Process for manufacturing of a fermented dairy product

A technology for fermenting dairy products and fermentation temperature, applied to dairy products, other dairy products, milk preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Production of Stirred Yogurt

[0056] Milk bases were prepared with corresponding concentrations of fat and protein content, i.e. 3.5% (w / w) fat, 3.72% (w / w) protein, 5.68% (w / w) lactose, 0.89% (w / w) ash and 13.79 % (w / w) total solids (Becker, T. and Puhan, Z. (1989) Milchwissenschaft 44, .626-629).

[0057] This specific amount of milk was mixed with the appropriate amount of skim milk powder and cream at 4°C.

[0058] Mix the base for 30 minutes. The milk base was heated at 92°C and 250 bar for 6.5 minutes and then cooled to 38°C before being placed in the fermenter, where the temperature was maintained at fermentation temperature. The milk matrix was inoculated with culture Y-051054 (marketed by Chr. Hansen) in an amount of 0.02% by weight of the milk matrix. The culture was made from three strains of Streptococcus thermophilus and one strain of Lactobacillus germanus subsp. bulgaricus.

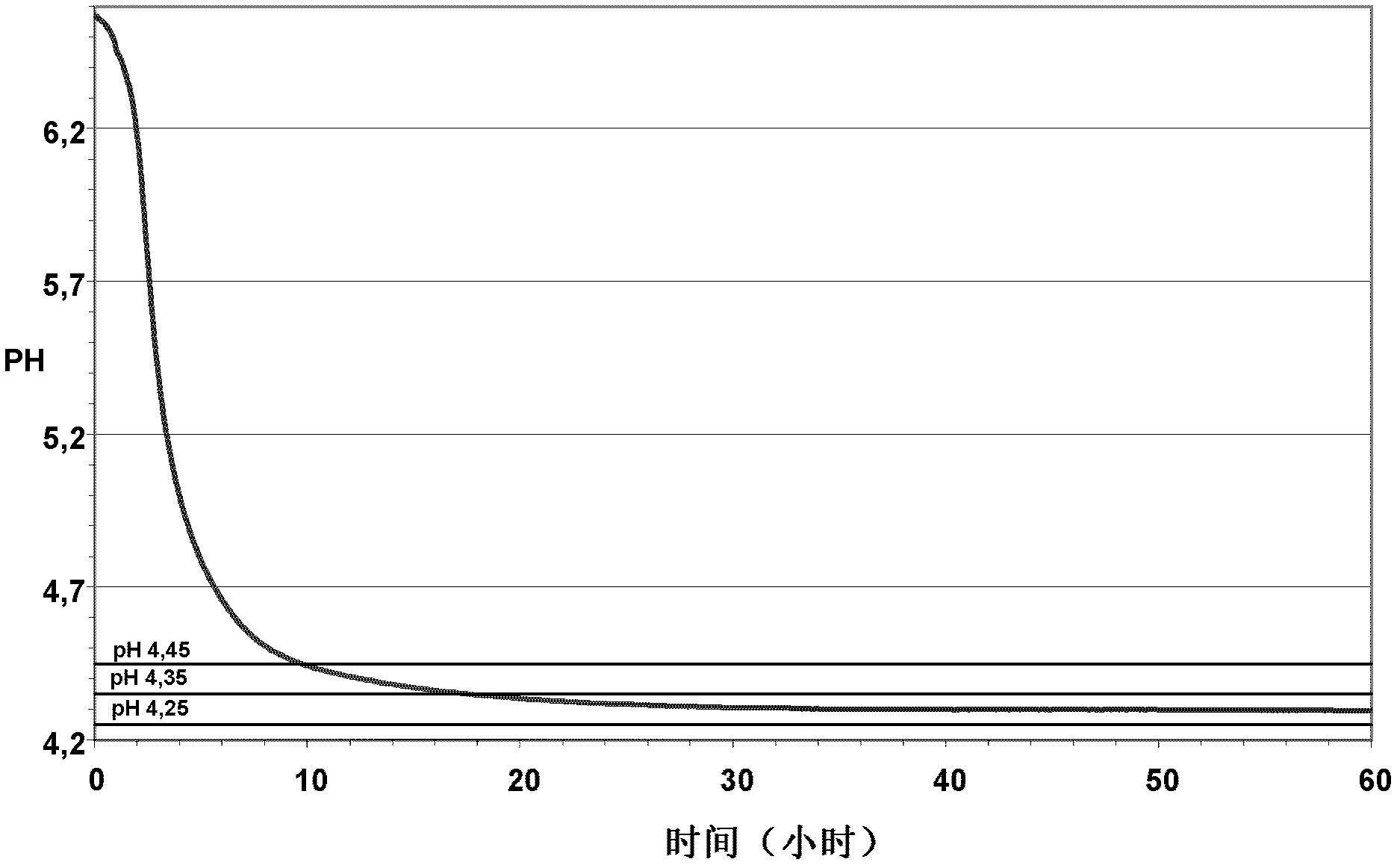

[0059] The cultivation was carried out at 38°C until the pH reached 4.45....

Embodiment 2

[0066] Production of Stirred Yogurt

[0067] The protocol was exactly the same as Example 1, except that the milk matrix was inoculated with M1B culture (marketed by Chr. Hansen) in an amount of 0.02% by weight of the milk matrix. The culture was prepared from Lactobacillus germanitis subsp. bulgaricus strain DSM 19252 and Streptococcus thermophilus strain, wherein DSM 19252 was deposited at the German Collection of Microorganisms and Cell Cultures on April 3, 2007.

[0068] Determination of acidification kinetics

[0069] Acidification was evaluated as in Example 1 with the CINAC system (acidification kinetics).

[0070] result

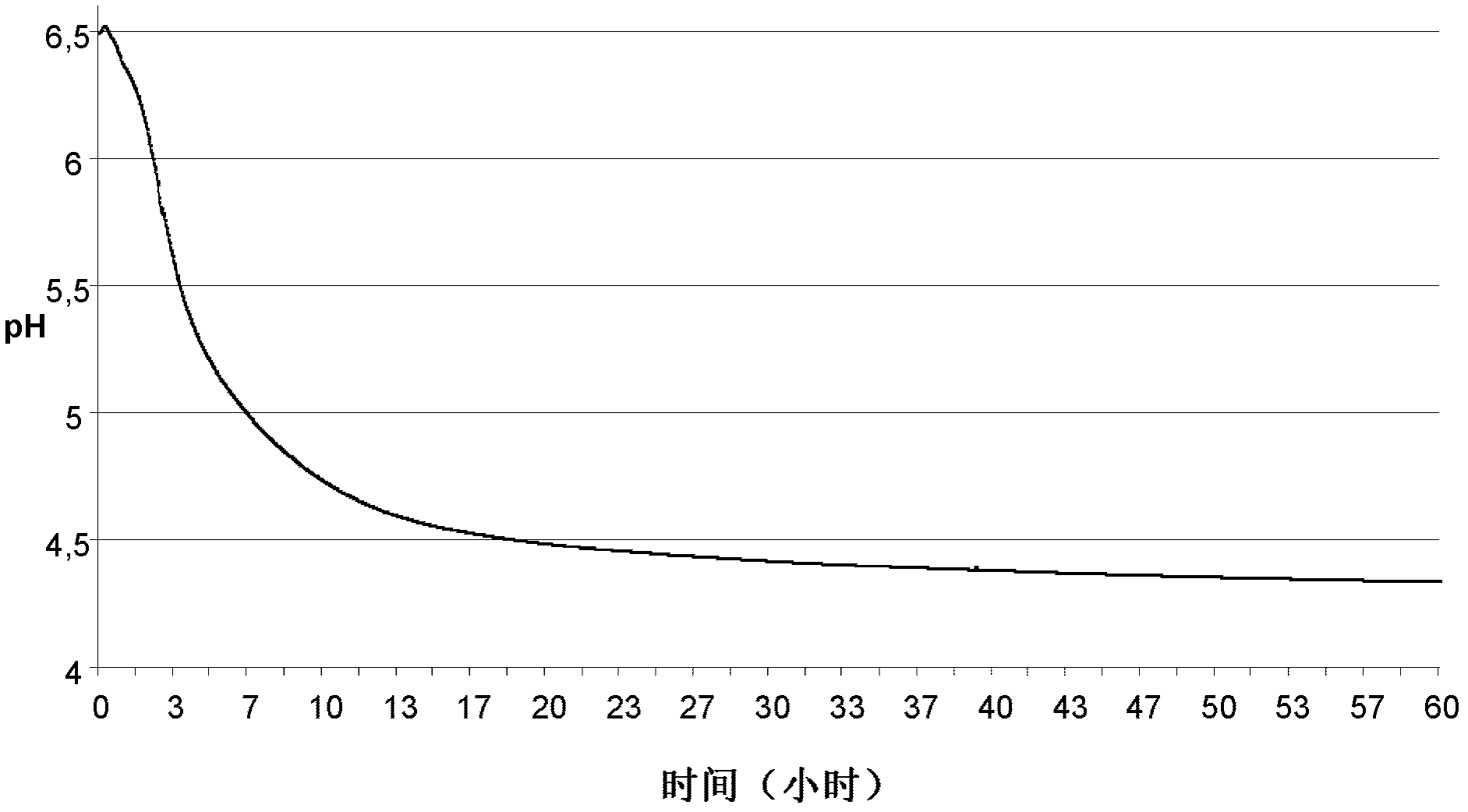

[0071] figure 2 The pH change during fermentation with M1B is shown. At fermentation temperature, the pH initially dropped to 4.45. The fermented milk is then stirred and kept at fermentation temperature for up to 60 hours. In 36 hours, the pH fluctuated by only 0.12 units.

[0072] These results therefore indicate that the method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com