Method for catalyzed synthesis of butyl oleate with oleic acid-based ionic liquid microemulsion

An ionic liquid, butyl oleate technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., can solve problems such as environmental risks, achieve low environmental impact, increase contact area, and speed up reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

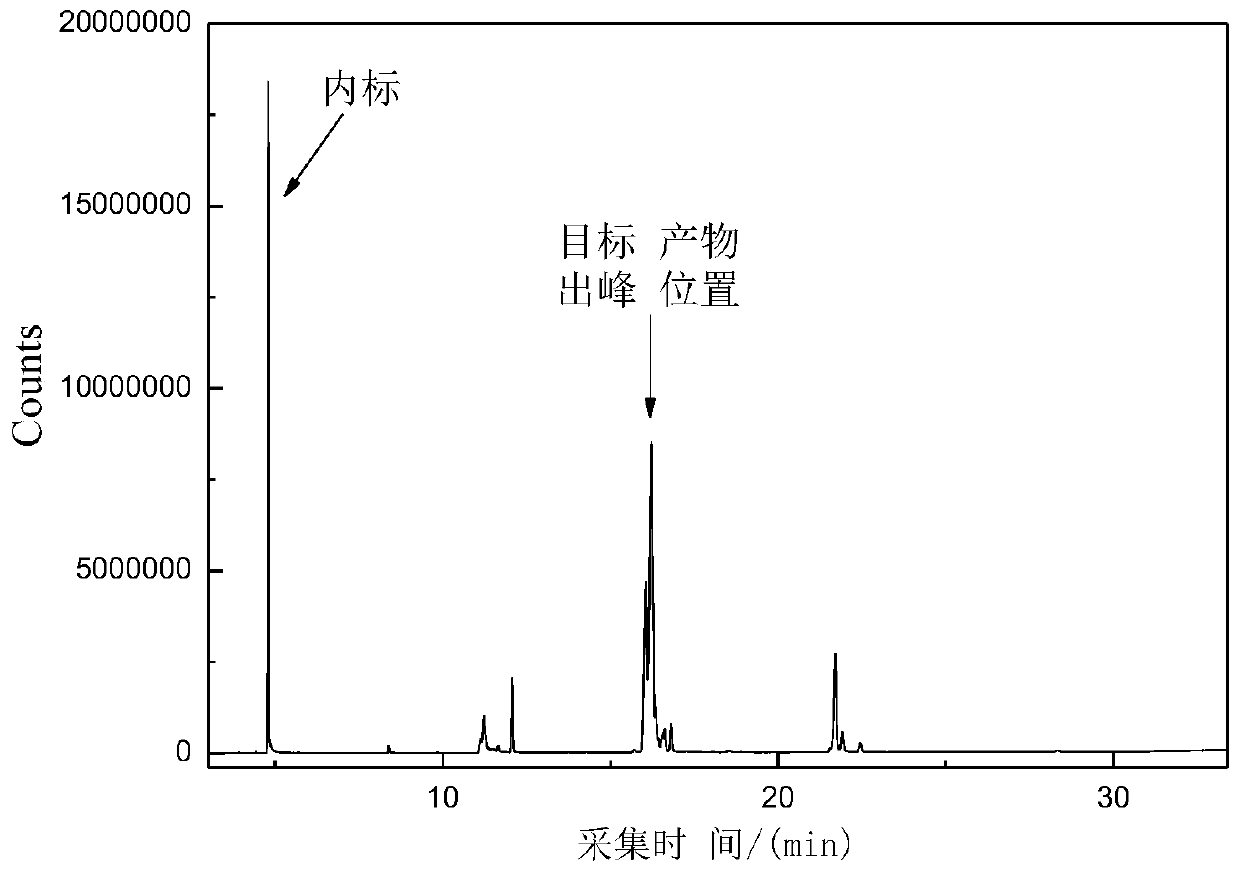

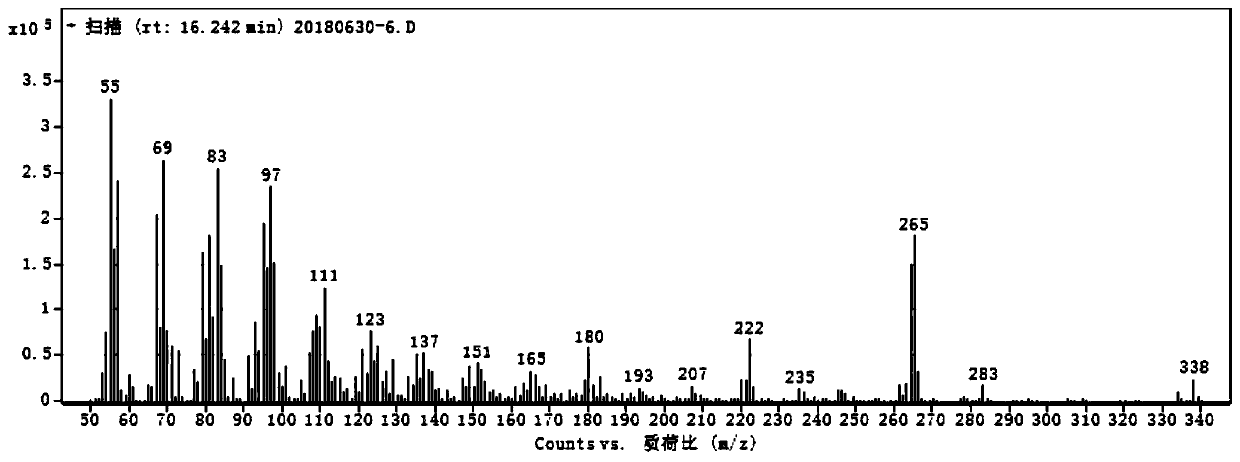

Image

Examples

Embodiment 1

[0032] Oleic acid-based ionic liquid microemulsion components and their dosage: 1.4 parts by weight of [Bmim]BF 4 , 39.8 parts by weight of oleic acid, 22.0 parts by weight of Triton X-100, 5.5 parts by weight of 1-hexyl-3-methylimidazolium bisulfate, 31.3 parts by weight of n-butanol;

[0033] At 30°C, mix Triton X-100 and 1-hexyl-3-methylimidazolium bisulfate evenly, stir at a speed of 300 rpm, and stir for 5 minutes to obtain a clear and transparent mixture, then add oleic acid Mix it with n-butanol at a stirring speed of 300 rpm, and stir for 15 minutes to obtain a clear and transparent mixture, and finally [Bmim] BF 4 Add it into the mixture and stir for 5 minutes to obtain a clear and transparent oleic acid-based ionic liquid microemulsion.

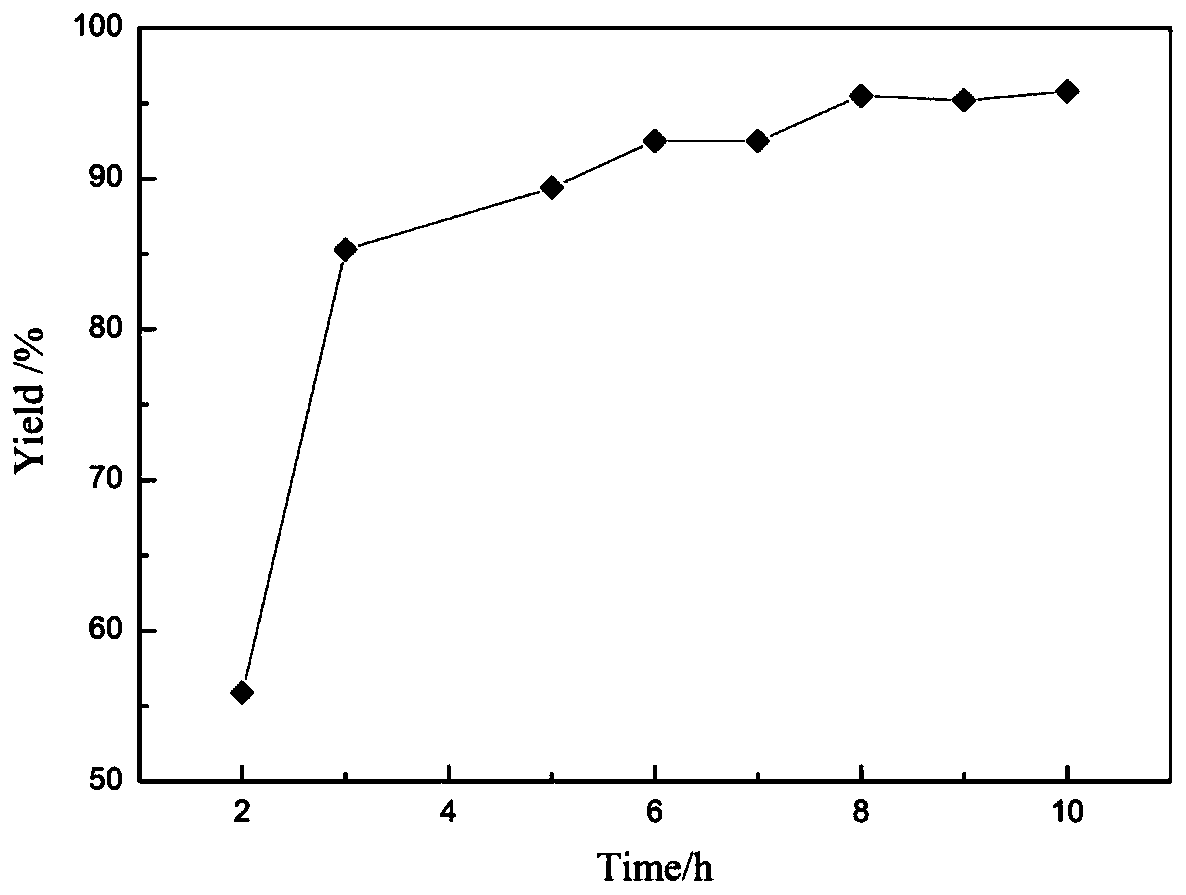

[0034] Take 50.98g of oleic acid-based ionic liquid microemulsion, and carry out esterification reaction under nitrogen atmosphere and heating and stirring, wherein the stirring speed is 600 rpm, the reaction temperature is 100°C, ...

Embodiment 2

[0037] Oleic acid-based ionic liquid microemulsion components and their dosage: 1.4 parts by weight of [Bmim]BF 4 , 40.5 parts by weight of oleic acid, 21.9 parts by weight of Triton X-100, 4.8 parts by weight of 1-octyl-3-methylimidazolium bisulfate, 31.4 parts by weight of n-butanol;

[0038] At 28°C, mix Triton X-100 and 1-octyl-3-methylimidazolium bisulfate evenly, stir at 400 rpm for 8 minutes to obtain a clear and transparent mixture, then add oil The acid and n-butanol were mixed with it, the stirring speed was 400 rpm, and stirred for 10 minutes to obtain a clear and transparent mixture. [Bmim]BF drop by drop 4 Add it into the mixture and stir for 5 minutes to obtain a clear and transparent oleic acid-based ionic liquid microemulsion.

[0039]Take 51g of oleic acid-based ionic liquid microemulsion, and carry out esterification reaction under nitrogen atmosphere and heating and stirring, wherein the stirring speed is 600 rpm, the reaction temperature is 100°C, and the...

Embodiment 3

[0042] Oleic acid-based ionic liquid microemulsion components and their dosage: 2.2 parts by weight of [Bmim]BF 4 , 26.6 parts by weight of oleic acid, 36 parts by weight of Triton X-114, 7.2 parts by weight of 1-hexyl-3-methylimidazolium bisulfate, 28.0 parts by weight of n-butanol;

[0043] At 32°C, mix Triton X-114 and 1-hexyl-3-methylimidazolium bisulfate evenly at a stirring speed of 400 rpm for 10 minutes to obtain a clear and transparent mixture, then add oleic acid Mix it with n-butanol, stir at a stirring speed of 400 rpm, and stir for 10 minutes to obtain a clear and transparent mixture. [Bmim]BF drop by drop 4 Add it into the mixture and stir for 10 minutes to obtain a clear and transparent oleic acid-based ionic liquid microemulsion.

[0044] Take 6.94g of oleic acid-based ionic liquid microemulsion, and carry out esterification reaction under nitrogen atmosphere and heating and stirring, wherein the stirring speed is 600 rpm, the reaction temperature is 100°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com