Halogen-free flame-retardant polypropylene compound and preparation method thereof

A technology of polypropylene and composites, applied in the field of flame retardant materials, can solve problems such as high cost and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 200g PP to the double-roller heating machine with a roll temperature of 175°C to 180°C. After melting the rolls, add 44g APP and 30gZnO, and mix for 8 minutes to fully disperse the flame retardant and additives in PP. Press hot on a flat vulcanizing machine for 3 minutes, then cool and shape in a 15MPa cold flat vulcanizing machine for 5 minutes. The oxygen index of the thermoplastic produced in this example is 34, and the tensile strength, flexural strength and impact strength are respectively 21.27MPa, 52.25MPa, and 4.83KJ / m 2 .

Embodiment 2

[0017] First add 100g PP to the double-roller heating machine with a roll temperature of 175°C to 180°C. After melting the rolls, add 20g APP, 2gPER, 10g starch and 2gMEL, and knead for 9 minutes to fully disperse the flame retardant and additives in PP. , hot-pressed in a 15MPa 180°C flat vulcanizer for 3min, and then cooled and shaped in a 15MPa cold flat vulcanizer for 5min. The oxygen index of the thermoplastic produced in this example is 33.4, and the tensile strength, flexural strength and impact strength are respectively 21.56MPa, 52.87MPa, and 4.99KJ / m 2 .

Embodiment 3~10

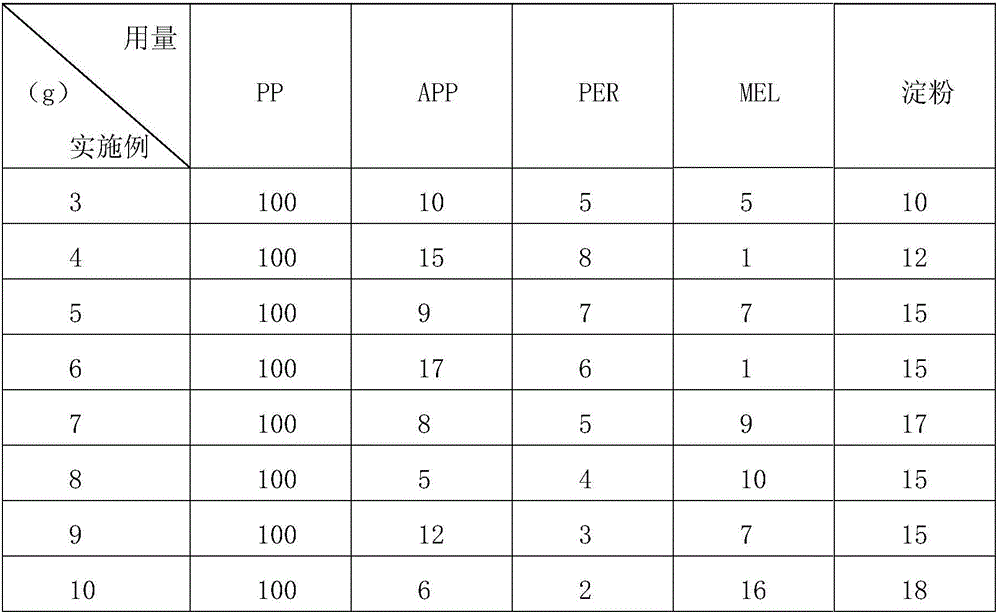

[0019] Each raw material and proportioning are shown in Table 1, the mixing time from embodiment 3 to 10 is respectively 8,10,9,9,15,11,13,9min, and hot pressing time is respectively 2,3,3,3, 5, 4, 3, 5 min, other steps and conditions are the same as in Example 2.

[0020] Table 1 Embodiment 3~10

[0021]

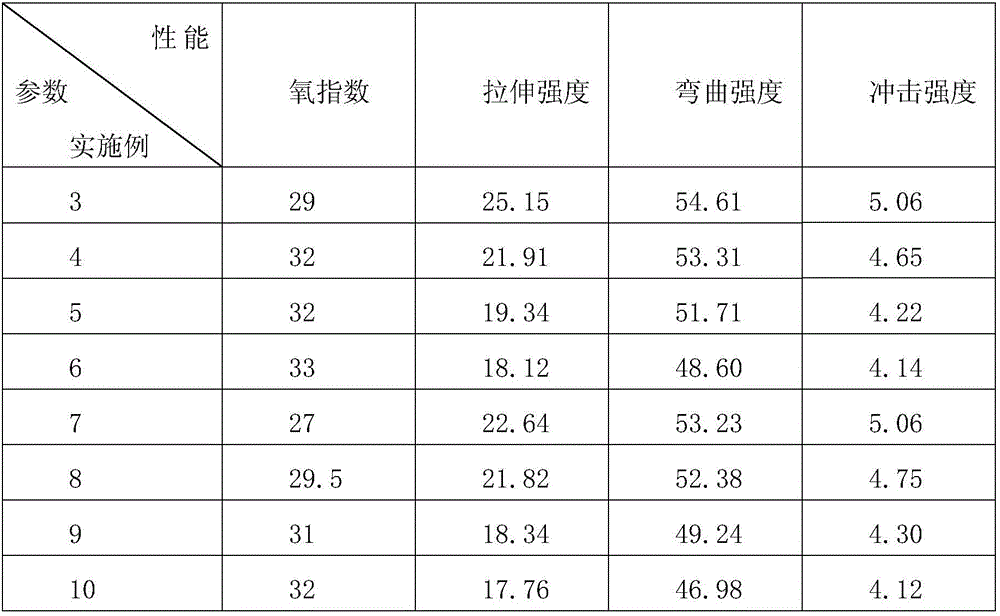

[0022] Table 2 The flame retardancy and mechanical properties of the materials of Examples 3 to 10

[0023]

[0024] It can be seen from the above table that the polypropylene composite material obtained in the present invention has good flame retardancy and mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com