Method for preparing manganese sulfate solution by using sulphur dioxide gas leach manganese dioxide ore

A manganese sulfate solution and sulfur dioxide technology, applied in the direction of manganese sulfate, etc., can solve the problems of affecting the absorption rate of sulfur dioxide, large volume flow, waste of sulfur resources, etc., and achieve continuous, stable, high-efficiency production, low grade requirements, and high utilization rate. Effect

Active Publication Date: 2010-12-01

成都合众新能源科技有限公司

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(1) Although the process can realize the continuity of production, it needs to switch between the main and secondary reaction pools instead of series reactors in terms of its operation steps. Therefore, it is still a batch reaction operation in essence, and the management is complicated;

(2) Aeration type mixers or pumps equipped with suction pipes are generally used for oxygenation and aeration in the field of sewage biochemical treatment. The basic principle of gas dispersion is to disperse the gas into the liquid by the shear impact of the liquid, so The operation of this type of equipment generally requires the gas-water volume ratio to reach 5-10 (L / L). If the gas-water ratio is too high, the sulfur dioxide gas will not be able to disperse, which will affect the absorption rate of sulfur dioxide;

(3) The volume flow rate per unit time of sulfur dioxide gas that needs to be pumped in industrial production is very large, often as high as thousands to tens of thousands of m3 / h, while aeration mixers or pumps equipped with suction pipes are mainly used for volume flow rate per unit time Fewer industrial occasions, generally hundreds of m3 / h, so it is difficult to apply to large-scale industrial production of sulfur dioxide leaching pyrolusite, which limits the actual industrial application of this method

The reason is mainly due to the following two key common problems in the leaching process that have not been resolved: (1) The equipment used cannot realize continuous reaction operation. Under the condition of intermittent reaction, the pulp is added at one time. Metering ratio, the absorption and utilization rate of sulfur dioxide gas is inversely proportional to the leaching rate of manganese. As the reaction progresses, the leaching rate of manganese is getting higher and higher, while the absorption and utilization rate of sulfur dioxide gas is getting lower and lower, which leads to the discharged Sulfur dioxide gas is seriously discharged beyond the standard, which not only wastes sulfur resources, but also causes serious environmental pollution problems; (2) The essence of the flue gas desulfurization process of leaching pyrolusite and pyrolusite pulp with SO2 solution is the complex relationship between SO2 and MnO2 Reaction, MnS2O6 is often accompanied by MnSO4 at the same time. If the solution is directly used to produce manganese sulfate, most of the MnS2O6 will be decomposed into MnSO4 and SO2 during the heating, evaporation and crystallization process. If the MnS2O6 content is too high, it will still affect MnSO4. H2O quality, measures need to be taken to suppress the formation of MnS2O6

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

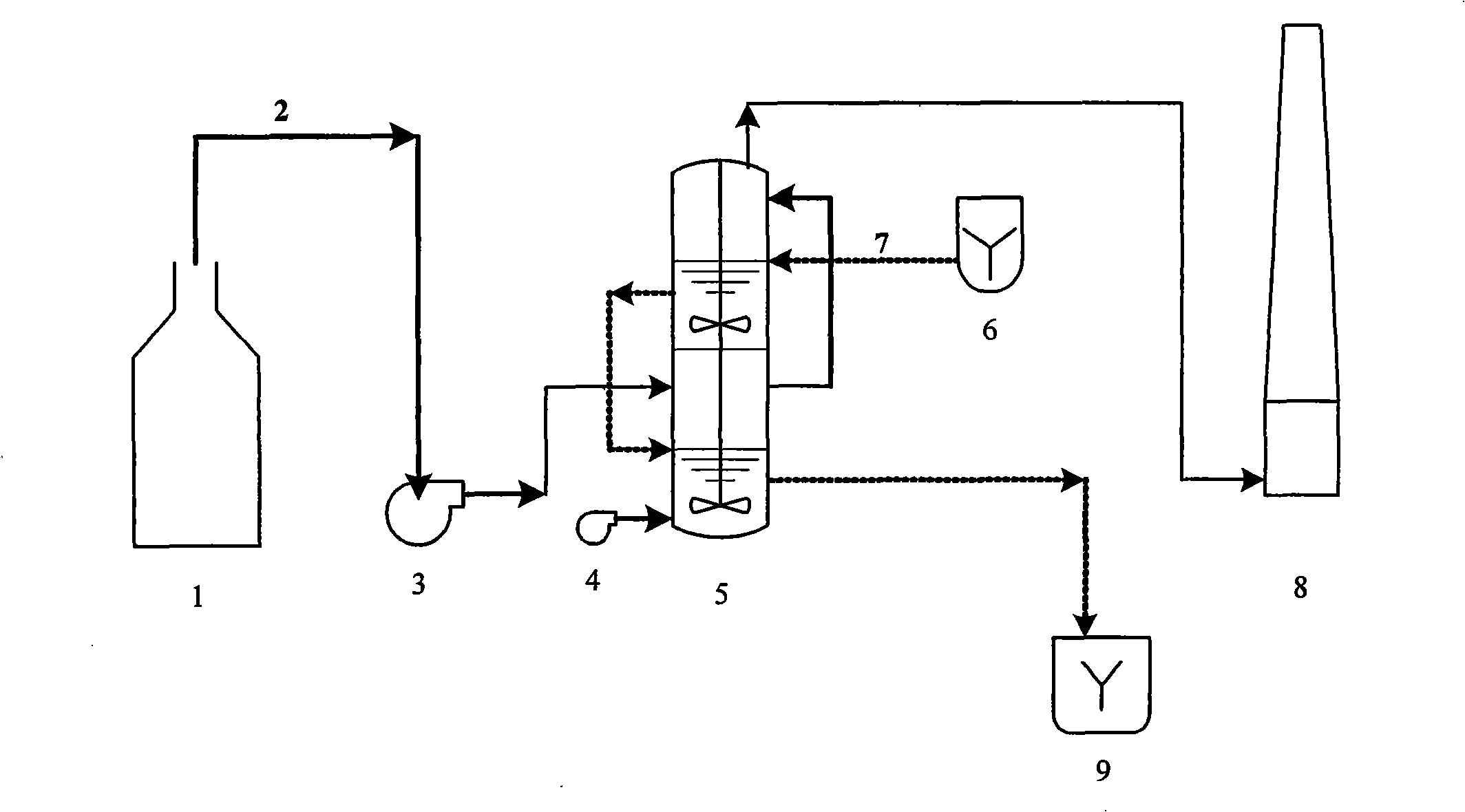

The invention discloses a method for preparing a manganese sulphate solution by leaching pyrolusite with sulfur dioxide gas. The method mainly comprises: pyrolusite and water are prepared into pyrolusite slurry with a liquid to solid ratio of between 5:1 and 1:1; the slurry, the sulfur dioxide gas and oxygen are continuously passed into a reactor provided with two stages of absorbing and leachingreaction chambers which are arranged and connected serially up and down; and absorbing and leaching reactions are carried out in the two absorbing and leaching reaction chambers sequentially at normal temperature, wherein each stage of absorbing and leaching reaction chamber is provided with a stirrer of no less than 5 kW for each cubic meter, the mass flow of the slurry is determined by the stoichiometric ratio of manganese dioxide required by the mass flow of the sulfur dioxide, and the amount of the added oxygen is determined by the pH values of reaction systems in the absorbing and leaching reaction chambers. Another invention applied by the applicant of the invention discloses a reactor for use in pyrolusite leaching. The reactor realizes stable and continuous production, achieves high sulfur and manganese resources recovery rate, meets tail gas exhaust standards and can effectively suppress the generation of MnS2O6 at the same time.

Description

Method for preparing manganese sulfate solution by leaching pyrolusite with sulfur dioxide gas technical field The invention relates to pyrolusite leaching technology, more specifically, relates to a method for performing absorption and leaching reaction with sulfur dioxide and pyrolusite, so that sulfur resources and manganese resources can be comprehensively and complementary utilized. Background technique At present, the main methods of hydrometallurgical leaching of pyrolusite are: (1) ferrous sulfate method, the mixed solution of manganese sulfate and ferric sulfate is generated by the reaction of pyrolusite and ferrous sulfate, and then manganese sulfate solution is obtained through purification and iron removal (2) two mines add acid method, adopt pyrolusite and pyrite to react under the condition that sulfuric acid exists to generate the mixed solution of manganese sulfate and ferric sulfate, and mixed solution makes manganese sulfate solution through purification a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G45/10

Inventor 苏仕军丁桑岚

Owner 成都合众新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com