Method for reducing preparation cost of sulphoaluminate cement

A technology of sulphoaluminate cement and low cost, which is applied in the field of preparation of new building materials, can solve the problems of increased production cost of sulphoaluminate cement, decline of sulphoaluminate cement body performance, and difficulty in grasping the composition range of admixtures, etc. To achieve the effect of avoiding the decline of strength performance, reducing energy consumption and lowering the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for reducing the preparation cost of sulphoaluminate cement, wherein the fly ash is modified to obtain the modified fly ash as a bauxite substitute material for the preparation of sulphoaluminate cement clinker;

[0019] The fly ash modification method is as follows: grind 1.2 kg of fly ash through a 50-mesh sieve, place it in a reaction kettle, add 1.8 times the volume of water and 25 grams of modifier, heat up to 66 ° C, and use multi-functional stirring Stir with a mixer, keep stirring until the water content is between 11-14%, press it into a cake shape with a thickness of 2 cm, then place it in an oven at 290 ° C for 2 hours, and obtain modified fly ash after cooling. The described fly ash is Class II fly ash.

[0020] The preparation method of the modifying agent is as follows: take 30 grams of rare earth sol, 7.2 grams of polyacrylamide, and 0.32 grams of sodium hexametaphosphate, add 115 milliliters of polyethylene glycol aqueous solution with a molar c...

Embodiment 2

[0026] A method for reducing the preparation cost of sulphoaluminate cement, wherein the fly ash is modified to obtain the modified fly ash as a bauxite substitute material for the preparation of sulphoaluminate cement clinker;

[0027] The fly ash modification method is: grind 1.3 kg of fly ash through a 55-mesh sieve, place it in a reaction kettle, add 1.9 times the volume of water and 28 grams of modifier, heat up to 68 ° C, and use multi-functional stirring Stir with a mixer, keep stirring until the water content is between 11-14%, press it into a cake shape with a thickness of 2.5 cm, and then place it in an oven at 295 ° C for 2.5 hours, and obtain modified fly ash after cooling. The described fly ash is Class II fly ash.

[0028] The preparation method of the modifying agent is as follows: take 33 grams of rare earth sol, 7.3 grams of polyacrylamide, and 0.33 grams of sodium hexametaphosphate, add 118 milliliters of polyethylene glycol aqueous solution with a molar conc...

Embodiment 3

[0034] A method for reducing the preparation cost of sulphoaluminate cement, wherein the fly ash is modified to obtain the modified fly ash as a bauxite substitute material for the preparation of sulphoaluminate cement clinker;

[0035] The fly ash modification method is as follows: 1.4 kg of fly ash is ground through a 60-mesh sieve, placed in a reaction kettle, 2.0 times the volume of water and 30 grams of modifier are added, the temperature is raised to 70 ° C, and the mixture is stirred by multi-function Stir with a mixer, keep stirring until the water content is between 11-14%, press it into a cake shape with a thickness of 3 cm, then place it in an oven at 300°C for 3 hours, and obtain modified fly ash after cooling. The described fly ash is Class II fly ash.

[0036] The preparation method of the modifying agent is as follows: take 35 grams of rare earth sol, 7.4 grams of polyacrylamide, and 0.35 grams of sodium hexametaphosphate, add 120 milliliters of polyethylene gly...

PUM

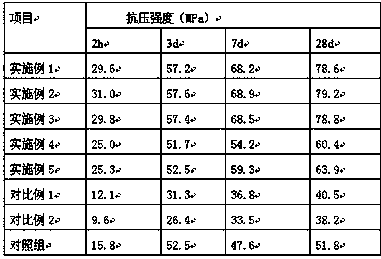

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com