Low-carbon alkane dehydrogenation catalyst with highly-dispersed multi-element active components and preparation method of low-carbon alkane dehydrogenation catalyst

A dehydrogenation catalyst and active component technology, applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of high catalyst composition, slowness, large Pt loading, etc., and achieve high dehydrogenation reaction activity , long life and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

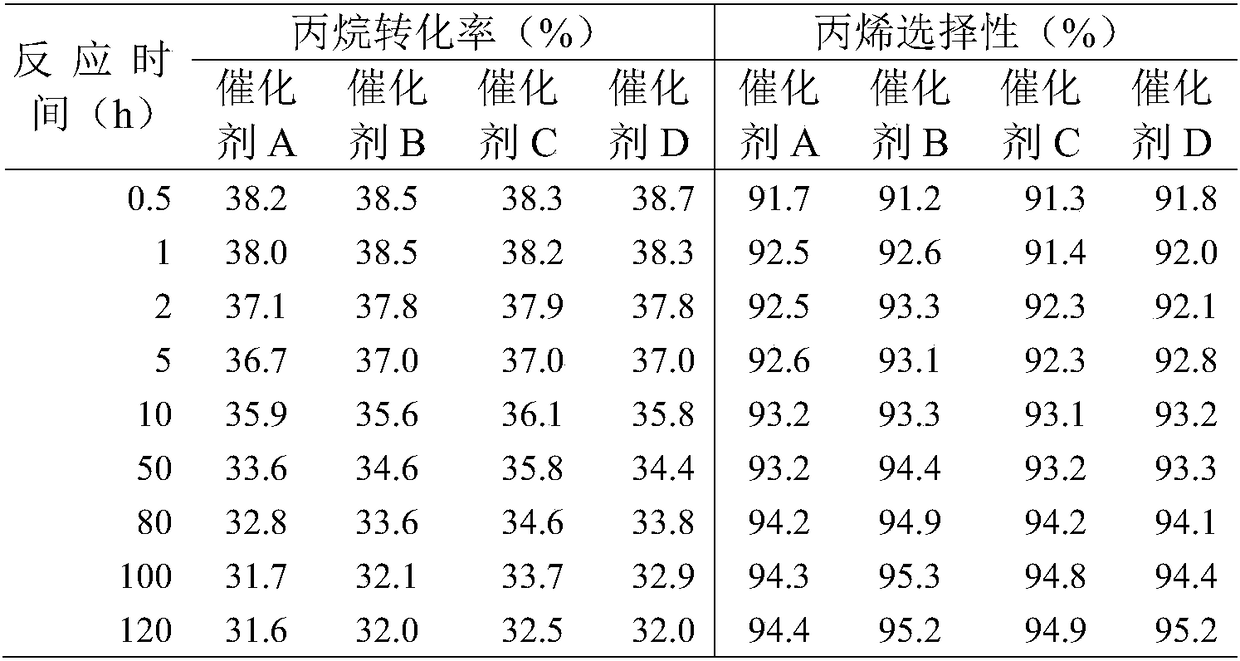

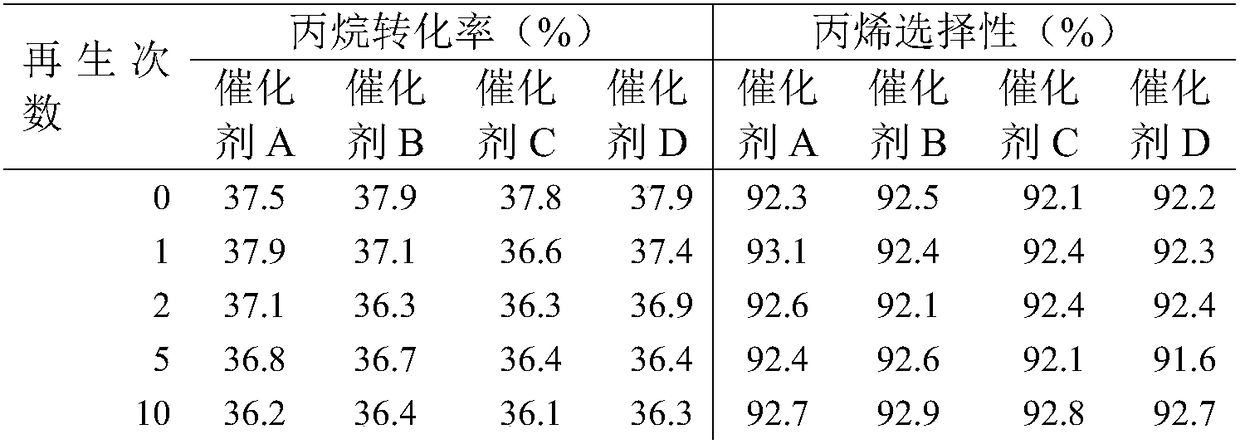

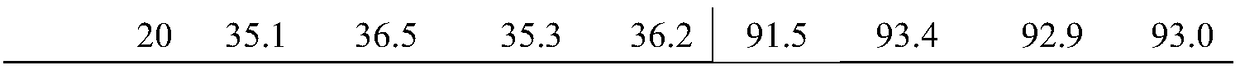

Examples

Embodiment 1

[0018] Catalyst A: Catalyst A contains Cu: 0.50w%, Ir: 0.10w%, Pt: 0.15w%, Rh: 0.05w% and K: 0.70w%, and the rest is Al 2 o 3 , the preparation method is as follows:

[0019] (1) Prepare the carrier containing the active ingredient

[0020] Weigh commercially available spherical alumina carrier (particle diameter 1.6mm, pore volume 0.60cm 3 / g, specific surface area 150m 2 / g, water absorption rate 80%, the following examples all use this carrier) 50g.

[0021] Mix 1.9ml of 0.2M chloroplatinic acid aqueous solution, 19.7ml of 0.2M copper chloride aqueous solution, 1.3ml of 0.2M chloroiridic acid aqueous solution and 1.2ml of 0.2M rhodium chloride aqueous solution , add 8ml of concentrated hydrochloric acid, and finally add deionized water to make the volume of the soaking solution finally constant to 40ml. Slowly add the impregnating liquid into the alumina carrier, and stir while adding, so that the impregnating liquid is evenly loaded on the carrier.

[0022] The carri...

Embodiment 2

[0026] Catalyst B: Catalyst B contains Cu: 0.50w%, Ir: 0.08w%, Pt: 0.15w%, Pd: 0.06w% and K: 0.90w%, and the rest is Al 2 o 3 , the preparation method is as follows:

[0027] (1) Prepare the carrier containing the active ingredient

[0028] Weigh 50 g of a commercially available spherical alumina carrier. Mix 1.9ml of 0.2M chloroplatinic acid aqueous solution, 19.7ml of 0.2M copper chloride aqueous solution, 1.0ml of 0.2M chloroiridic acid aqueous solution and 1.4ml of 0.2M palladium chloride aqueous solution , add 5ml of concentrated hydrochloric acid, and finally add deionized water to make the impregnation solution finally constant to 40ml. Slowly add the impregnating liquid into the alumina carrier, and stir while adding, so that the impregnating liquid is evenly loaded on the carrier.

[0029] The steps of aging, drying, roasting and chlorination of the carrier loaded with active components are the same as the method in (1) of Implementation 1, except that the chlorin...

Embodiment 3

[0033] Catalyst C: Catalyst C contains Cu: 0.60w%, Ir: 0.05w%, Pt: 0.20w%, Au: 0.05w% and K: 0.80w%, the rest is Al 2 o 3 , the preparation method is as follows:

[0034] (1) Prepare the carrier containing the active ingredient

[0035]Weigh 50 g of a commercially available spherical alumina carrier. Mix 2.6ml of 0.2M chloroplatinic acid aqueous solution, 23.6ml of 0.2M copper chloride aqueous solution, 0.65ml of 0.2M chloroiridic acid aqueous solution and 0.7ml of 0.2M chloroauric acid aqueous solution , add 5ml of concentrated hydrochloric acid, and finally add deionized water to make the impregnation solution finally constant to 40ml. Slowly add the impregnating liquid into the alumina carrier, and stir while adding, so that the impregnating liquid is evenly loaded on the carrier.

[0036] The steps of aging, drying, roasting and chlorination treatment of the carrier loaded with active components are the same as the method in (1) of implementing 1, and the difference is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com