A kind of quaternary platinum-based low-carbon alkane dehydrogenation catalyst and preparation method thereof

A technology for dehydrogenation catalysts and low-carbon alkanes, which is applied in the fields of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., which can solve the problems of unsatisfactory catalyst activity and selectivity, not involving catalyst performance, and outstanding stability. and other problems, to achieve the effect of improving the high temperature regeneration stability, improving the single-pass conversion rate, and improving the ability to resist carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

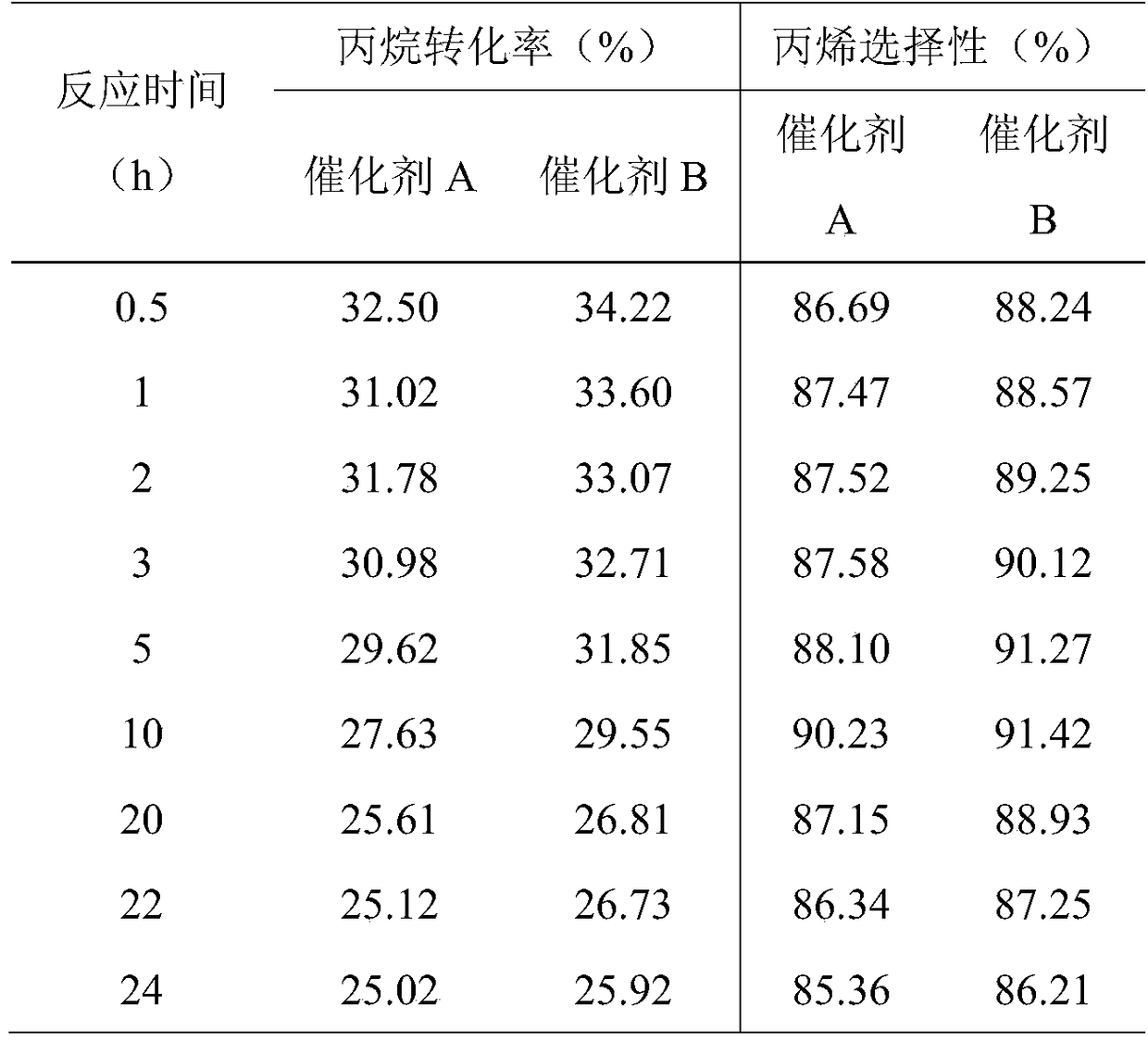

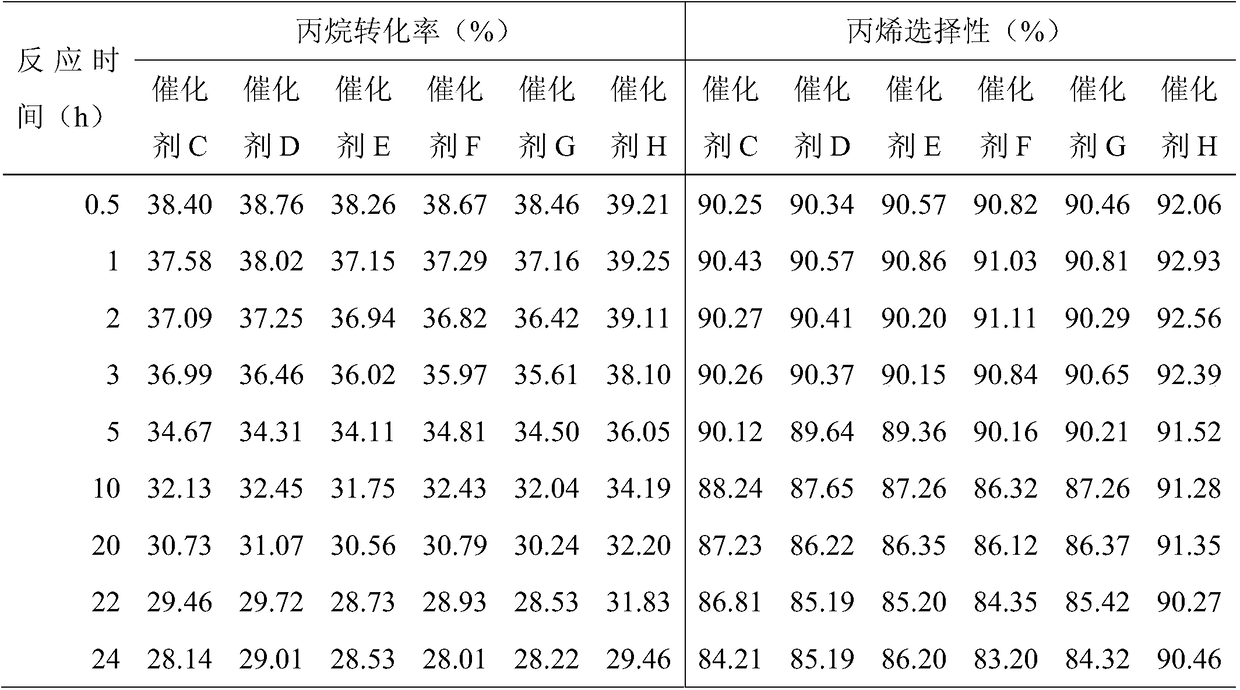

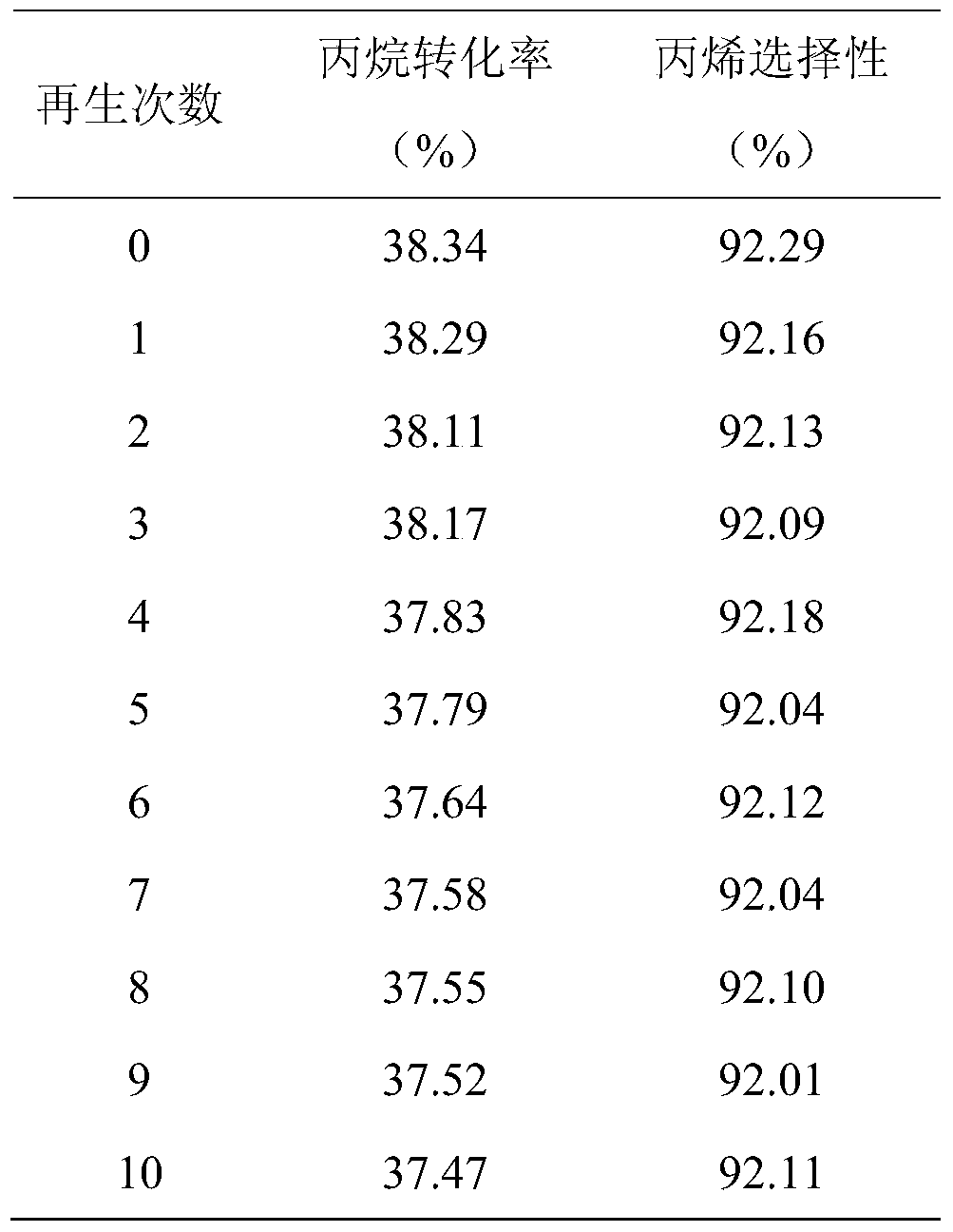

Examples

Embodiment 1

[0032] (1) After mixing the 1M aluminum chloride solution with the 0.02M zirconium oxychloride and 0.013M cerium nitrate solution in a volume of 7:1, add ammonia water with a mass concentration of 10%, and put it in a neutralization tank at 70°C Mix evenly under low pressure, control the pH value to 8.0, filter, wash with water, and acidify, pressurize the oily ammonia column into balls, dry, age, and roast at 850°C for one hour to obtain alumina containing 0.5w% Zr and 0.5w% Ce small ball.

[0033] (2) Mix 1ml concentration of 0.2M chloroplatinic acid aqueous solution and 3.7ml concentration of 0.18M stannous chloride hydrochloric acid solution, and add hydrochloric acid and water to the above-mentioned Pt-Sn dipping solution according to the saturated water absorption of the carrier used The concentration of hydrochloric acid in the finally prepared dipping solution is 1.5M. Immerse the configured impregnating solution and the 13.33g carrier in (1) in equal volume for 12 ho...

Embodiment 2

[0037] (1) After mixing the 1M aluminum chloride solution with the 0.04M zirconium oxychloride and 0.013M cerium nitrate solution in a volume of 7:1, add ammonia water with a mass concentration of 10%, and put it in a neutralization tank at 70°C Mix evenly under low pressure, control the pH value to 8.0, filter, wash with water, and acidify, pressurize the oily ammonia column into balls, dry, age, and roast at 850°C for one hour to obtain alumina containing 1.0w% Zr and 0.5w% Ce small ball.

[0038] (2) 1ml concentration of 0.2M chloroplatinic acid aqueous solution and 3.7ml concentration are mixed evenly with the hydrochloric acid solution of 0.18M tin protochloride, according to the saturated water absorption of the carrier used, add hydrochloric acid hydrochloride and Water makes the concentration of hydrochloric acid in the final prepared impregnating solution 1.5M. Immerse the configured impregnating solution and 13.33g of the carrier in (1) in an equal volume for 12 hou...

Embodiment 3

[0042] (1) After mixing the 1M aluminum chloride solution with the 0.06M zirconium oxychloride and 0.013M cerium nitrate solution in a volume of 7:1, add ammonia water with a mass concentration of 10%, and put it in a neutralization tank at 70°C Mix evenly under low pressure, control the pH value to 8.0, filter, wash with water, and acidify, pressurize the oily ammonia column into balls, dry, age, and roast at 850°C for one hour to obtain alumina containing 1.0w% Zr and 0.5w% Ce small ball.

[0043] (2) Mix 1ml concentration of 0.2M chloroplatinic acid aqueous solution and 3.7ml concentration of 0.18M stannous chloride hydrochloric acid solution, and add hydrochloric acid and water to the above-mentioned Pt-Sn dipping solution according to the saturated water absorption of the carrier used The concentration of hydrochloric acid in the finally prepared dipping solution is 1.5M. Immerse the configured impregnating solution and the 13.33g carrier in (1) in equal volume for 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com