Loading device and loading method for expansion loop

A loading device and expansion ring technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of uncontrollable loading process, poor loading reliability, high sample temperature, etc., to achieve simple and practical loading device, stable loading process, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings.

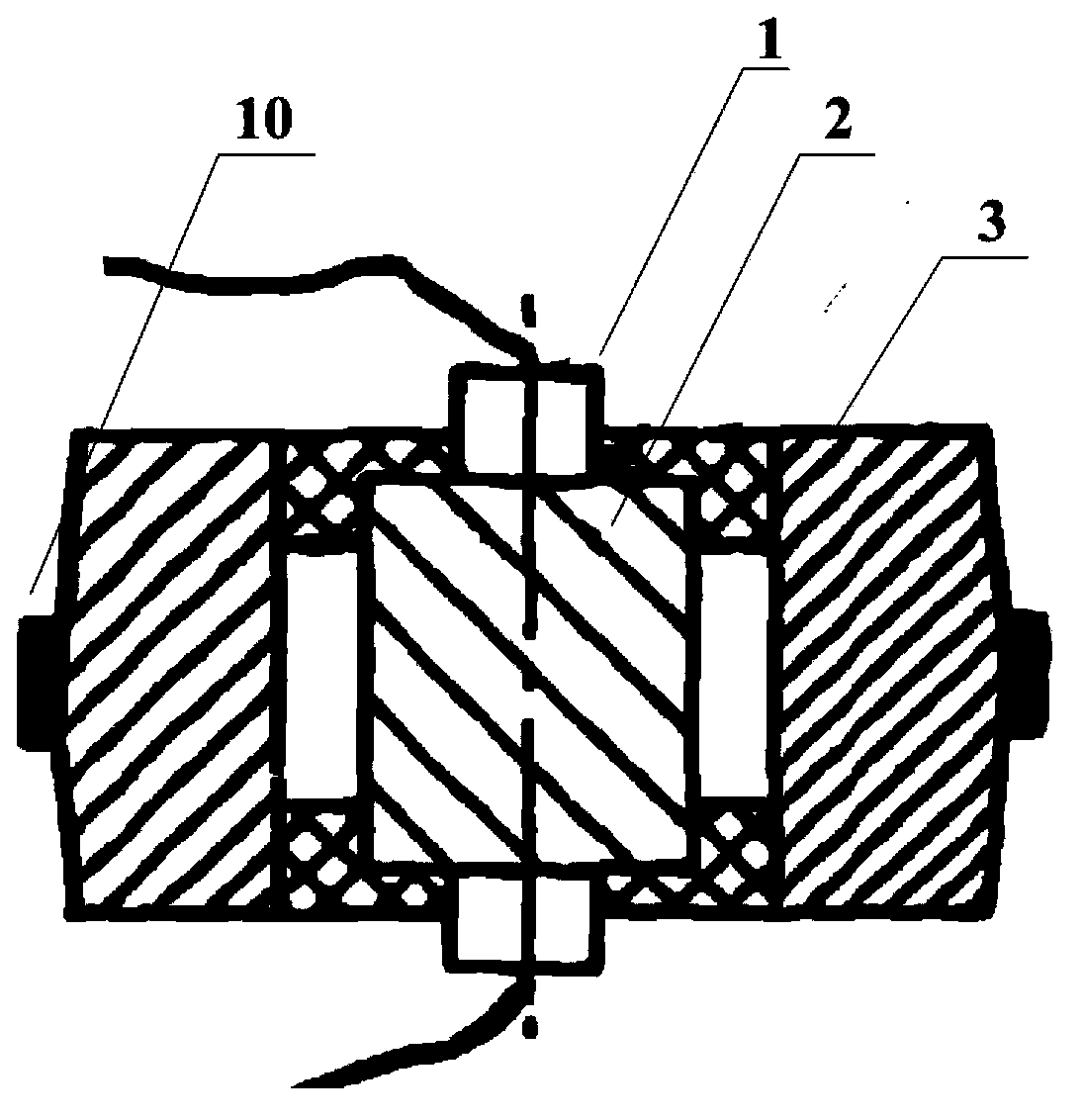

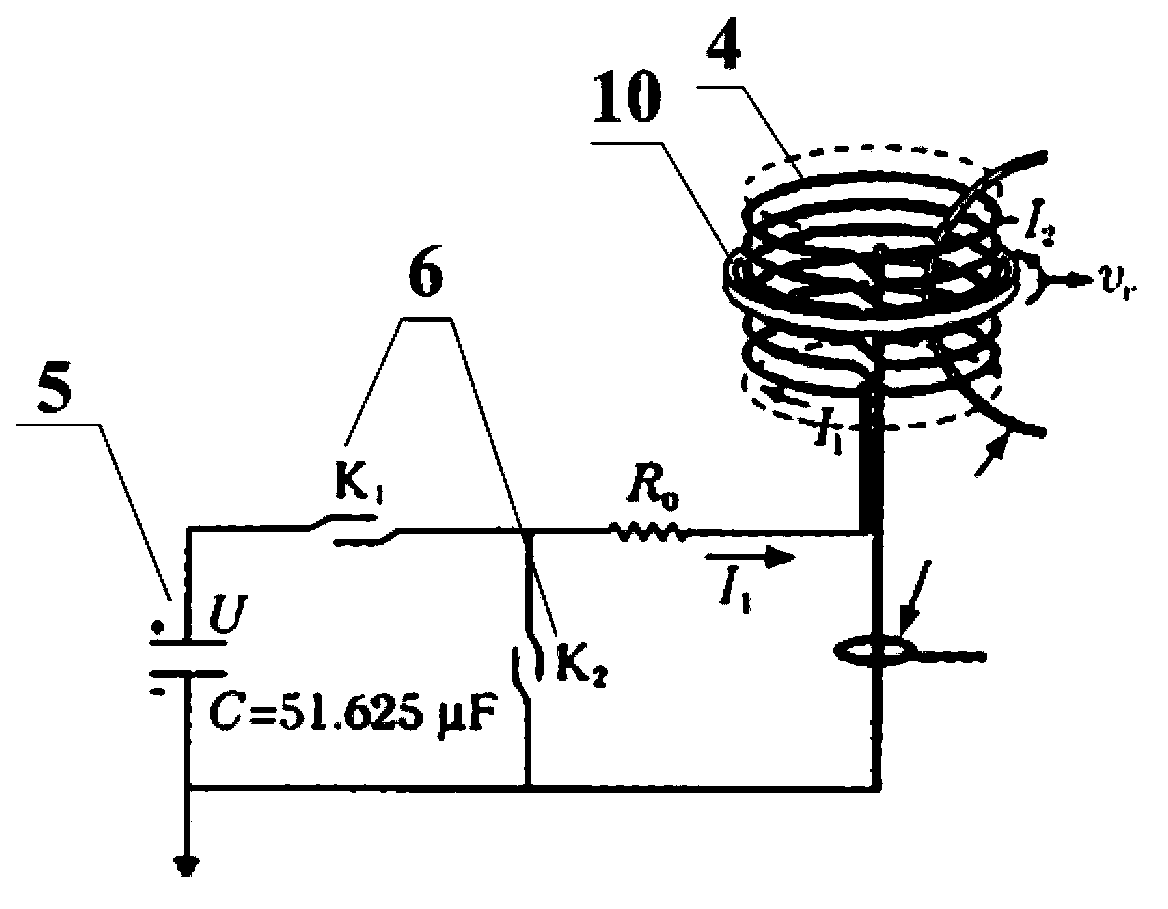

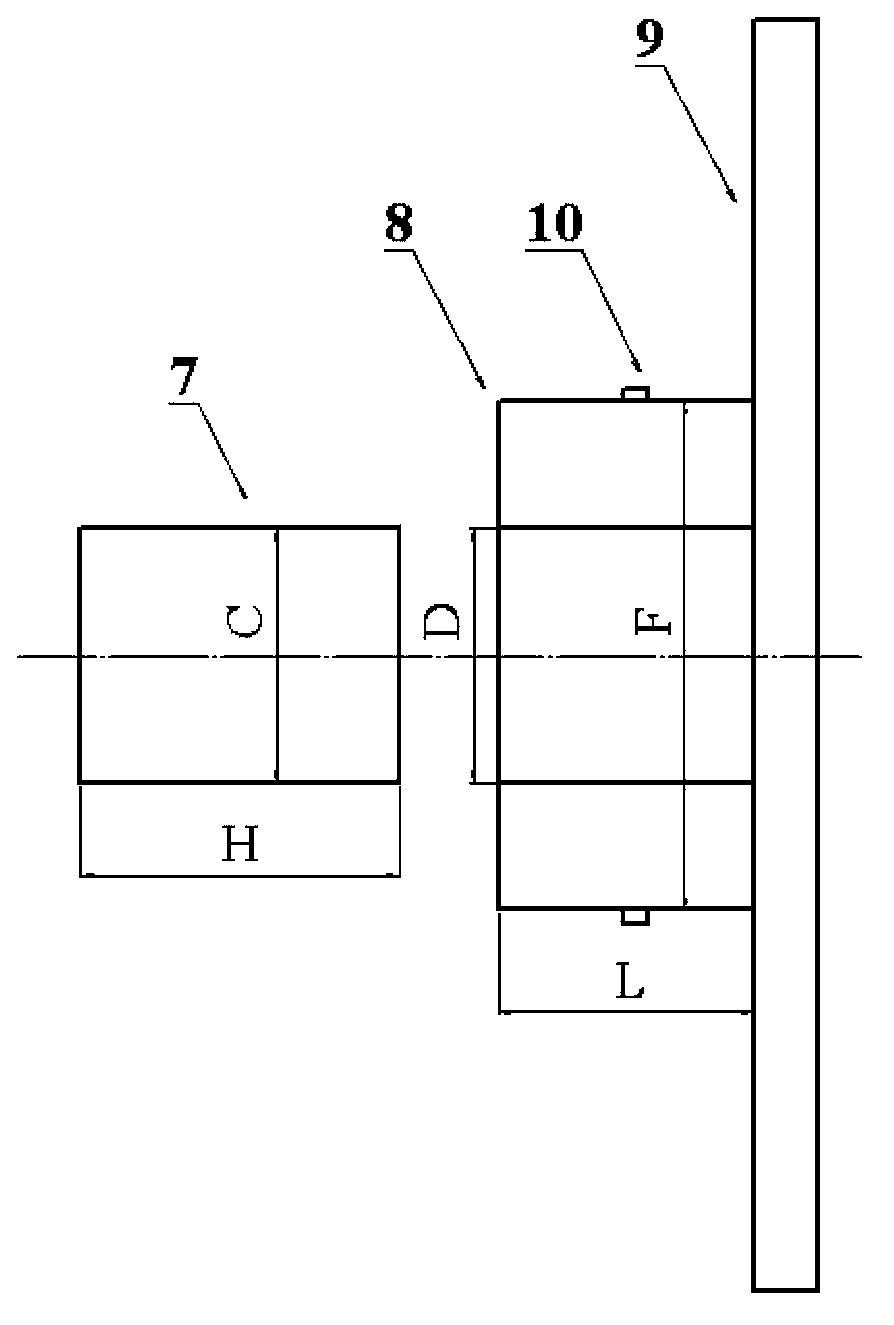

[0030] image 3 Is the main view of the loading device of the present invention; image 3 As shown, the loading device is composed of a projectile 7, a driver 8 and a target board 9.

[0031] Projectile 7 selects density ρ 3 The yield strength is within the range of 20MPa-50MPa, and it is easy to deform under impact, and the compression rate is less than 5%. The projectile 7 is cylindrical, with a diameter of C and a length of H. The velocity V of the projectile 7 before colliding with the target 9 1 Between 100 and 1000 m / s, the projectile 7 needs to be accelerated to this speed range by the acceleration device 11, and the acceleration device 11 generally uses a light gas gun. The diameter C of the projectile 7 is determined by the inner diameter φ of the acceleration device 11, and the value of C / φ is between 0.5 and 0.95. The value of H / C is between 0.6 and 3.

[0032] The driver 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com