A kind of ordered mesoporous titanium-aluminum composite oxide and its preparation method and application

An aluminum composite and oxide technology, applied in chemical instruments and methods, catalyst activation/preparation, organic chemistry, etc., can solve the problems of low catalytic activity and stability, large titanium oxide grain size, etc., and achieve uniform mesopore pore size Adjustable, large pore volume, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Under strong stirring at 38°C, 0.8g deionized water, 0.46g citric acid, 3.2g EO 106 PO 70 EO 106 , 2.17g of aluminum isopropoxide and 1.51g of titanium isopropoxide were completely dissolved in 25mL of absolute ethanol in turn to obtain a clear solution.

[0041] The obtained clear solution was heated to 100° C. for reflux treatment for 24 h to prepare a reaction sol. Then, the obtained reaction sol was subjected to solvent volatilization treatment at 65°C in an open state for 24 hours to obtain a solid sample.

[0042] The obtained solid sample was heated up to 550°C at a heating rate of 2°C / min and roasted for 5 hours to remove the organic template existing in the mesoporous channels, and prepare an ordered mesoporous titanium-aluminum composite oxide sample.

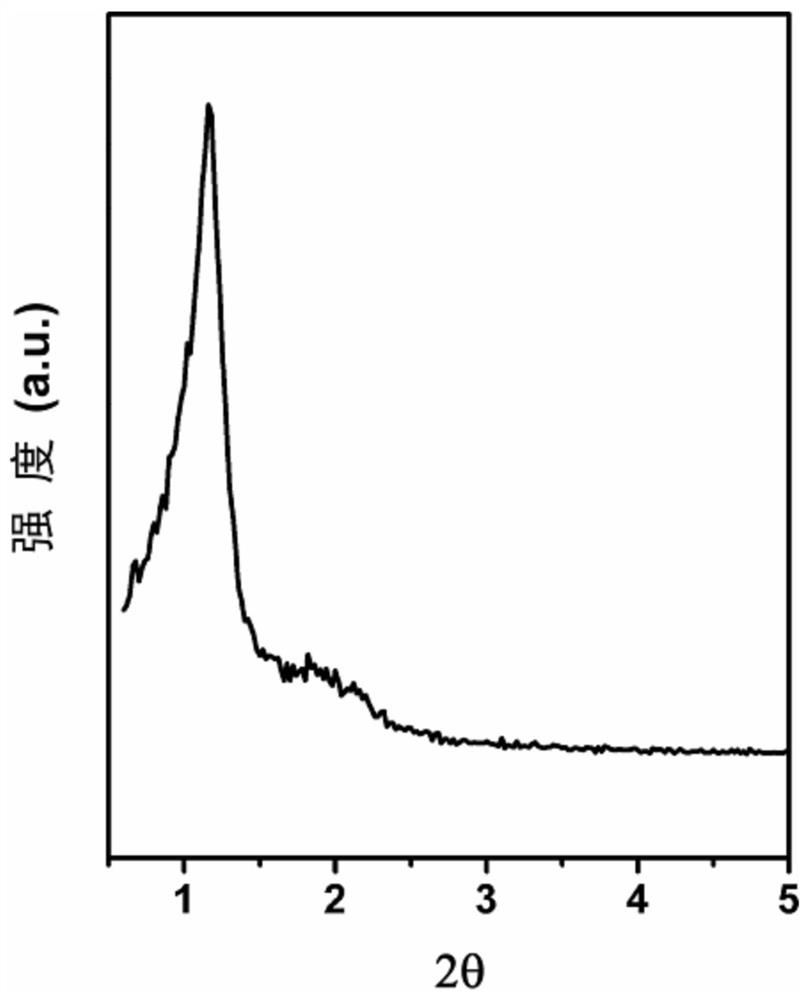

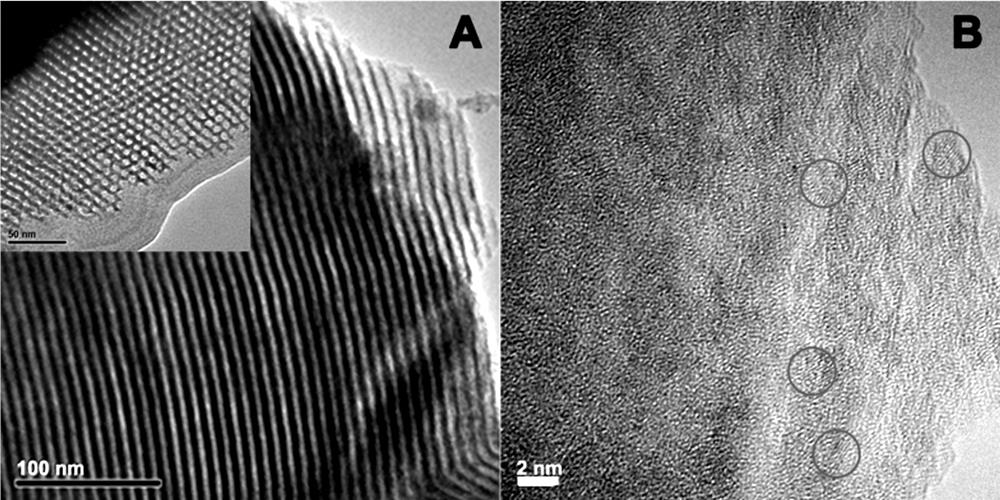

[0043] From figure 1 It can be seen from the XRD spectrum of the sample that the sample shows a strong diffraction peak and two relatively weak diffraction peaks at 2θ=1.16, 1.89 and 2.20°, respectively. T...

Embodiment 2

[0055] Under vigorous stirring at 25°C, 1.2g deionized water, 0.60g glacial acetic acid, 2.8g EO 30 PO 70 EO 30 , 2.17g of aluminum isopropoxide and 1.51g of titanium isopropoxide were completely dissolved in 30mL of absolute ethanol in sequence to obtain a clear solution.

[0056] The obtained clear solution was heated to 90° C. for reflux treatment for 24 h to prepare a reaction sol. Then, the obtained reaction sol was subjected to solvent volatilization treatment at 45° C. for 24 hours in an open state to obtain a solid sample.

[0057] The obtained solid sample was heated to 550°C at a heating rate of 5°C / min and roasted for 5h to remove the organic template existing in the mesoporous channels, and to prepare ordered mesoporous titanium-aluminum composite oxide samples.

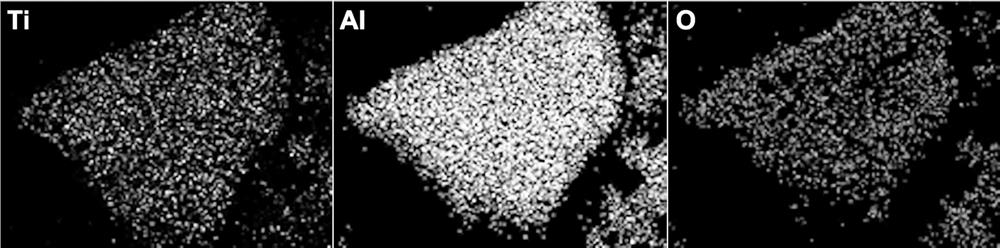

[0058] XRD, TEM, EDX and N 2 Adsorption-desorption and other characterization results confirmed that the prepared sample has an ordered two-dimensional hexagonal phase mesoporous channel structure, an...

Embodiment 3

[0061] Under vigorous stirring at 35°C, 1.5g deionized water, 0.60g tartaric acid, 3.5g EO 17 PO 60 EO 17 , 2.35 g of aluminum isopropoxide and 1.20 g of methyl titanate were completely dissolved in 30 mL of absolute ethanol in sequence to obtain a clear solution.

[0062] The obtained clear solution was heated to 80° C. for reflux treatment for 24 h to prepare a reaction sol. Then, the obtained reaction sol was subjected to solvent volatilization treatment at 60°C in an open state for 24 hours to obtain a solid sample.

[0063] The obtained solid sample was heated up to 550°C at a heating rate of 1°C / min and roasted for 5 hours to remove the organic template existing in the mesoporous channels, and prepare an ordered mesoporous titanium-aluminum composite oxide sample.

[0064] XRD, TEM, EDX and N 2 Adsorption-desorption and other characterization results confirmed that the prepared sample has an ordered two-dimensional hexagonal phase mesoporous channel structure, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com