Acid-resistant nanofiltration membrane as well as preparation method and application thereof

A nanofiltration membrane and acid-resistant technology, which is applied in the field of membrane separation, can solve the problems of low reactivity of cyanuric chloride, high difficulty in large-scale preparation, high price of polyethyleneimine, etc., and is conducive to industrial scale production, Easy to repeat and improve the effect of conjugation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

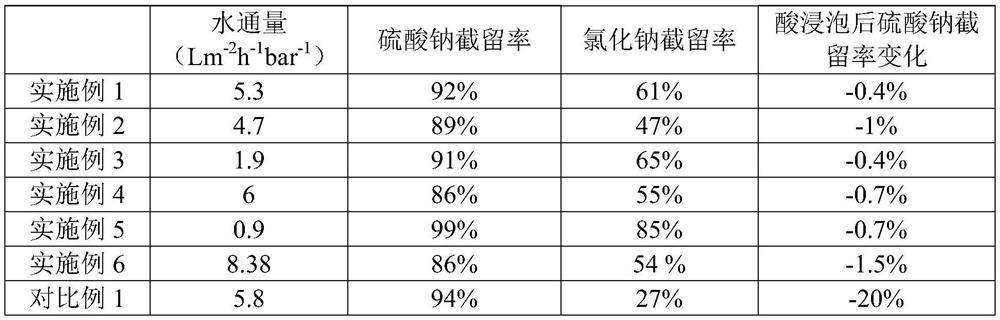

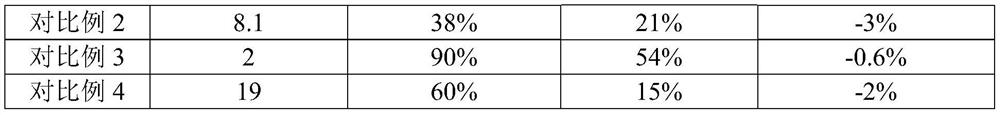

Examples

Embodiment 1

[0057] In this embodiment, an acid-resistant nanofiltration membrane is provided, the acid-resistant nanofiltration membrane includes a support membrane and an active separation layer loaded on the support membrane, and the active separation layer includes a water phase reactant and an oil phase reactant The interfacial polymerization product, the water phase reactant includes 3-aminobenzenesulfonamide, triethylamine and sodium dodecylsulfonate, and the oil phase reactant includes trimesoyl chloride.

[0058] The preparation method comprises the following steps:

[0059] (1) The aqueous phase reactant solution containing 3-aminobenzenesulfonamide, triethylamine and sodium dodecylsulfonate is prepared by physical blending method, so that every 100g of said aqueous phase reactant solution contains 0.2g of 3-aminobenzenesulfonamide, 0.2g of triethylamine and 0.2g of sodium dodecylsulfonate, adjust the pH of the solution to be 11.5;

Embodiment 2

[0066] In this embodiment, an acid-resistant nanofiltration membrane is provided, the acid-resistant nanofiltration membrane includes a support membrane and an active separation layer loaded on the support membrane, and the active separation layer includes a water phase reactant and an oil phase reactant The interfacial polymerization product, the water phase reactants include sulfapyridine, triethylamine and sodium dodecylsulfonate, and the oil phase reactants include trimesoyl chloride.

[0067] The preparation method comprises the following steps:

[0068] (1) The aqueous phase reactant solution containing sulfapyridine, triethylamine and sodium dodecyl sulfonate is prepared by physical blending method, so that 0.1g of sulfapyridine, 0.1 g of sulfapyridine, 0.1 The triethylamine of 1g and the sodium dodecylsulfonate of 0.1g adjust the pH of the solution to be 11;

[0069] (2) taking n-hexane as a solvent to prepare an oil phase reactant solution containing trimesoyl chlori...

Embodiment 3

[0075] In this embodiment, an acid-resistant nanofiltration membrane is provided, the acid-resistant nanofiltration membrane includes a support membrane and an active separation layer loaded on the support membrane, and the active separation layer includes a water phase reactant and an oil phase reactant The interfacial polymerization product, the water phase reactant includes 3-aminobenzenesulfonamide, sodium hydroxide and sodium dodecylbenzenesulfonate, and the oil phase reactant includes trimesoyl chloride.

[0076] The preparation method comprises the following steps:

[0077] (1) The aqueous phase reactant solution containing 3-aminobenzenesulfonamide, sodium hydroxide and sodium dodecylbenzenesulfonate is prepared by physical blending method, so that every 100g of said aqueous phase reactant solution contains 1g of 3-aminobenzenesulfonamide, 0.01g of sodium hydroxide and 0.05g of sodium dodecylbenzenesulfonate, adjust the pH of the solution to be 12;

[0078] (2) taking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com