Method for preparing fermented dairy products with unique flavor

A technology of fermented milk products and fermented milk, applied in dairy products, milk preparations, applications, etc., can solve problems such as product quality decline, milk color browning, protein denaturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

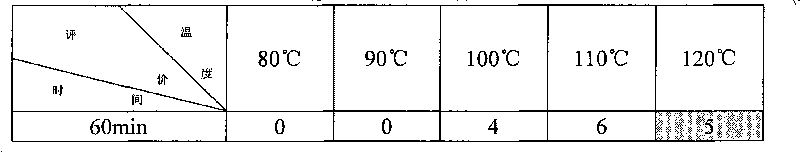

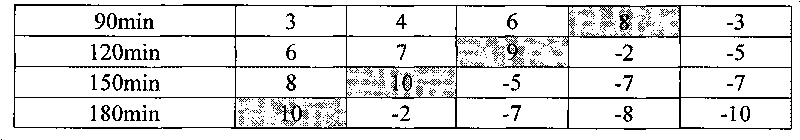

Method used

Image

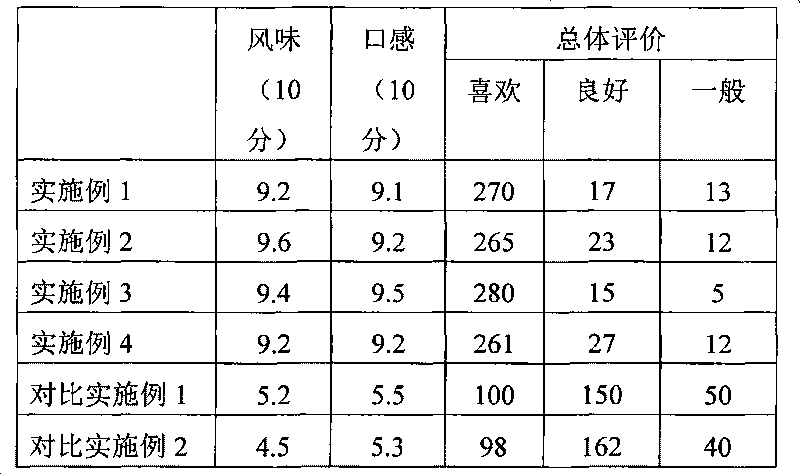

Examples

Embodiment 1

[0031] 40 parts of milk, 10 parts of white sugar, 2 parts of fructose, 0.3 parts of pectin, 0.3 parts of sodium alginate, 0.05 parts of sodium citrate, 0.04 parts of fermented bacteria, 0.02 parts of food flavor, 0.02 parts of citric acid , 47.27 parts of water ingredients.

[0032] Specific steps are as follows:

[0033] (a) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0034] (b) Standardize the raw milk after cleansing, add fructose into the milk, stir evenly, pasteurize at 95°C for 3 hours (Maillard reaction occurs), and then cool the raw milk to 37°C, Fermentation is carried out for 4 hours, and the fermentation liquid is cooled to below 8° C. after the fermentation is completed.

[0035] (c) Prepare stabilizer solution: water and stabilizer are prepared in a weight ratio of 70:1, then white granulated sugar is added and dissolved completely.

[0036] (d) Mix the acidity reg...

Embodiment 2

[0041] 30 parts of milk, 12 parts of white sugar, 3 parts of high fructose syrup, 0.2 parts of sodium carboxymethyl cellulose, 0.05 parts of microcrystalline cellulose, 0.12 parts of fermented bacteria, 0.08 parts of food flavor, citric acid: 0.02 parts, lactic acid: 0.01 parts, 54.52 parts of ingredient water

[0042] Specific steps are as follows:

[0043] (a) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0044] (b) Standardize the raw milk after cleansing, add reducing sugar to the milk, stir evenly, pasteurize at 90°C for 2 hours (Maillard reaction occurs), and then cool the raw milk to 42°C , carry out fermentation, ferment for 7 hours, and cool the fermented liquid to below 8° C. after the fermentation is completed.

[0045] (c) Prepare stabilizer solution: water and stabilizer are prepared in a weight ratio of 100:1, then white granulated sugar is added and dissolved comple...

Embodiment 3

[0051] Milk: 60 parts, white sugar: 8 parts, white sugar (reducing sugar): 5 parts, microcrystalline cellulose: 0.4 parts, pectin: 0.1 parts, fermented bacteria: 0.3 parts, lactic acid: 0.2 parts, food flavor: 0.07 parts, 25.93 parts of ingredients water.

[0052] Specific steps are as follows:

[0053] (a) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0054] (b) Standardize the raw milk after cleansing, add white sugar (reducing sugar) into the milk, stir evenly, pasteurize at 100°C for 60 minutes, then cool the raw milk to 45°C for fermentation , fermented for 10 hours, and cooled the fermented liquid to below 8° C. after the end of the fermentation.

[0055] (c) Preparation of stabilizer solution: water and stabilizer are prepared in a weight ratio of 20:1, then white sugar is added and dissolved completely.

[0056] (d) Mix the acidity regulator and water at a ratio of 1:40 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com