Heterogeneous catalysis pretreatment method of Carlin type refractory gold ore

A technology for refractory gold ore and heterogeneous catalysis, applied in the field of ore mining, can solve the problems of high investment in hot-pressing alkaline leaching, low concentration of pretreated ore pulp, low normal-pressure alkaline leaching rate, etc. Low equipment requirements and guaranteed leaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

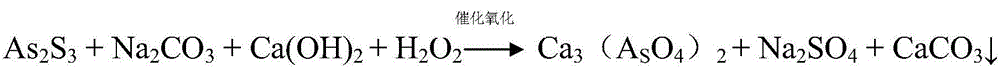

Image

Examples

Embodiment 1

[0027] In the treatment of a refractory gold mine in Guizhou, the metal minerals in the ore are pyrite, followed by arsenopyrite; the gangue minerals are mainly dolomite, calcite, quartz, hydromica, etc. The contents of gold, sulfur and arsenic in the ore are 12.3g / t, 3.1%, 0.3%.

[0028] (1) Pre-crushing 300g of ore through coarse crushing, fine crushing and ball milling until the particle size of 90% of the ore is less than 0.044mm;

[0029] (2) Add 21g of sodium carbonate, 12g of quicklime, 20g of sodium lignansulfonate, 4.5g of hydrogen peroxide (30%) and water with a molecular weight range of 5000 to 10000 to the crushed ore under the condition of aeration and mechanical stirring. 900mL of chemical heterogeneous catalytic pre-oxidation treatment to obtain pre-oxidized ore pulp, wherein the pre-oxidation treatment temperature is 80°C, the stirring speed is 750rpm, and the aeration flow rate per ton of ore is 5-50m 3 / h, the pretreatment time is 24 hours.

[0030] (3) Sti...

Embodiment 2

[0041] When dealing with a bauxite mine, the metal minerals in the ore are mainly diaspore, followed by hematite; the gangue minerals are mainly calcite. The contents of aluminum oxide, iron oxide and silicon dioxide in the ore are 65%, 6.11% and 8.56% respectively.

[0042] (1) Pre-crushing 200g of ore through coarse crushing, fine crushing and ball milling until 80% of the ore has a particle size of less than 0.075mm;

[0043](2) Add 200g of sodium carbonate, 230g of quicklime, 15g of sodium lignansulfonate in the molecular weight range of 5000 to 10000, 2.0g of sodium peroxide and 900mL of water to the crushed ore under the condition of aeration and mechanical stirring. The pre-oxidized pulp is obtained by heterogeneous catalytic pre-oxidation treatment, wherein the pre-oxidation treatment temperature is 60°C, the stirring speed is 750rpm, and the aeration flow rate per ton of ore is 5-50m 3 / h, the pretreatment time is 1 hour.

[0044] (3) The above-mentioned pre-oxidize...

Embodiment 3

[0048] When dealing with a molybdenum concentrate, the metal minerals in the ore sample are mainly molybdenite, followed by chalcopyrite; the gangue minerals are mainly sericite, quartz and plagioclase. The contents of molybdenum, copper and sulfur in molybdenum concentrate are 42.7%, 3.28% and 34.12% respectively.

[0049] (1) Pre-crushing 100g of ore through coarse crushing, fine crushing and ball milling until 90% of the ore has a particle size of less than 0.074mm;

[0050] (2) Under the conditions of aeration and mechanical stirring, add 132.5g of sodium carbonate, 78g of quicklime, 5g of sodium lignansulfonate with a molecular weight range of 5000 to 10000, and pre-fill with 1MPa of oxygen to carry out chemical heterogeneous catalysis The pre-oxidized pulp is obtained through pre-oxidation treatment, wherein the pre-oxidation treatment temperature is 150°C, the total pressure is 2MPa, the oxygen partial pressure is 1.52MPa, and the heat preservation and pressure treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com