Colored liquid metal and manufacturing method thereof

A technology of liquid metal and production method, applied in the direction of additive processing, etc., can solve the problems of lack of conductivity, achieve good conductivity, improve aesthetics and experience, and improve anti-oxidation and anti-rust properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

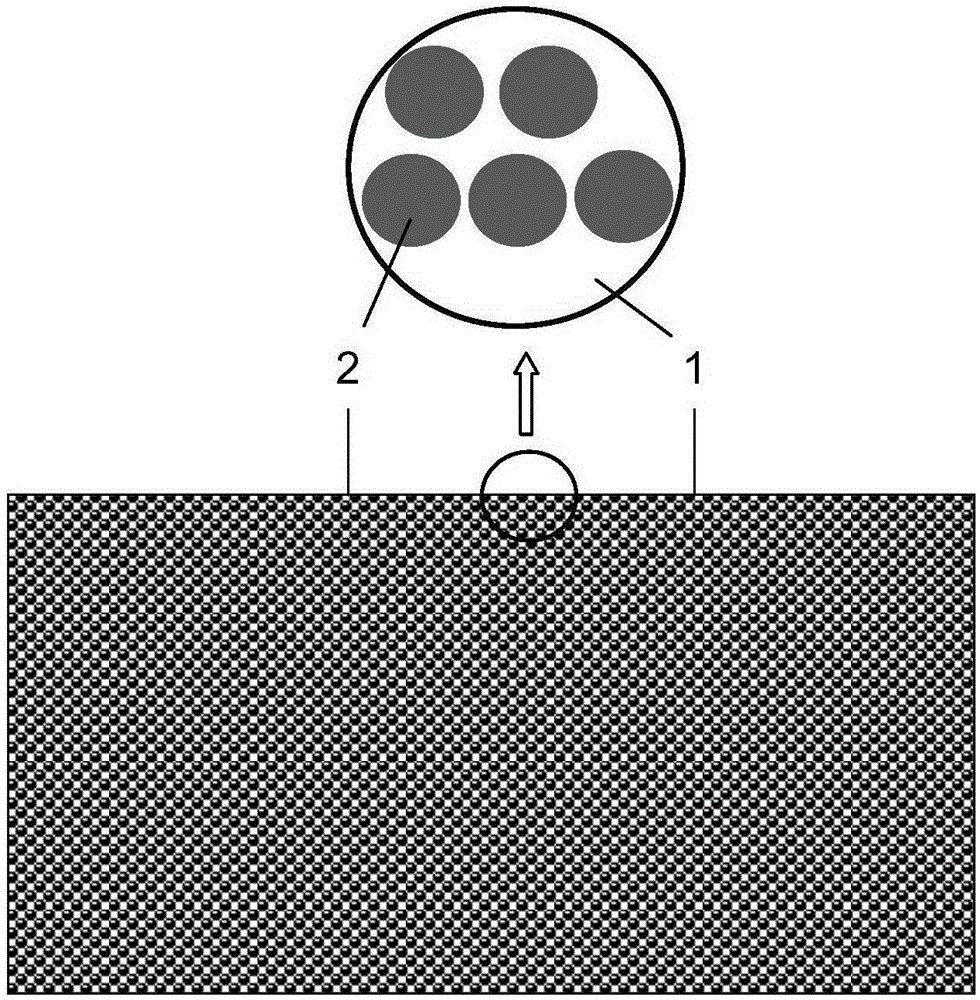

Image

Examples

Embodiment 1

[0059] A kind of colored liquid metal, its raw material comprises liquid metal and pigment; Said liquid metal is gallium indium alloy Ga 24.5 In, the pigment is cinnabar, and the mass ratio of the liquid metal to the pigment is 10:1.

[0060] This embodiment also provides a method for making the colored liquid metal, comprising the following steps:

[0061] S1: Take the liquid metal gallium indium alloy Ga according to the ratio 24.5 In and pigment cinnabar;

[0062] S2: placing the liquid metal in an air environment for constant temperature treatment, the treatment temperature is 50° C., and the treatment time is 1 hour; then, stirring is performed at a stirring rate of 500 rpm, and the stirring time is 5 hours; liquid metal in a liquid state is obtained;

[0063] S3: The pigment cinnabar is made into particles with a diameter of 600 nm, added to the above-mentioned liquid metal, and mechanically stirred for 80 minutes until the mixture is uniform.

[0064] The colored liq...

Embodiment 2-11

[0066] The colored liquid metal, whose raw material includes liquid metal and pigment, differs from embodiment 1 only in that the pigment is different. The preparation method of this colored liquid metal is the same as embodiment 1.

[0067] serial number

Embodiment 12

[0069] A kind of colored liquid metal, its raw material comprises liquid metal, pigment and nano conductive particle; Said liquid metal is gallium indium alloy Ga 24.5 In, the pigment is cinnabar, and the nano-conductive particles are nano-gold with a diameter of 300nm; wherein the mass ratio of the liquid metal, pigment and nano-conductive particles is 40:4:6.

[0070] This embodiment also provides a method for making the colored liquid metal, comprising the following steps:

[0071] S1: Take the liquid metal gallium indium alloy Ga according to the ratio 24.5 In, pigment cinnabar and nano-conductive particles (nano-gold with a diameter of 300nm);

[0072] S2: placing the liquid metal in an air environment for constant temperature treatment, the treatment temperature is 50° C., and the treatment time is 1 hour; then, stirring is performed at a stirring rate of 500 rpm, and the stirring time is 5 hours; liquid metal in a liquid state is obtained;

[0073] S3: The pigment cin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com