Full decontamination waste gas recovering flexible pressurization system

A technology of supercharging system and exhaust gas, applied in electrical components, exhaust devices, controlling mechanical energy, etc., can solve problems such as reducing power and increasing exhaust back pressure, so as to increase power, reduce fuel consumption, and reduce fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

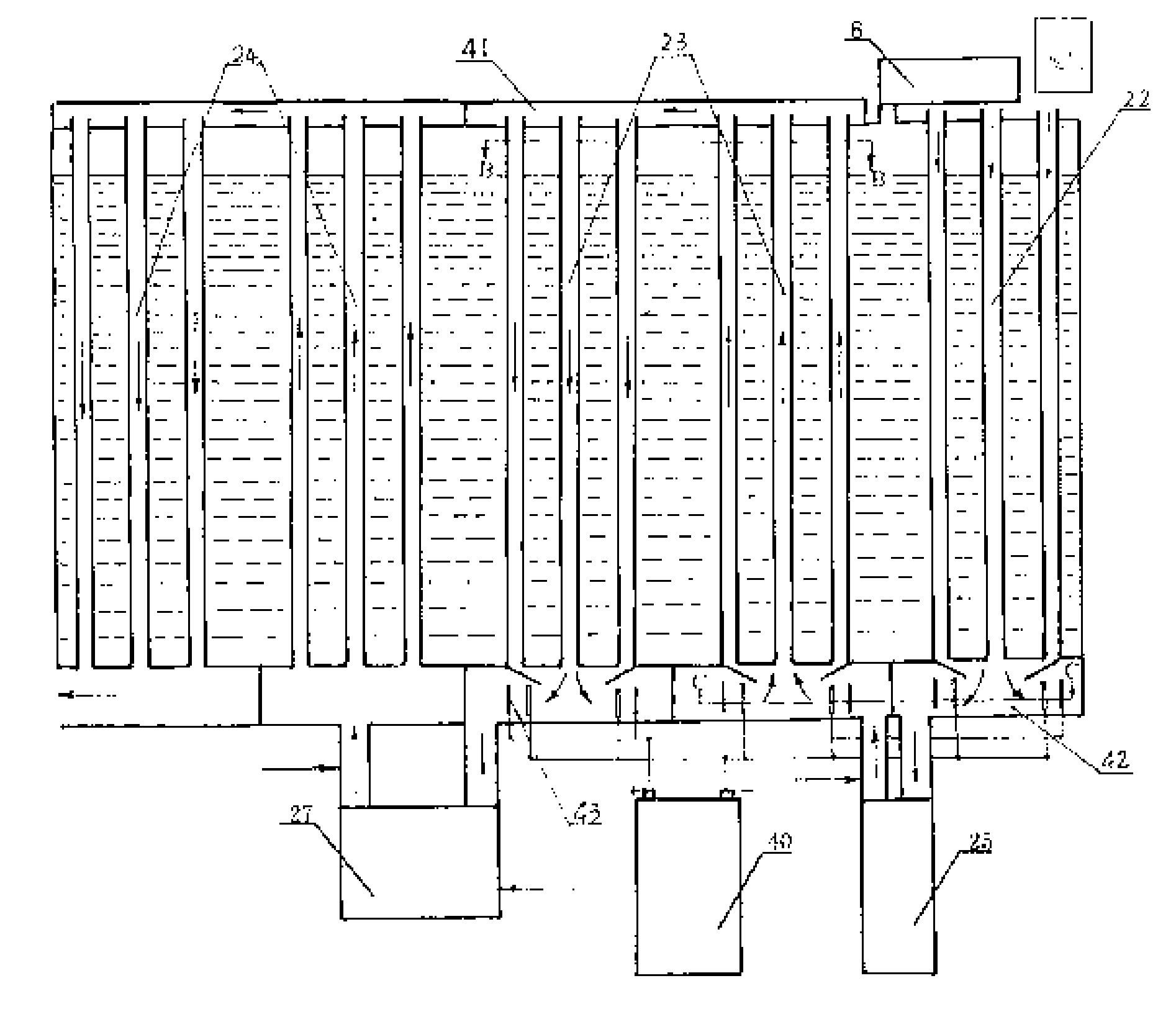

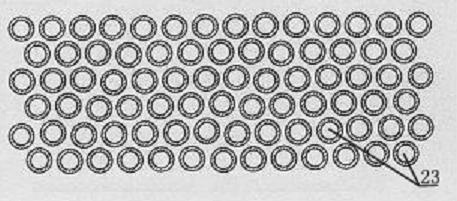

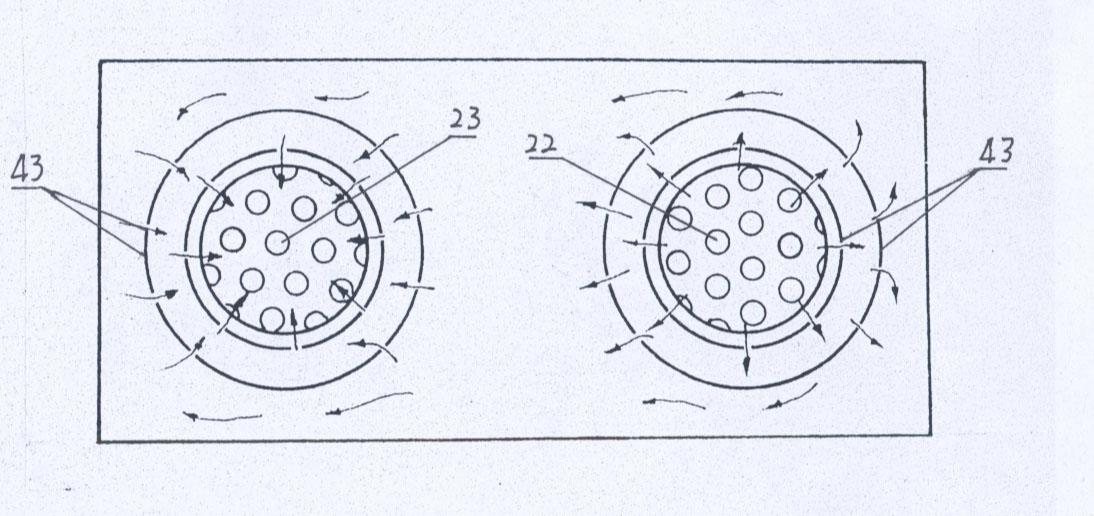

[0091] Examples, as attached figure 1 , figure 2 As shown, a fully decontaminated exhaust gas energy recovery flexible supercharging system includes a diesel engine 1, the diesel engine 1 is provided with an intake pipe 1a and an exhaust pipe 3, and the intake pipe 1a is connected to a compressor 2 for flexible supercharging , the exhaust pipe 3 is connected with a turbine generator 4, and the turbine generator 4 is connected with a decontamination heat exchange device through a pipeline.

[0092] The decontamination heat exchange device includes a heat exchange box 5 communicated with the turbine generator 4 through a pipeline, the heat exchange box 5 is provided with a water chamber 8, the top of the water chamber 8 is provided with a steam storage chamber 7, and the water chamber A superheater 6 is arranged between 8 and the steam storage chamber 7 , and one end of the superheater 6 communicates with the water chamber 8 , and the other end communicates with the steam sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com