Non-bittern expanding flame-proof material and method for making same

An intumescent flame retardant and flame retardant material technology, applied in the field of flame retardant materials, can solve environmental pollution, damage and other problems, achieve good mechanical properties, small amount of flame retardant addition, and reduce the effect of heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First add 100gPP to the double-roller heating machine with a roll temperature of 160-170°C. After melting the rolls, add 20gAPP, 10gPER and 10gMEL, and mix for 8 minutes to fully disperse the flame retardant in PP. Vulcanize on a 15MPa180°C plate Machine hot pressing for 3 minutes, and then cooling and shaping in a 15MPa cold plate vulcanizing machine for 5 minutes. The oxygen index of the halogen-free intumescent flame-retardant polypropylene prepared in this example is 33, and the tensile strength, flexural strength, and impact strength are 20.87MPa, 50.64MPa, and 4.42KJ / m respectively. 2 .

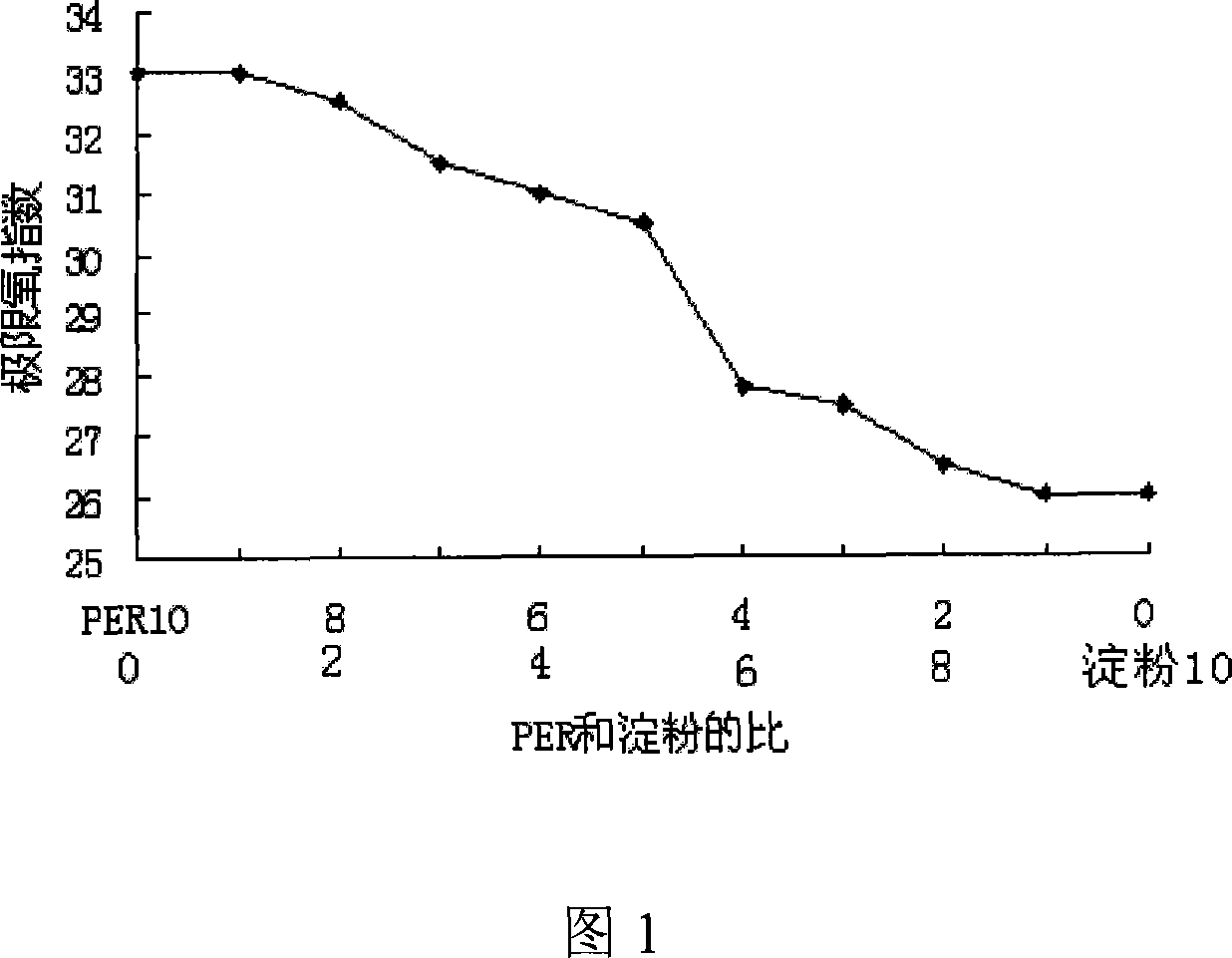

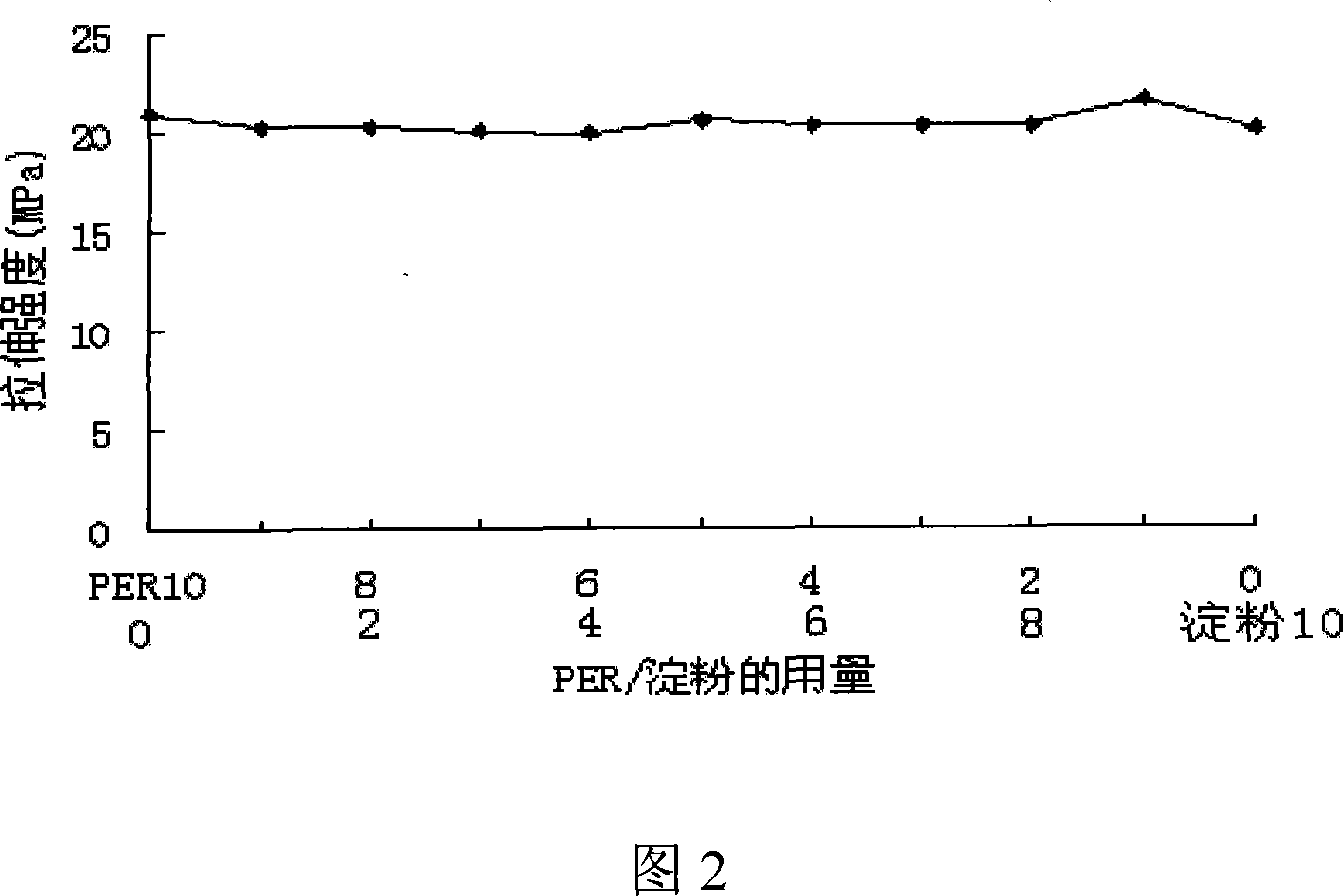

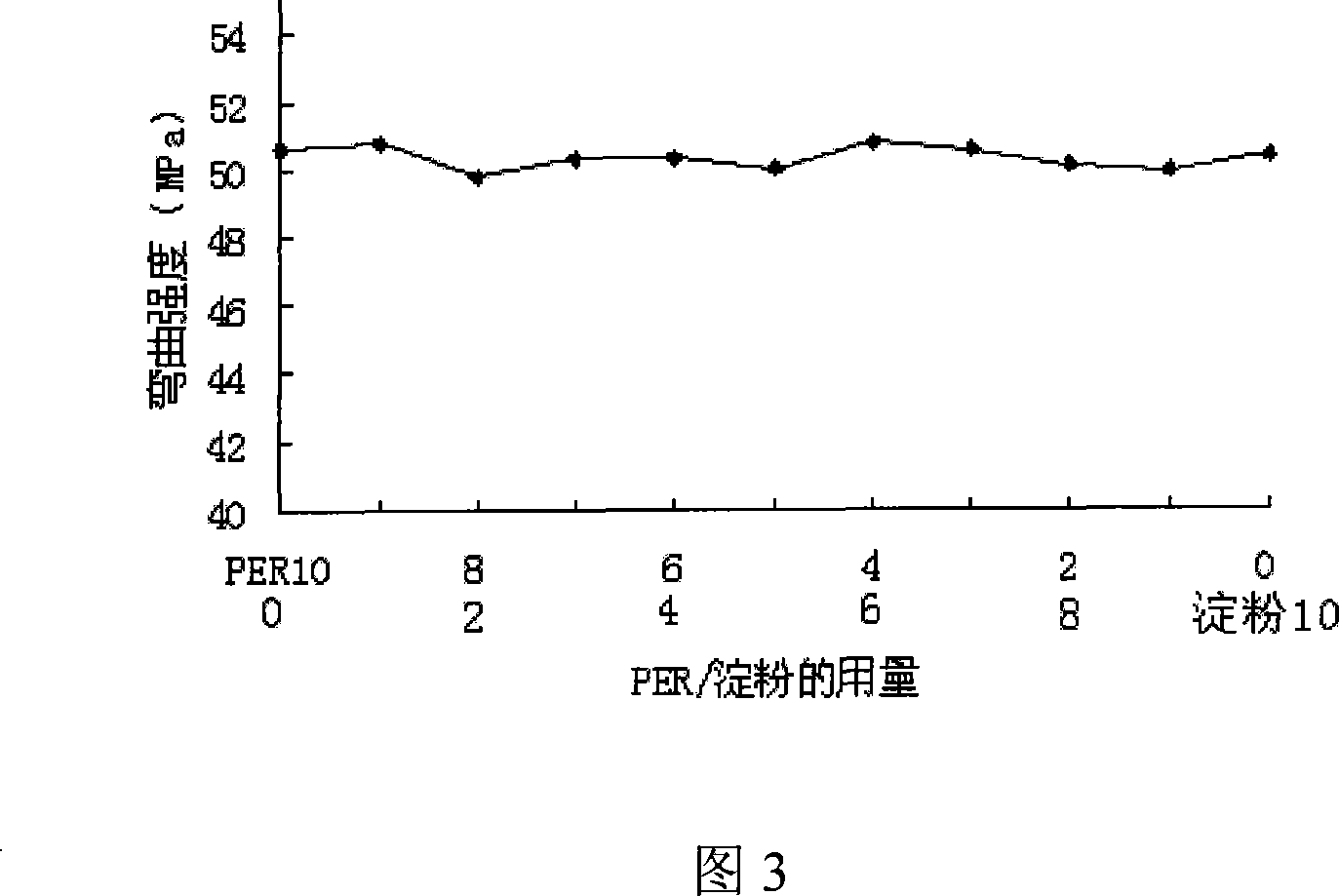

Embodiment 2~9

[0026] Each raw material and proportioning are shown in Table 1, the mixing time from embodiment 2 to 9 is respectively 8, 10, 9, 9, 15, 11, 13, 9min, and hot pressing time is respectively 2, 3, 3, 3, 5, 4, 3, 5 min, other steps and conditions are the same as in Example 1.

[0027] Table 1 Examples 2-9

[0028]

[0029] The flame retardancy and mechanical properties of the halogen-free intumescent flame retardant materials prepared in Examples 2 to 9 are as follows

[0030] Table 2:

[0031] Table 2 The flame retardancy and mechanical properties of the materials of Examples 2 to 9

[0032]

Embodiment 10

[0034] First add 100gPP to a double-roller heat-refining machine with a roll temperature of 160-170°C. After melting the rolls, add 20gAPP, 9gPER, 1g starch and 10gMEL, and knead for 9 minutes to fully disperse the flame retardant in PP. Hot press at 180°C for 3 minutes in a flat vulcanizing machine, then cool and set in a cold flat vulcanizing machine at 15MPa for 5 minutes. The oxygen index of the halogen-free intumescent flame-retardant polypropylene prepared in this example is 33, and its tensile strength, bending strength and impact strength are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com