Method for catalyzing dehydrogenation of methylcyclohexane by using platinum-carbon catalyst

A catalyst technology for catalyzing methylcyclohexane and platinum carbon catalysts, applied in the field of catalysis, can solve problems such as the inability to meet the requirements of stability, activity and selectivity, and achieve strong synergy, high anti-coking performance, and stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

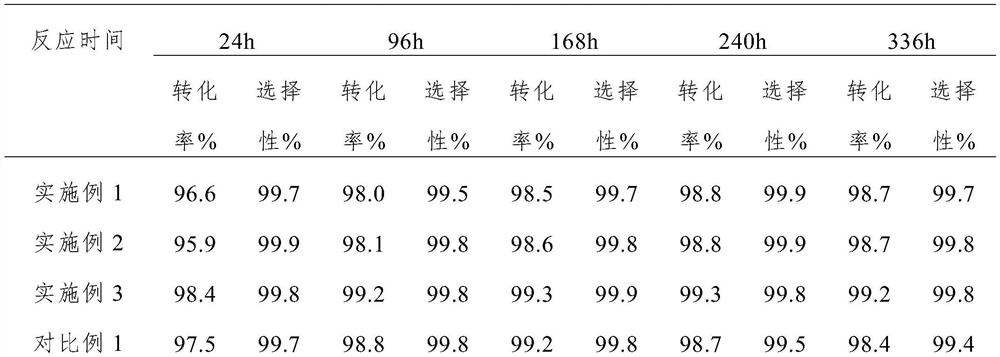

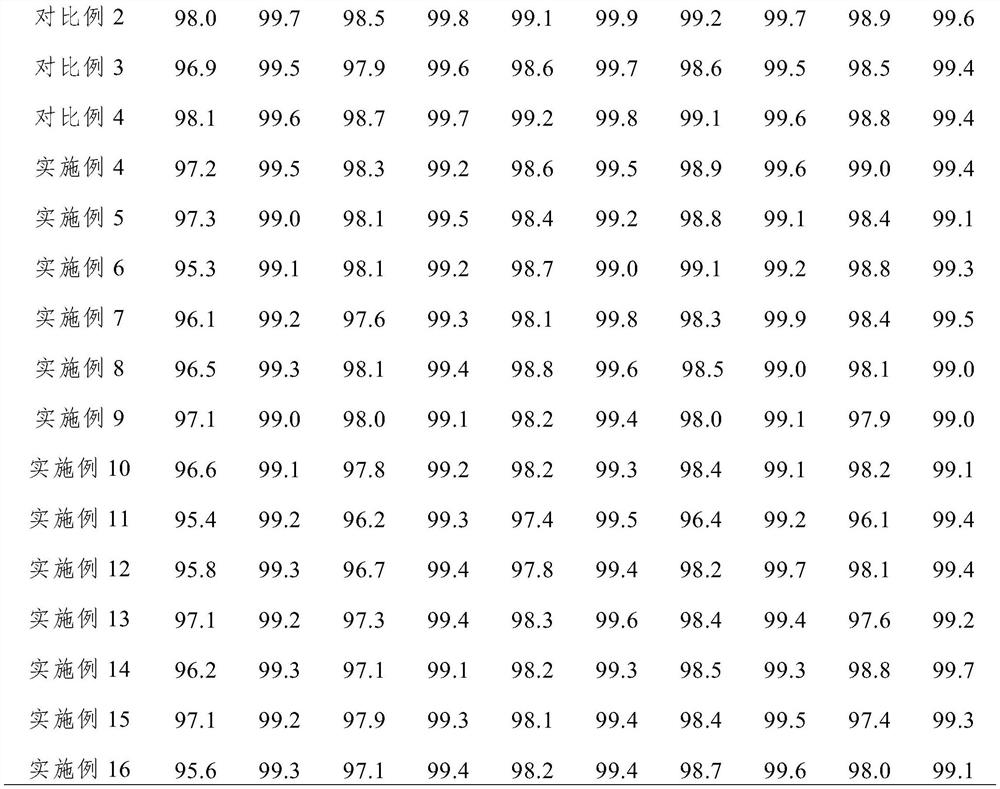

Examples

Embodiment 1

[0032] This embodiment provides a platinum carbon catalyst, including an activated carbon carrier and a metal component loaded on the activated carbon carrier, the metal component is Pt and a promoter metal, the promoter metal is Ni, and in the catalyst The mass percent content of Pt is 1.0%, and the mass percent content of the auxiliary metal Ni is 1.0%.

[0033] The present embodiment provides a kind of method for preparing above-mentioned platinum carbon catalyst, comprises the following steps:

[0034] Step 1, place 20g of activated carbon in the furnace, feed into nitrogen / argon atmosphere, raise the temperature to 800°C at a rate of 5°C / min and keep for 8h, then cool; the flow ratio of nitrogen / argon is 50sccm:50sccm;

[0035] Step 2, soak and stir the cooled material in step 1 in 100 mL of pentafluoroaniline aqueous solution for 24 hours, filter, and dry to obtain the pretreated carrier; the mass percentage of the pentafluoroaniline aqueous solution is 1%;

[0036] Ste...

Embodiment 2

[0042]This embodiment provides a platinum carbon catalyst, including an activated carbon carrier and a metal component loaded on the activated carbon carrier, the metal component is Pt and a promoter metal, the promoter metal is Fe, and in the catalyst The mass percent content of Pt is 0.2%, and the mass percent content of auxiliary metal Fe is 2.5%.

[0043] The present embodiment provides a kind of method for preparing above-mentioned platinum carbon catalyst, comprises the following steps:

[0044] Step 1. Put 20g of activated carbon in the furnace, pass into nitrogen / argon atmosphere, raise the temperature to 1000°C at a rate of 10°C / min and keep for 10h, then cool; the flow ratio of nitrogen / argon is 80sccm:20sccm;

[0045] Step 2. Soak the cooled material in Step 1 in 100 mL of pentafluoroaniline aqueous solution and stir for 24 hours, filter, and dry to obtain the pretreated carrier; the mass percentage of the pentafluoroaniline aqueous solution is 3%;

[0046] Step th...

Embodiment 3

[0052] This embodiment provides a platinum carbon catalyst, including an activated carbon carrier and a metal component loaded on the activated carbon carrier, the metal component is Pt and a promoter metal, the promoter metal is Cu, and in the catalyst The mass percent content of Pt is 0.8%, and the mass percent content of the additive metal Cu is 2.0%.

[0053] The present embodiment provides a kind of method for preparing above-mentioned platinum carbon catalyst, comprises the following steps:

[0054] Step 1, place 20g of activated carbon in the furnace, pass into a nitrogen / argon atmosphere, rise to 1100°C at a heating rate of 5°C / min and keep for 5h, then cool; the flow ratio of the nitrogen / argon is 70sccm:30sccm;

[0055] Step 2: soak and stir the cooled material in step 1 in 100 mL of pentafluoroaniline aqueous solution for 24 hours, filter, and dry to obtain the pretreated carrier; the mass percentage of the pentafluoroaniline aqueous solution is 2%;

[0056] Step t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com