Method for preparing black phosphorus nanosheets

A technology for nanosheets and black phosphorus, applied in the field of preparing black phosphorus nanosheets, can solve the problems of difficulty in controlling thickness and size, uneven size and size of phosphorene, affecting the purity of black phosphorus sheets, etc. Efficiency, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing black phosphorus nanosheets, comprising the steps of:

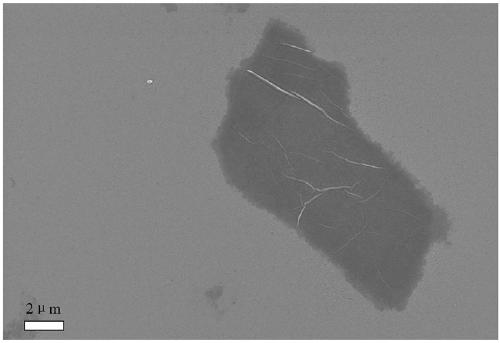

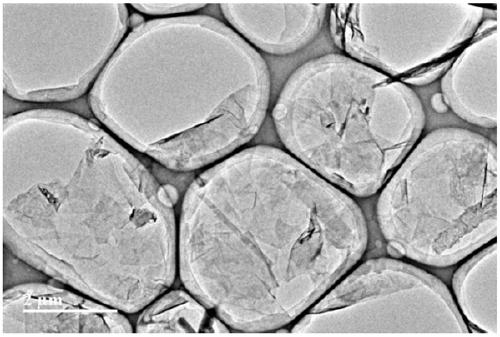

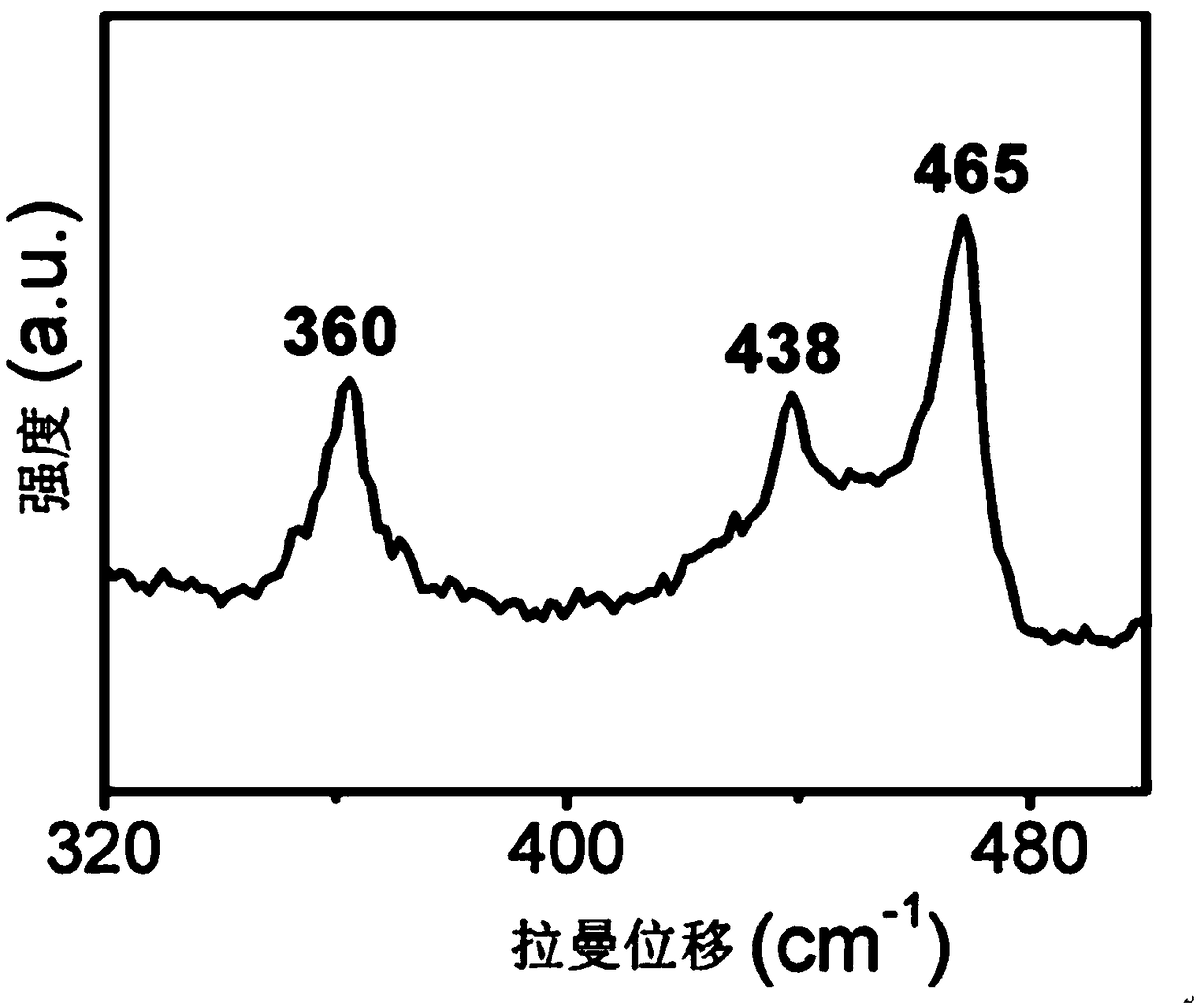

[0047] (1) Take the two electrode holders and wrap them with an electrical insulating film, respectively clamp 0.01g of black phosphorus crystals as the cathode and anode, and use N,N-dimethylformamide dissolved in tetrabutylammonium bromide as the electrolytic solution, the concentration of which is 0.5M, and assembled into an H-type electrolytic cell; using chronopotentiometry, the black phosphorus crystals are intercalated for 30 minutes under the condition of a current of 1mA; after the intercalation is completed, continue to use Current-time curve, under the condition of voltage 10V, the black phosphorus after intercalation is expanded for 10 minutes, and after the expansion is completed, black phosphorus with rough surface and doubled volume is obtained;

[0048] (2) Adopt 400 mesh filter screens to filter the expanded black phosphorus, then use N-methylpyrrolidone to wash the expanded ...

Embodiment 2

[0066] A method for preparing black phosphorus nanosheets, comprising the steps of:

[0067] (1) After taking two electrode holders and wrapping them with an electrical insulating film, respectively clamp 0.01g of black phosphorus crystals as cathode and anode, and use N,N-dimethylformamide dissolved with tetra-n-octyl ammonium bromide as Electrolyte solution with a concentration of 1.0M was assembled into an H-type electrolytic cell; cyclic voltammetry was used to cycle 10 times in the potential range of 0-3V at a scan rate of 5mV / s, and the black phosphorus crystal was intercalated for 60min ; After the intercalation is completed, continue to expand the intercalated black phosphorus for 34 minutes in the electrolyte by using linear sweep voltammetry, with a scanning potential range of -5 to 15V and a scanning speed of 5mV / s;

[0068] (2) Use a 400-mesh filter screen to filter the expanded black phosphorus, then wash the expanded black phosphorus with ethanol for 3 times, and...

Embodiment 3

[0085] A method for preparing black phosphorus nanosheets, comprising the steps of:

[0086] (1) Take two electrode clips and wrap them with an electrical insulating film, respectively clamp 0.01g of black phosphorus crystals as the working electrode and auxiliary electrode, and use the Ag / AgCl electrode as the reference electrode to dissolve tetrabutylamine hexafluorophosphate N,N-dimethylformamide was used as the electrolyte with a concentration of 0.5M, and an H-type electrolytic cell was assembled; using the current-time curve, the black phosphorus crystal was intercalated at a potential of -3V for 1h; the intercalation After completion, continue to use the same method in the electrolyte, and carry out expansion treatment on the black phosphorus after intercalation at a potential of -10V for 20 minutes;

[0087] (2) Use a 400-mesh filter to filter the expanded black phosphorus. After filtering, wash the expanded black phosphorus with tetrahydrofuran for 3 times. After wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com