Isobutane dehydrogenation catalyst, preparation method thereof and method for preparing isobutene through isobutane dehydrogenation

A dehydrogenation catalyst, isobutane technology, applied in catalyst activation/preparation, catalyst, molecular sieve catalyst, etc., can solve problems such as poor catalytic activity and stability, uneven dispersion of precious metal active components, and achieve conditions that are easy to control and reduce The risk of carbon deposition and the effect of reducing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] Preferably, in step (a), the mixing and contacting conditions include: a temperature of 25-60°C, and a time of 0.1-48h. In order to be more conducive to the uniform mixing of various substances, according to a preferred embodiment of the present invention, the mixing and contacting is carried out under stirring conditions.

[0039] In the present invention, the consumption of described templating agent, nonionic surfactant and industrial sodium silicate can change in a wide range, for example described template agent, described nonionic surfactant and described industrial sodium silicate The molar ratio of the amount used is 0.1-0.6:0.1-0.5:1; more preferably, the molar ratio of the template agent, the nonionic surfactant and the industrial sodium silicate is 0.1-0.3:0.1-0.3: 1.

[0040] In the present invention, the industrial sodium silicate refers to the industrial sodium silicate having the parameters specified in GB / T 4209-2008.

[0041] Preferably, in the step (b)...

Embodiment 1

[0073] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

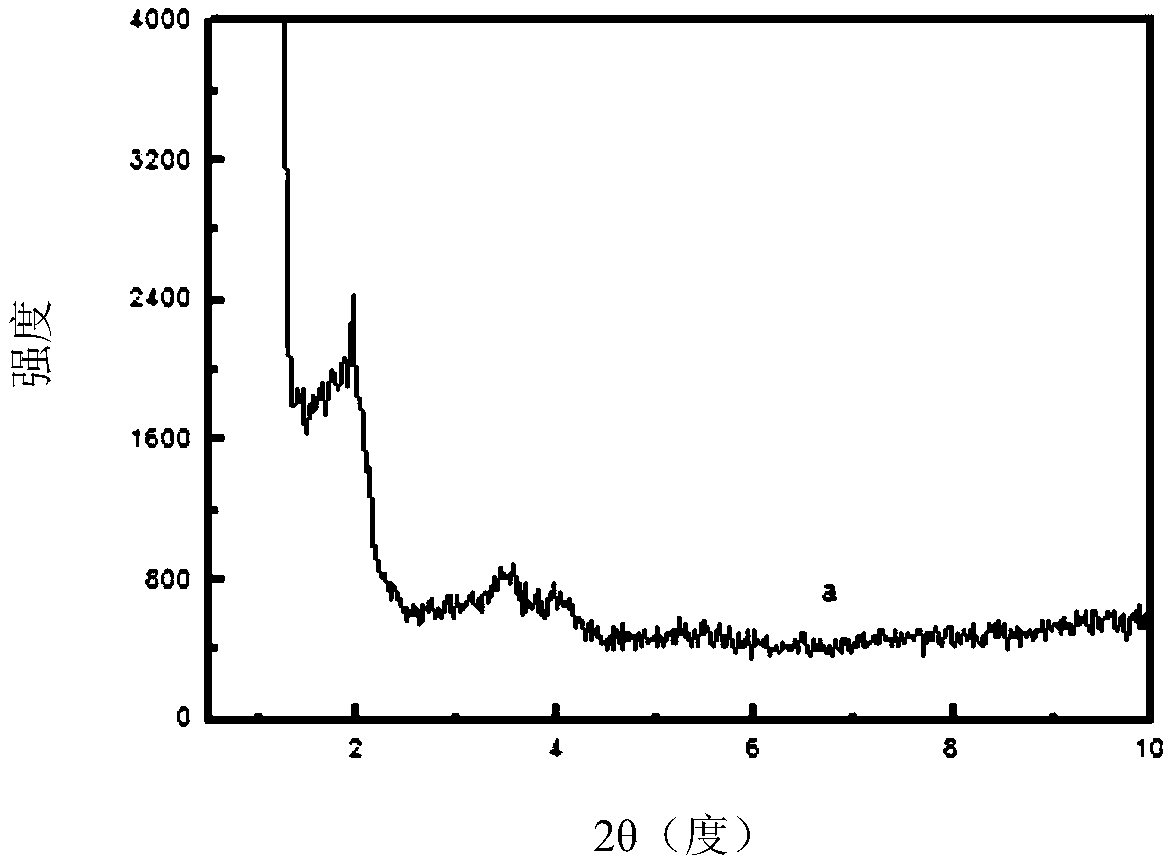

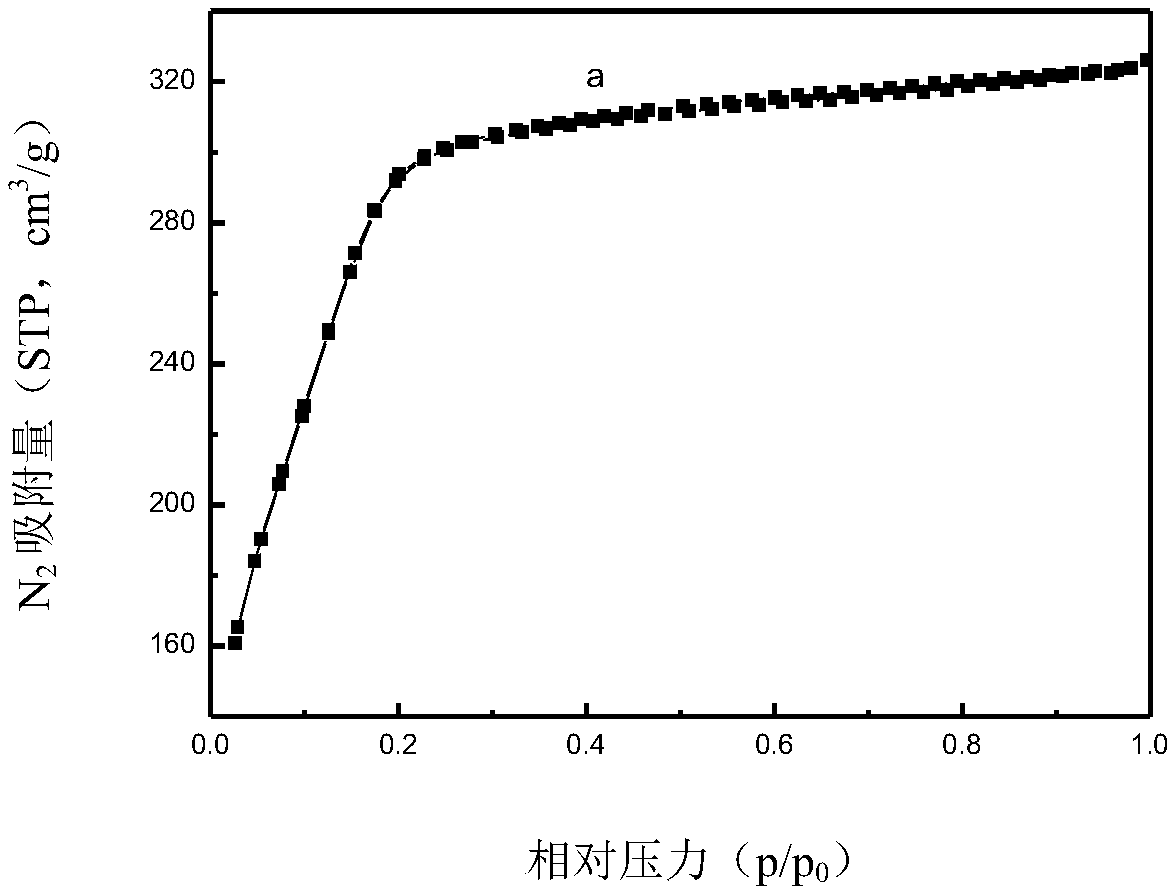

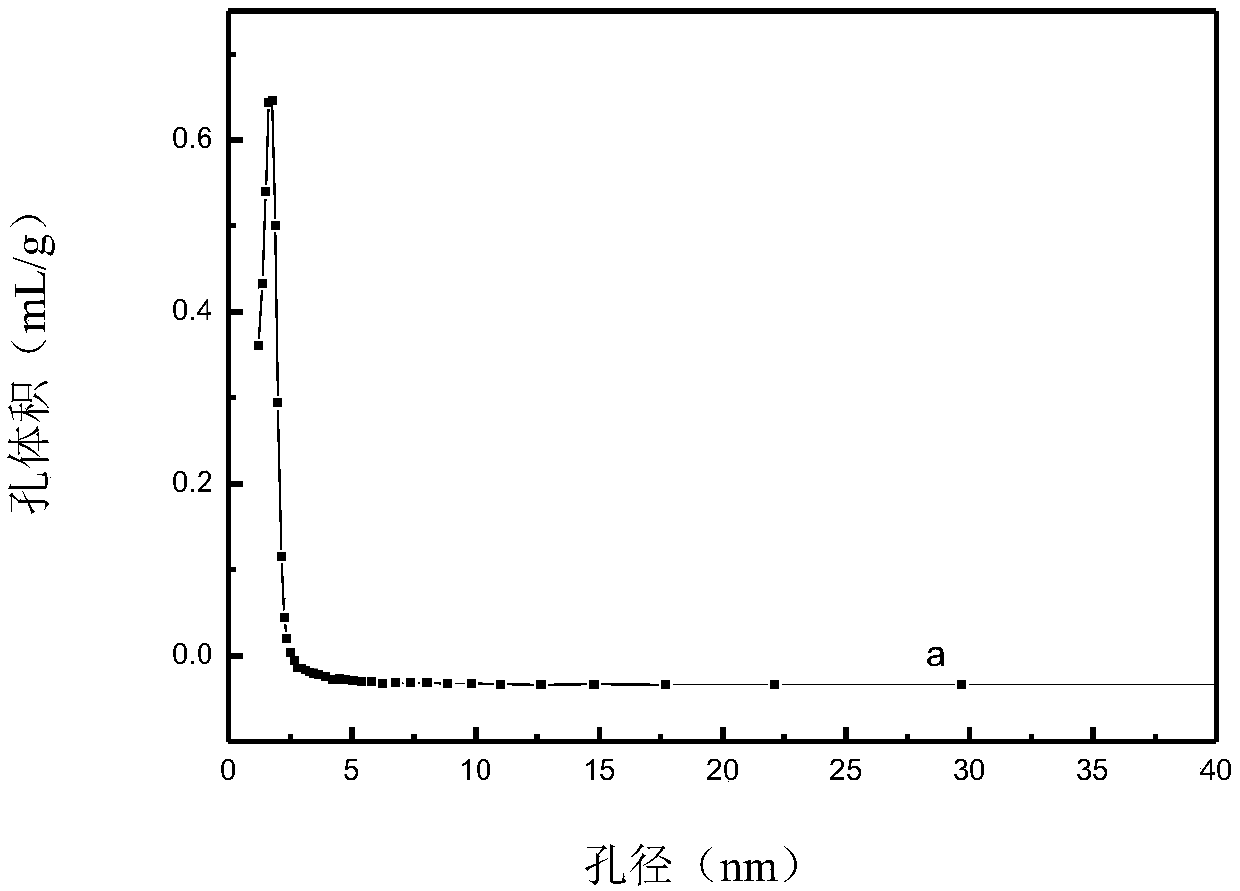

[0074] (1) Preparation of carrier

[0075] Add 1.5g (0.004mol) of template agent CTAB (cetyltrimethylammonium bromide) and 1.5ml (0.002mol) of polyethylene glycol octylphenyl ether (Triton-X100) to 37 In the solution of weight % hydrochloric acid (29.6g) and water (75g), stir until CTAB dissolves completely at 40 ℃; Then add 4.6g industrial sodium silicate in the above-mentioned solution, stir at 40 ℃ for 15 minutes, then The obtained solution was transferred to a polytetrafluoroethylene-lined reactor, crystallized at 120°C for 24 hours, then filtered and washed with deionized water for 4 times, then suction filtered and dried to obtain the original powder of the mesoporous material ; Calcining the raw powder of the mesoporous material at 600° C. for 24 hours to remove the template agent to obtain spherical mesoporous molecular sieve material C1.

[0076] (2) Prepar...

Embodiment 2

[0097] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0098] (1) Preparation of carrier

[0099] Add 0.75g (0.002mol) of template agent CTAB (cetyltrimethylammonium bromide) and 3ml (0.004mol) of polyethylene glycol octylphenyl ether (Triton-X100) to 37 wt. % hydrochloric acid (29.6g) and water (75g) solution, stirred at 40 ° C until CTAB was completely dissolved; then added 4.35 g of industrial sodium silicate to the above solution, stirred at 40 ° C for 15 minutes, and then The obtained solution was transferred to a polytetrafluoroethylene-lined reaction kettle, crystallized at 100°C for 24 hours, then filtered and washed with deionized water for 4 times, then suction filtered and dried to obtain the original powder of the mesoporous material; The raw powder of the mesoporous material was calcined at 600° C. for 24 hours to remove the template agent to obtain spherical mesoporous molecular sieve material C2.

[0100]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com