Production method of feed-grade granular calcium hydrogen phosphate III-type product

A technology of calcium hydrogen phosphate and production methods, applied in animal feed, animal feed, chemical instruments and methods, etc., can solve the problems of long aging cycle of semi-finished products, irregular finished product particles, high maintenance cost of phosphoric acid defluorination equipment, etc. and product quality advanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

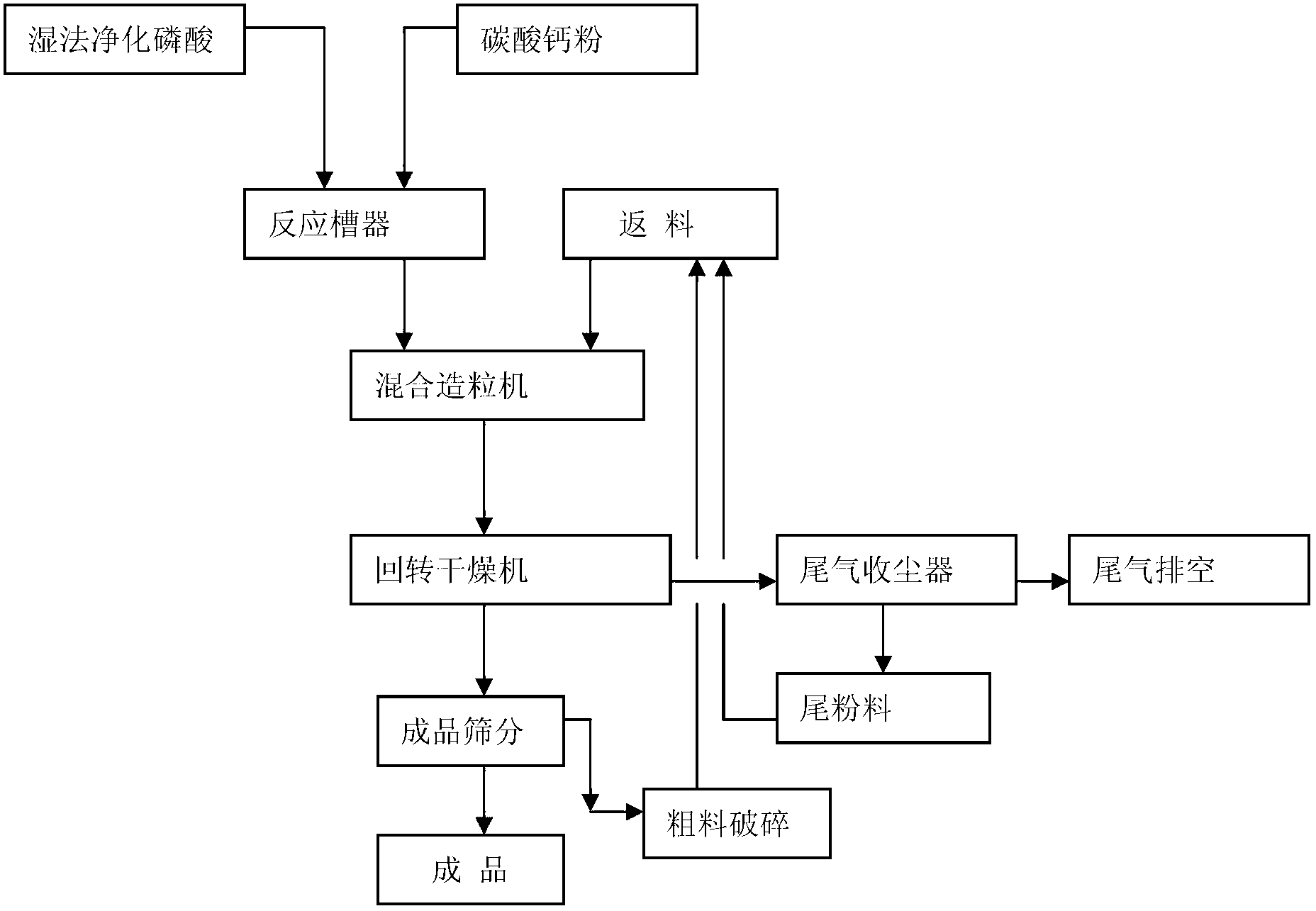

[0020] Attached below figure 1 Further describe the process route of the production feed grade granular calcium hydrogen phosphate type III product of the present invention. The method of the present invention is not limited to the description of the following examples.

[0021] Phosphate rock or apatite with a grade above 25wt% is crushed and ground into a slurry by adding water, and 98wt% industrial sulfuric acid is added to the extraction reaction tank, and the wet-process dilute phosphoric acid is extracted by the half-water method or the dihydrate-semi-water method, and the reaction The temperature is 75-85°C. The dilute phosphoric acid is extracted by filtration, and the phosphogypsum slag is sent to the slag yard for stacking. 2 o 5 Concentration 36–45wt%, concentrated phosphoric acid is purified and removed to obtain acid for the production of feed grade calcium hydrogen phosphate type III, and the acid residue is returned to the extraction tank to recover P 2 o 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com