A kind of alkane dehydrogenation exothermic auxiliary agent and its preparation method and use method

A technology of alkane dehydrogenation and exothermic additives, which is applied in the field of alkane dehydrogenation, can solve problems that are rarely seen in reports, achieve good selectivity, high yield, improve severity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

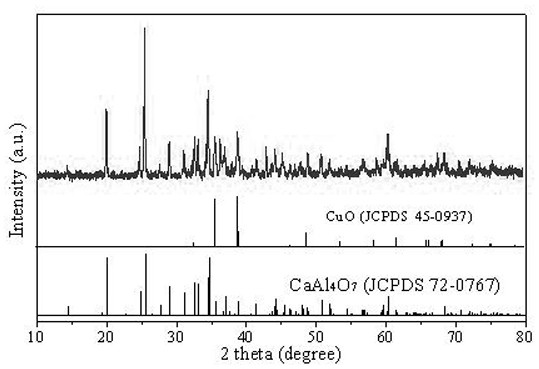

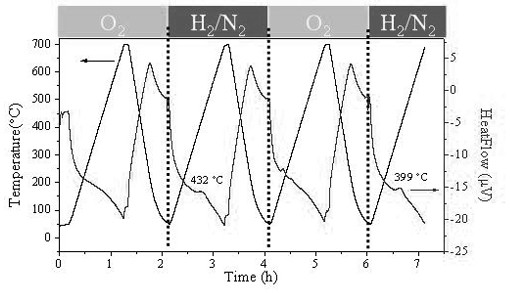

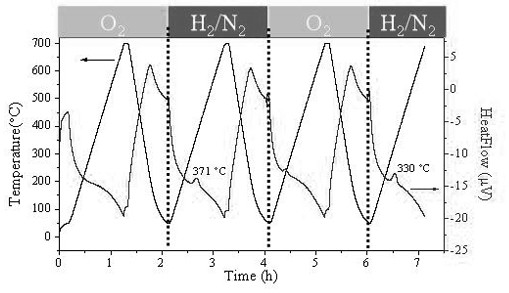

[0038] Example 1: The pseudo-boehmite, calcium hydroxide, and copper oxide were stirred evenly, and then slowly added water and mixed evenly, and the material was prepared and formed by the extrusion molding method. The shaped mass was then dried at 60°C for 12 hours. Then, the dried material was calcined at a high temperature of 1200° C. for 4 hours to obtain the desired exothermic auxiliary. The elemental composition of the sample is shown in Table 1, the specific surface area, specific heat capacity and heat of water absorption and heat release are shown in Table 2, and the X-ray diffraction pattern is shown in Table 2. figure 1 , DSC curve see image 3 .

[0039] This sample is used in propane dehydrogenation, and the exothermic aid for alkane dehydrogenation is added to the dehydrogenation catalyst (K 2 O / Cr 2 O 3 / γ-Al 2 O 3 Catalyst with 21.3wt% Cr in the catalyst 2 O 3 ), at a reaction temperature of 600 °C, a reaction pressure of 0.5 MPa, and a volumetric spa...

Embodiment 2

[0040] Example 2: The pseudo-boehmite, calcium oxide, and copper hydroxide were stirred evenly, and then dilute nitric acid with a solubility of 1 wt% was slowly added to mix evenly, and the material was prepared and formed by extrusion molding. The shaped mass was then dried at 60°C for 24 hours. Then, the dried material was calcined at a high temperature of 1000° C. for 3 hours to obtain the desired exothermic auxiliary. The elemental composition of the sample is shown in Table 1, and the specific surface area is shown in Table 2.

[0041] This sample is used in butane dehydrogenation, and the exothermic aid for alkane dehydrogenation is added to the dehydrogenation catalyst (K 2 O / Cr 2 O 3 / γ-Al 2 O 3 Catalyst with 21.3wt% Cr in the catalyst 2 O 3 ), at a reaction temperature of 550°C, a reaction pressure of 0.05MPa, and a volumetric space velocity (LHSV) for 50 hours -1 The contact reaction is carried out under the conditions of 100 °C, the molar ratio of hydrogen ...

Embodiment 3

[0042] Example 3: The pseudo-boehmite, calcium hydroxide, and cuprous oxide were stirred uniformly, and then water was slowly added to mix uniformly, and the material was prepared and formed by the extrusion molding method. The shaped mass was then dried at 80°C for 7 hours. After that, the dried material was calcined at a high temperature of 1300° C. for 6 hours to obtain the desired exothermic auxiliary. The elemental composition of the sample is shown in Table 1, and the specific surface area is shown in Table 2.

[0043] This sample is used in ethane dehydrogenation, and the exothermic aid for alkane dehydrogenation is added to the dehydrogenation catalyst (K 2 O / Cr 2 O 3 / γ-Al 2 O 3 Catalyst with 21.3wt% Cr in the catalyst 2 O 3 ), at a reaction temperature of 700°C, a reaction pressure of 1MPa, and a volumetric space velocity (LHSV) of 0.1 hour -1 The contact reaction is carried out under the conditions of , the molar ratio of hydrogen and ethane is 3, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com