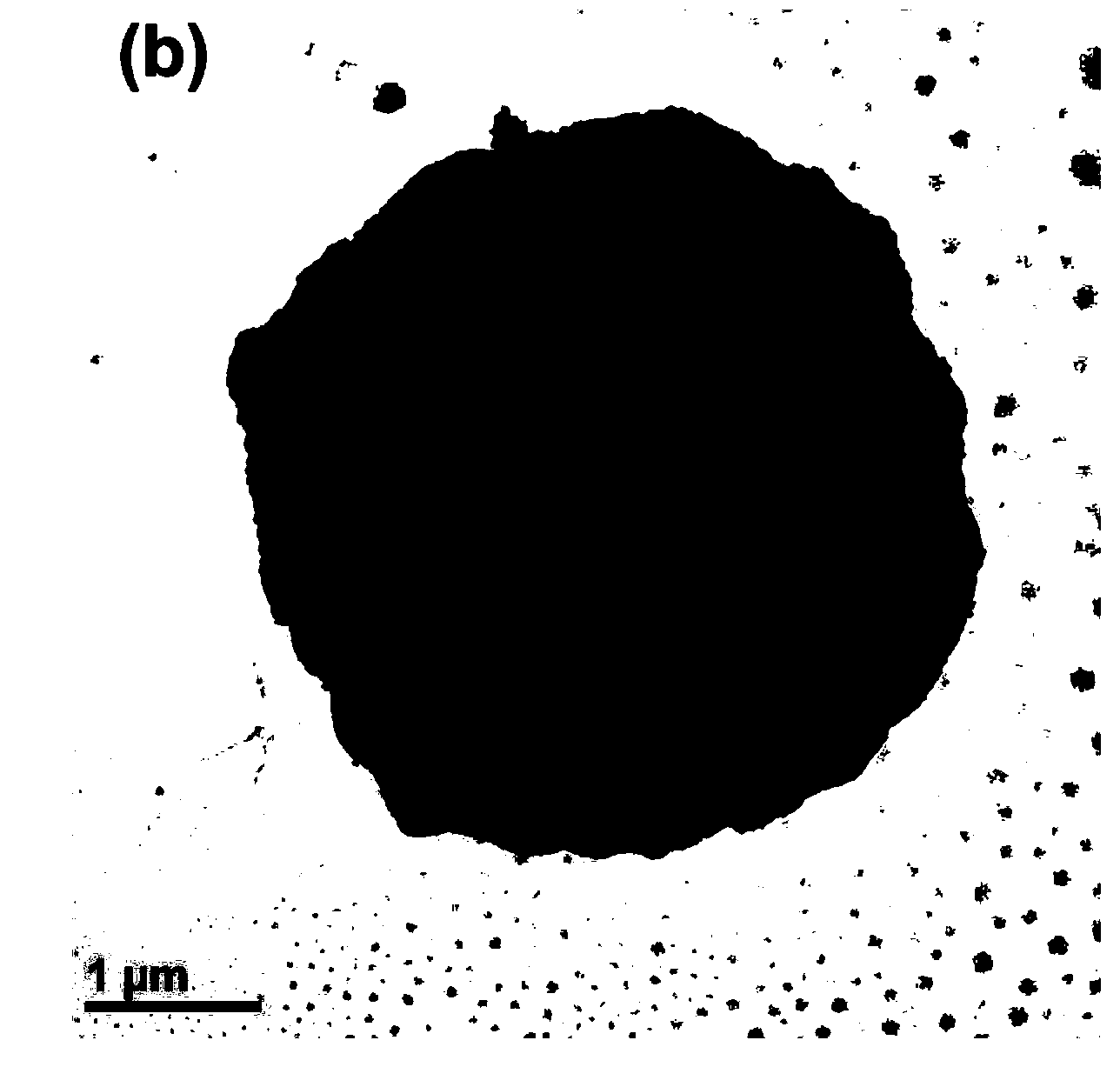

Embodiment 2

[0046] Adopt the method provided by the invention to prepare the FeCo particle that particle diameter is about 4 microns, concrete steps are as follows:

[0047] i) 0.2810g CoSO with a molar ratio of 1:1 4 ·7H 2 O and 0.2780 g FeSO 4 ·7H 2 O is placed in a container A with a volume of 50 mL, and 1 mL of distilled water is added to the container A, and stirred with a glass rod until fully dissolved;

[0048] ii) Weigh 12mL (42 times CoCl 2 ·6H 2 The mass of O) n-hexane, placed in a suitable size container B; measure 3mL n-butanol into container B, stir with a glass rod for 10 minutes; then add 3g hexadecyl trimethyl bromide to container B ammonium (CTAB), add 1mL distilled water at the same time, stir for 10 minutes;

[0049] iii) Place container B treated in step ii) on a heating stirrer, heat to 30 degrees Celsius, and stir for 15 minutes;

[0050] iv) Slowly pour the solution in container A treated in step i) into container B in step iii), and stir for 10 minutes;

...

Embodiment 3

[0059] FeCo particles with a particle size of about 3.5 microns were prepared by the method provided by the present invention.

[0060] i) 0.2810g CoSO with a molar ratio of 1:1 4 ·7H 2 O and 0.2780 g FeSO 4 ·7H 2 O is placed in a container A with a volume of 50 mL, and 1 mL of distilled water is added to the container A, and stirred with a glass rod until fully dissolved;

[0061] ii) Weigh 20mL (84 times the CoCl 2 ·6H 2 The mass of O) n-hexane, placed in a suitable size container B; measure 6.5mL n-butanol into container B, stir with a glass rod for 15 minutes; then add 9g hexadecyl trimethyl bromide to container B ammonium chloride (CTAB), while adding 1 mL of distilled water, stirring for 15 minutes;

[0062] iii) Place container B treated in step ii) on a heating stirrer, heat to 50 degrees Celsius, and stir for 10 minutes;

[0063] iv) Slowly pour the solution in container A treated in step i) into container B in step iii), and stir for 15 minutes;

[0064] v) A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com