Isobutane dehydrogenation catalyst with supporter being composite material containing silica gel and hexagonal mesoporous material as well as preparation method and application thereof

A technology for dehydrogenation catalysts and mesoporous materials, applied in catalyst activation/preparation, carbon compound catalysts, catalysts, etc., can solve problems such as uneven dispersion of noble metal active components, poor catalytic activity and stability, and reduce the risk of carbon deposition , the conditions are easy to control, and the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] The present invention has no special limitation on the conditions of the mixing and contacting, for example, the conditions of the mixing and contacting may include: a temperature of 25-60° C., a time of 10-72 hours, and a pH value of 1-7. In order to be more conducive to the uniform mixing of various substances, according to a preferred embodiment of the present invention, the mixing and contacting is carried out under stirring conditions.

[0041] In the present invention, the crystallization conditions are not particularly limited. For example, the crystallization conditions may include: a temperature of 30-150°C, preferably 90-150°C; a time of 10-72h, preferably 10 -40h. According to a preferred embodiment, the crystallization is carried out by hydrothermal crystallization.

[0042] In the present invention, in the above-mentioned process of preparing the hexagonal mesoporous material, the process of obtaining the raw powder of the hexagonal mesoporous material by ...

Embodiment 1

[0083] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0084] (1) Preparation of carrier

[0085] 2g (1.4×10 -4 mol) template agent F108, 5.24g (0.03mol) of K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 (2N) at 38°C until F108 is completely dissolved;

[0086] Add 4.2g (0.02mol) of tetraethyl orthosilicate to the above solution, stir at 38°C for 15min, and stand at 38°C for 24h;

[0087] After adding 100 grams of deionized water to dilute, filter, wash and dry, the original powder mesoporous material is obtained;

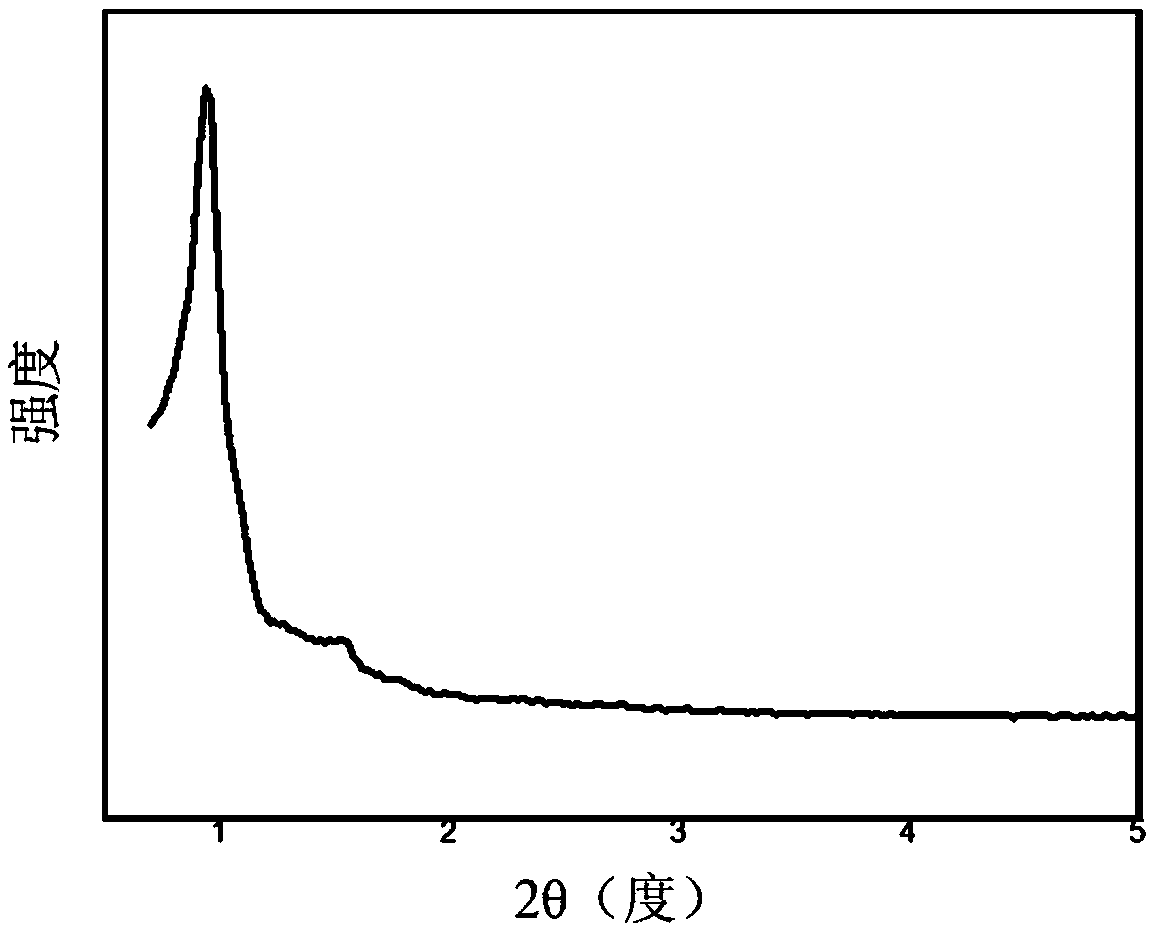

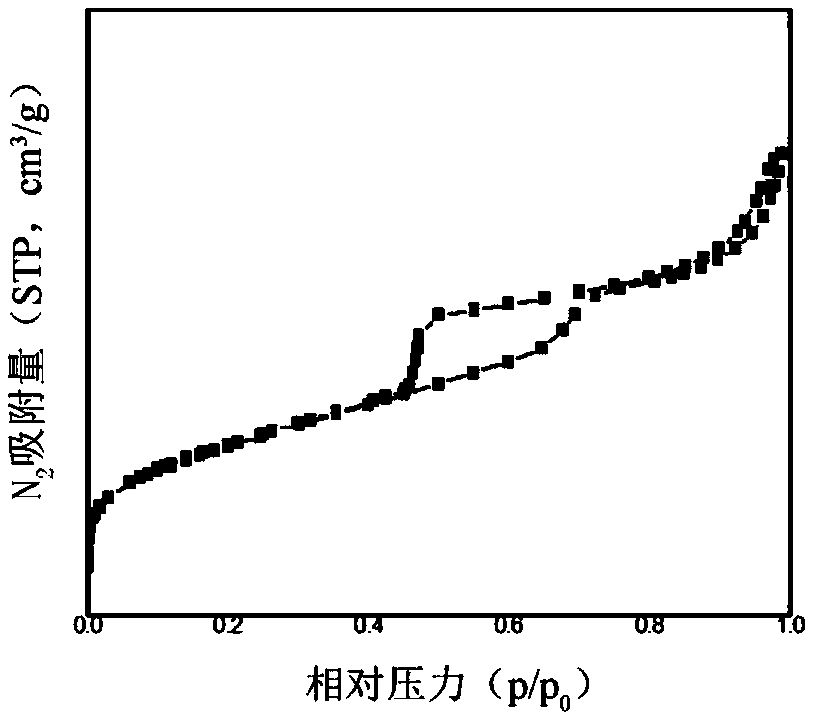

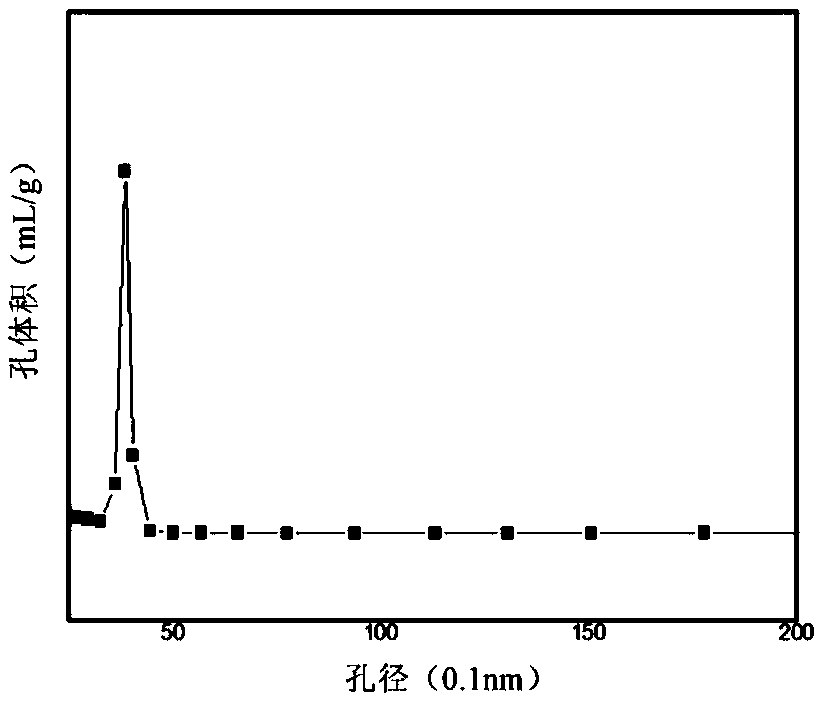

[0088] Calcining the original powder mesoporous material at 400°C for 10 hours to remove the template agent and obtain the hexagonal mesoporous material;

[0089] The hexagonal mesoporous material was calcined at 400°C for 10 hours under the protection of nitrogen (the first heat activation), the hydroxyl group and residual moisture were removed, and the hexagonal mesoporous ma...

Embodiment 2

[0108] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0109] (1) Preparation of carrier

[0110] 1.46g (1×10 -4 mol) template agent F108, 6.96g (0.04mol) of K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 (2N) at 38°C until F108 is completely dissolved;

[0111] Add 3.1g (0.015mol) of tetraethyl orthosilicate to the above solution, stir at 38°C for 15min, and stand at 38°C for 24h;

[0112] After adding 100 grams of deionized water to dilute, filter, wash and dry, the original powder mesoporous material is obtained;

[0113] Calcining the original powder mesoporous material at 400°C for 10 hours to remove the template agent and obtain the hexagonal mesoporous material;

[0114] The hexagonal mesoporous material was calcined at 400°C for 10 hours under the protection of nitrogen (the first heat activation), the hydroxyl group and residual moisture were removed, and the hexagonal mesoporous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com