Self-changing gearbox flywheel bracket tray deep-drawing hammer down forming process and mould

A technology of automatic transmission and forming die, applied in the direction of manufacturing tools, forging presses, forging presses, etc., can solve the problems of low forming strength and non-forming strength, and achieve the effects of good forging quality, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

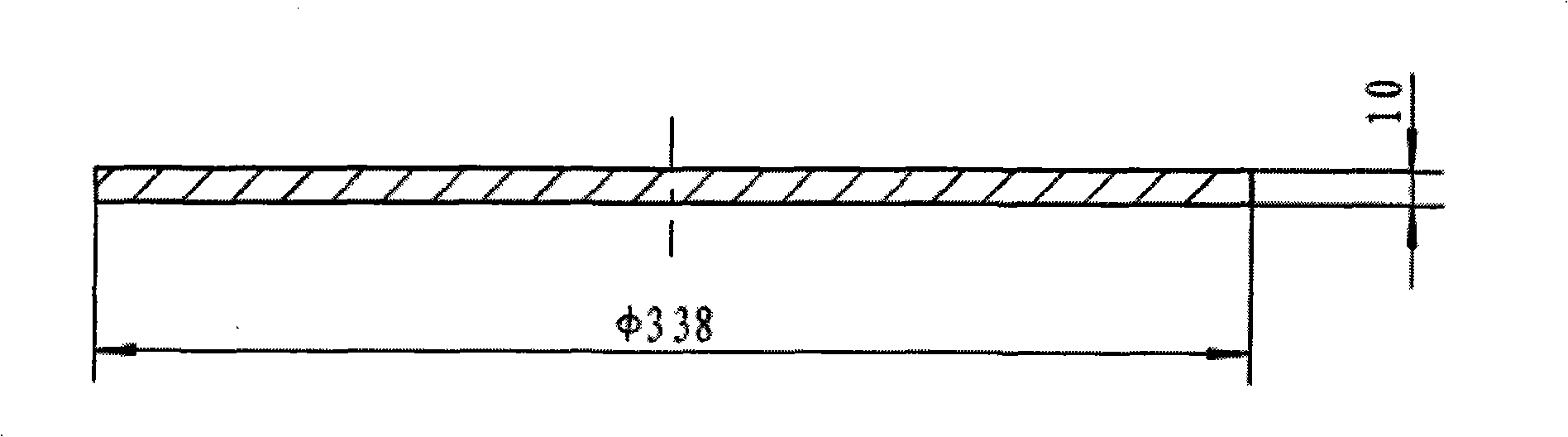

[0023] figure 1 This is an example of a flywheel pallet blank to be processed, with a thickness of 10mm and a diameter of 338mm.

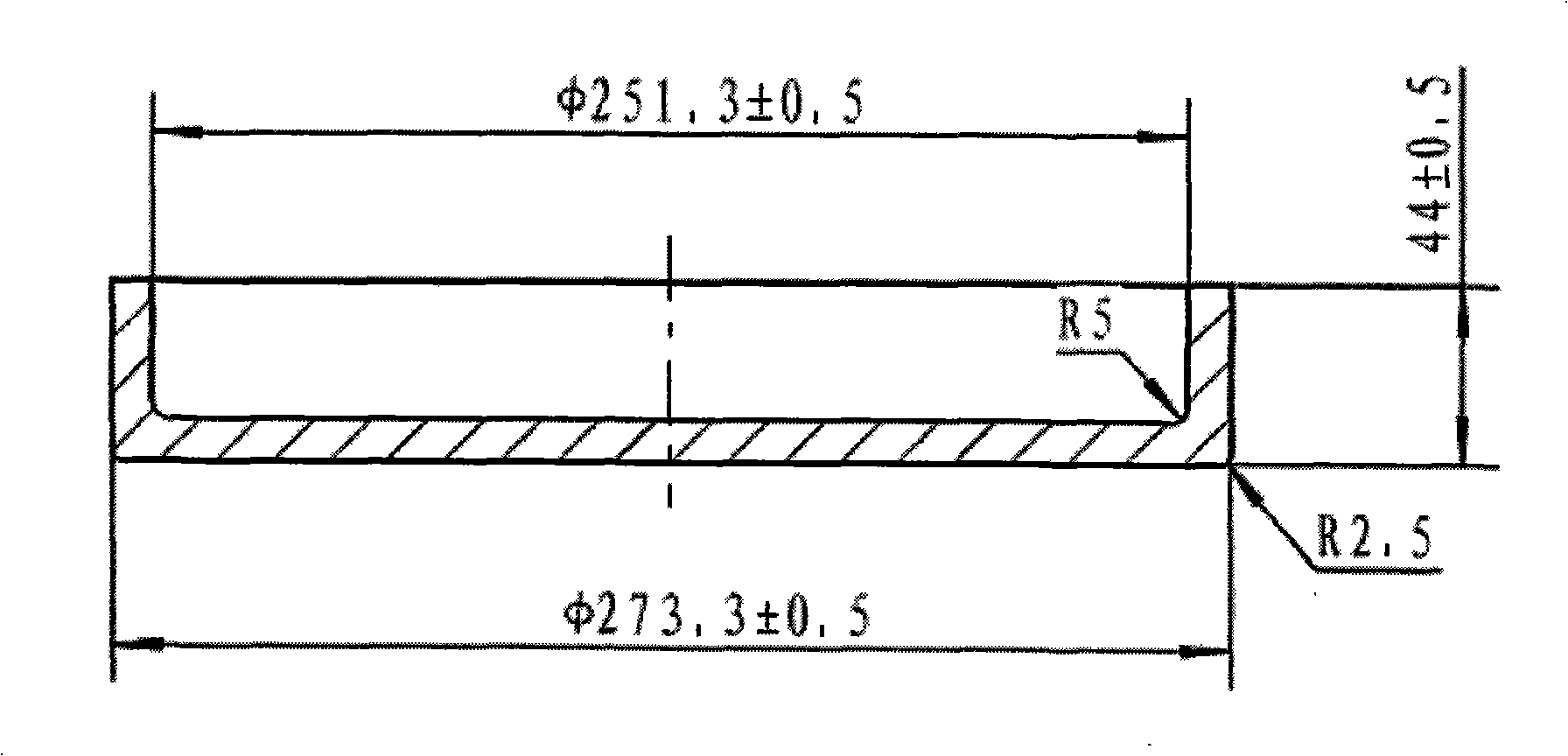

[0024] figure 2 It is an example of a flywheel pallet forging processed by the present invention, with an inner diameter of 251.3±0.5mm, an outer diameter of 273.3±0.5mm, a height of 44±0.5mm, an inner fillet radius of R5, and an outer fillet radius of R2.5.

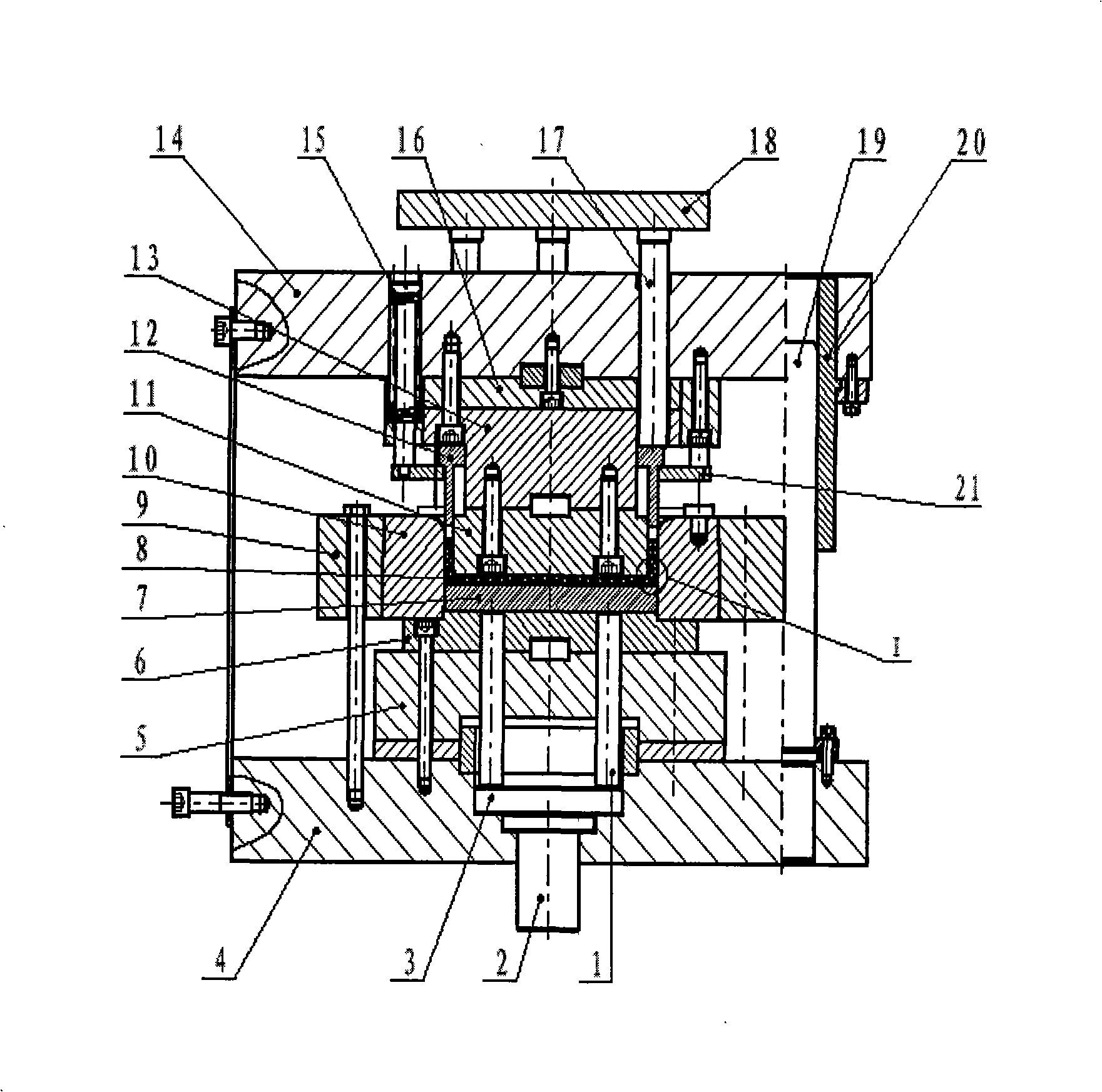

[0025] Such as image 3 As shown, the mold of the present invention includes a deep drawing die, an ejector, a deep drawing upset punch and a guide:

[0026] The drawing die is composed of a lower template 4, a lower backing plate 5, a bottom plate 6, a top plate 7 and a die 10 stacked in sequence; the die 10 is cylindrical, placed on the bottom plate 6 and set outside the top plate 7, The mold 10 is overcoated with a prestressed outer ring 9;

[0027] The ejector device is composed of ejector rod 2, supporting plate 3 and force transmission column 1; , the force transmission column 1 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com