Method for activating platinum-containing light alkane dehydrogenation catalyst

A dehydrogenation catalyst and low-carbon alkanes technology, which is applied in the direction of catalyst activation/preparation, carbon compound catalysts, catalysts, etc., can solve the problem of low conversion selectivity of platinum-containing low-carbon alkane dehydrogenation catalysts, and achieve the goal of inhibiting carbon deposition The effect of forming, promoting dehydrogenation activity, and stabilizing catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

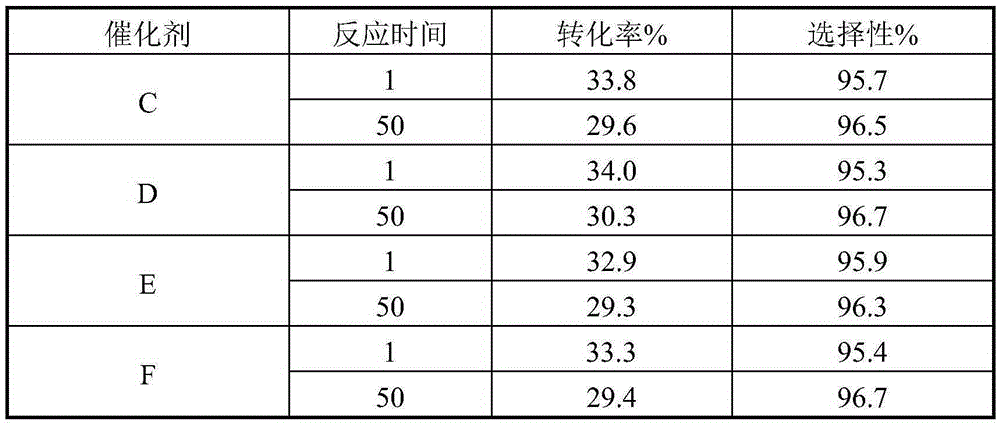

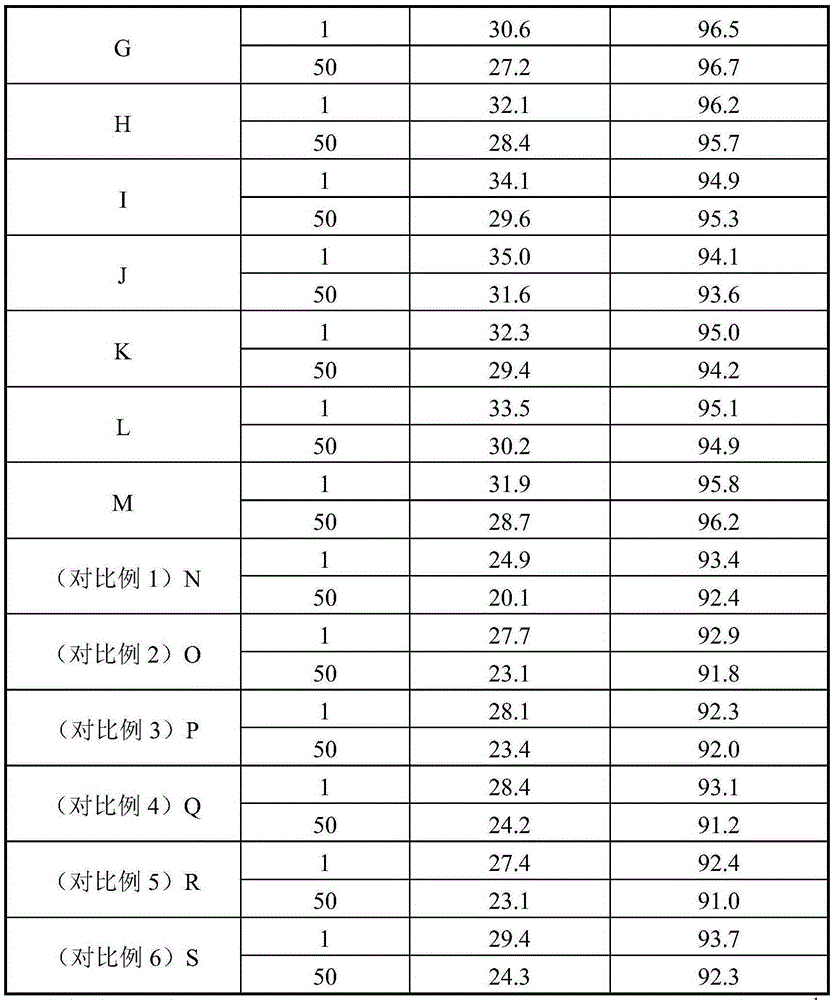

[0023] 5.0 grams of catalyst precursor A was activated on a continuous flow quartz tube reactor miniature catalytic reaction device. Under air atmosphere, catalyst precursor A was treated at 250° C. for 1 hour, and then at 550° C. for 6 hours; Carrier gas containing 5mol% O 2 The gas flow was treated at 600°C for 4 hours, and finally with 3ppm H 2 S of H 2 The catalyst was treated with air flow at 600°C for 2 hours to obtain activated catalyst C.

Embodiment 2

[0025] 5.0 grams of catalyst precursor A was activated on a continuous flow quartz tube reactor miniature catalytic reaction device. Under air atmosphere, catalyst precursor A was treated at 250° C. for 2 hours, and then at 600° C. for 4 hours; Carrier gas containing 5mol% O 2 The gas flow was treated at 600°C for 4 hours, and finally with 3ppm H 2 S of H 2 The catalyst was treated with air flow at 600°C for 2 hours to obtain activated catalyst D.

Embodiment 3

[0027] 5.0 grams of catalyst precursor A was activated on a continuous flow quartz tube reactor miniature catalytic reaction device. Under air atmosphere, catalyst precursor A was treated at 250° C. for 1 hour, and then at 550° C. for 8 hours; Carrier gas containing 5mol% O 2 The gas flow was treated at 600°C for 4 hours, and finally with 3ppm H 2 S of H 2 The catalyst was treated with air flow at 600°C for 2 hours to obtain activated catalyst E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com