Solid-phase compound metal catalyst used for magnesium desulphurization technology

A metal catalyst and magnesium desulfurization technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the secondary pollution of heavy metal by-products of desulfurization and the limitation of catalyst application , Catalyst is difficult to recycle and other problems, to achieve the effect of solid phase catalytic effect, less residue, easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

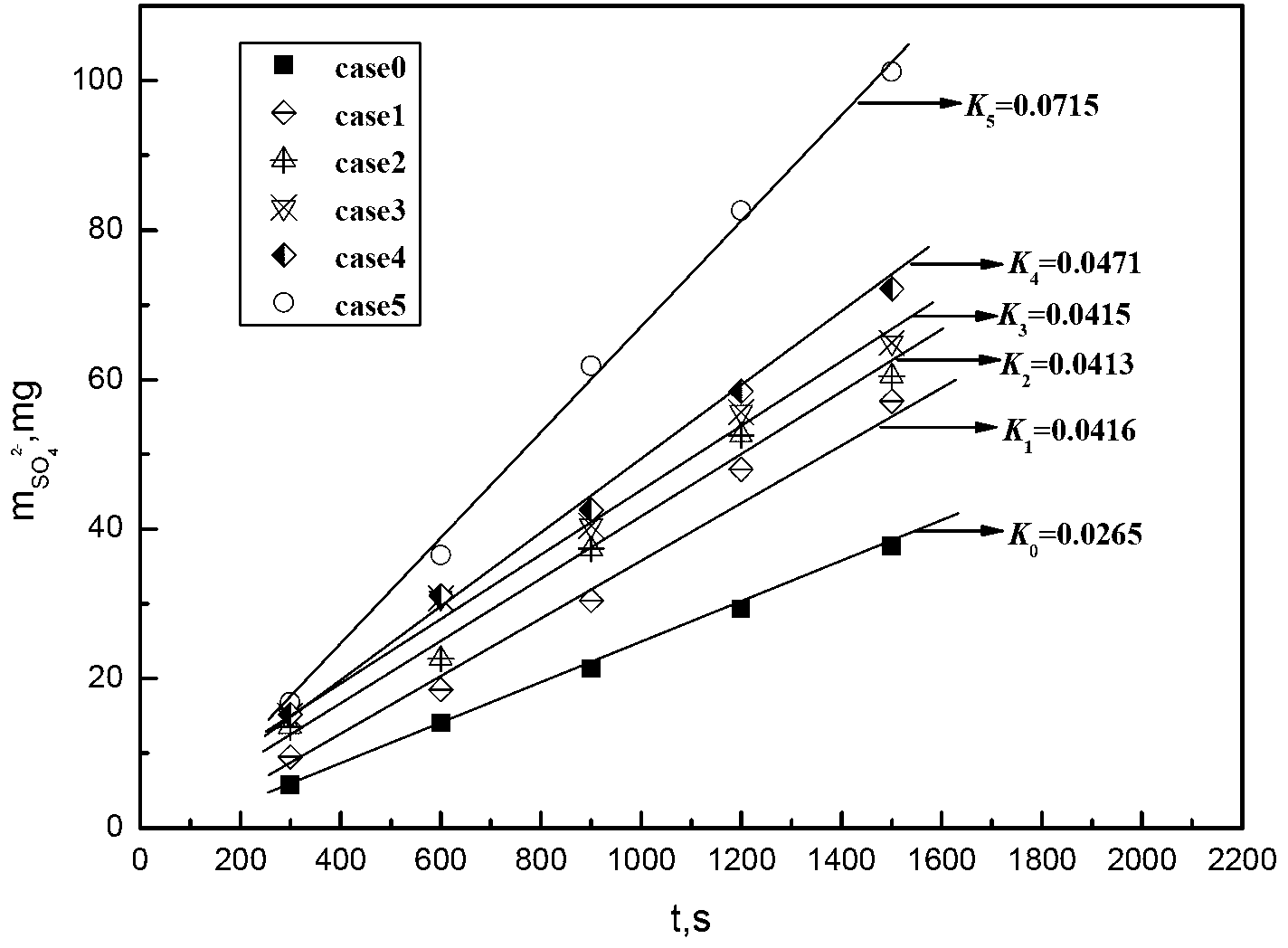

[0018] Weigh Co(NO 3 ) 2 ·6H 2 O 1.798g, Cu(NO 3 ) 2 ·3H 2 O 0.442g, Fe(NO 3 ) 3 9H 2 O 1.265g, Bi(NO 3 ) 3 ·5H 2 O 0.247g, Mn(NO 3 ) 2 0.48ml, Ni(NO 3 ) 2 ·6H 2 O 0.233g, (NH 4 ) 3 Mo 7 o 24 4H 2 O 1.994g, was dissolved in 20ml deionized water respectively at room temperature, mixed and stirred successively, evaporated to dryness in a water bath, 120 o Drying at C for 8 hours, 300 o Drying at C for 9 hours, 520 o C under the condition of roasting for 5 hours to make a solid phase catalyst.

[0019] Weigh 0.202g of the above catalyst and add it into the magnesium sulfite oxidation reactor. The volume of the reaction solution is 200ml. At this time, the catalytic reaction rate is increased by about 0.570 times compared with the non-catalytic condition.

Embodiment 2

[0021] Weigh Co(NO 3 ) 2 ·6H 2 O 1.949g, Cu(NO 3 ) 2 ·3H 2 O 0.508g, Fe(NO 3 ) 3 9H 2 O 1.951g, Bi(NO 3 ) 3 ·5H 2 O 0.203g, Mn(NO 3 ) 2 0.52ml, Ni(NO 3 ) 2 ·6H 2 O 0.226g, (NH 4 ) 3 Mo 7 o 24 4H 2 O 3.054g, was dissolved in 20ml deionized water respectively at room temperature, mixed and stirred successively, evaporated to dryness in a water bath, 120 o Drying at C for 8 hours, 300 o Drying at C for 9 hours, 480 o C under the condition of roasting for 5 hours to make a solid phase catalyst.

[0022] Weigh 0.202g of the above catalyst and add it into the magnesium sulfite oxidation reactor. The volume of the reaction solution is 200ml. At this time, the catalytic reaction rate is increased by about 0.558 times compared with the non-catalytic condition.

Embodiment 3

[0024] Weigh Co(NO 3 ) 2 ·6H 2 O 2.005g, Cu(NO 3 ) 2 ·3H 2 O 0.597g, Fe(NO 3 ) 3 9H 2 O 1.840g, Bi(NO 3 ) 3 ·5H 2 O 0.276g, Mn(NO 3 ) 2 0.49ml, Ni(NO 3 ) 2 ·6H 2 O 0.260g, (NH 4 ) 3 Mo 7 o 24 4H 2 O 2.969g, was dissolved in 20ml deionized water respectively at room temperature, mixed and stirred successively, evaporated to dryness in a water bath, 120 o Drying at C for 8 hours, 300 o Drying at C for 9 hours, 500 o C under the condition of roasting for 5 hours to make a solid phase catalyst.

[0025] Weigh 0.203g of the above catalyst and add it into the magnesium sulfite oxidation reactor. The volume of the reaction solution is 200ml. At this time, the catalytic reaction rate is increased by about 0.566 times compared with the non-catalytic condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com