A kind of alkane dehydrogenation catalyst containing mixed Pt crystals and preparation method thereof

An alkane dehydrogenation and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. efficiency, good regeneration stability, good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

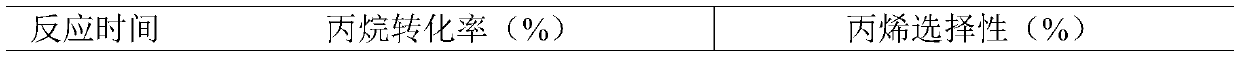

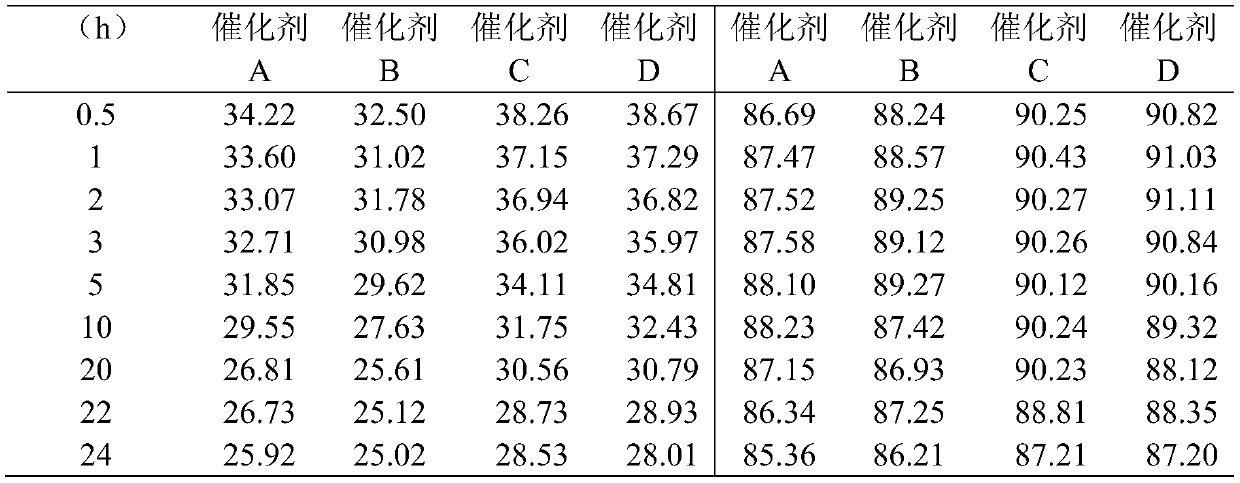

[0024] Catalyst C: Catalyst C is prepared by co-impregnating Pt and Sn into the interior of the carrier first, and then co-impregnating Pt and K on the surface of the carrier. This preparation method makes the catalyst contain two crystals of Pt-Sn and Pt-K, Pt: 0.3w %, Sn: 0.6w% and K: 0.9w%.

[0025] (1) Carrier preparation is the same as the carrier preparation method in (1) of Comparative Example 1.

[0026] (2) 1.5ml concentration of 0.2M chloroplatinic acid aqueous solution and 7.4ml concentration of 0.18M stannous chloride aqueous acid solution are mixed evenly, according to the saturated water absorption of the carrier used, add hydrochloric acid and Water makes the hydrochloric acid concentration of the impregnating solution finally prepared to be 1.5M, the volume of the impregnating solution is 22ml, shake well and impregnate on a 26.66g carrier, place at room temperature for 12 hours, dry at 120°C for 5 hours, and bake at 550°C After 4 hours, a Pt-Sn-containing car...

Embodiment 2

[0029] Catalyst D: Catalyst D is prepared by co-impregnating Pt and Sn into the interior of the carrier first, and then co-impregnating Pt and Rb onto the surface of the carrier. This preparation method makes the catalyst contain two crystals of Pt-Sn and Pt-Rb, Pt: 0.3w %, Sn: 0.6w%, and Rb: 0.9w%.

[0030] (1) Carrier preparation is the same as the carrier preparation method in (1) of Comparative Example 1.

[0031] (2) 1.5ml concentration of 0.2M chloroplatinic acid aqueous solution and 7.4ml concentration of 0.18M stannous chloride aqueous acid solution are mixed evenly, according to the saturated water absorption of the carrier used, add hydrochloric acid and Water makes the hydrochloric acid concentration of the impregnating solution finally prepared to be 1.5M, the volume of the impregnating solution is 22ml, shake well and impregnate on a 26.66g carrier, place at room temperature for 12 hours, dry at 120°C for 5 hours, and bake at 550°C After 4 hours, a Pt-Sn-containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com