Loaded solid phase metal catalyst for magnesium desulfurization process, and preparation method thereof

A metal catalyst and magnesium desulfurization technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of secondary pollution of catalysts, achieve high reuse rate, high efficiency, and avoid secondary pollution The effect of pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

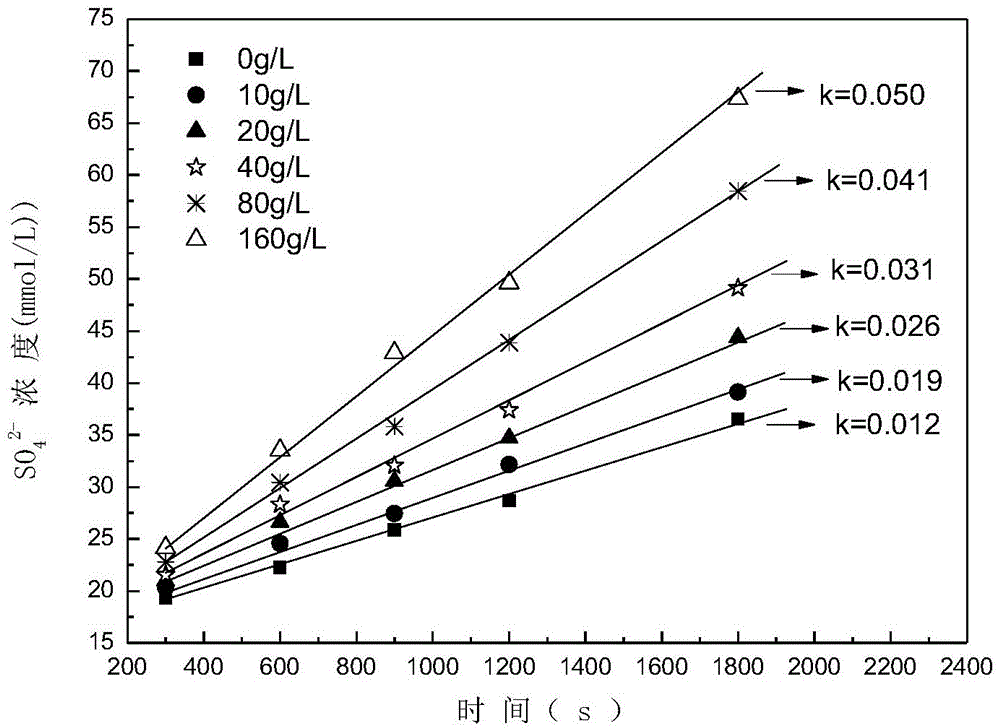

[0032] Embodiment 1: the catalytic effect of different concentration supported solid-phase metal catalysts

[0033] Weigh Co(NO 3 ) 2 ·6H 2 O0.9688g, Fe(NO 3 ) 3 9H 2 O2.8386g, Mn(NO 3 ) 2 4H 2 O2.6779g and Ni(NO 3 ) 2 ·6H 2 0.9720g, uniformly mixed and made into an aqueous solution; and 20.002g of 4A type molecular sieve after pretreatment was weighed, mixed with the configured nitrate solution, shaken at a constant speed of 120r / min for 8 hours, and left standstill for 24 hours. After filtering and washing with deionized water several times, drying at 120° C. for 10 hours, and calcining at 500° C. for 5 hours, a supported solid-phase metal catalyst was obtained.

[0034] Take the prepared catalyst and add it to the absorption slurry of five parallel magnesium desulfurization systems, the concentration of the catalyst is 10g L -1 , 20g·L -1 , 40g·L -1 , 80g·L -1 and 160g·L -1 , to compare their catalytic effects under the same reaction conditions.

[0035] Ex...

Embodiment 2

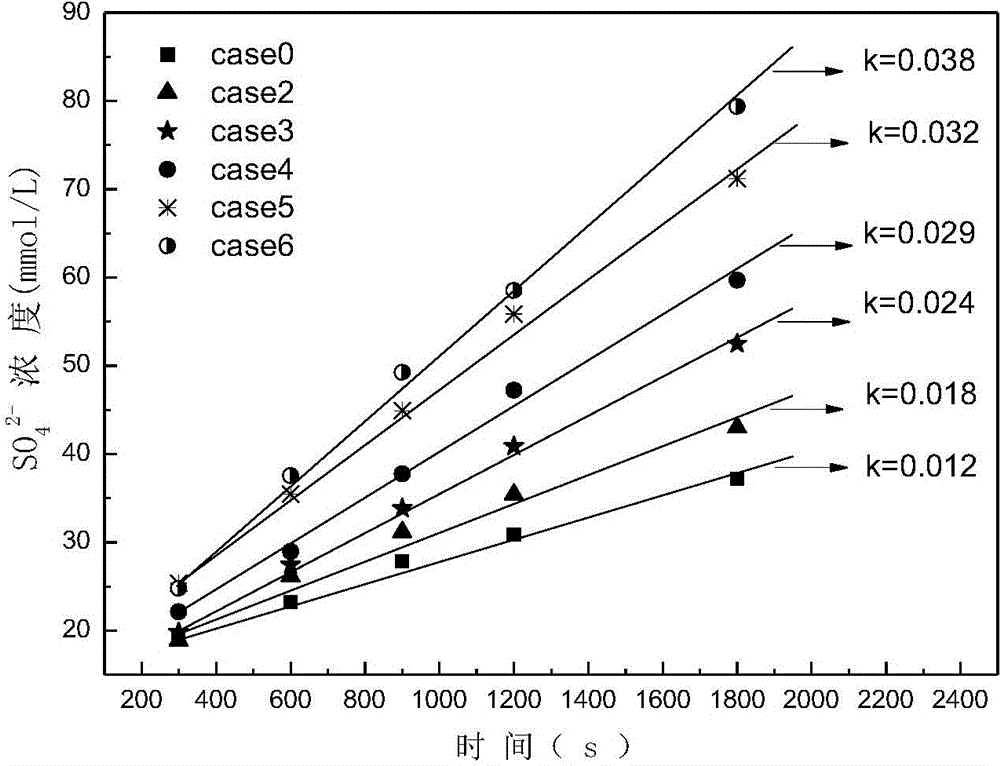

[0036] Embodiment 2: the catalytic effect of the loaded solid-phase metal catalyst of different active ingredient ratios

[0037] case2:

[0038] Weigh Co(NO 3 ) 2 ·6H 2 O0.4745g, Fe(NO 3 ) 3 9H 2 O0.3300g, Mn(NO 3 ) 2 4H 2 O0.4084g and Ni(NO 3 ) 2 ·6H 20.2375g, uniformly mixed and made into solution; and take by weighing 20.002g of 4A type molecular sieve after the pretreatment, it is mixed with the nitrate solution that configures, shake table constant speed 120r / min vibration 6 hours, leave standstill 24 hours, After filtering and washing with deionized water several times, drying at 110° C. for 12 hours, and calcining at 400° C. for 6 hours, a supported solid-phase metal catalyst was obtained. Take 4.002g of the prepared catalyst and add it to the absorption slurry of the magnesium desulfurization system, so that the catalyst concentration is 20g L -1 , the catalytic rate increased by about 0.50 times compared with the non-catalytic condition.

[0039] case3:...

Embodiment 3

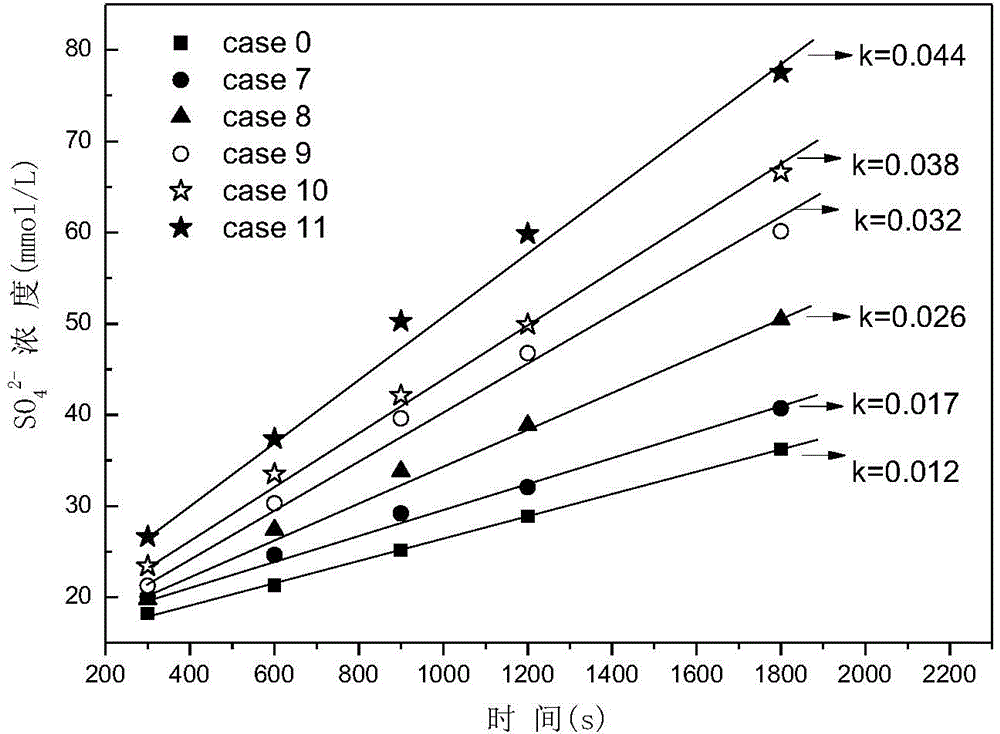

[0048] Embodiment 3: the catalytic effect of the loaded solid-phase metal catalyst of different loads

[0049] case7:

[0050] Weigh Co(NO 3 ) 2 ·6H 2 O0.1493g, Fe(NO 3 ) 3 9H 2 O0.4374g, Mn(NO 3 ) 2 4H 2 O0.4127g and Ni(NO 3 ) 2 ·6H 2 0.1497g, uniformly mixed and made into solution; and 20.002g of 4A type molecular sieves after pretreatment was weighed, mixed with the configured nitrate solution, shaken at a constant speed of 120r / min for 7 hours, and left standstill for 24 hours. After filtering, washing with deionized water several times, drying at 130°C for 12 hours, and calcining at 600°C for 4 hours, a supported solid-phase metal catalyst with a loading capacity (mass fraction of total metal ions in the catalyst) of 1% was obtained. Take 4.002g of the prepared catalyst and add it to the absorption slurry of the magnesium desulfurization system, so that the catalyst concentration is 20g L -1 , the catalytic rate increased by about 0.42 times compared with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com