Patents

Literature

38results about How to "Reduce the risk of carbon accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

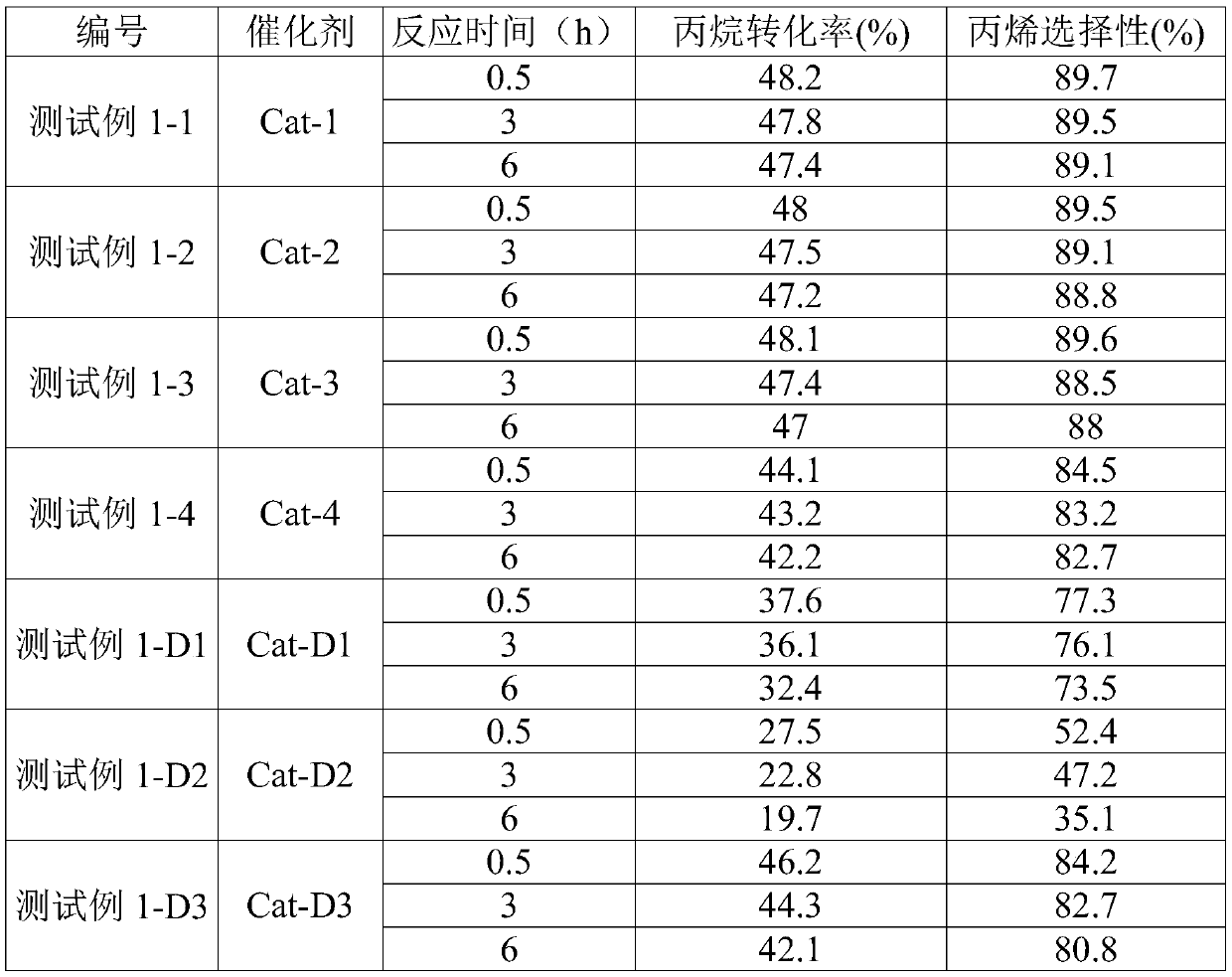

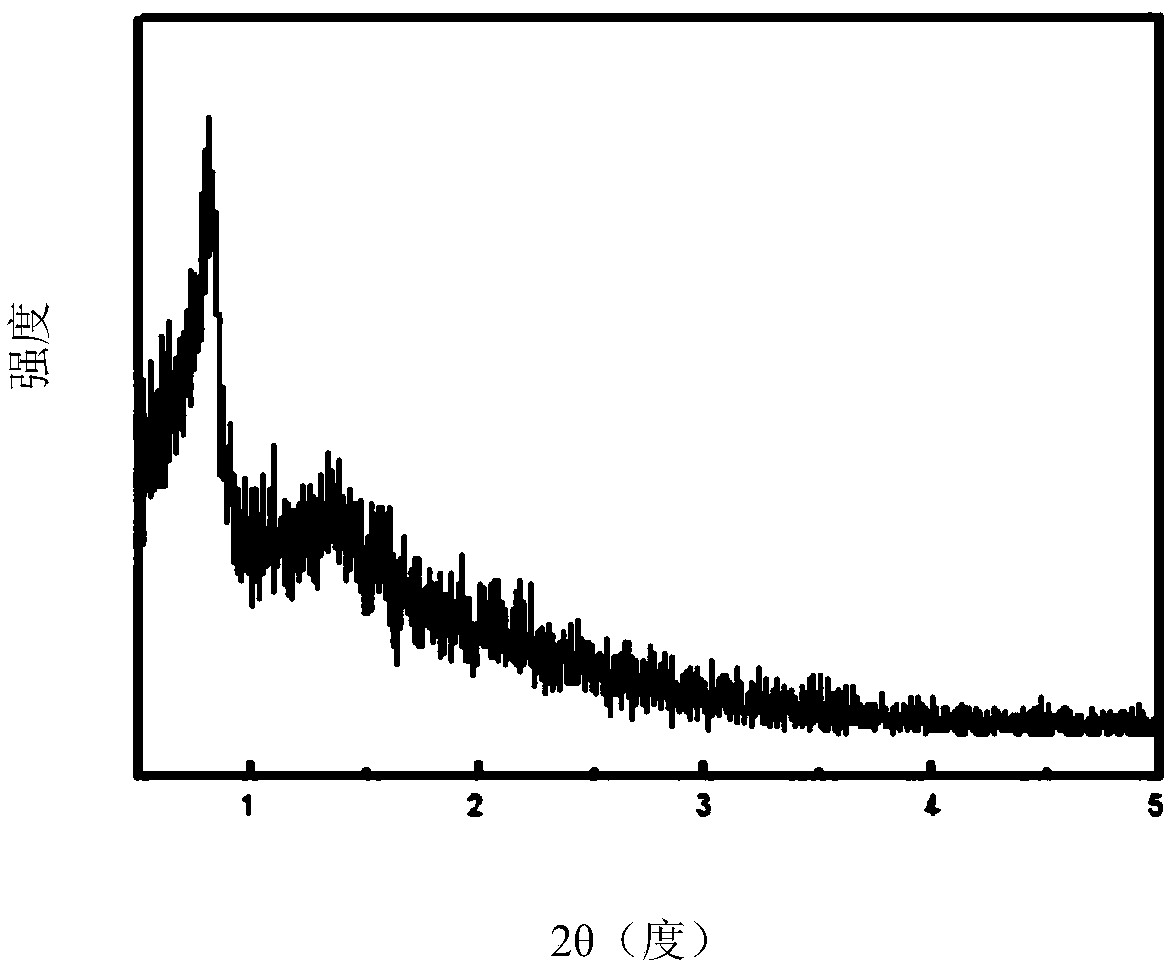

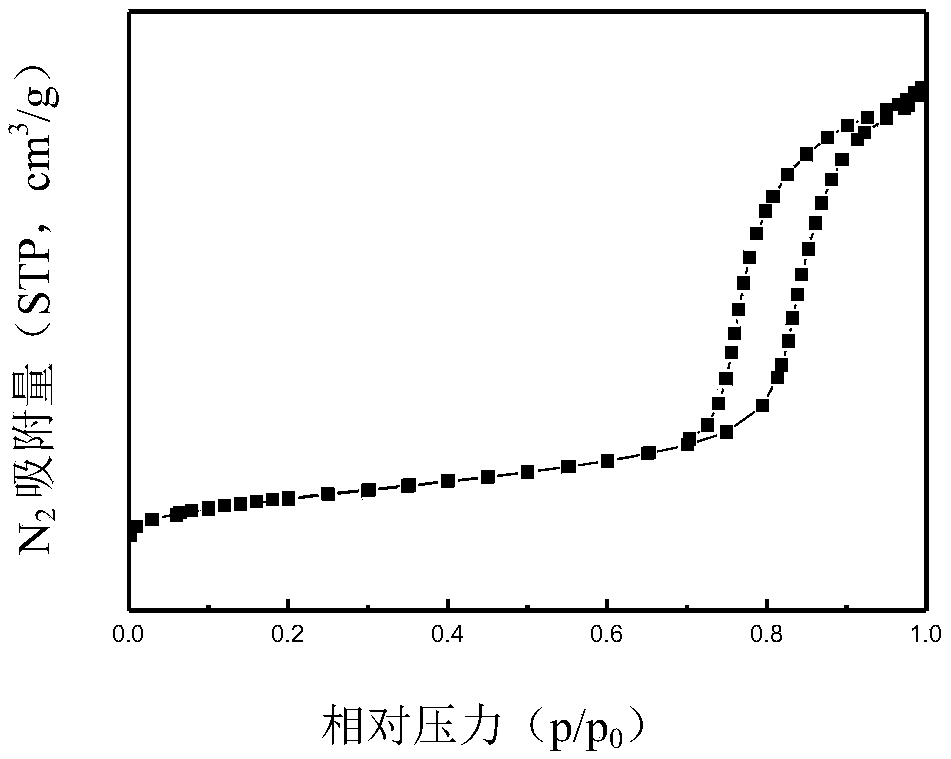

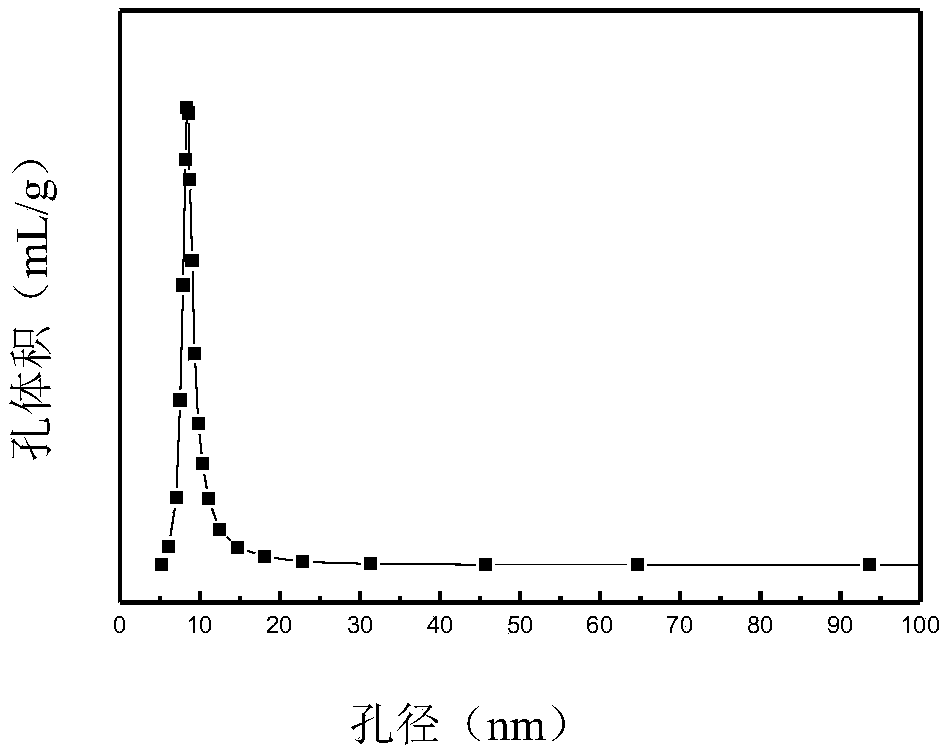

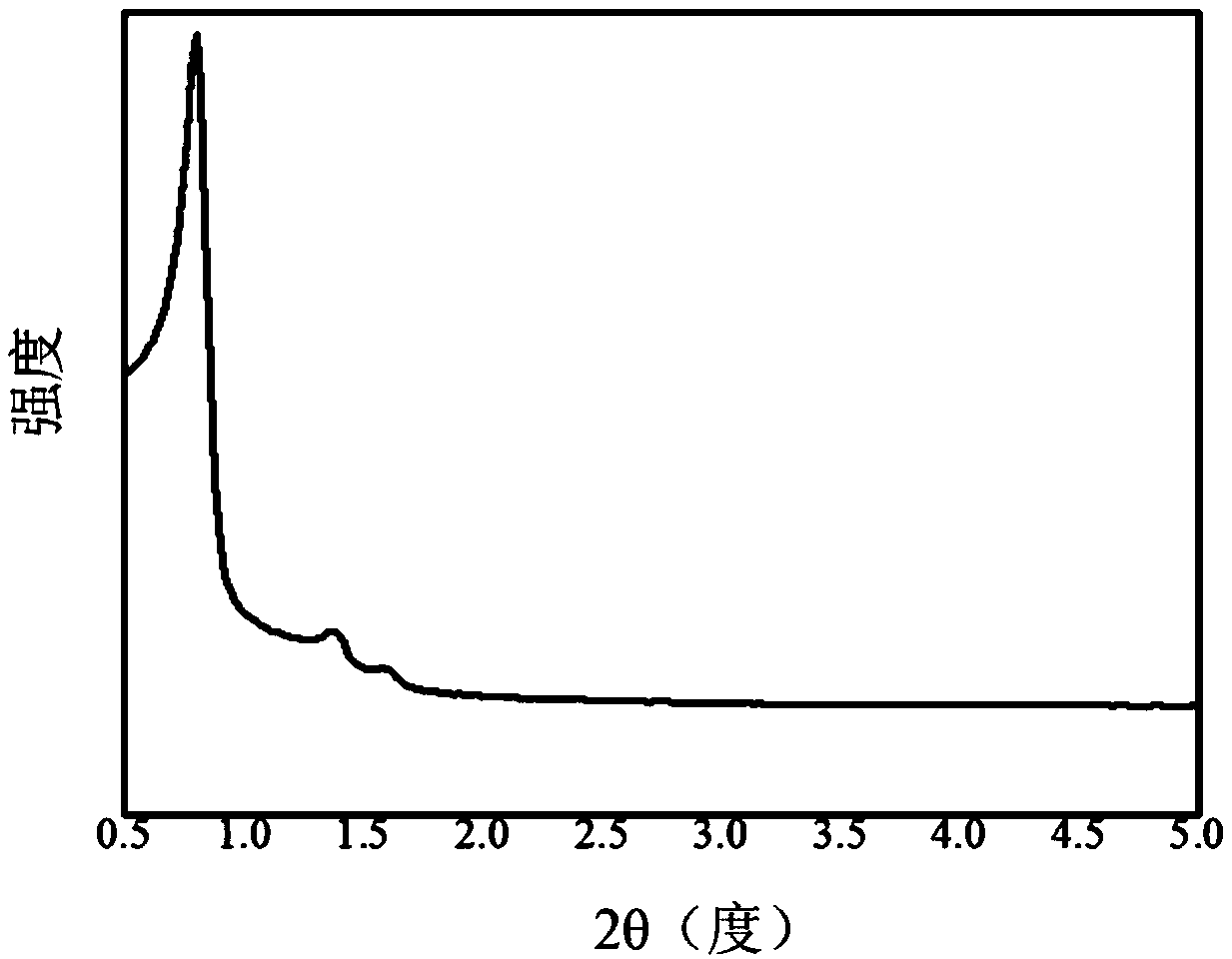

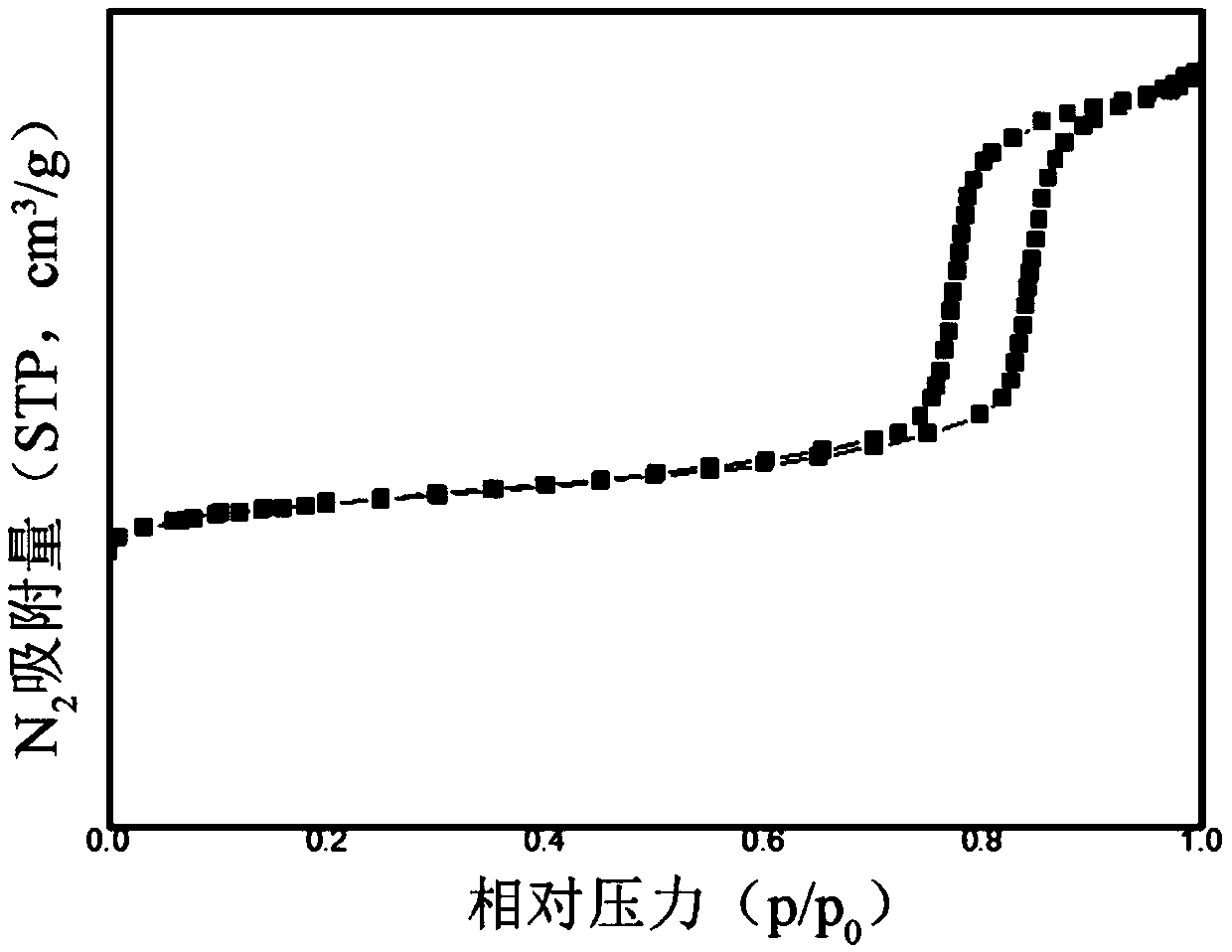

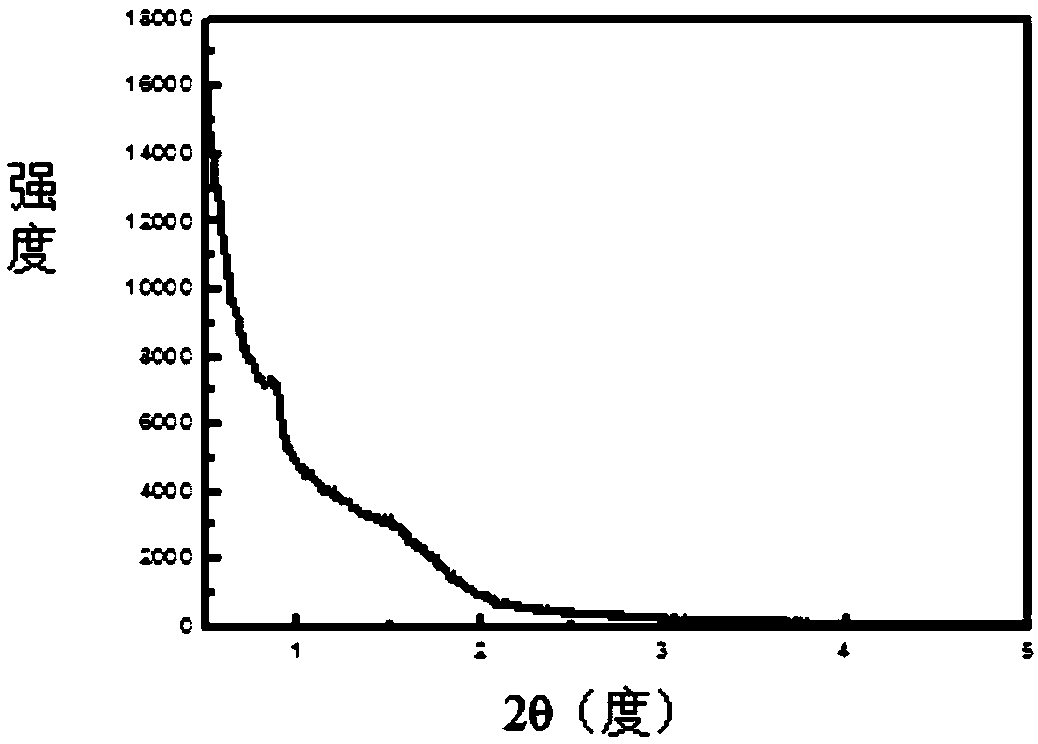

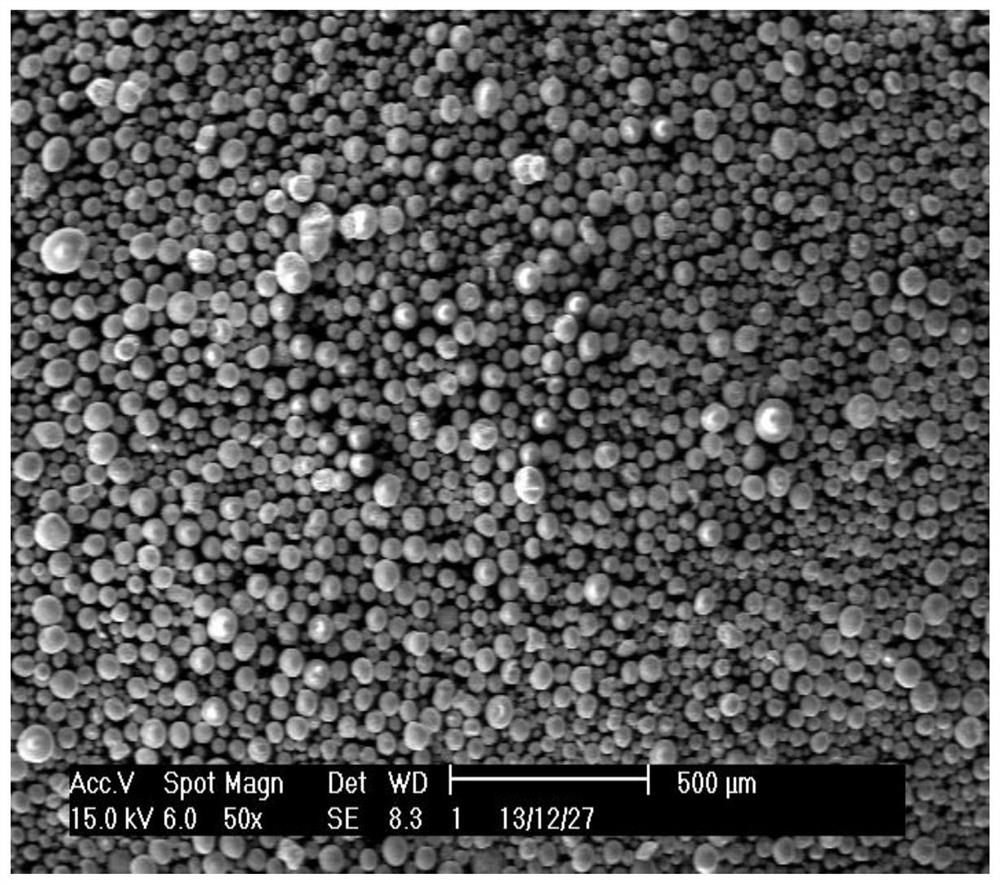

Non-noble metal propane dehydrogenation catalyst taking rod-like mesoporous molecular sieve as carrier, preparation method and applications thereof

InactiveCN111135853AReduce manufacturing costReduce the risk of carbon accumulationMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

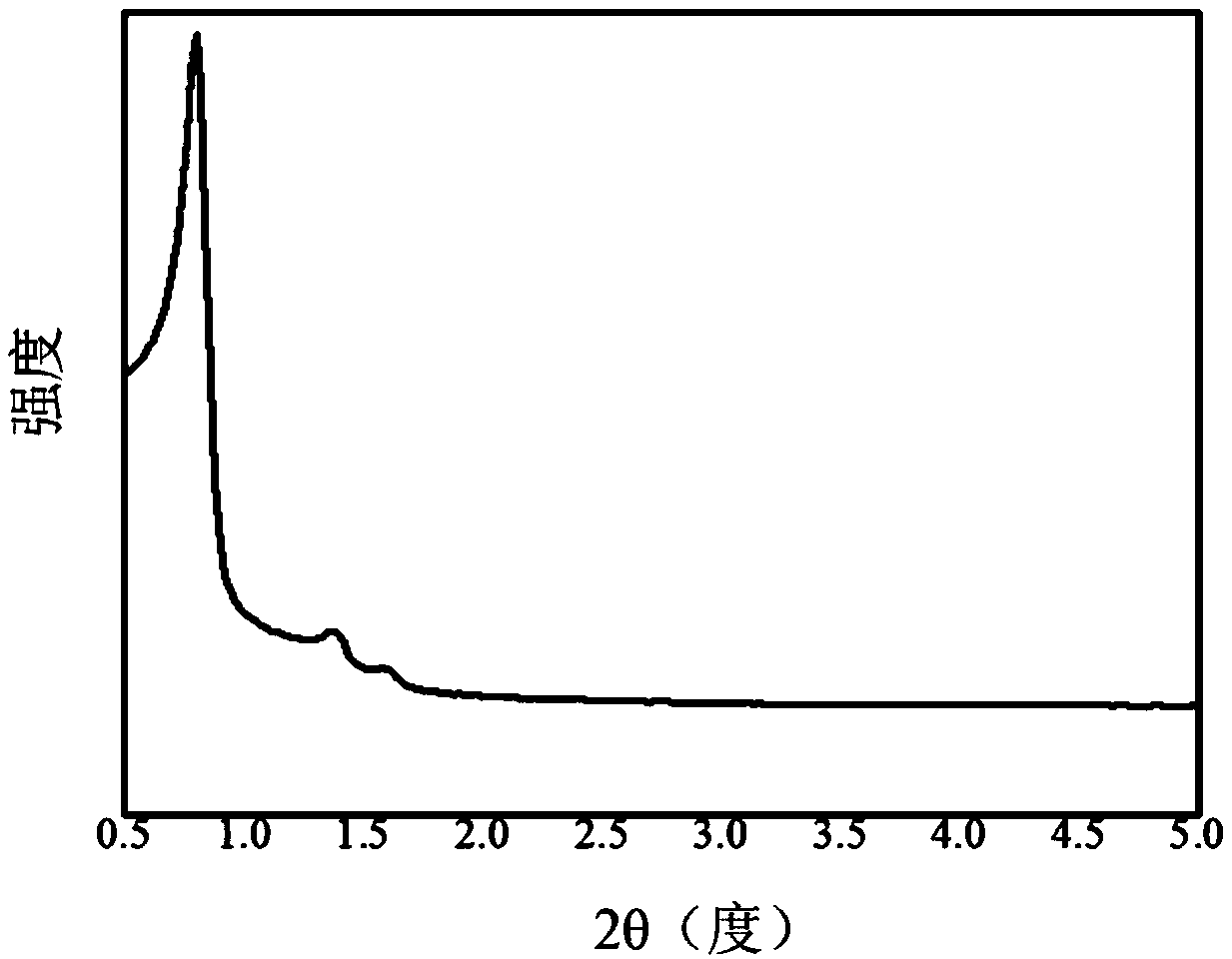

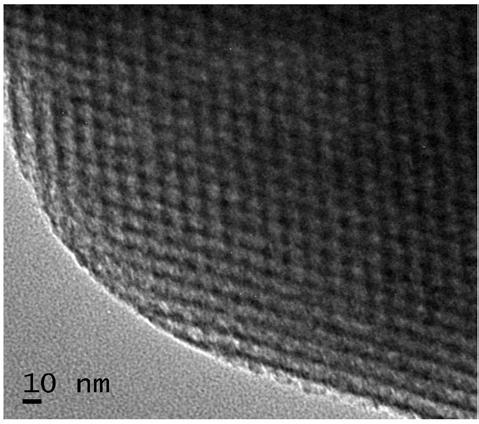

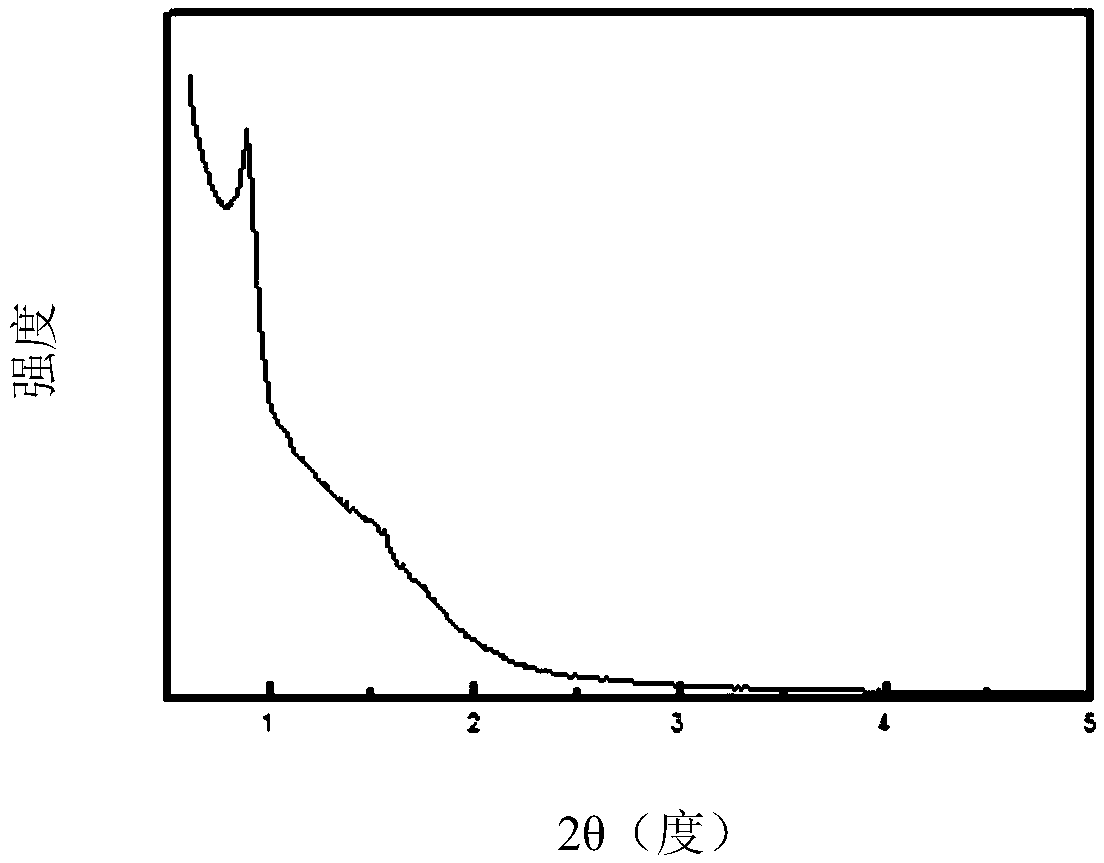

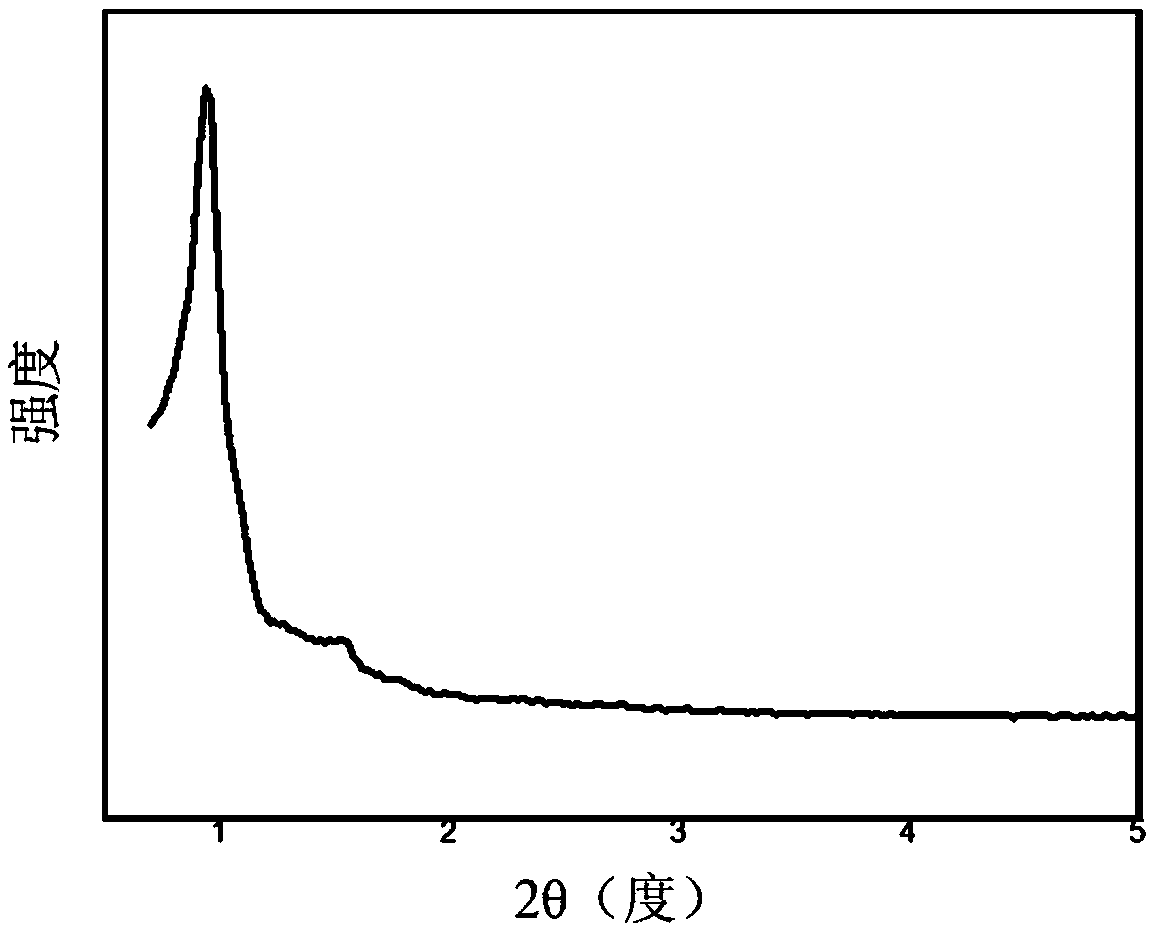

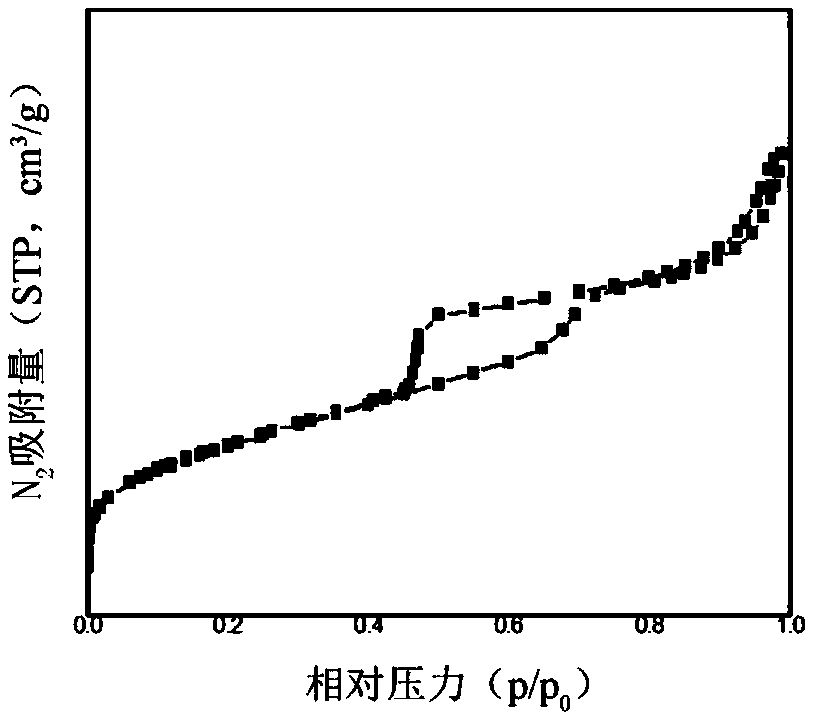

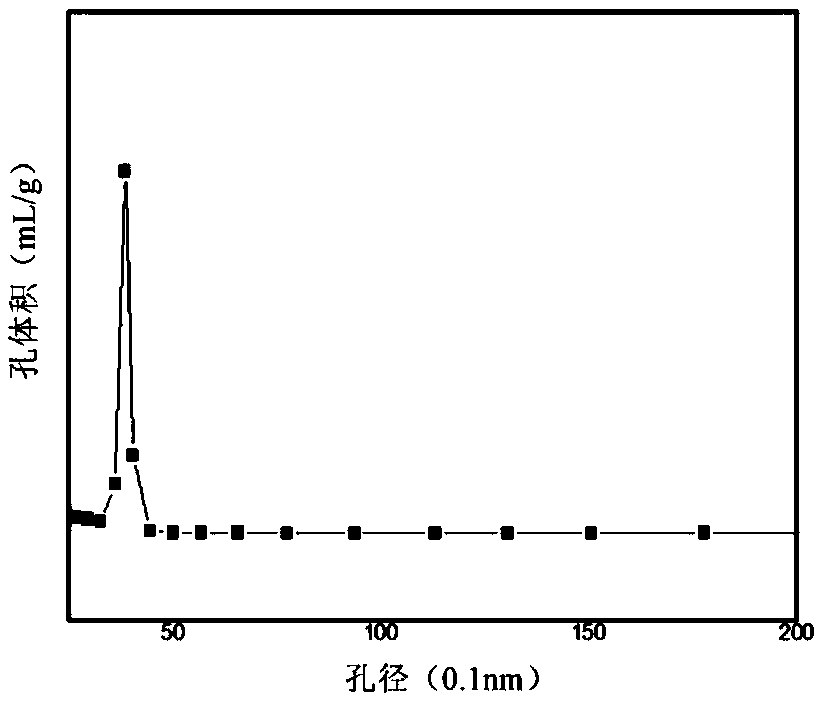

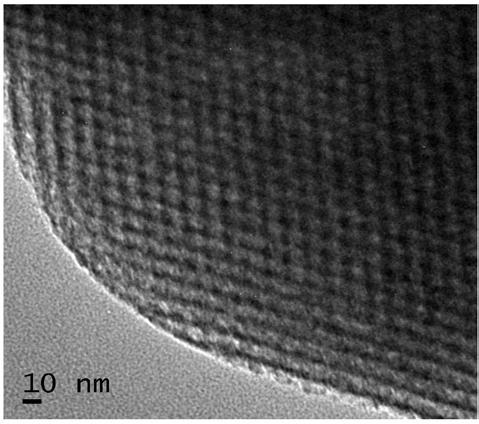

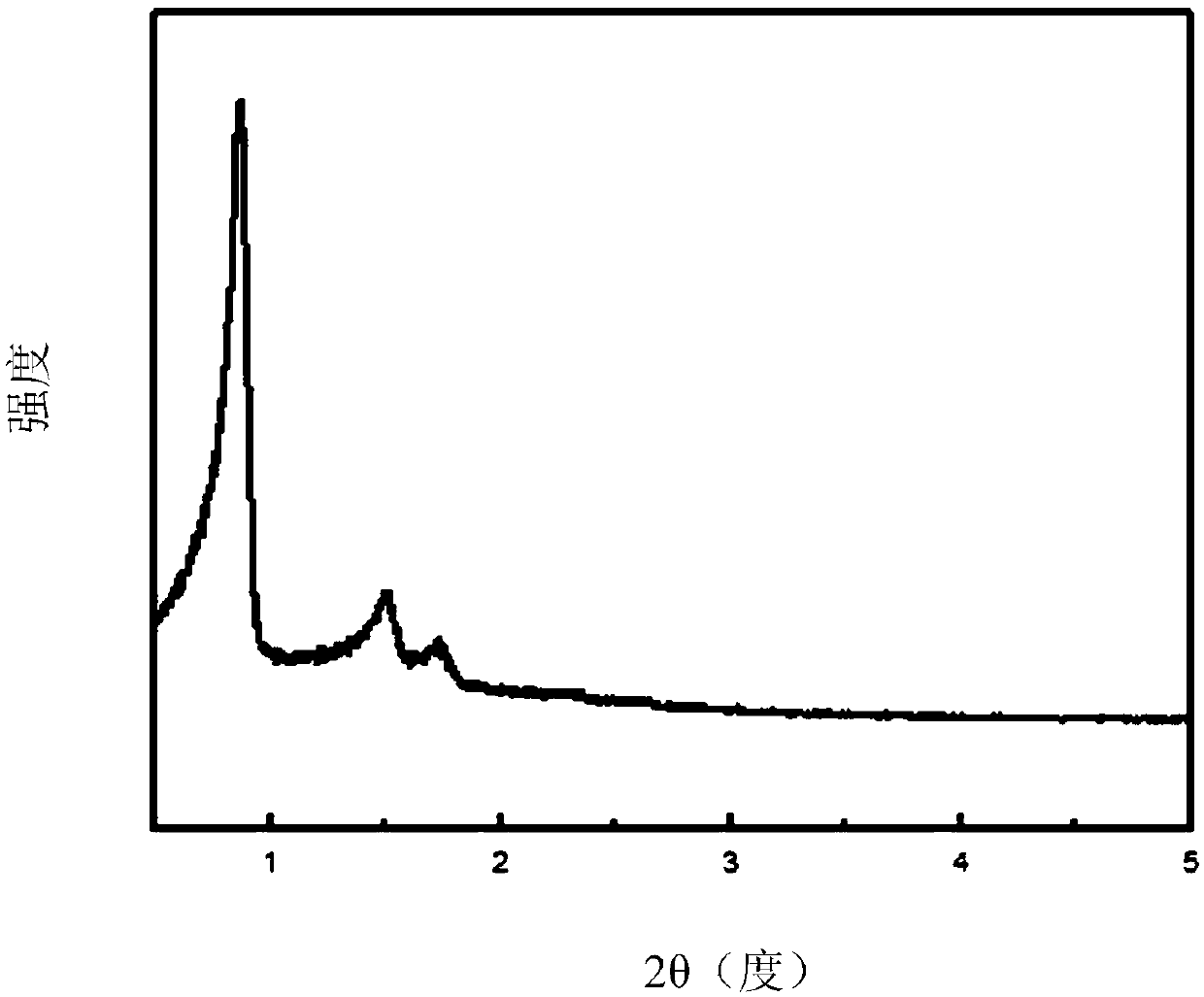

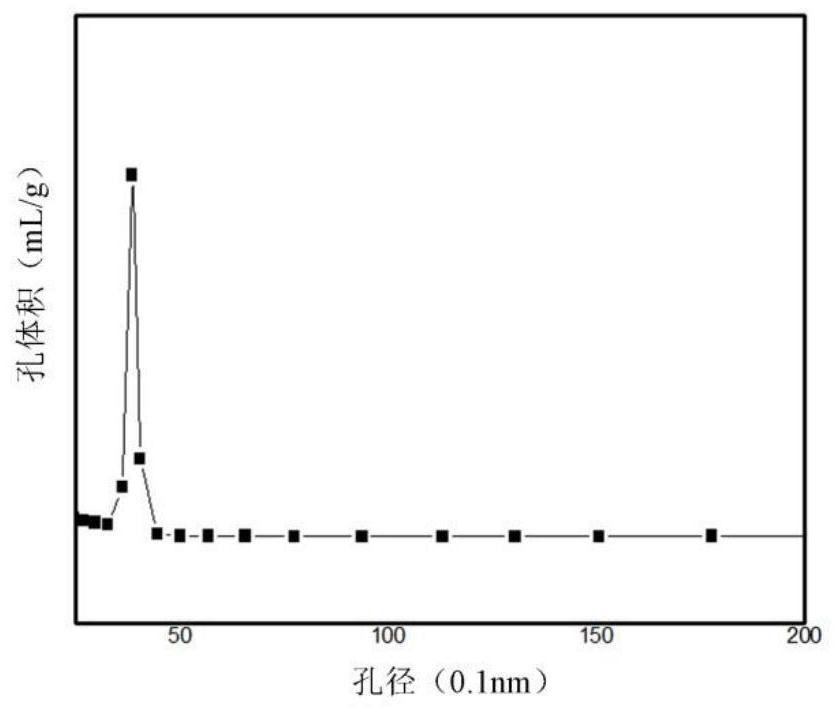

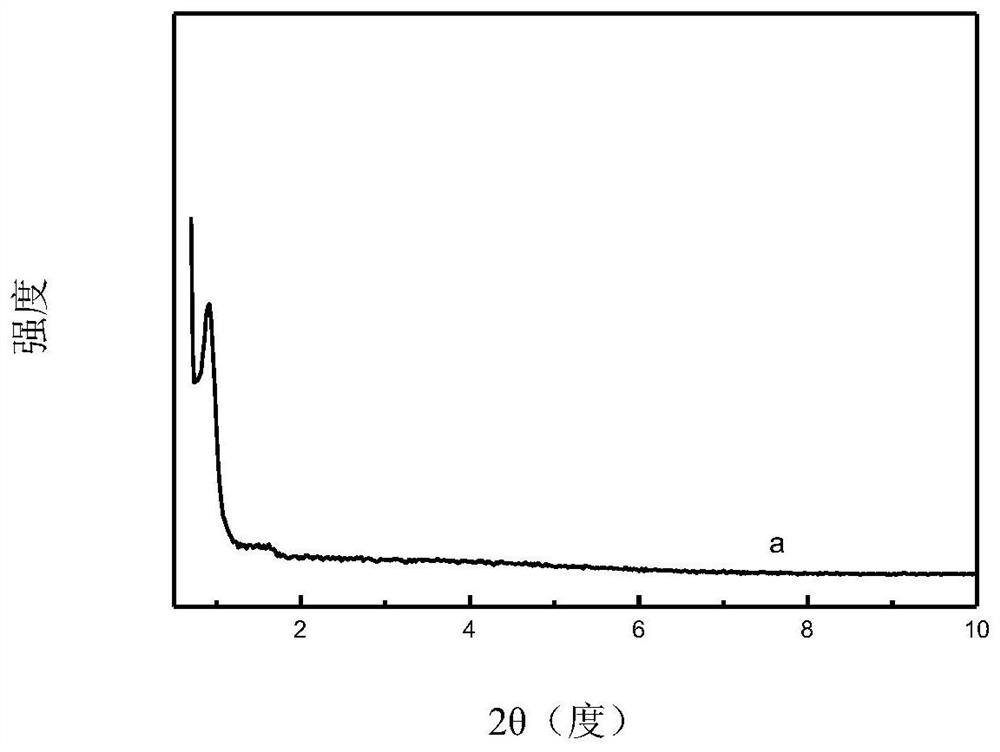

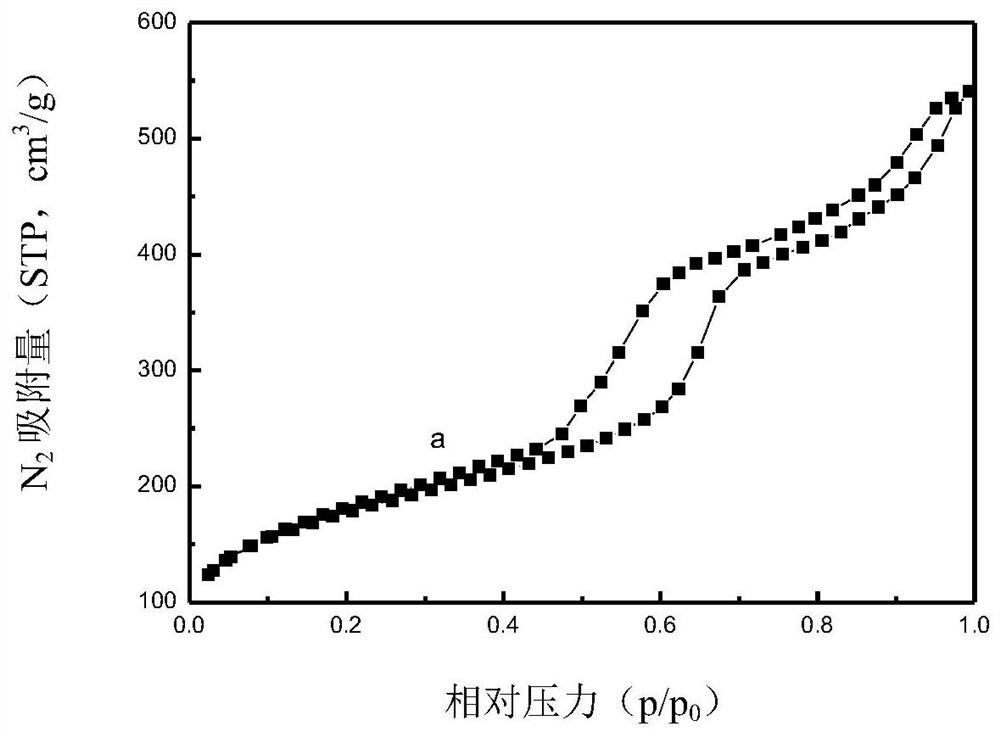

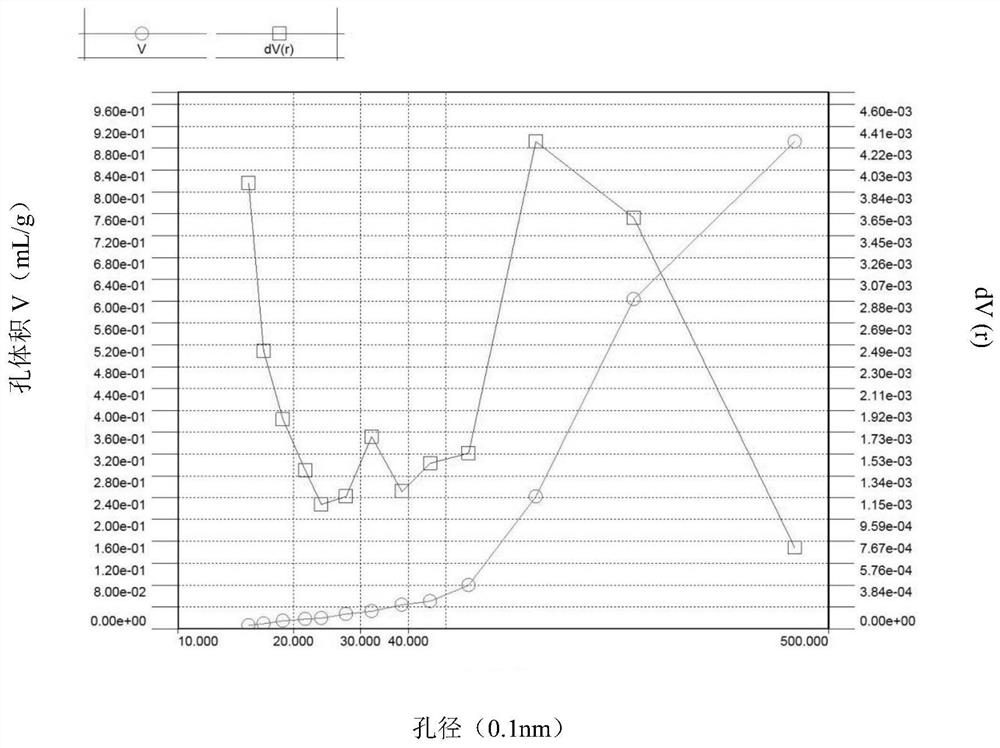

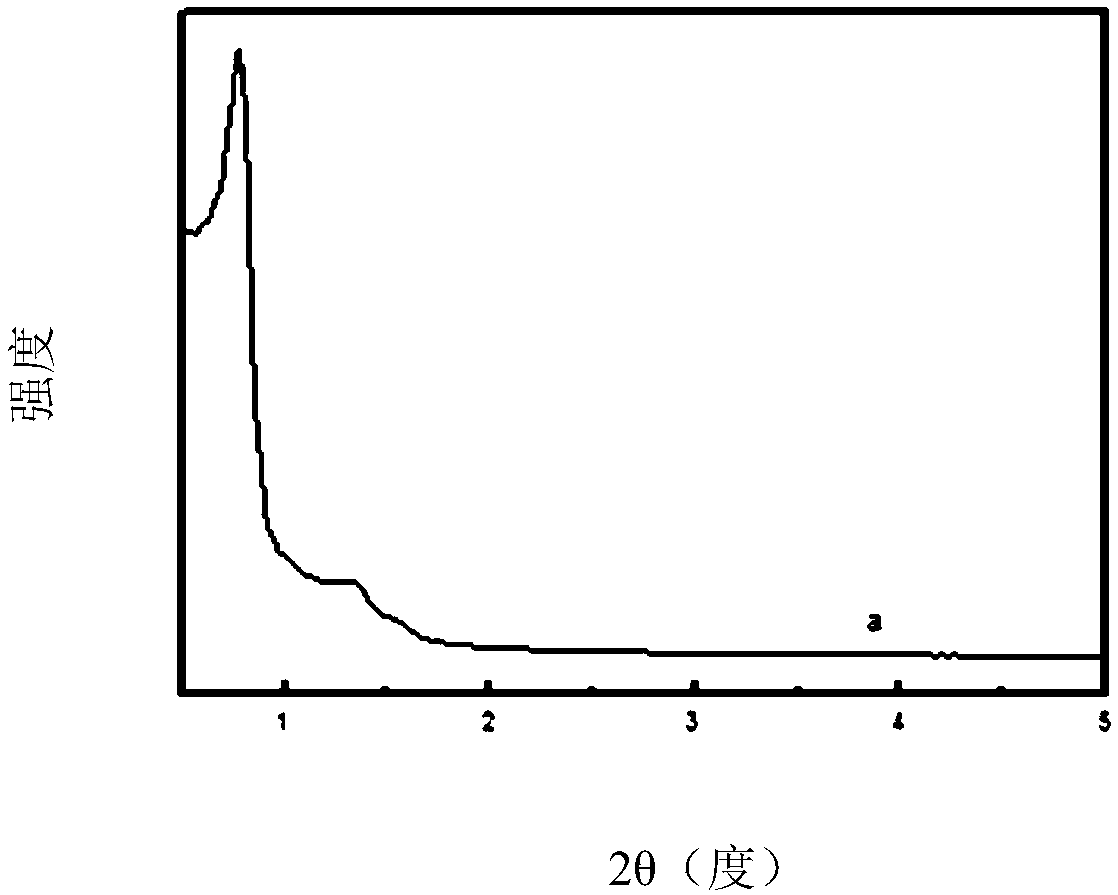

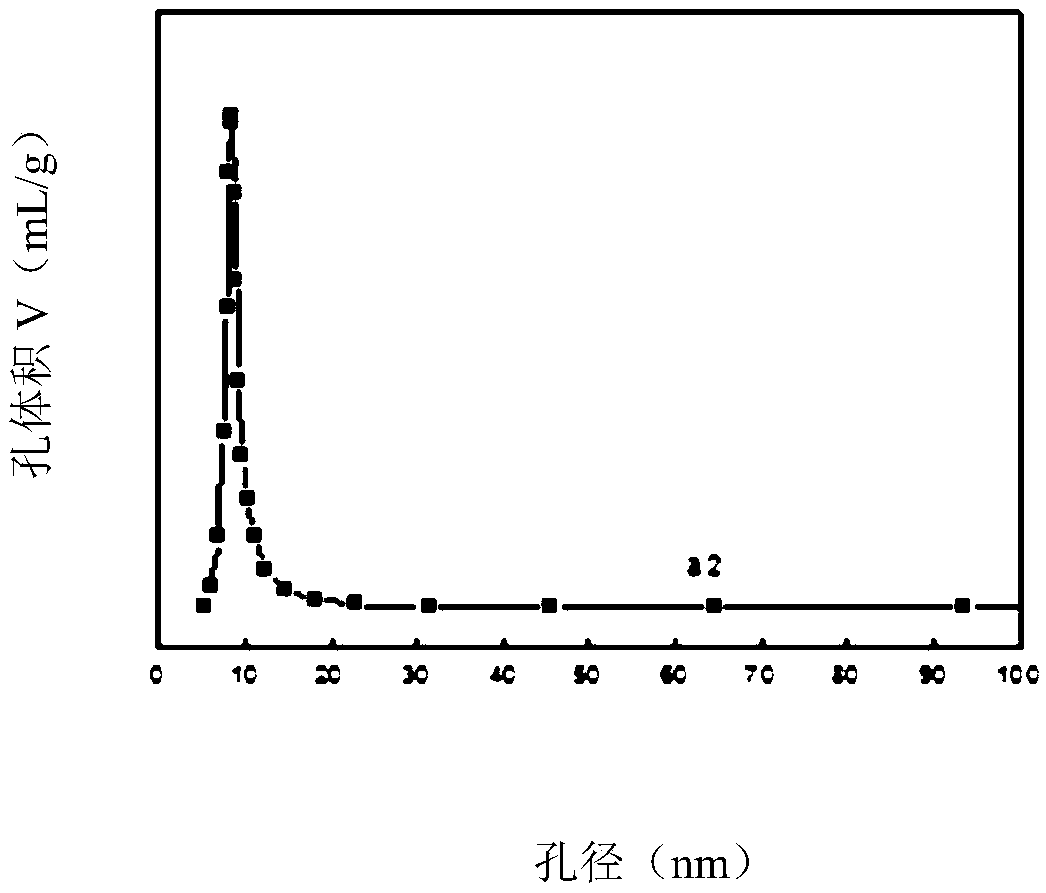

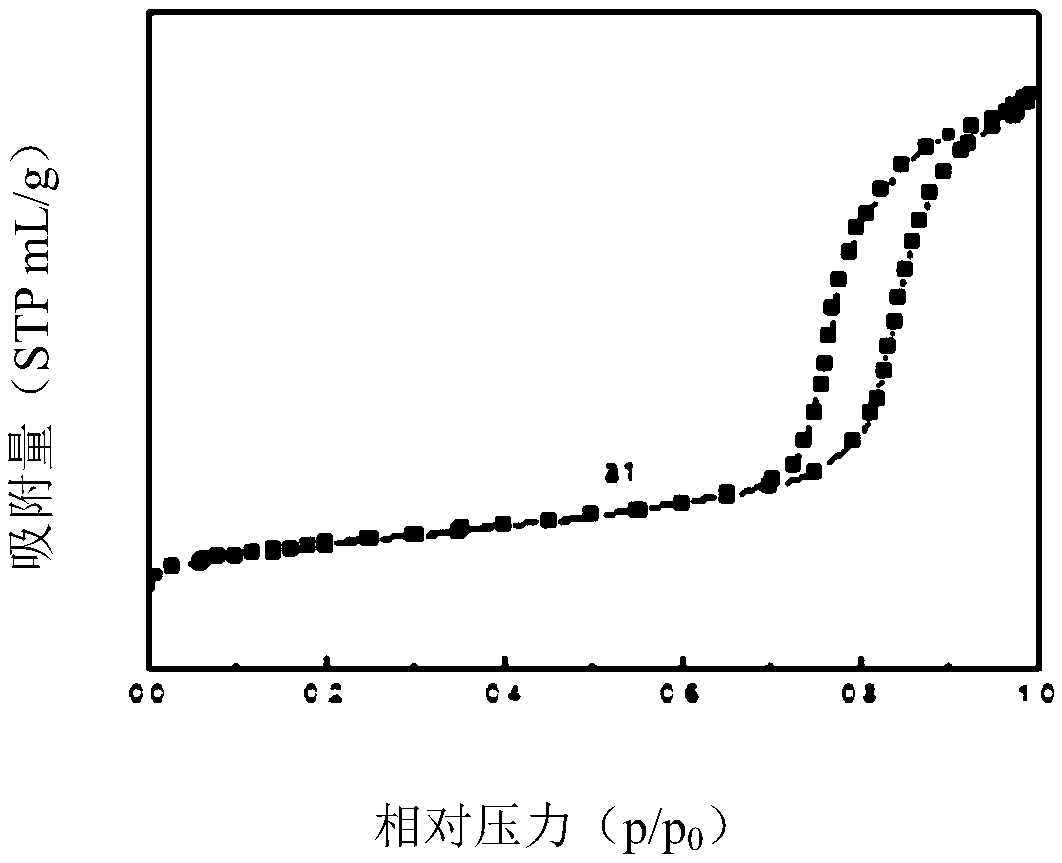

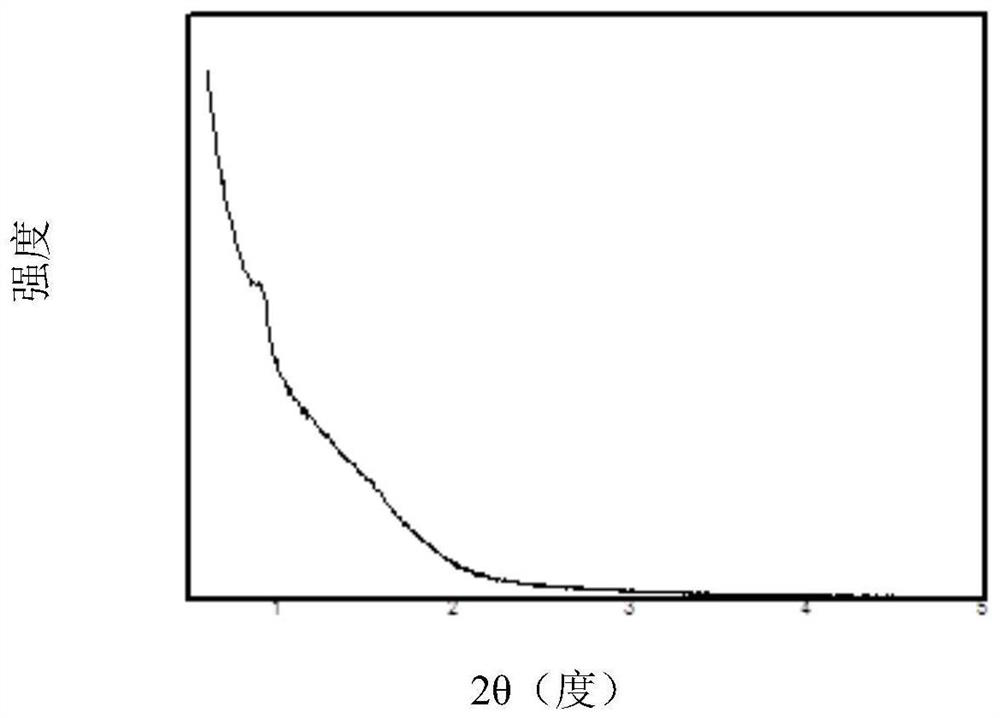

The invention relates to the field of catalysts, and discloses a non-noble metal propane dehydrogenation catalyst, a preparation method and applications thereof. The method comprises the following steps: (a) in the presence of a template agent, carrying out mixing contacting on a silicon source and an acid agent, and sequentially crystallizing, filtering and drying the mixture obtained after mixing contacting to obtain mesoporous material raw powder; (b) carrying out template agent removal treatment on the mesoporous material raw powder to obtain a rod-like mesoporous molecular sieve carrier;and (c) carrying out dipping treatment on the rod-like mesoporous molecular sieve carrier in a solution containing an active non-noble metal component precursor, and then sequentially carrying out solvent removal treatment, drying and roasting. The obtained non-noble metal propane dehydrogenation catalyst has good dehydrogenation activity, good selectivity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

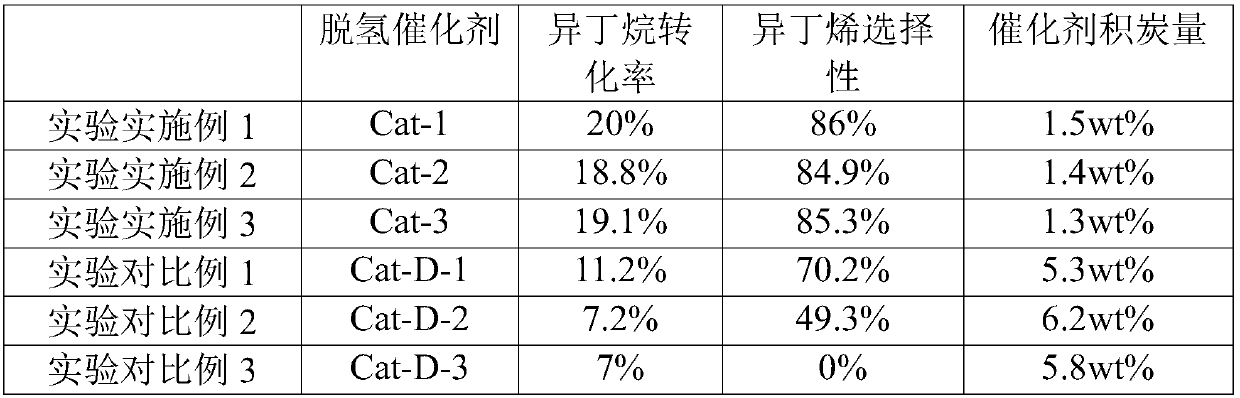

Isobutane dehydrogenation catalyst using chlorite composite material with three-dimensional cubic and hexagonal pore channel structures as carrier, preparation method and applications thereof

InactiveCN110732342ASimple preparation processConditions are easy to controlMolecular sieve catalystsMolecular sieve catalystPtru catalystDehydrogenation

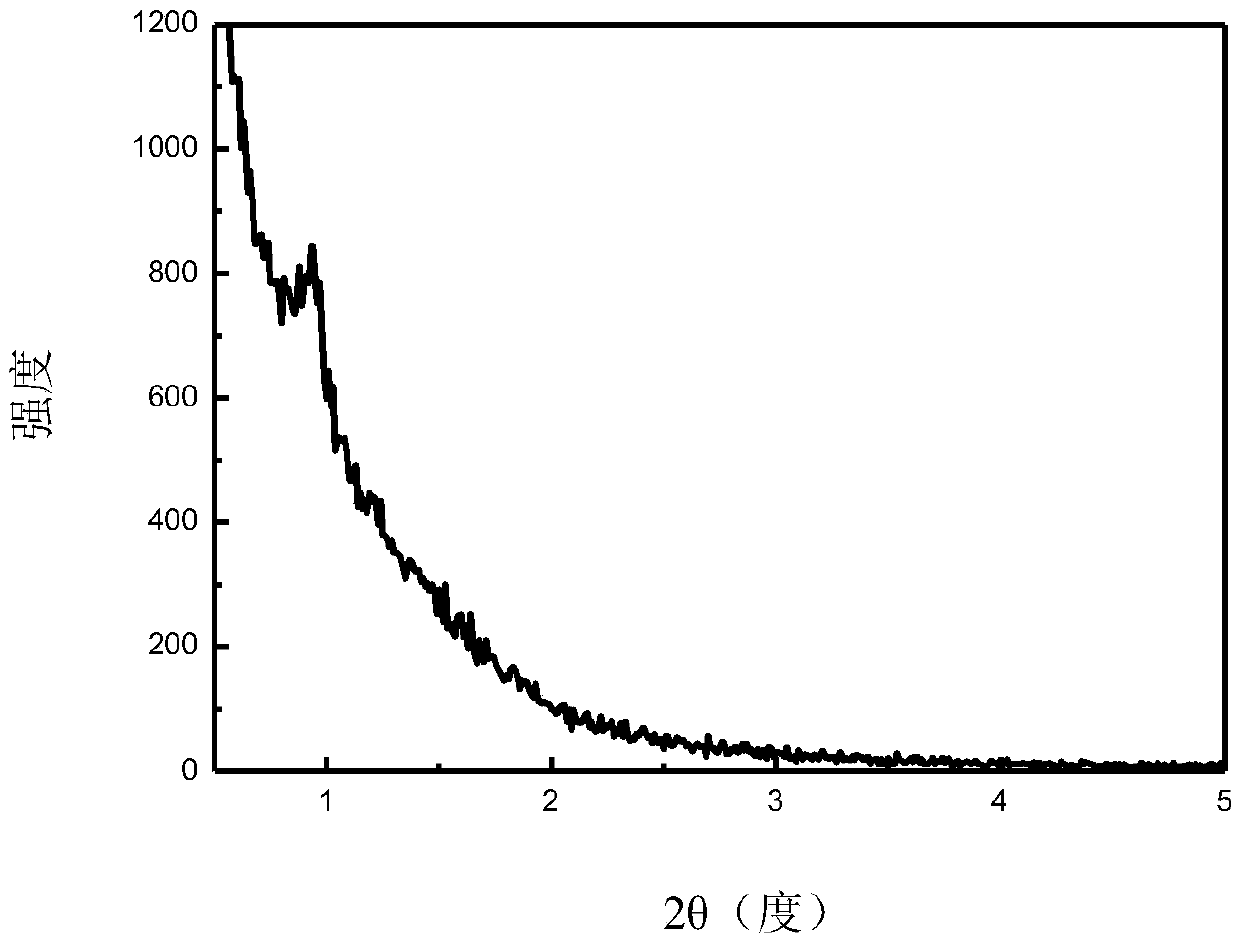

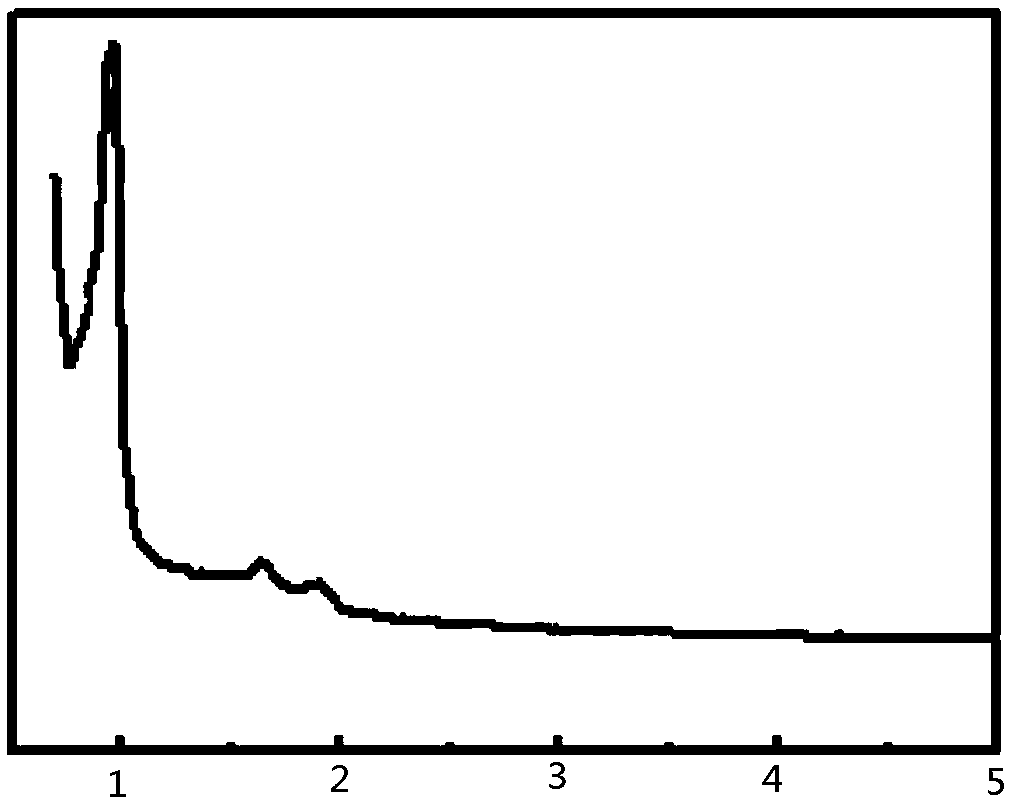

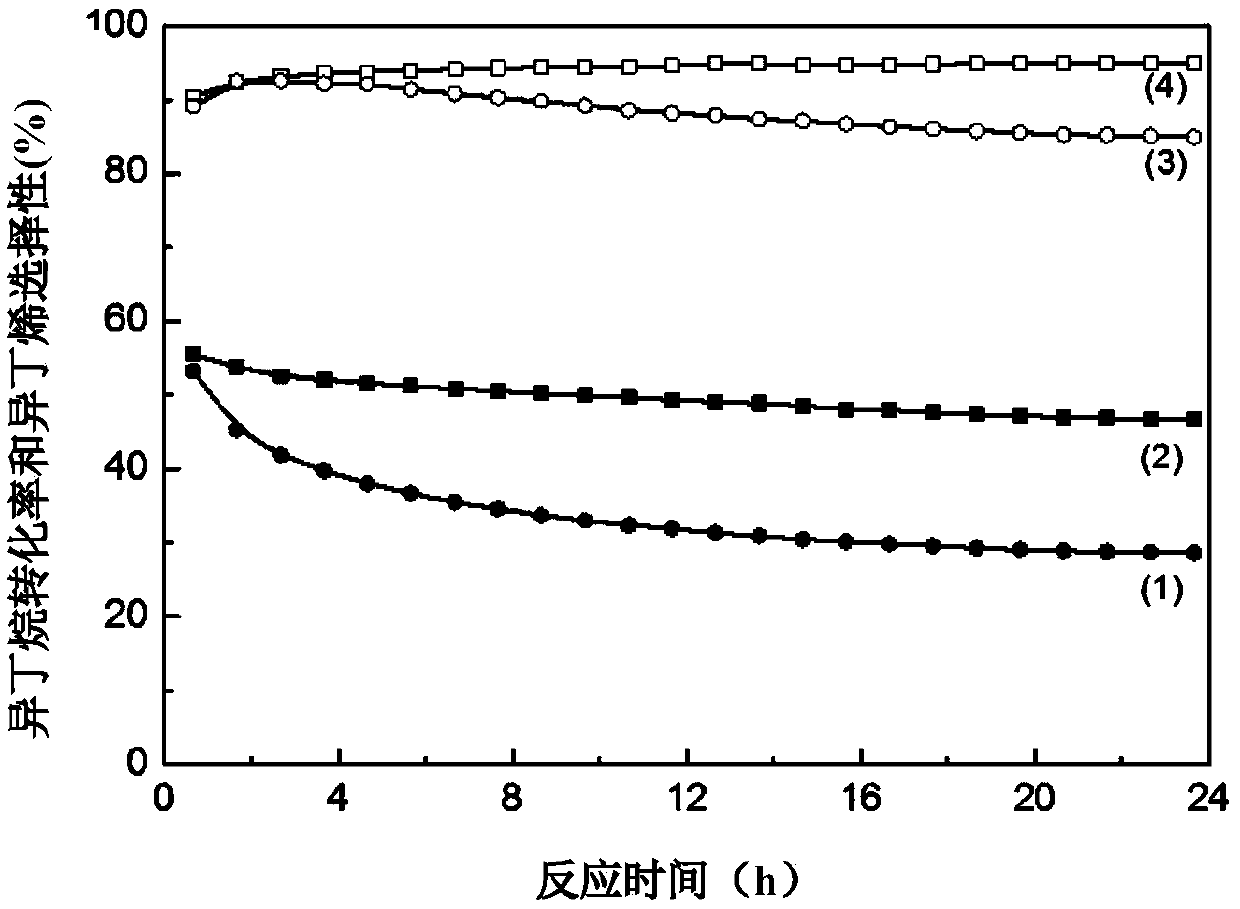

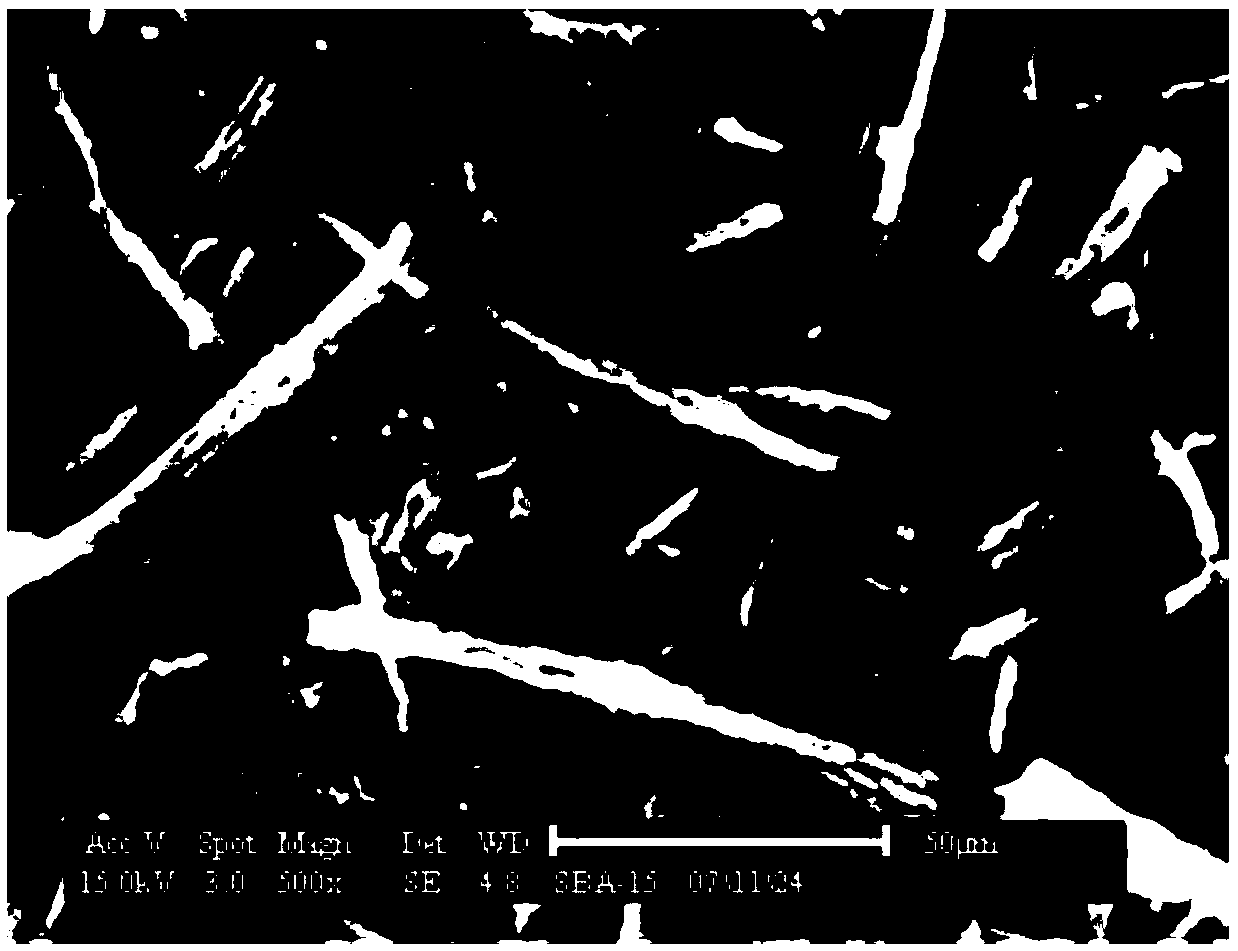

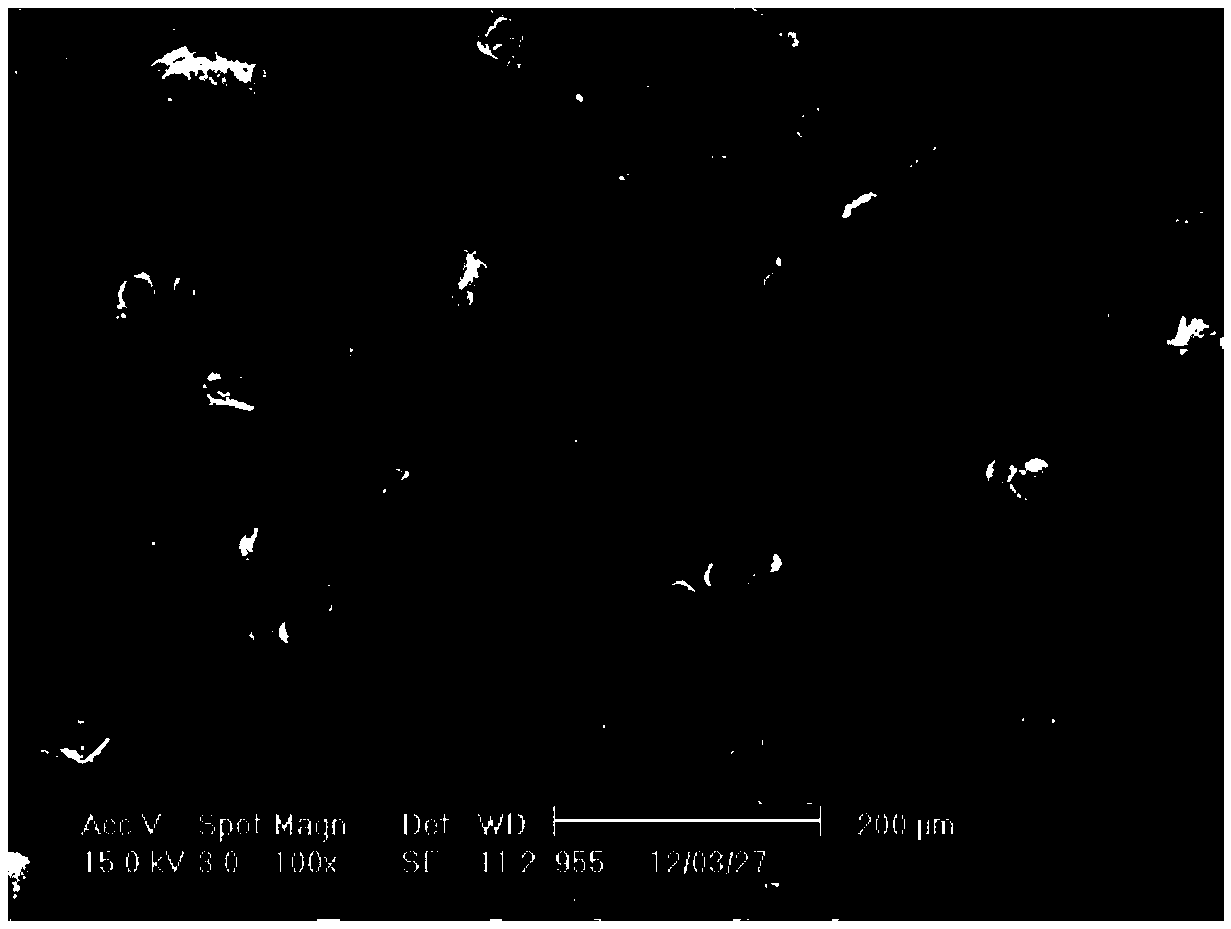

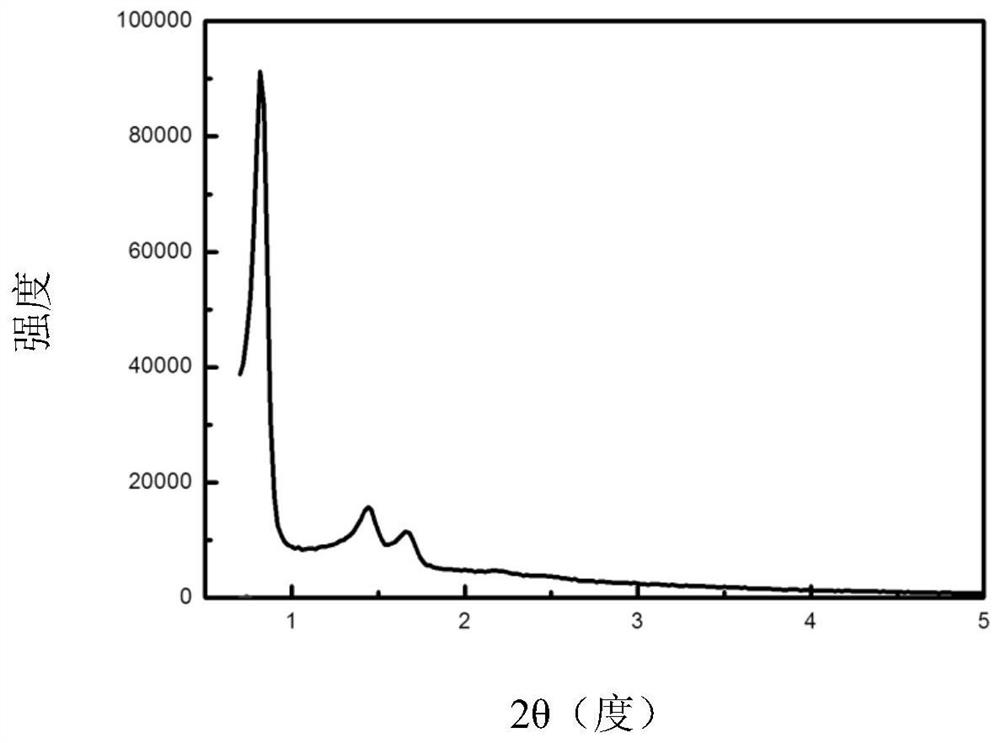

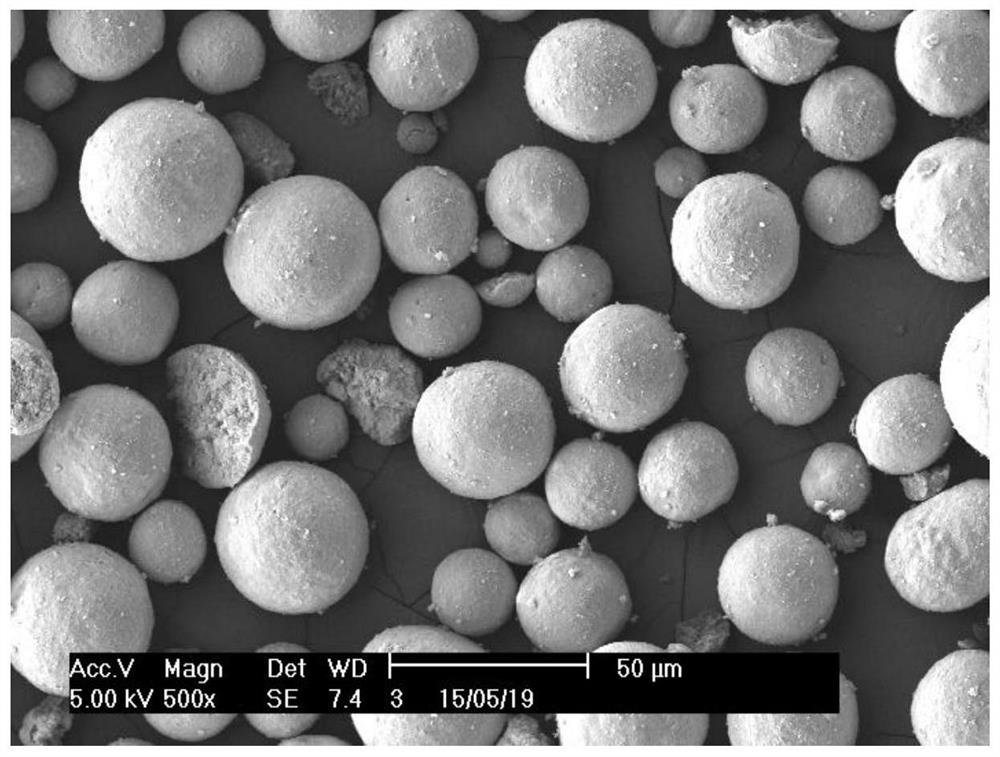

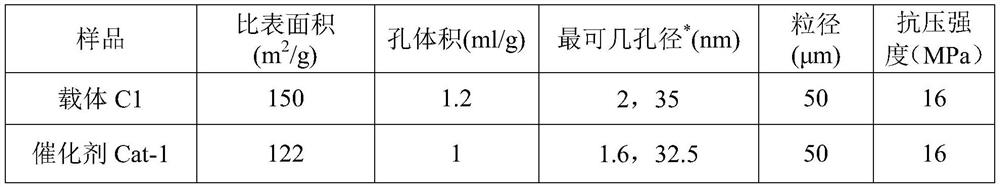

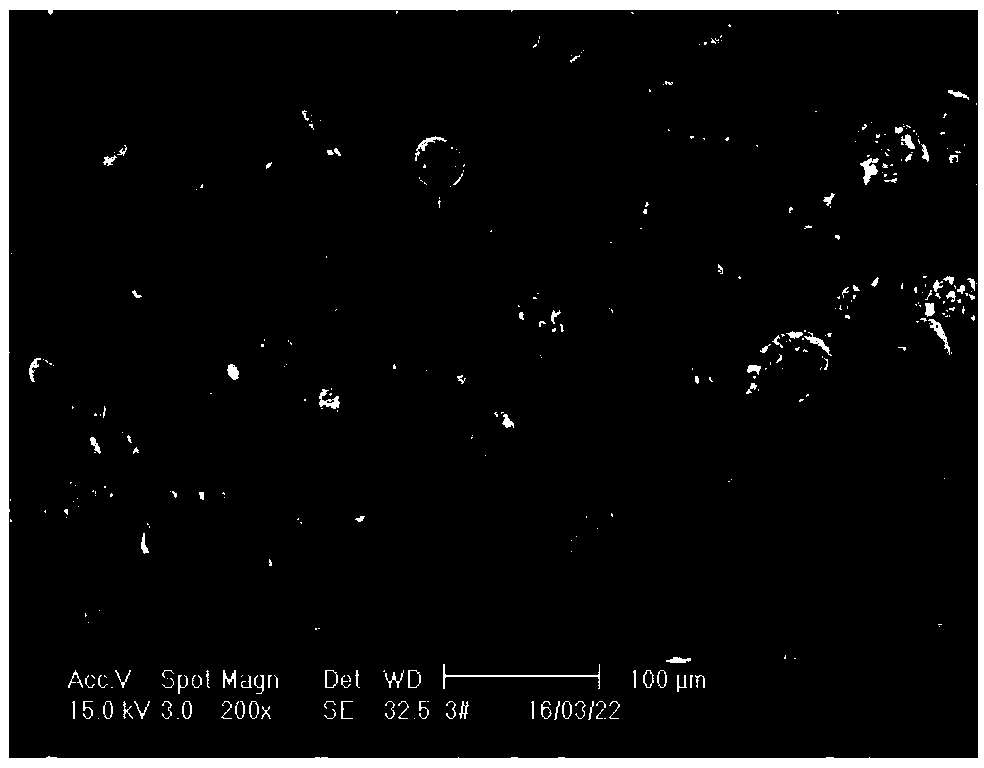

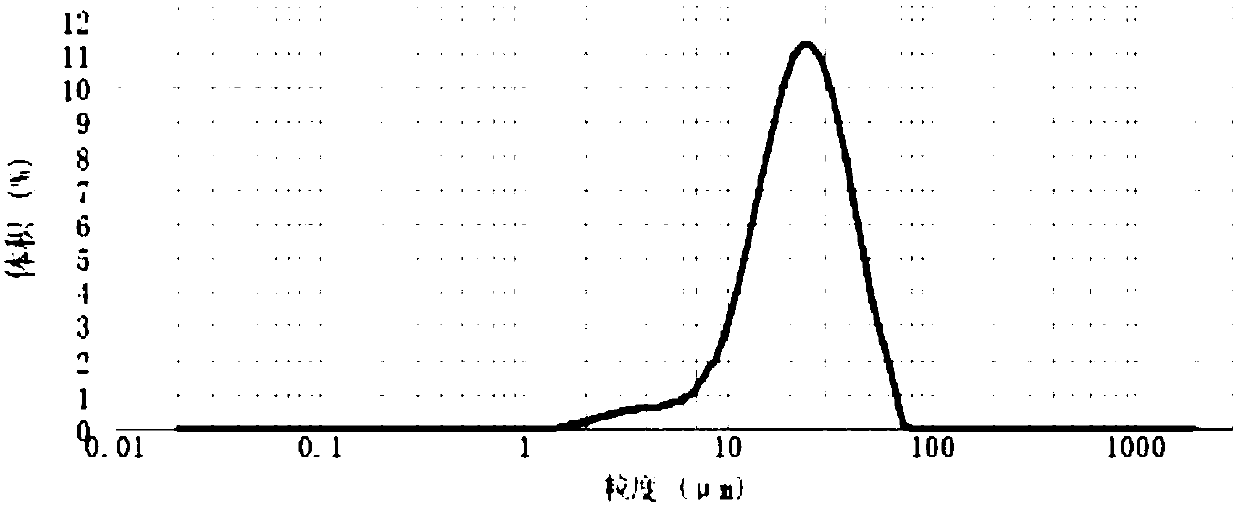

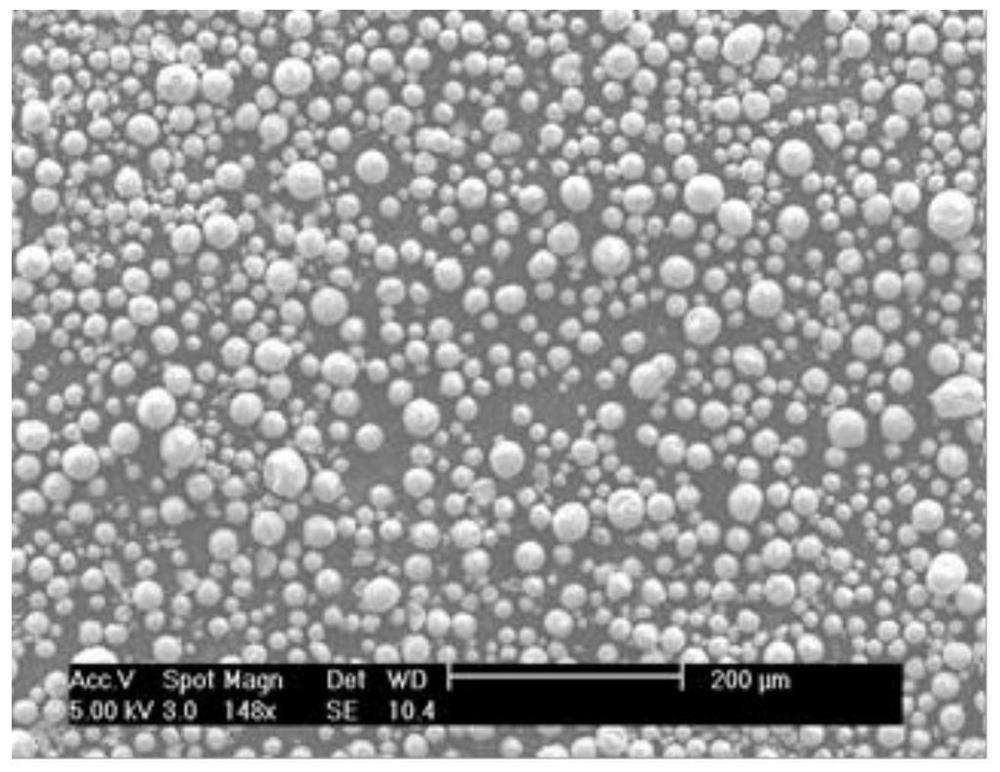

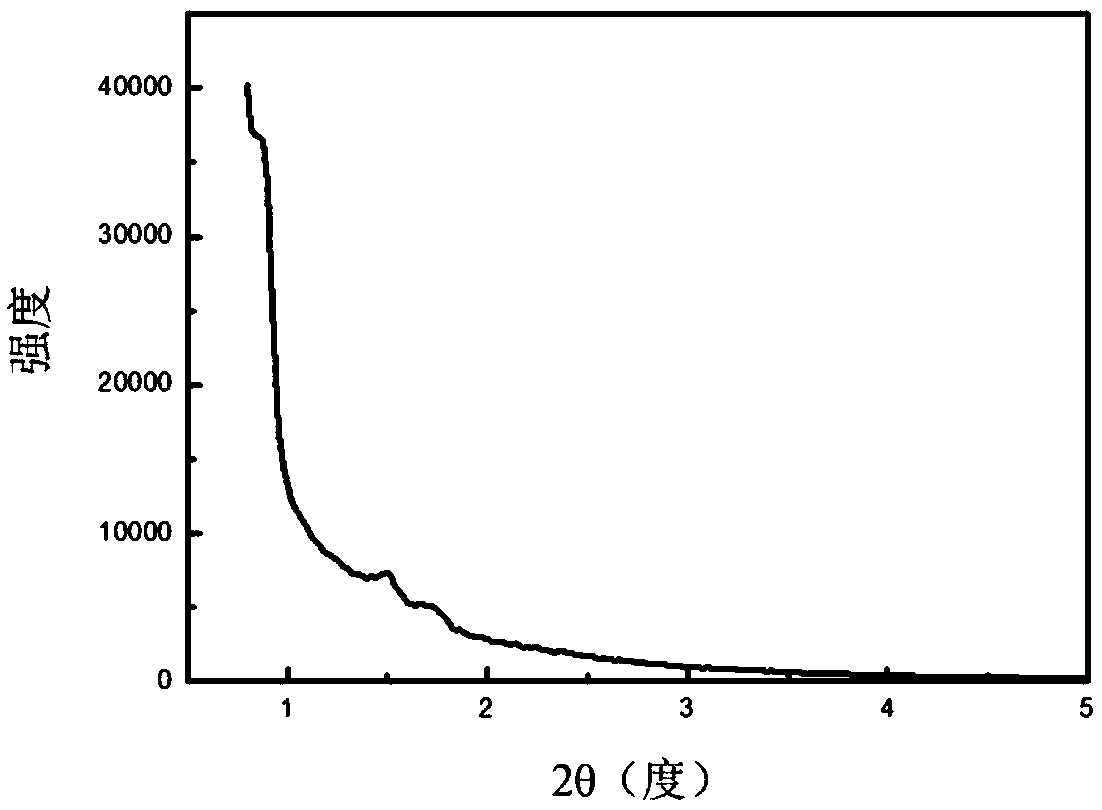

The invention relates to the field of catalysts, and discloses a method for preparing an isobutane dehydrogenation catalyst, the isobutane dehydrogenation catalyst prepared by the method, and a methodfor preparing isobutene through dehydrogenation of isobutane. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) preparing a first mesoporous material filter cake with a three-dimensional cubic pore channel structure and a second mesoporous material filter cake with a two-dimensional hexagonal pore channel structure; (b) preparing a silica gel filter cake; (c) mixing the first mesoporous material filter cake, the second mesoporous material filter cake, the silica gel filter cake and chlorite, and sequentially carrying out ball milling, pulping, drying and templateagent removal to obtain a spherical double-mesoporous chlorite composite material carrier; and (d) carrying out dipping treatment on the obtained spherical double-mesoporous chlorite composite material carrier in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying and roasting. The obtained isobutane dehydrogenation catalyst of the invention has good dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-noble metal isobutane dehydrogenation catalyst taking hexagonal mesoporous material as carrier, preparation method and application thereof

InactiveCN111250096AReduce manufacturing costReduce the risk of carbon accumulationHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystMetallurgy

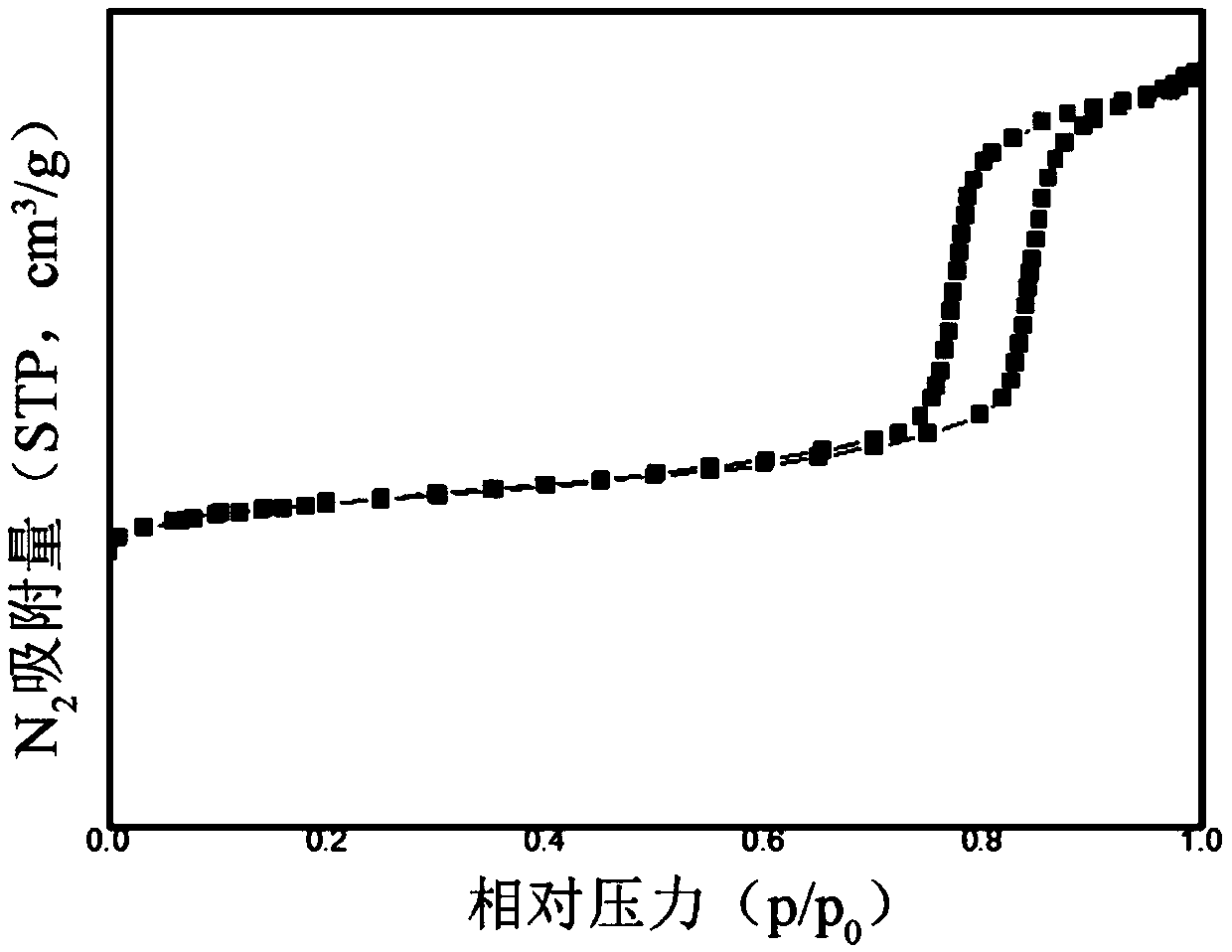

The invention relates to the field of catalysts, and discloses a non-noble metal isobutane dehydrogenation catalyst, a preparation method and application thereof. The method for preparing the non-noble metal isobutane dehydrogenation catalyst comprises the following steps: (a) providing hexagonal mesoporous material raw powder; (b) carrying out template agent removal treatment and thermal activation treatment on the mesoporous material raw powder to obtain a hexagonal mesoporous material carrier; (c) under an ultrasonic condition, loading a first active non-noble metal component and a second active non-noble metal component on the hexagonal mesoporous material carrier to obtain an initial non-noble metal isobutane dehydrogenation catalyst; and (d) vulcanizing the initial non-noble metal isobutane dehydrogenation catalyst by using a sulfur-containing gas. The obtained non-noble metal isobutane dehydrogenation catalyst has good dehydrogenation activity, good selectivity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isobutane dehydrogenation catalyst using three-hole hollow spherical mesoporous molecular sieve silica gel composite material as carrier, preparation method and applications thereof

InactiveCN110732343ASimple preparation processConditions are easy to controlMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention relates to the field of catalysts, and discloses a method for preparing an isobutane dehydrogenation catalyst, the isobutane dehydrogenation catalyst prepared by the method, and a methodfor preparing isobutene through dehydrogenation of isobutane. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) preparing a mesoporous molecular sieve filter cake with one-dimensional straight-through pore channels; (b) mixing the mesoporous molecular sieve filter cake and a silica gel, mixing, carrying out first ball milling, mixing the obtained first ball-milled slurry and water, pulping, carrying out second ball milling to obtain second ball-milled slurry, carrying out spray drying on the second ball-milled slurry, screening by adopting a cyclone separation technology, and removing the template agent from the screened product to obtain a composite material; and (c) carrying out thermal activation on the composite material, carrying out dipping treatment, removing the solvent, drying, roasting, and loading a Pt component and a Zn component. According to the invention, the obtained isobutane dehydrogenation catalyst has good dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isobutane dehydrogenation catalyst with supporter being composite material containing silica gel and hexagonal mesoporous material as well as preparation method and application thereof

InactiveCN110614097ASimple preparation processConditions are easy to controlCatalyst carriersCatalystsDehydrogenationMesoporous material

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst with a supporter being a composite material containing silica gel and hexagonal mesoporous materialas well as a preparation method and application of the isobutane dehydrogenation catalyst. The method comprises the following steps: (a) preparing hexagonal mesoporous material raw powder; (b) preparing a hexagonal mesoporous material; (c) carrying out activation treatment on the hexagonal mesoporous material; and (d) carrying out activation treatment on the supporter, then carrying out impregnation treatment in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying treatment and roasting treatment. According to the method, the isobutane dehydrogenation catalyst with high catalytic activity can be synthesized by using a low-cost silicon source.

Owner:CHINA PETROLEUM & CHEM CORP +1

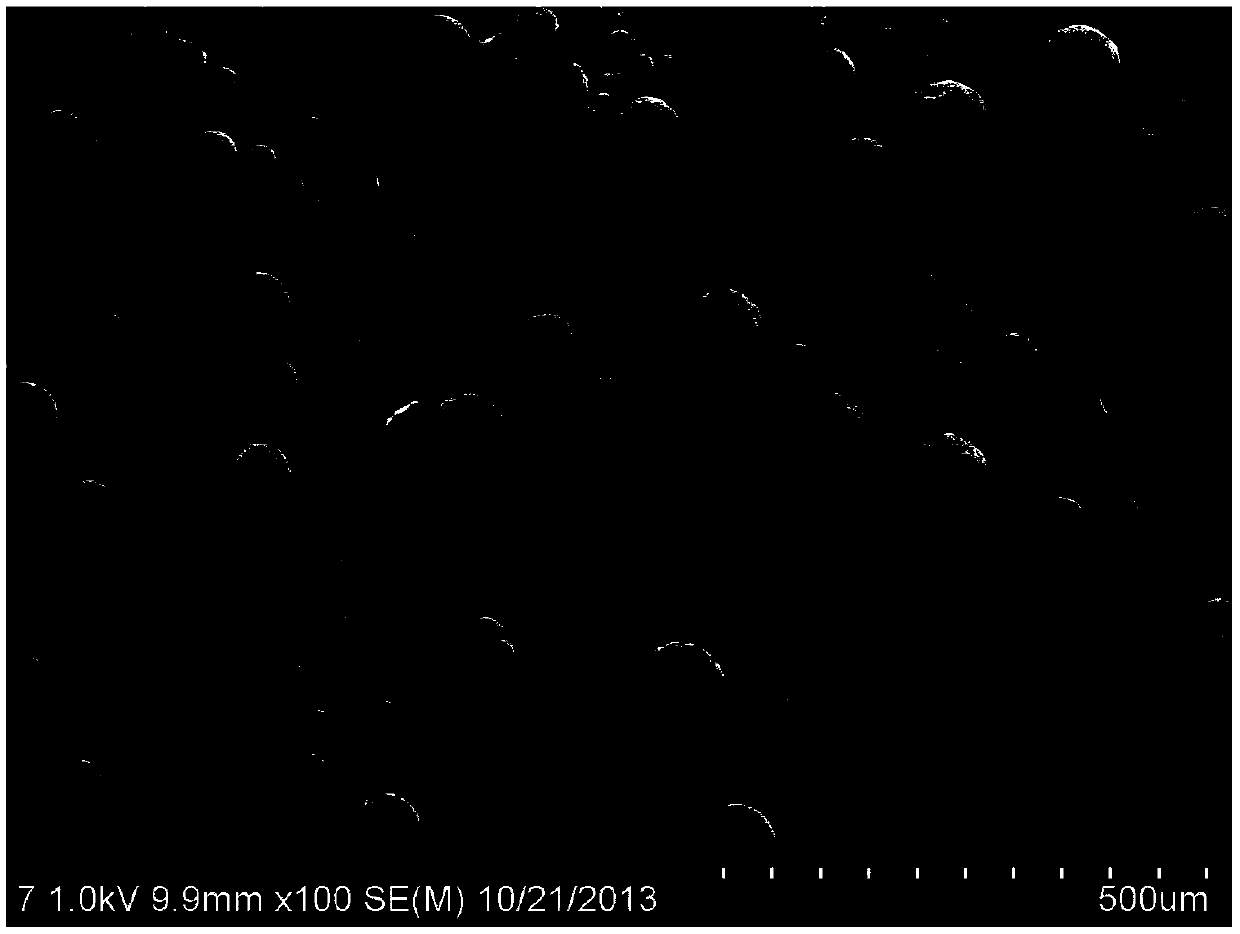

Isobutane dehydrogenation catalyst with spherical doughnut mesoporous material silica gel composite material as carrier, and preparation method and application of catalyst

InactiveCN110813285ASimple preparation processConditions are easy to controlCatalystsHydrocarbon preparation catalystsPtru catalystDehydrogenation

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst with a spherical doughnut mesoporous material silica gel material as a carrier, and a preparation method and application of the catalyst. The preparation method of the isobutane dehydrogenation catalyst comprises the following steps: (a) preparing a doughnut mesoporous material filter cake; (b) preparing a silica gel filter cake; (c) mixing the doughnut mesoporous material filter cake and the silica gel filter cake and performing ball-milling, water-pulping the solid powder obtained after ball-milling and then performing spray-drying, and then removing a template agent in the obtained product to obtain the spherical doughnut mesoporous material silica gel composite material; and (d) performing impregnation treatment on the obtained spherical doughnut mesoporous material silica gel composite material in a solution containing a Pt component precursor and a Zn component precursor, and thenperforming solvent removal treatment, drying, and baking in order. The obtained isobutane dehydrogenation catalyst has relatively good dehydrogenation activity and carbon-deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-noble metal propane dehydrogenation catalyst taking modified spherical doughnut mesoporous material silica gel composite material as carrier, preparation method and application thereof

InactiveCN111250084AReduce manufacturing costReduce the risk of carbon accumulationCatalyst carriersCatalystsPtru catalystSulfite salt

The invention relates to the field of catalysts, and discloses a non-noble metal propane dehydrogenation catalyst, a preparation method and application thereof. The method for preparing the non-noblemetal propane dehydrogenation catalyst comprises the following steps: (a) preparing a doughnut mesoporous material filter cake; (b) preparing a silica gel filter cake; (c) carrying out mixing and ball-milling on the doughnut mesoporous material filter cake and the silica gel filter cake, pulping the solid powder obtained by ball-milling with water, performing spray drying, and removing the template agent in the obtained product to obtain a spherical doughnut mesoporous material silica gel composite material; (d) under an ultrasonic condition, modifying the composite material by using an aqueous solution containing sulfate and / or sulfite to obtain a modified spherical doughnut mesoporous material silica gel composite material carrier; and (e) impregnating and loading an active non-noble metal component on the modified spherical doughnut mesoporous material silica gel composite material carrier. The obtained non-noble metal propane dehydrogenation catalyst has good dehydrogenation activity, good selectivity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isobutane dehydrogenation catalyst with composite material containing doughnut mesoporous material and silica gel as carrier, and preparation method and application thereof

InactiveCN110813286ASimple preparation processConditions are easy to controlMolecular sieve catalystsMolecular sieve catalystPtru catalystDehydrogenation

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst with a composite material containing a doughnut-shaped mesoporous material and silica gel as a carrier, a preparation method of the isobutane dehydrogenation catalyst, the isobutane dehydrogenation catalyst prepared by the method, and application of the isobutane dehydrogenation catalyst in preparation of isobutene through isobutane dehydrogenation. The method for preparing the isobutane dehydrogenation catalyst comprises the following steps of (a) preparing doughnut-shaped mesoporous materialraw powder; (b) performing plate-stripping agent treatment on the doughnut-shaped mesoporous material raw powder to obtain the doughnut-shaped mesoporous material; (c) mixing the doughnut-shaped mesoporous material with the silica gel to obtain the composite material containing the doughnut-shaped mesoporous material and the silica gel; and (d) performing dipping treatment in a solution containinga PT component precursor and a Zn component precursor after thermally activating the composite material, and then sequentially performing solvent removal treatment, drying and roasting. The obtainedisobutane dehydrogenation catalyst has better dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dehydrogenation catalyst and preparation method and application thereof

ActiveCN109954487AReduce manufacturing costHigh selectivityCatalyst carriersHydrocarbon by dehydrogenationComponent LoadAlcohol

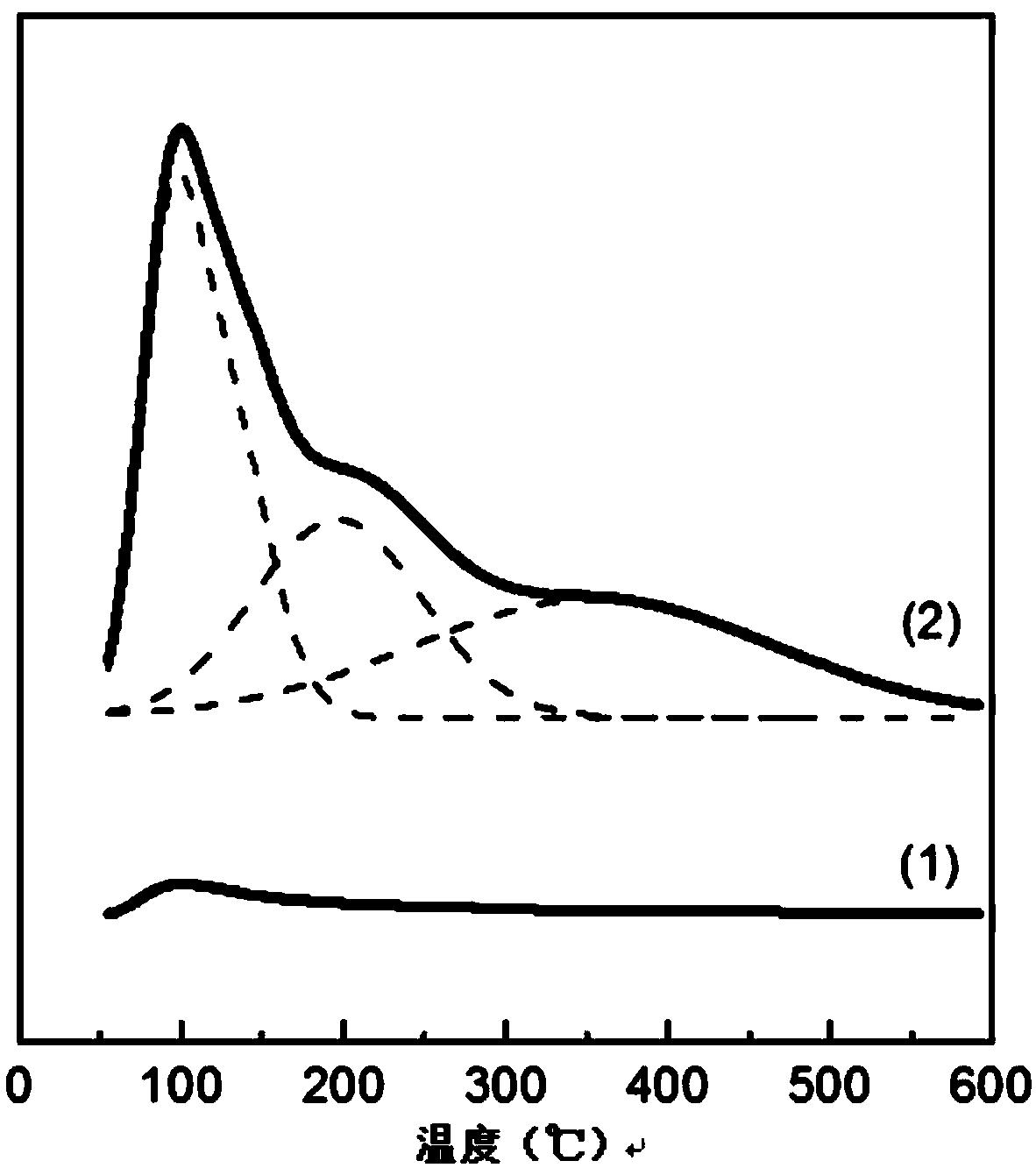

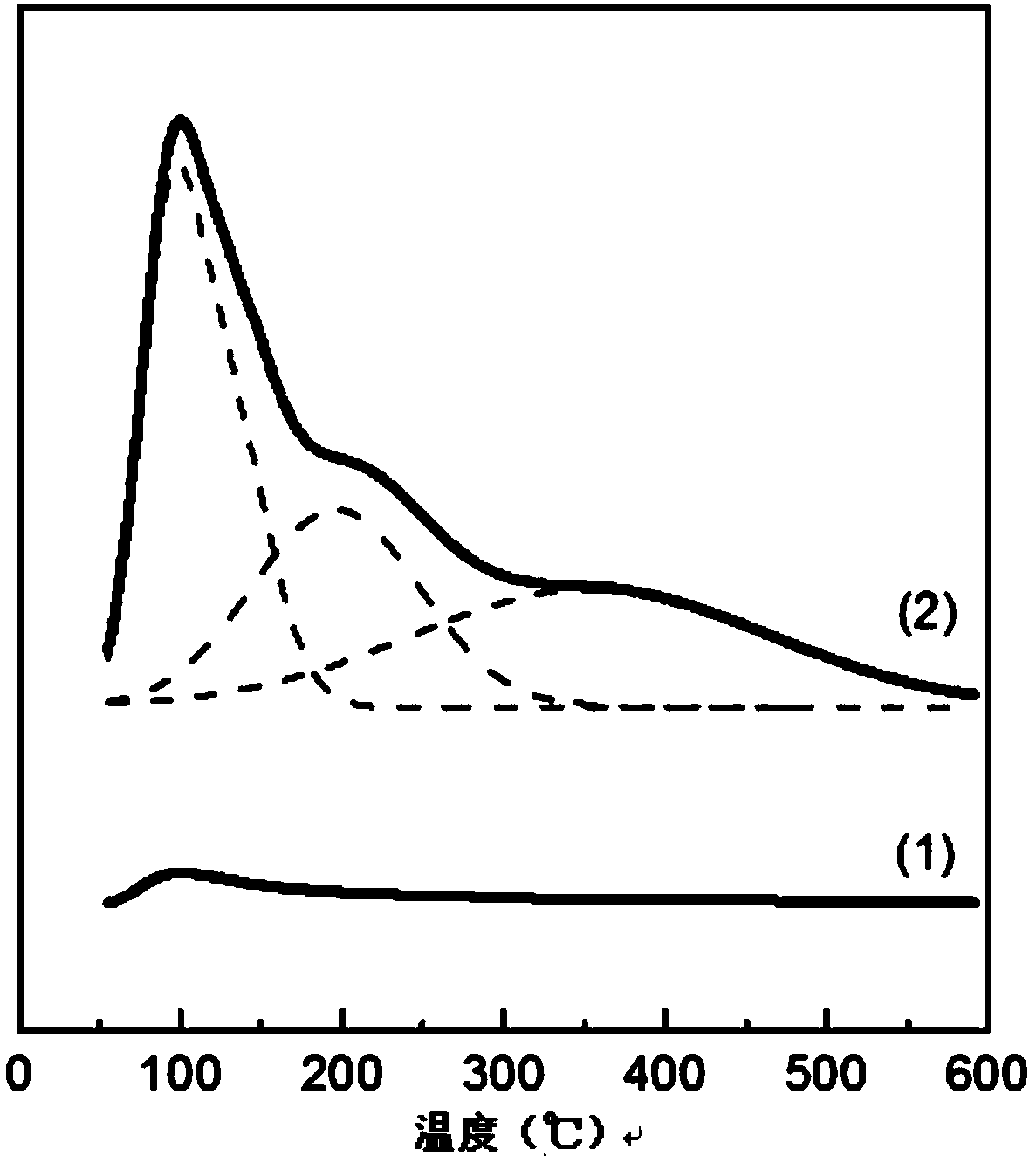

The invention relates to the field of dehydrogenation catalysts, in particular to a dehydrogenation catalyst and a preparation method thereof and an application thereof. The dehydrogenation catalyst comprises a carrier and a main active metal component loaded on the carrier, wherein the main active metal component is a noble metal, and the carrier is a magnesium-aluminum composite carrier. The preparation method of the dehydrogenation catalyst comprises the following steps: (1) under the alkaline condition, an aluminum salt solution contacts with a precipitating agent, and an aluminum hydroxide hydrogel is obtained after aging and separation; the aluminum hydroxide hydrogel is cleaned by respectively using water and an alcohol solvent; and the aluminum hydroxide alcogel contacts with an alcohol solution of a magnesium salt under the ultrasonic condition, then the solvent is removed, and drying and roasting are performed to obtain the magnesium-aluminum composite carrier; and (2) the main active metal component is loaded on the magnesium-aluminum composite carrier. The dehydrogenation catalyst can achieve relatively good dehydrogenation activity, selectivity, stability and carbon deposition resistance under the condition of a very low noble metal loading capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

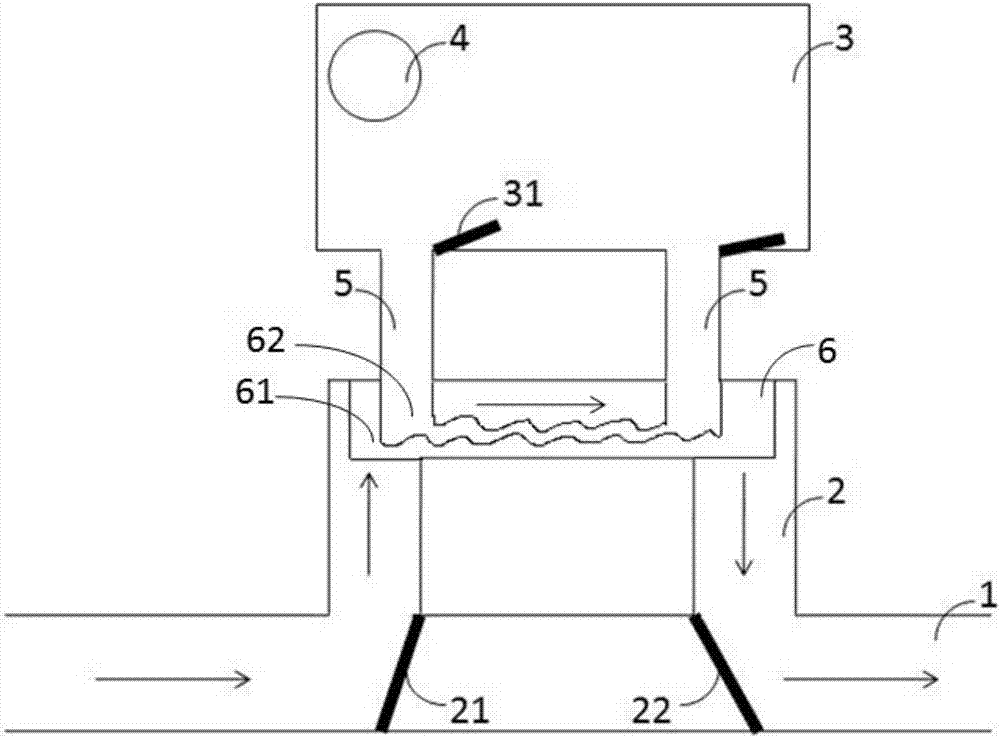

Online baking method for heat insulation type natural gas catalytic oxidation furnace

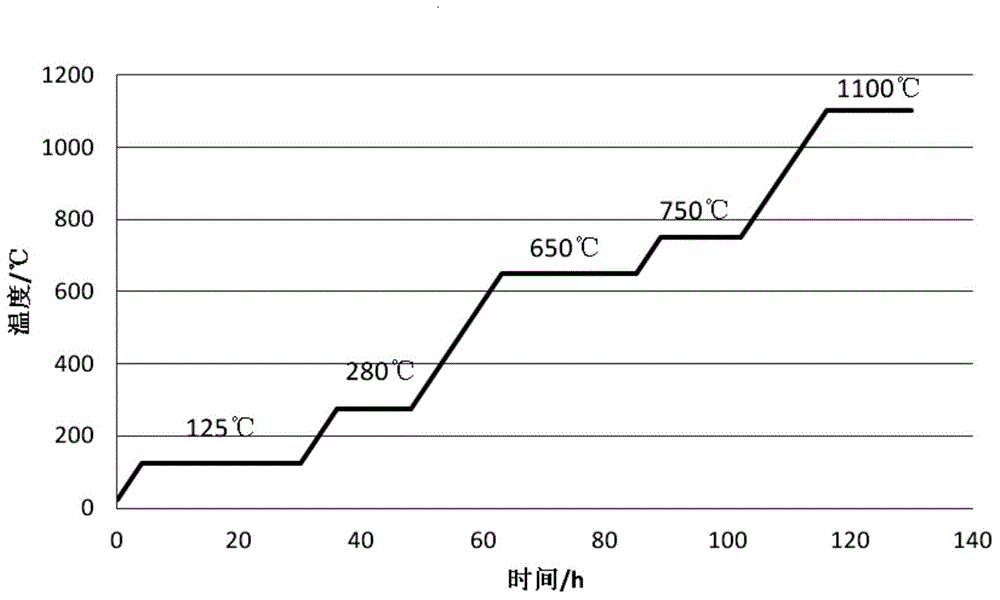

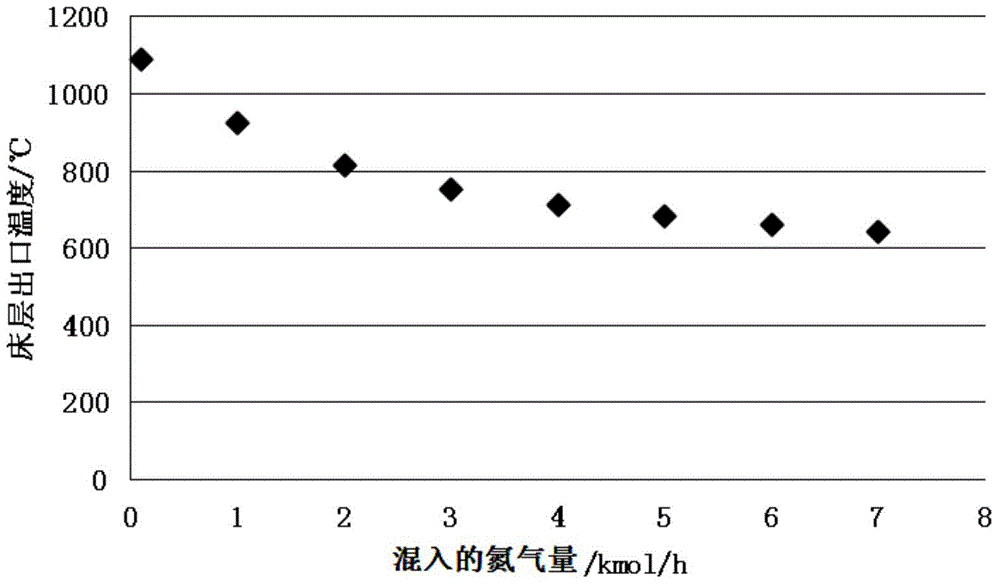

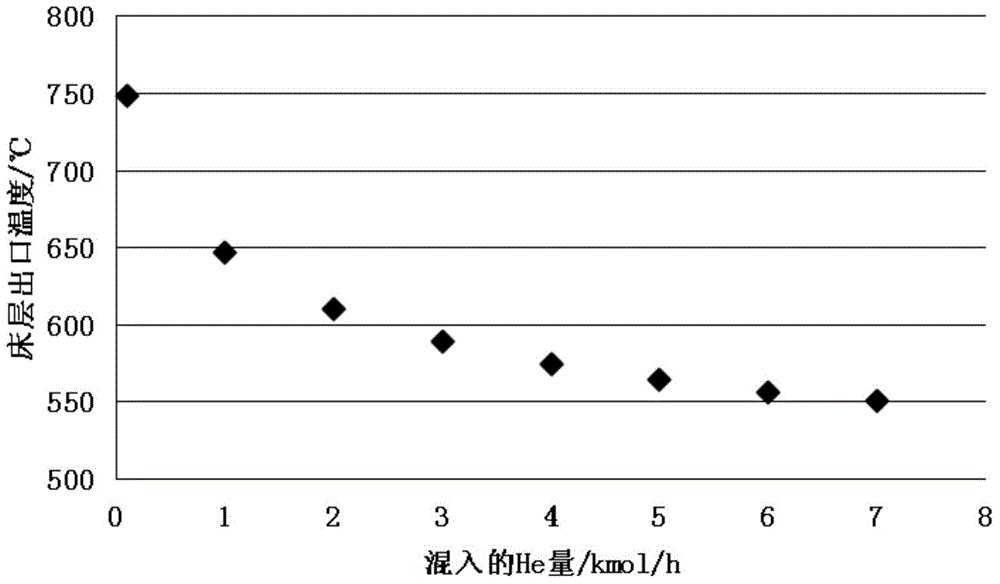

ActiveCN104692324AReduce temperature rise fluctuationsAvoid sudden heatHydrogenCarbon monoxideReaction temperatureWorking temperature

The invention discloses an online baking method for a heat insulation type natural gas catalytic oxidation furnace. The method comprises the steps of 1, injecting oxygen, natural gas and temperature control gas capable of reducing reaction temperature rising rate into the natural gas catalytic oxidation furnace at the same time, wherein the mole ratio of oxygen to natural gas is controlled to be 0.3-0.6 to 1, and the mole ratio of the temperature control gas to feed gas composed of oxygen and natural gas is controlled to be 0.1-7 to 1.3-1.6; 2, preheating the mixed gas to increase temperature gradually to oxidizing reaction triggering temperature; 3, reducing the mole ratio of temperature control gas to feed gas gradually to enable reaction temperature to rise according to the temperature rising rate required by a designed furnace baking curve, and stopping injection of temperature control gas when reaction temperature reaches working temperature. The method solves the problem that temperature rises too quickly during furnace baking, the situation that a heat insulation and refractory material cracks under shock heating is avoided, the natural gas catalytic oxidation furnace is protected, and the natural gas catalytic oxidation furnace can change to the normal operating state stably.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

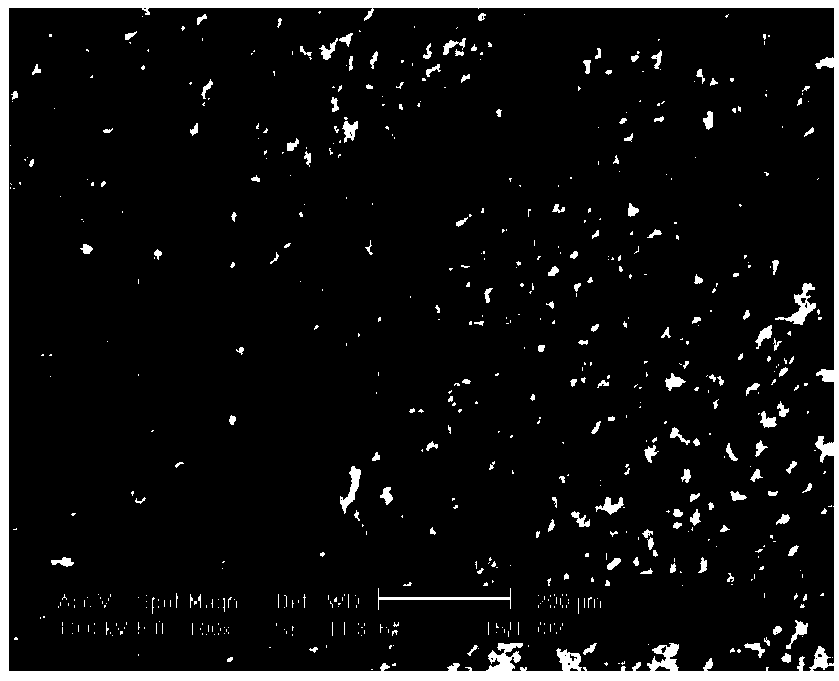

Non-noble metal isobutane dehydrogenation catalyst taking rod-like mesoporous molecular sieve as carrier, preparation method and applications thereof

InactiveCN111135852ALow cost of preparationReduce the risk of carbon accumulationMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNon noble metal

The invention relates to the field of catalysts, and discloses a non-noble metal isobutane dehydrogenation catalyst, a preparation method and applications thereof. The method comprises the following steps: (a) providing mesoporous material raw powder; (b) carrying out template agent removal treatment on the mesoporous material raw powder to obtain a rod-like mesoporous molecular sieve carrier; (c)under an ultrasonic condition, loading a first active non-noble metal component and a second active non-noble metal component on the rod-like mesoporous molecular sieve carrier to obtain an initial non-noble metal isobutane dehydrogenation catalyst; and (d) vulcanizing the initial non-noble metal isobutane dehydrogenation catalyst by using a sulfur-containing gas. The obtained non-noble metal isobutane dehydrogenation catalyst has good dehydrogenation activity, good selectivity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isobutane dehydrogenation catalyst with rodlike mesoporous molecular sieve silica gel composite material as supporter as well as preparation method and application thereof

InactiveCN110614113ASimple preparation processConditions are easy to controlCatalyst carriersMolecular sieve catalystsMolecular sieveDehydrogenation

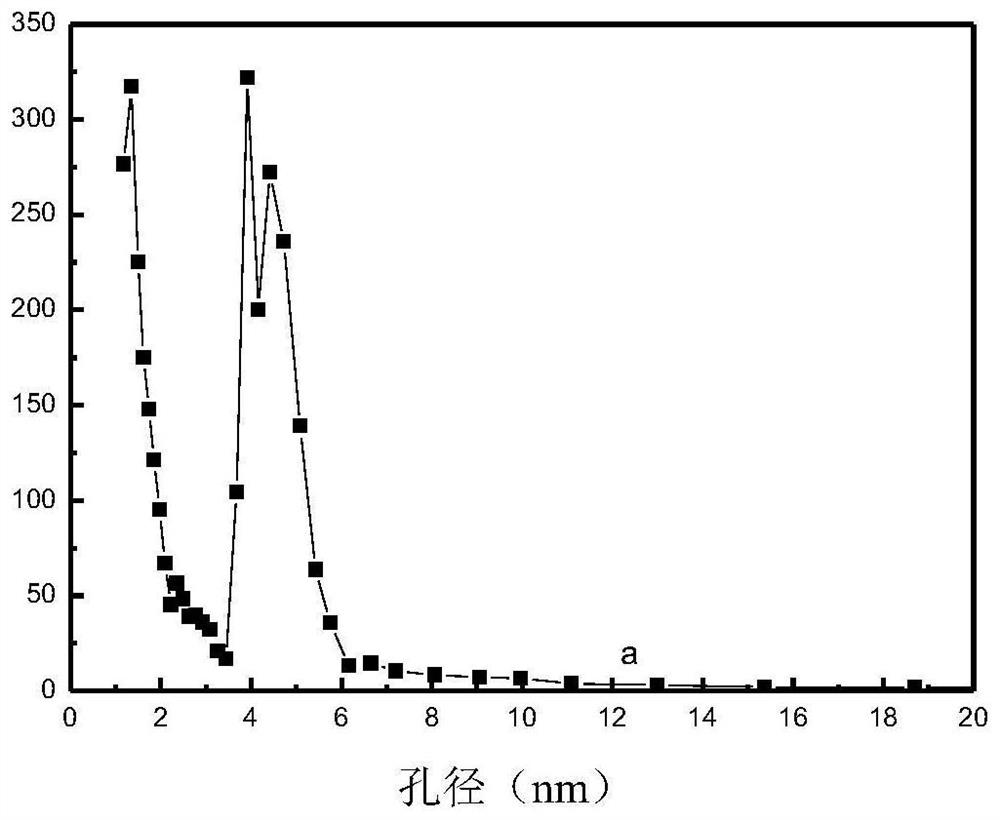

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst with a rodlike mesoporous molecular sieve silica gel composite material as a supporter, a preparation method of the isobutane dehydrogenation catalyst, the isobutane dehydrogenation catalyst prepared by the method, and an application of the isobutane dehydrogenation catalyst in isobutene preparation by isobutane dehydrogenation. The method for preparing the isobutane dehydrogenation catalyst comprises the following steps: (a) preparing mesoporous material raw powder; (b) carrying out template agent removal treatment on the mesoporous material raw powder to obtain a rod-like mesoporous molecular sieve; (c) preparing a rodlike mesoporous molecular sieve silica gel composite material supporter; and (d) carrying out dipping treatment on the rod-like mesoporous molecular sieve silica gel composite material supporter in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying treatment and roasting treatment. The obtained isobutane dehydrogenation catalyst has good dehydrogenation activity and carbondeposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

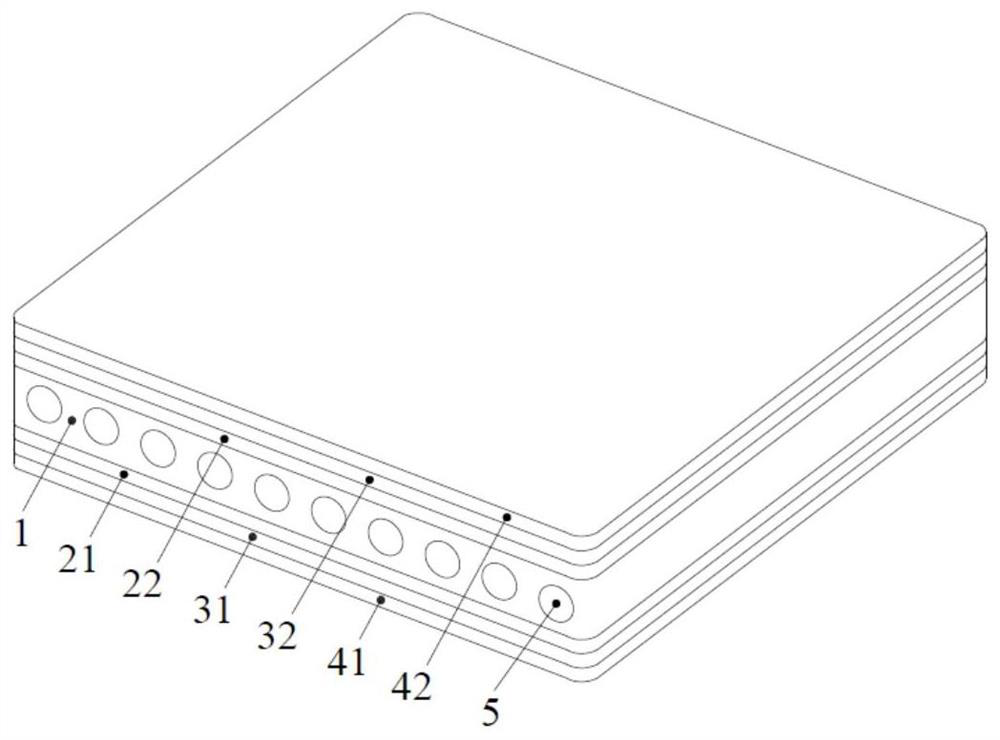

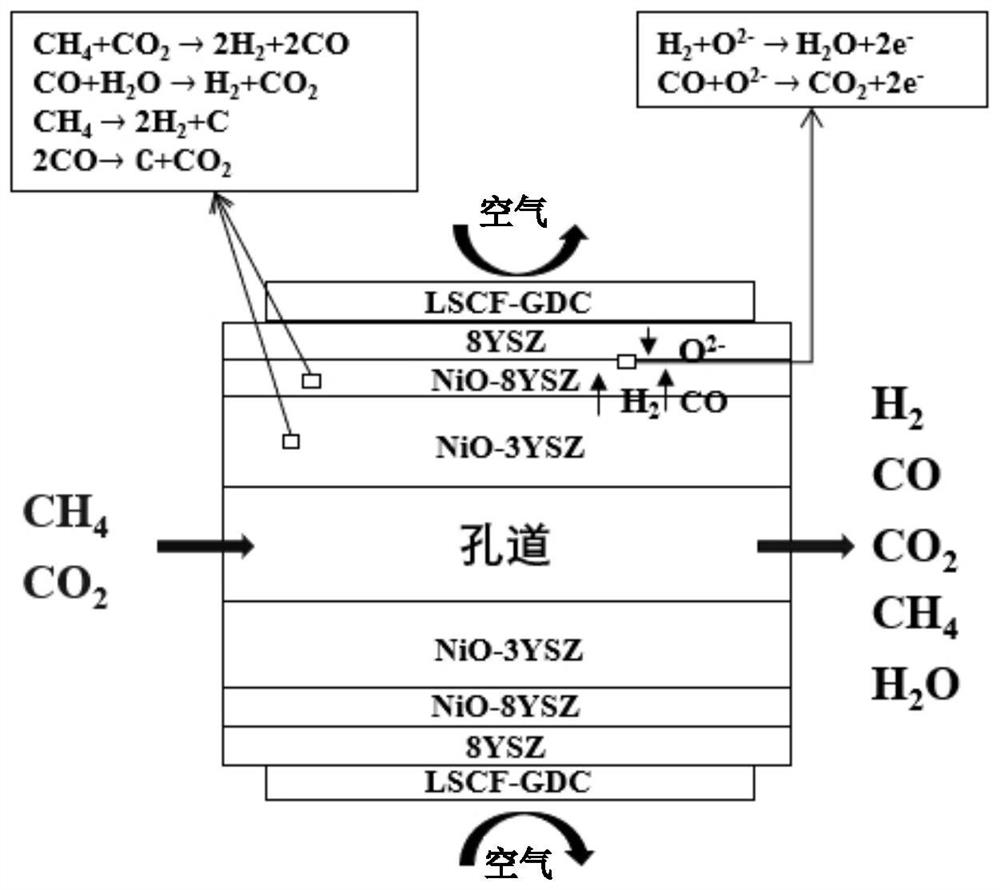

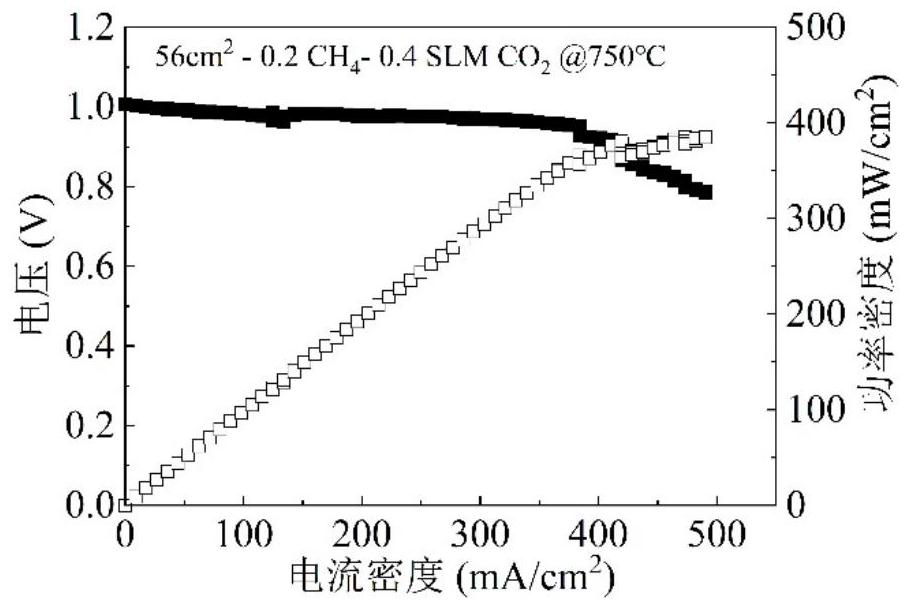

Direct methane dry reforming power generation method based on symmetrical double-cathode structure solid oxide fuel cell

InactiveCN112993267AExtended service lifeOperating conditions are easy to controlCell electrodesFuel cellsFuel cellsElectrical battery

The invention provides a direct methane dry reforming power generation method based on a symmetric double-cathode structure solid oxide fuel cell. The cell takes an anode layer as a supporting electrode layer, and an electrolyte layer and a cathode layer are stacked up and down along the thickness direction to form a symmetric structure; the cell is heated by a heating unit, so that the temperature of the cell is more than 650 DEG C in the operation process of the cell, a mixed gas of carbon dioxide and methane is introduced into a pore channel of the anode layer, and air is introduced into the cathode layer, so that methane dry reforming can be directly carried out in the cell, and direct and efficient utilization of methane in the solid oxide fuel cell is realized; and the method has the advantages of simple and easily-controlled operation conditions, low cost, safety, high efficiency and good reaction selectivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

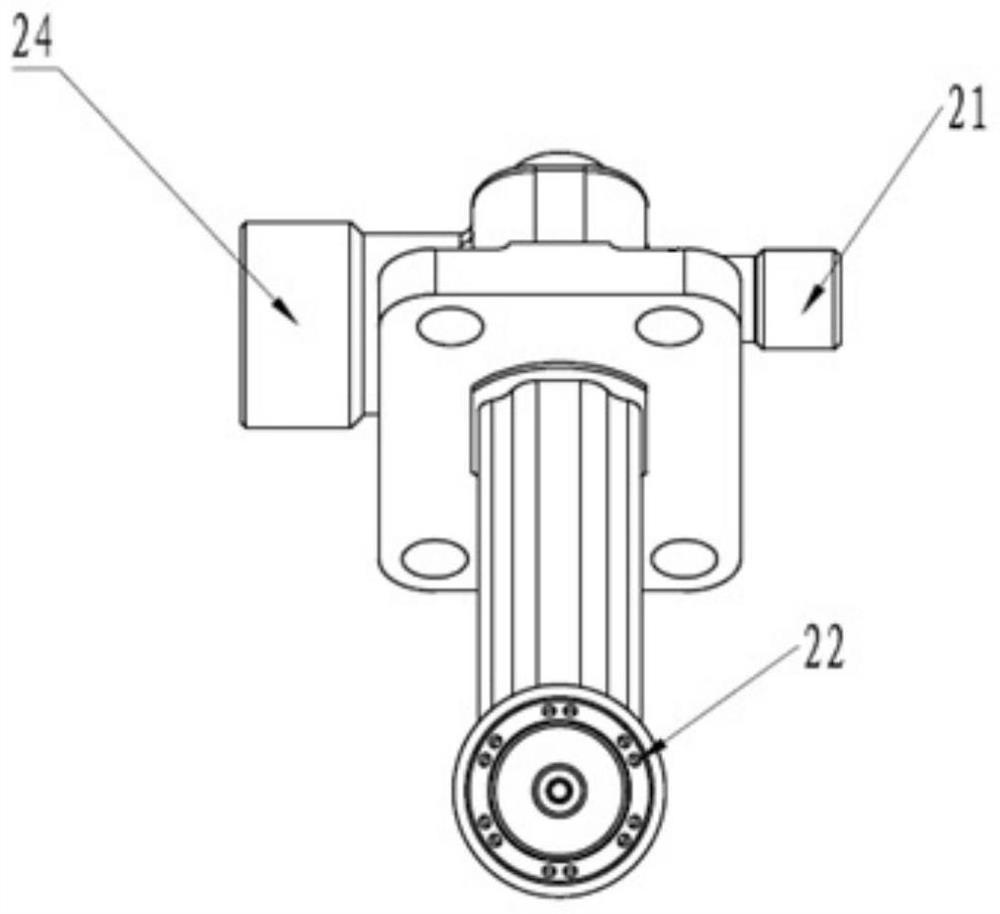

Heating system for cooling liquid of engine

InactiveCN106968863AReduce friction timeReduce the risk of carbon accumulationInternal combustion piston enginesExhaust apparatusEngineeringRecuperator

The invention provides a heating system for cooling liquid of an engine which is used for heating cooling liquid to heat the engine when the system is started at low-temperature environment. The system comprises an exhaustion pipeline for exhausting tail gas of the engine, wherein the exhaustion pipeline comprises a main pipe which is provided with an air inlet end and an exhaust end and is used for transmitting the tail gas to the outside of vehicles, a branch pipe of which one end is connected with the air inlet end of the main pipe and the other end is connected with the exhaust end of the main pipe, a valve which is arranged at a connection part of the main pipe and the branch pipe and is configured to selectively open or close the main pipe according to the temperature of the cooling liquid of the engine, and a heat exchanger which is communicated with the branch pipe and is used for transmitting the heat energy of the tail gas to the cooling liquid in the heat exchanger, wherein the branch pipe is configured to stop when the main pipe is opened and start when the main pipe is closed. By adopting the heating system for the cooling liquid of the engine, the carbon accumulation risk of idling speed of vehicles can be reduced, so that the vehicles can be quickly started and get away under a cold environment.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

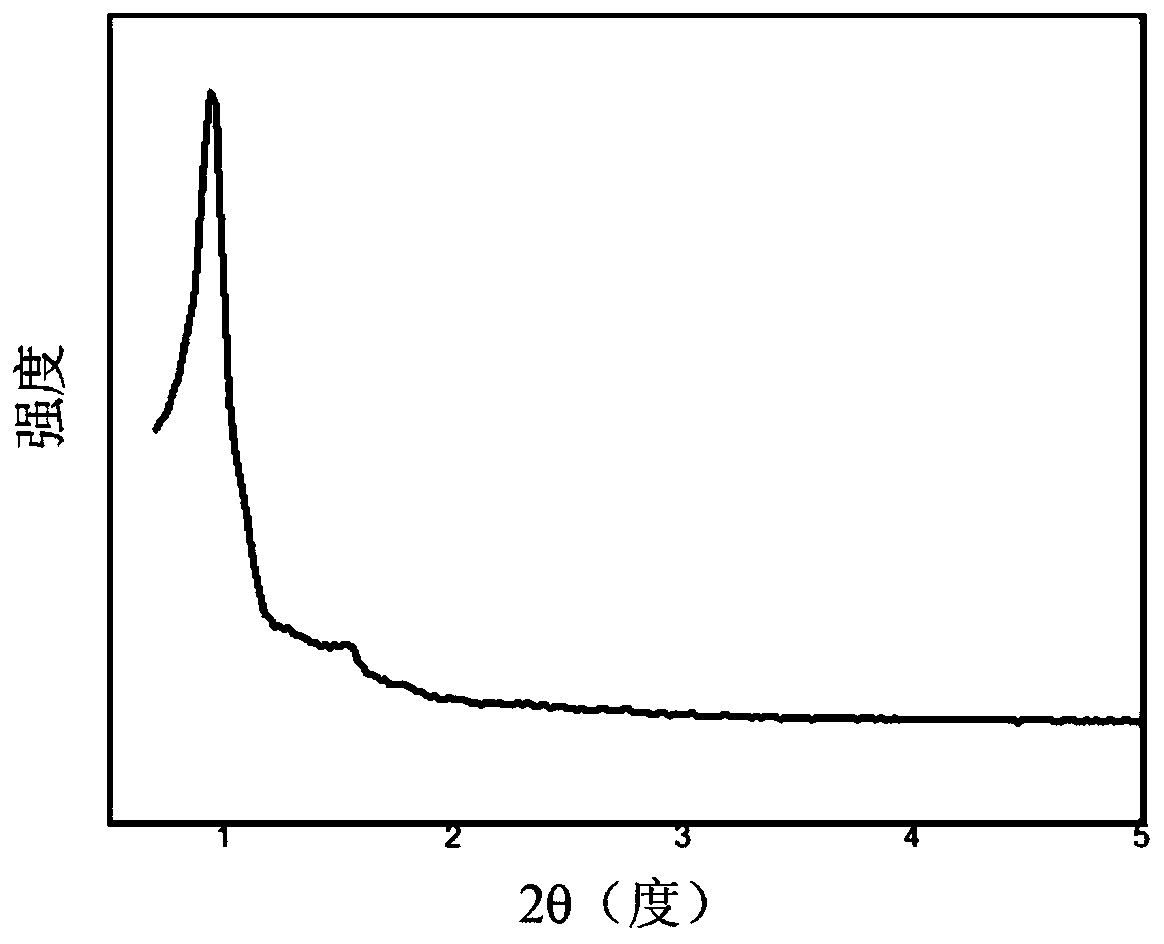

Isobutane dehydrogenation catalyst with supporter being mesoporous molecular sieve with three-dimensional cubic cage-shaped pore channel distribution structure as carrier as well as preparation method and application thereof

ActiveCN110614108ASimple preparation processConditions are easy to controlMolecular sieve catalystsHydrocarbonsMolecular sieveDehydrogenation

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst with supporter being a mesoporous molecular sieve with a three-dimensional cubic cage-shaped pore channel distribution structure, as well as a preparation method and application of the isobutane dehydrogenation catalyst. The method comprises the following steps: (a) preparing a mesoporous molecularsieve filter cake; (b) preparing a silica gel filter cake; (c) mixing the mesoporous molecular sieve filter cake and the silica gel filter cake, adding a binder, carrying out ball milling and spray drying, and removing the template agent and the binder in the obtained product; and (d) carrying out thermal activation treatment on the supporter obtained in the step (c), then carrying out dipping treatment in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying treatment and roasting treatment. Accordingto the method, the isobutane dehydrogenation catalyst with high catalytic activity can be synthesized by using a low-cost silicon source.

Owner:CHINA PETROLEUM & CHEM CORP +1

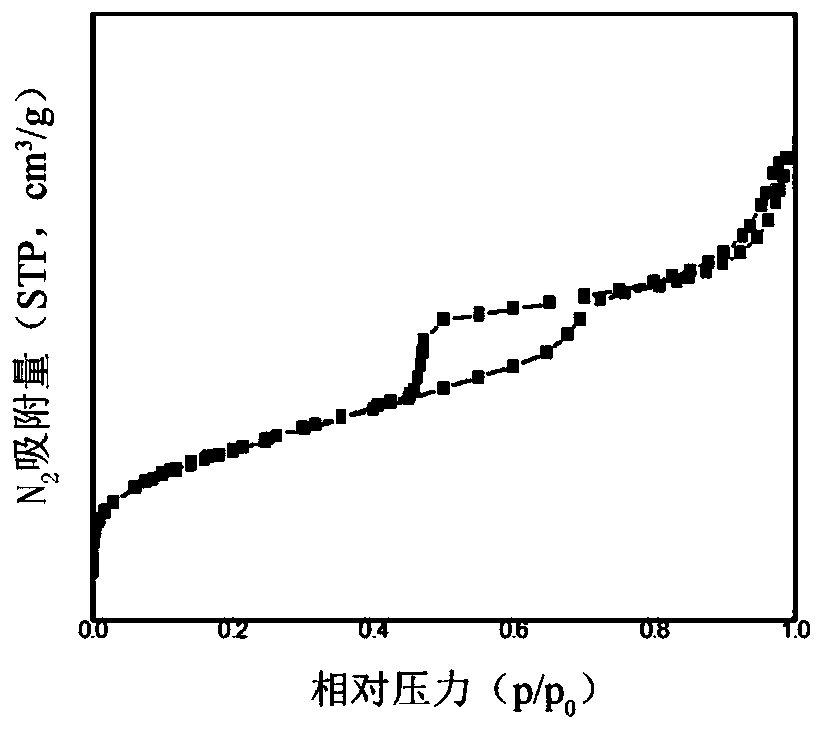

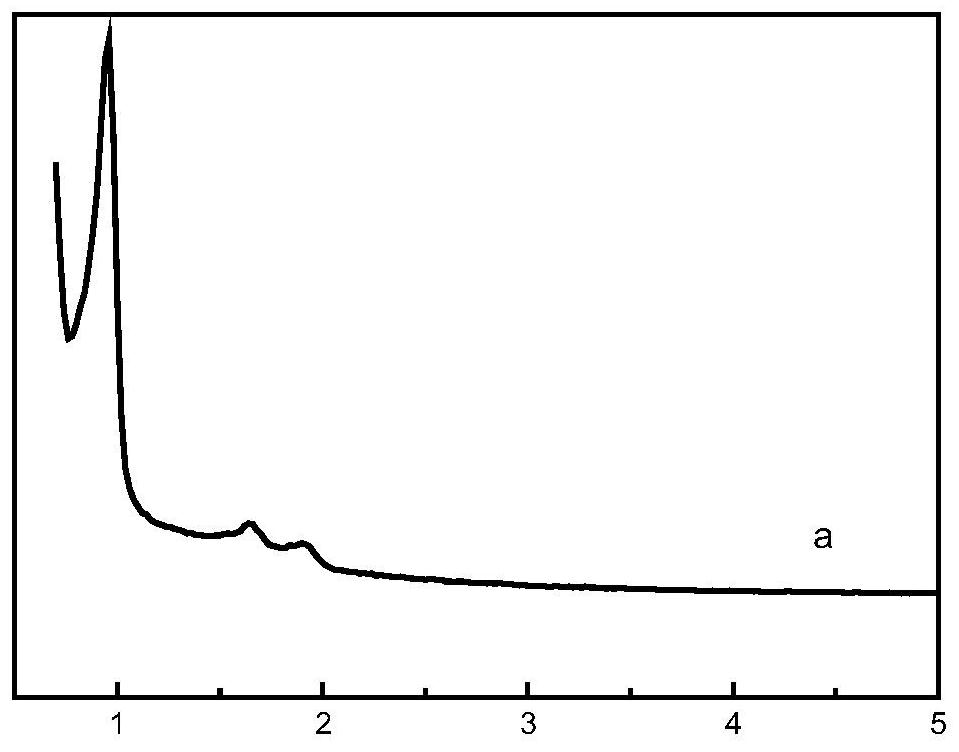

Isobutane dehydrogenation catalyst and preparation method thereof, and method for producing isobutene from isobutane dehydrogenation

ActiveCN110496633BSimple preparation processConditions are easy to controlMolecular sieve catalystsMolecular sieve catalystPtru catalystDehydrogenation

The invention relates to the field of catalysts, and discloses a method for preparing an isobutane dehydrogenation catalyst, an isobutane dehydrogenation catalyst prepared by the method and a method for preparing isobutene from isobutane dehydrogenation. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) preparing a mesoporous molecular sieve filter cake; (b) preparing a silica gel filter cake; (c) mixing the mesoporous molecular sieve filter cake and silica gel filter cake at high temperature Ball milling is carried out in an aluminum ceramic tank, and the solid powder obtained after ball milling is slurried with water and then spray-dried, and then the template agent in the obtained product is removed to obtain a spherical double-hole aluminum-containing silica gel mesoporous molecular sieve composite material carrier (d) impregnating the aforementioned spherical double-hole aluminum-containing silica gel mesoporous molecular sieve composite carrier in a solution containing a Pt component precursor and a Zn component precursor, followed by solvent removal, drying and calcination. The obtained isobutane dehydrogenation catalyst has good compressive strength, dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

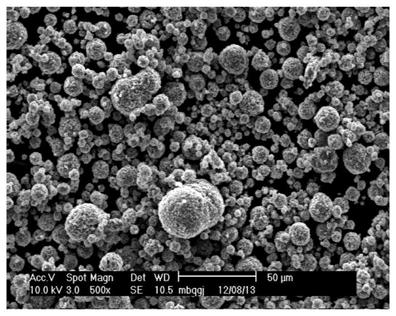

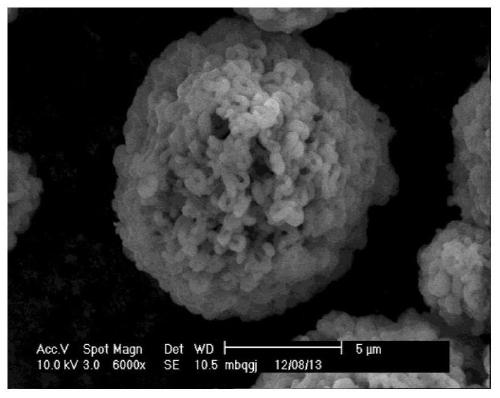

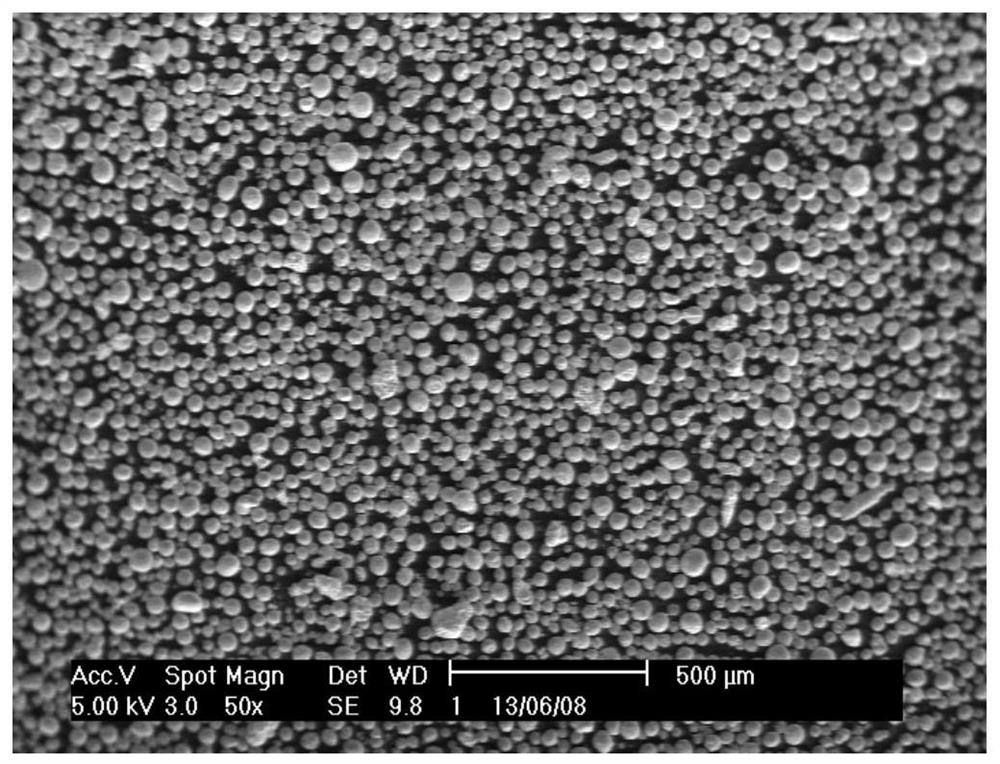

Isobutane dehydrogenation catalyst with spherical small-pore mesoporous silica gel composite material as supporter as well as preparation method and application of isobutane dehydrogenation catalyst

InactiveCN110614114ASimple preparation processConditions are easy to controlCatalyst carriersMolecular sieve catalystsMolecular sieveDehydrogenation

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst with a spherical small-pore mesoporous silica gel composite material as a supporter, and a preparation method and an application thereof; the method comprises the following steps: (a) preparing a spherical mesoporous molecular sieve; (b) preparing a silica gel filter cake; (c) mixing the sphericalmesoporous molecular sieve filter cake with silica gel, carrying out first ball milling and second ball milling, and carrying out spray drying; and (d) carrying out thermal activation treatment on thesupporter, then carrying out dipping treatment in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying treatment and roasting treatment. According to the method, the isobutane dehydrogenation catalyst with high catalytic activity can be synthesized by using a low-cost silicon source.

Owner:CHINA PETROLEUM & CHEM CORP +1

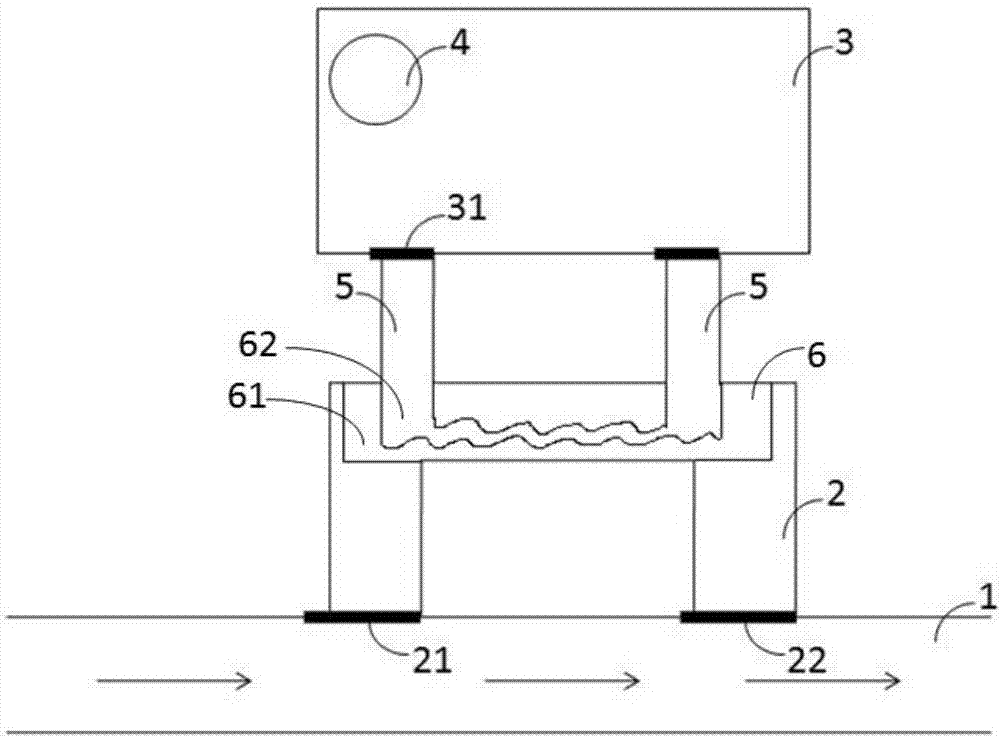

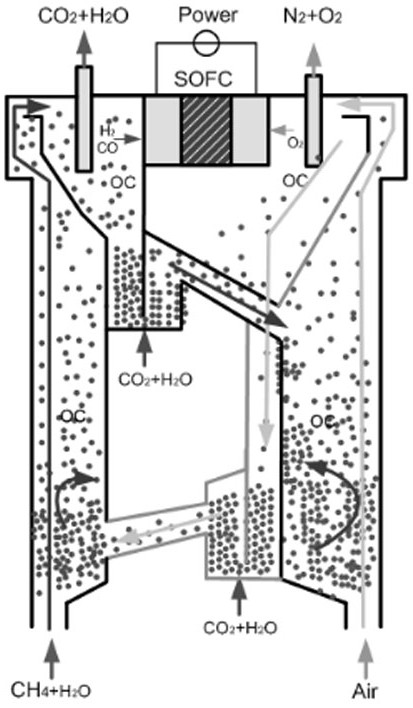

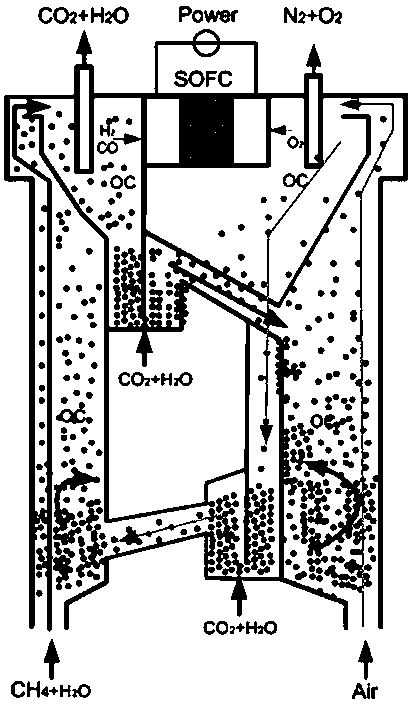

Chemical Looping Partial Oxidation Reforming Conversion Directly Coupled Fuel Cell Power Generation System

ActiveCN110364755BDoes not involve energy-intensive oxygen production stepsLow costSolid electrolyte fuel cellsPartial oxidationMethanation

The present invention aims at the problem of poor adaptability of solid oxide fuel cells to carbon-containing fuels. In particular, the present invention discloses a chemical chain partial oxidation reforming transformation direct coupling fuel cell power generation system. This system follows the chemical chain reforming transformation direct internal In the scheme of coupling high-temperature solid oxide fuel cells, the cathode and anode of high-temperature solid oxide fuel cells are directly placed in the exhaust space of the oxidation and reduction reactor tails of the chemical chain reforming transformation to form a closely connected cathode chamber and anode chamber. The hydrogen-rich gas produced by methane chemical chain reformation and the oxygen in the reaction air are directly supplied to the anode and cathode of the high-temperature solid oxide fuel cell. This system makes the heat and mass transfer and utilization of the two processes efficiently connected, rationally utilizes the low-grade heat energy in the process, reduces the exergy loss in the process of chemical energy-thermal energy exchange, and realizes the cascade utilization of energy; at the same time, it breaks the thermodynamic limitation of the reaction process. Ultimately realize the efficient power generation of methane and the enrichment of carbon dioxide.

Owner:山西中谱能源科技有限公司

Isobutane dehydrogenation catalyst and preparation method thereof, and method for producing isobutene from isobutane dehydrogenation

ActiveCN110496629BSimple preparation processConditions are easy to controlMolecular sieve catalystsCatalyst activation/preparationPtru catalystPhysical chemistry

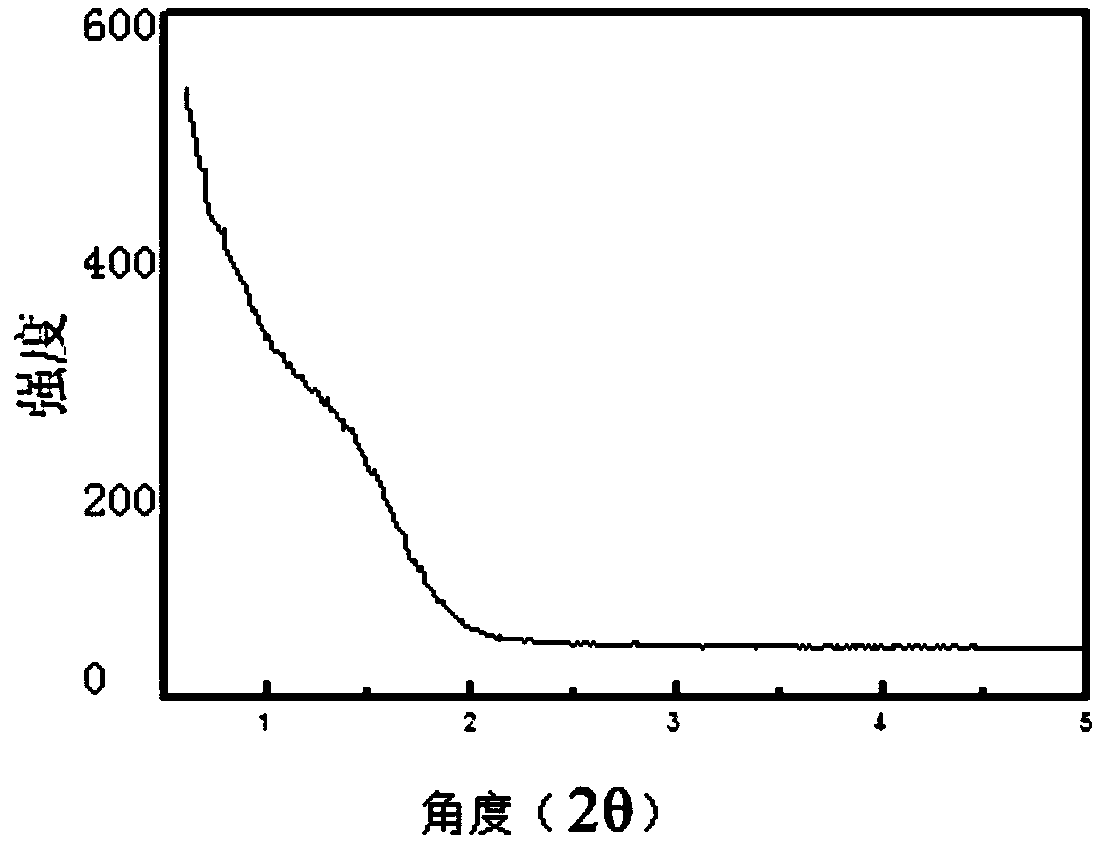

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst, a preparation method thereof and a method for preparing isobutene from isobutane dehydrogenation. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) carrying out thermal activation treatment on the zeolite to obtain a thermally activated zeolite carrier; (b) applying the thermally activated zeolite carrier obtained in step (a) to the The precursor and the Zn component precursor solution are impregnated, followed by solvent removal, drying and roasting. The method is simple to operate, and the raw materials are readily available, and the obtained isobutane dehydrogenation catalyst can achieve better dehydrogenation activity, selectivity, stability and carbon deposition resistance under the condition that the loaded amount of noble metal is very low.

Owner:CHINA PETROLEUM & CHEM CORP +1

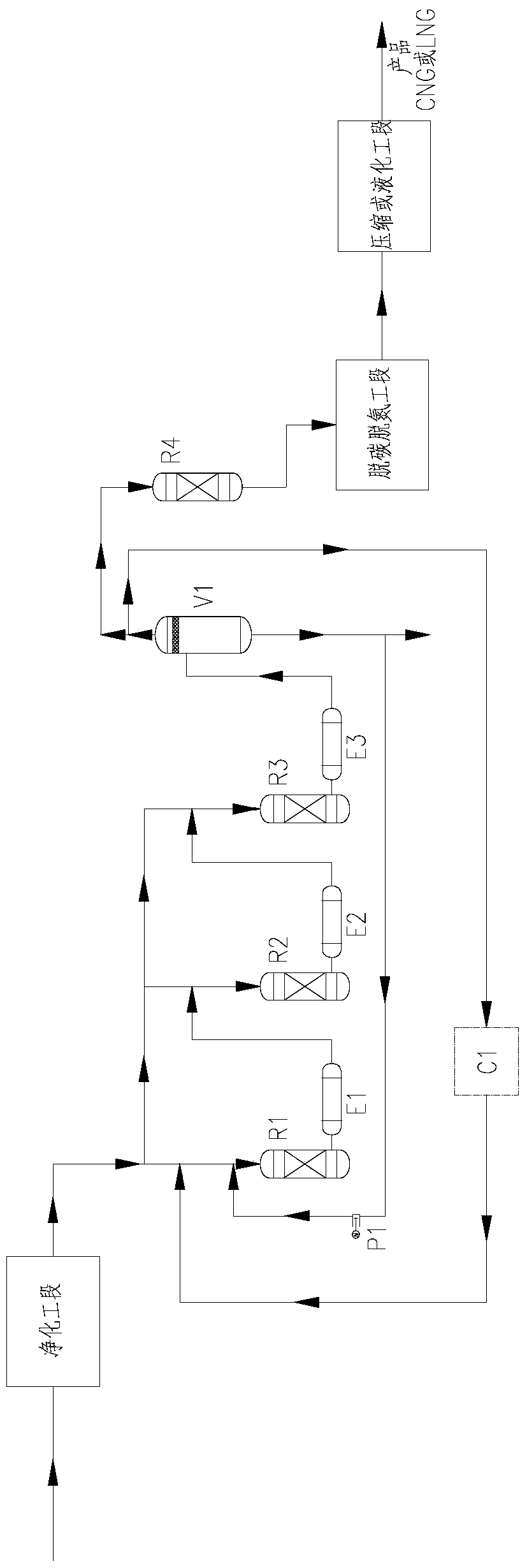

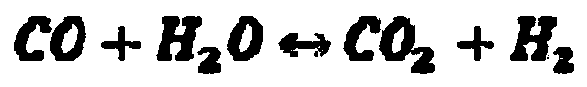

A method and device for producing natural gas from low-hydrogen carbon bilan coke tail gas

ActiveCN105647607BGuaranteed responseTemperature controlGaseous fuelsMethanationResource utilization

A method for producing natural gas from low hydrogen carbon bicarbonate tail gas, comprising: the semicoke tail gas is divided into three shares after being purified and desulfurized, the first unit is mixed with circulating gas or circulating liquid, and enters a first-stage transformation-methanation integrated reactor; After the two streams are mixed with the outlet gas of the first-stage transformation-methanation integrated reactor, they enter the second-stage methanation reactor; after the third stream is mixed with the outlet gas of the second-stage methanation reactor, they enter the third-stage methanation reactor; The outlet gas of the first-stage methanation reactor enters the fourth-stage methanation reactor to generate methane-enriched gas; the methane-enriched gas is decarbonized or / and liquefied to obtain natural gas or liquefied natural gas. Through the method of the present invention, at a low hydrogen-to-carbon ratio other than the conventional process, the semi-coke tail gas is used to generate natural gas, which effectively improves the utilization efficiency of effective gas; and the present invention adopts the post-decarbonization process, which can reduce the circulation amount and reduce the risk of carbon deposition ; The present invention has the advantages of simple process, simple operation, low investment and high utilization rate of resources.

Owner:XINDI ENERGY ENG TECH

Isobutane dehydrogenation catalyst and preparation method thereof and method for preparing isobutene from isobutane dehydrogenation

ActiveCN110496618BSimple preparation processConditions are easy to controlCatalyst activation/preparationHydrocarbonsPtru catalystSilicic acid

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst, a preparation method thereof and a method for preparing isobutene from isobutane dehydrogenation. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) template agent, potassium sulfate, acid agent and tetraethyl orthosilicate are mixed and contacted, and the obtained mixture is crystallized and filtered to obtain a cubic center of Im3m The original powder of the hexagonal mesoporous material with the structure; (b) carrying out the release template treatment with the original powder of the hexagonal mesoporous material with the cubic center Im3m structure, to obtain the hexagonal mesoporous material carrier; (c) the hexagonal mesoporous material carrier; (c) the hexagonal mesoporous material carrier The porous material carrier is subjected to thermal activation treatment, then impregnated in a solution containing a Pt component precursor and a Zn component precursor, followed by solvent removal treatment, drying and calcination in sequence. The obtained isobutane dehydrogenation catalyst has good dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isobutane dehydrogenation catalyst and preparation method thereof and method for preparing isobutene from isobutane dehydrogenation

ActiveCN110496617BSimple preparation processConditions are easy to controlCatalystsHydrocarbon preparation catalystsPtru catalystSilicic acid

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst, a preparation method thereof and a method for preparing isobutene from isobutane dehydrogenation. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) mixing a template agent, N, N-dimethylformamide and hydrochloric acid until the solids are fully dissolved; (b) mixing the solution obtained in step (a) with silicon (c) the product obtained in step (b) is contacted with silica gel for the second time, and the mixture obtained after the second contact is successively crystallized, filtered, washed and dried to obtain silica gel mesoporous dioxide Silicon composite raw powder; (d) remove the template agent in the product obtained in step (c) to obtain a silica gel mesoporous silica composite material carrier; (e) prepare the silica gel mesoporous silica composite material obtained in step (d) The carrier contains Pt component precursor and Zn component. The isobutane dehydrogenation catalyst prepared by the method has better dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

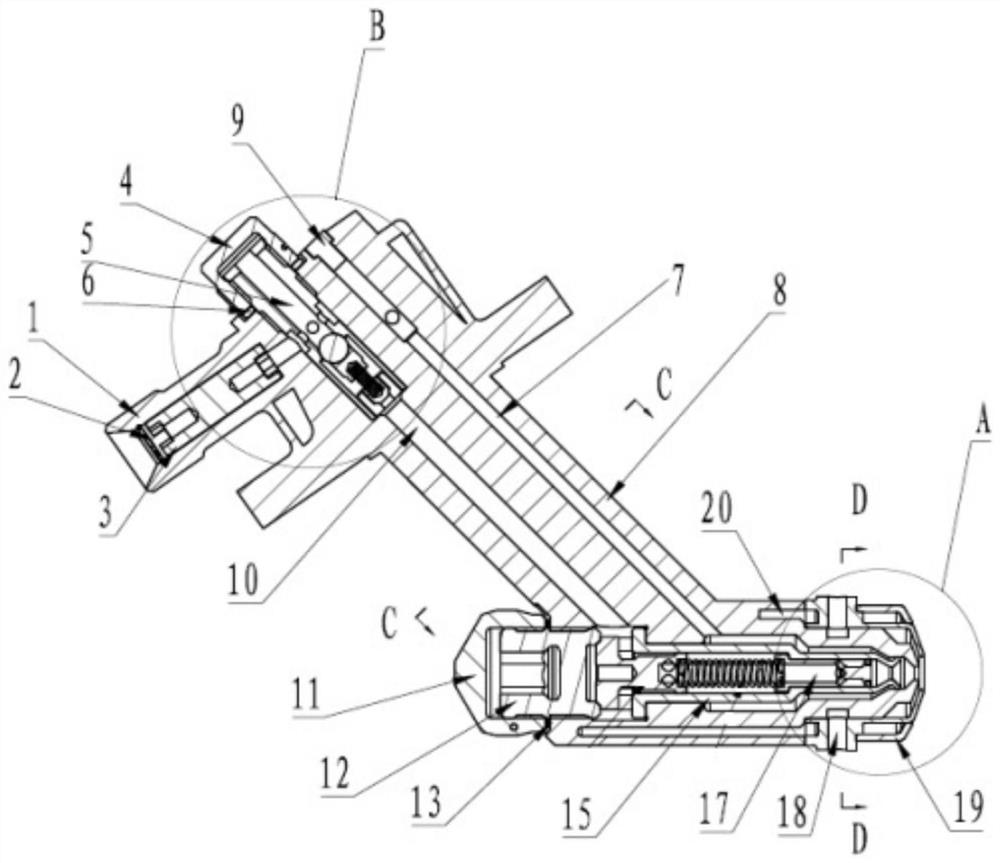

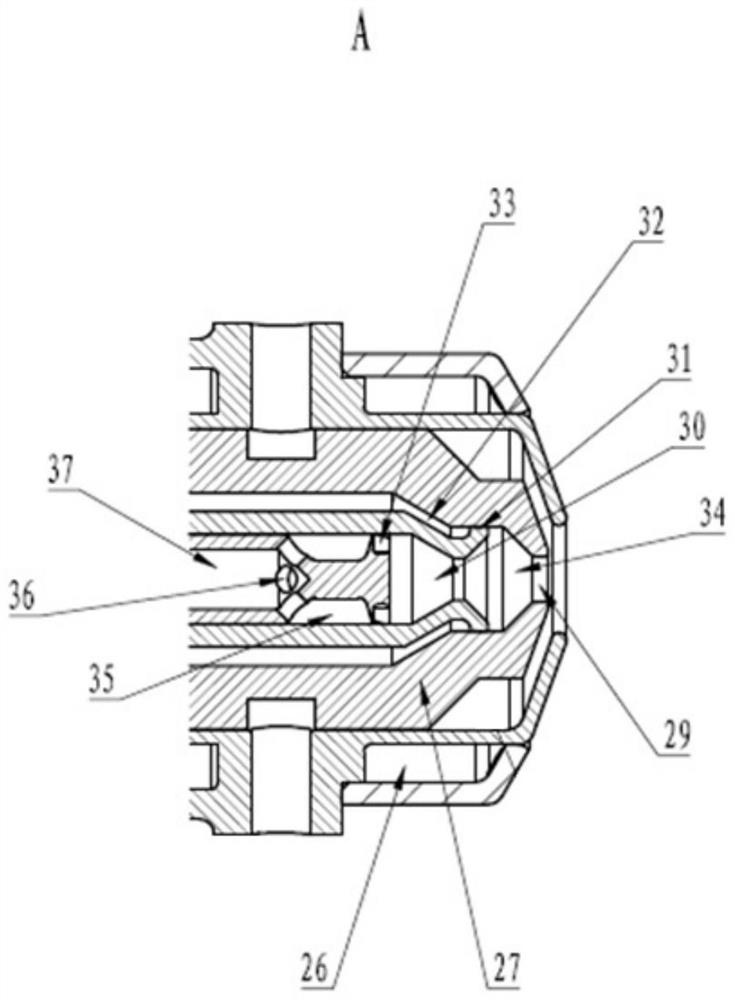

A dual fuel nozzle with dual oil passages and single nozzle

ActiveCN112460636BRealize bumpless online switchingPromote atomizationContinuous combustion chamberProcess engineeringLiquid fuel

The object of the present invention is to provide a dual fuel nozzle with dual oil paths and single nozzles, which includes a nozzle housing, a main oil path swirl atomization assembly, an auxiliary oil path swirl atomization assembly, and a gaseous fuel nozzle; the main oil path swirl atomization assembly The atomization assembly includes the main oil circuit swirler, the main fuel flow channel, the main oil circuit pre-swirl chamber, the swirl chamber, and the fuel nozzle; the auxiliary oil circuit swirl atomization assembly includes the auxiliary oil circuit swirler, the auxiliary fuel flow channel , swirl chamber, and fuel nozzle; the invention can realize the undisturbed online switching of gaseous fuel and liquid fuel without stopping the machine; the design of double oil circuit ensures the good fuel atomization effect before the idle condition, and the idle condition In the future, the fuel injection flow rate can be greatly increased without greatly increasing the fuel supply pressure; the design of the anti-carbon deposition air cooling component and the common nozzle of the main and auxiliary oil circuits can effectively prevent carbon deposition at the nozzle; the structural design of the auxiliary fuel flow channel surrounding the main fuel flow channel is effective The problem of thermal coking of the residual oil in the main fuel flow channel is avoided.

Owner:中国船舶重工集团公司第七0三研究所

Isobutane dehydrogenation catalyst and preparation method thereof and method for preparing isobutene from isobutane dehydrogenation

ActiveCN110496631BImprove throughputReduce accumulationMolecular sieve catalystsMolecular sieve catalystPtru catalystDehydrogenation

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst, a preparation method thereof and a method for preparing isobutene from isobutane dehydrogenation. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) contacting water glass, inorganic acid solution, n-butanol and glycerol, and then sequentially filtering and washing, ball milling, slurrying and spraying the obtained contact product Drying to obtain a silica gel carrier; (b) impregnating the silica gel carrier obtained in step (a) in a solution containing a Pt component precursor and a Zn component precursor, and then performing solvent removal and drying successively, wherein the step ( The filtering and washing described in a) is carried out in a ceramic membrane filter, and the content of sodium ions in the filtered and washed material in terms of sodium element is not higher than 0.2% by weight. The method has the advantages of simple operation, energy saving and environmental friendliness, and the obtained isobutane dehydrogenation catalyst can achieve better catalytic activity and stability under the condition that the loaded amount of noble metal is very low.

Owner:CHINA PETROLEUM & CHEM CORP +1

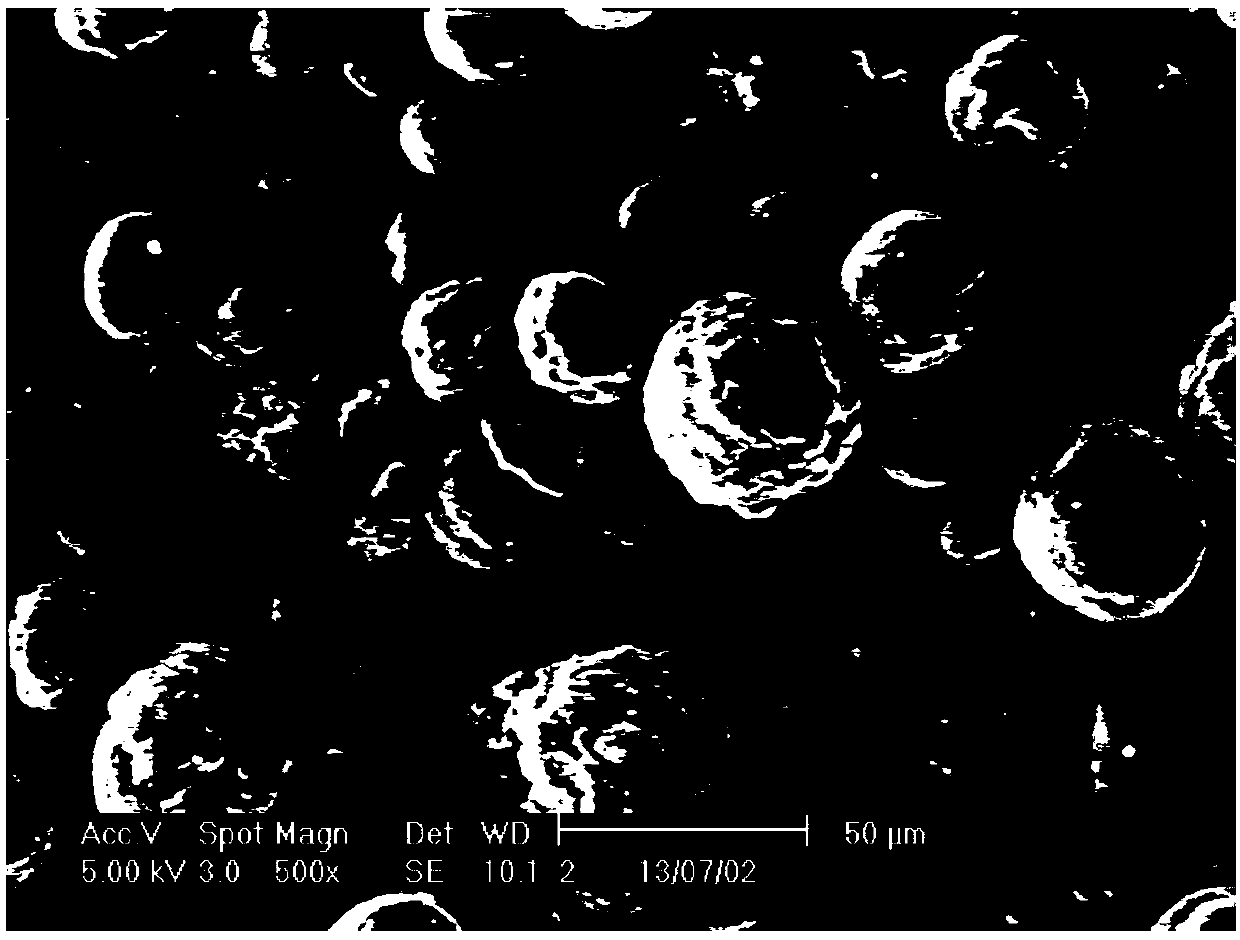

Non-noble metal isobutane dehydrogenation catalyst taking eggshell-shaped mesoporous material as carrier, preparation method and application thereof

InactiveCN111250111AReduce manufacturing costReduce the risk of carbon accumulationCatalyst activation/preparationHydrocarbonsPtru catalystPhysical chemistry

The invention relates to the field of catalysts, and discloses a non-noble metal isobutane dehydrogenation catalyst, a preparation method and application thereof. The method for preparing the non-noble metal isobutane dehydrogenation catalyst comprises the following steps: (a) providing eggshell-shaped mesoporous material raw powder; (b) carrying out template agent removing treatment on the eggshell-shaped mesoporous material raw powder to obtain an eggshell-shaped mesoporous material carrier; (c) under an ultrasonic condition, loading a first active non-noble metal component and a second active non-noble metal component on the eggshell-shaped mesoporous material carrier to obtain an initial non-noble metal isobutane dehydrogenation catalyst; and (d) vulcanizing the initial non-noble metalisobutane dehydrogenation catalyst by using a sulfur-containing gas. The obtained non-noble metal isobutane dehydrogenation catalyst has good dehydrogenation activity, good selectivity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

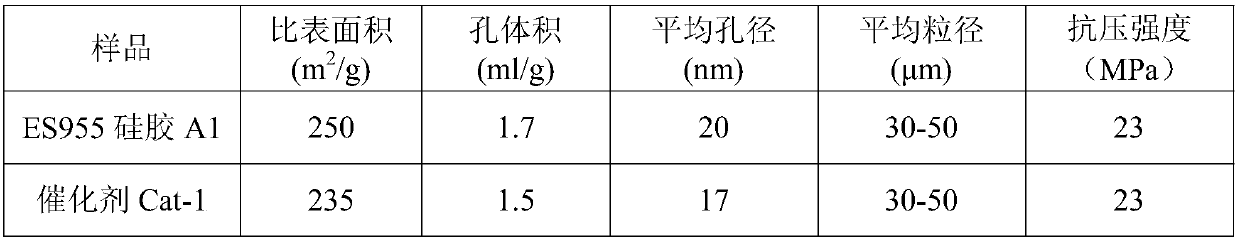

Isobutane dehydrogenation catalyst employing silica gel as support, preparation method for isobutane dehydrogenation catalyst and application of isobutane dehydrogenation catalyst

InactiveCN110813284ASimple preparation processConditions are easy to controlCatalystsHydrocarbon preparation catalystsPtru catalystPhysical chemistry

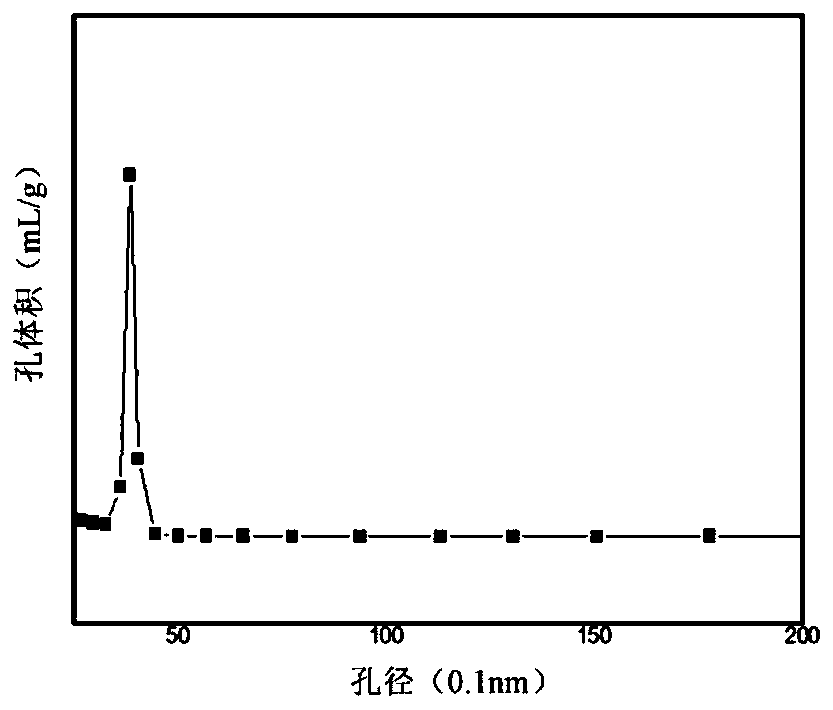

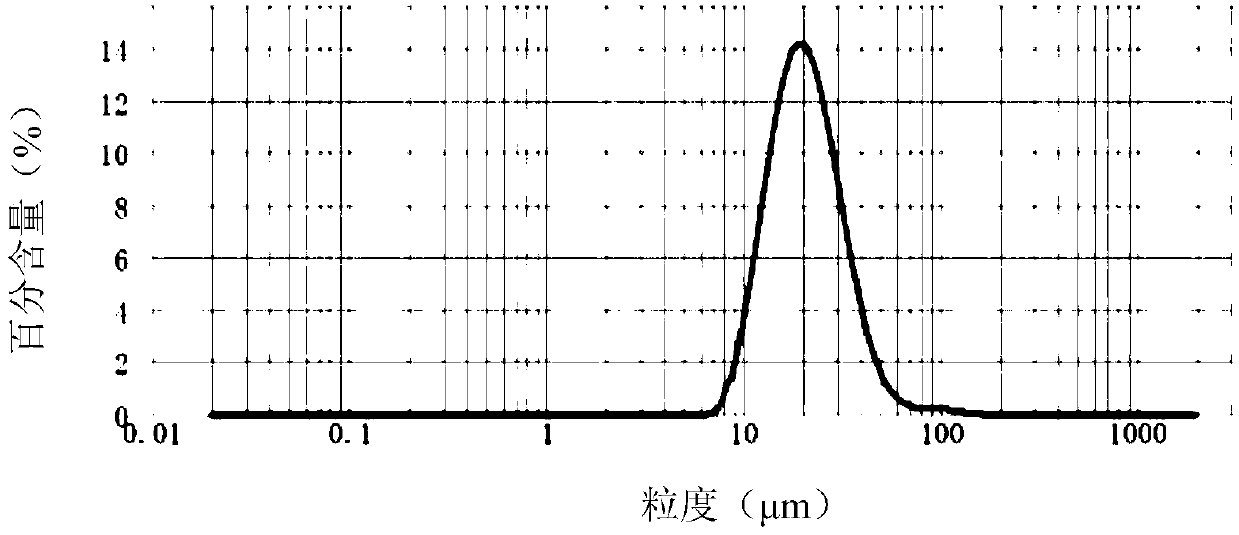

The invention relates to the field of catalysts and discloses an isobutane dehydrogenation catalyst employing silica gel as a support, a preparation method for the isobutane dehydrogenation catalyst,the isobutane dehydrogenation catalyst prepared by the method and an application of the isobutane dehydrogenation catalyst in isobutane dehydrogenated isobutene preparation. The preparation method forthe isobutane dehydrogenation catalyst comprises the steps: (a) subjecting the silica gel to thermal activating treatment, so as to obtain a thermal activated silica gel support; and (b) subjecting the thermal activated silica gel support obtained in the step (a) to dipping treatment in a solution containing a Pt ingredient precursor and a Zn ingredient precursor, and then, carrying out solvent removing treatment, drying and roasting sequentially, wherein the silica gel has a specific surface area of 200m<2> / g to 300m<2> / g, a pore volume of 1mL / g to 2mL / g, an average pore size of 10nm to 30nmand a mean particle size of 20 to 100 microns. According to the method, the operation is simple and convenient, the raw materials are readily available, and the obtained isobutane dehydrogenation catalyst can achieve relatively good dehydrogenation activity, selectivity, stability and resistance to carbon deposition under the condition that the load amount of noble metal is very small.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fuel cell power generation system with partial oxidization, reforming, conversion and direct coupling of chemical chains

ActiveCN110364755ADoes not involve energy-intensive oxygen production stepsLow costSolid electrolyte fuel cellsThermal energyPartial oxidation

The invention especially discloses a fuel cell power generation system with partial oxidization, reforming, conversion and directly coupling of chemical chains in view of poor adaptability of solid oxide fuel cells to carbon-bearing fuel. The system follows the scheme of a high-temperature solid oxide fuel cell with reforming, conversion and direct internal coupling of chemical chains, directly arranges the cathode and the anode of the high-temperature solid oxide fuel cell in exhaust spaces at the tail parts of an oxidization reactor and a reduction reactor for reforming and conversion of thechemical chains respectively to form a cathode chamber and an anode chamber which are tightly connected, a hydrogen-rich gas generated by the reforming and conversion of methane chemical chains and oxygen in reaction air are directly supplied to the anode and the cathode of the high-temperature solid oxide fuel cell. The system enables the heat and mass transfer and utilization in the two processes to be efficiently connected, reasonably utilizes low-grade heat energy in the process, reduces the process exergy loss of chemical energy-heat energy exchange, and realizes the cascade utilizationof energy; and meanwhile, the thermodynamic limit in the reaction process is broken through. Finally, the high-efficiency power generation of methane is realized, and carbon dioxide is enriched.

Owner:山西中谱能源科技有限公司

Isobutane dehydrogenation catalyst and preparation method thereof and method for preparing isobutene from isobutane dehydrogenation

ActiveCN110496636BImprove throughputReduce accumulationMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention relates to the field of catalysts, and discloses an isobutane dehydrogenation catalyst, a preparation method thereof and a method for preparing isobutene from isobutane dehydrogenation. The method for preparing an isobutane dehydrogenation catalyst includes: (a) preparing a mesoporous molecular sieve material; (b) mixing the aforementioned mesoporous molecular sieve material with silica gel, and then filtering and washing the mixed material, ball milling, slurrying and spraying in sequence Drying to obtain a spherical double mesoporous composite material carrier; (c) impregnating the aforementioned spherical double mesoporous composite material carrier in a solution containing a Pt component precursor and a Zn component precursor, followed by solvent removal and Drying, wherein, the filtering and washing described in step (b) is carried out in a ceramic membrane filter, the content of sodium ions in the mixed material after filtering and washing is not higher than 0.2% by weight in terms of sodium element, and the content of template agent is not higher than 1% by weight. The obtained isobutane dehydrogenation catalyst has good dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isobutane dehydrogenation catalyst using spherical double-mesoporous zeolite composite material as carrier, preparation method and applications thereof

InactiveCN110732340ASimple preparation processConditions are easy to controlMolecular sieve catalystsMolecular sieve catalystPtru catalystDehydrogenation

The invention relates to the field of catalysts, and discloses a method for preparing an isobutane dehydrogenation catalyst, the isobutane dehydrogenation catalyst prepared by the method, and a methodfor preparing isobutene through dehydrogenation of isobutane. The method for preparing the isobutane dehydrogenation catalyst comprises: (a) preparing a mesoporous material filter cake with a one-dimensional hexagonal structure; (b) preparing a silica gel filter cake; (c) mixing the mesoporous material filter cake, the silica gel filter cake and zeolite, carrying out ball milling, pulping the solid powder obtained after ball milling with water, carrying out spray drying, and removing the template agent in the obtained product to obtain a spherical double-mesoporous zeolite composite materialcarrier; and (d) carrying out dipping treatment on the spherical double-mesoporous zeolite composite material carrier obtained in the step (c) in a solution containing a Pt component precursor and a Zn component precursor, and then sequentially carrying out solvent removal treatment, drying and roasting. The obtained isobutane dehydrogenation catalyst of the invention has good dehydrogenation activity and carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

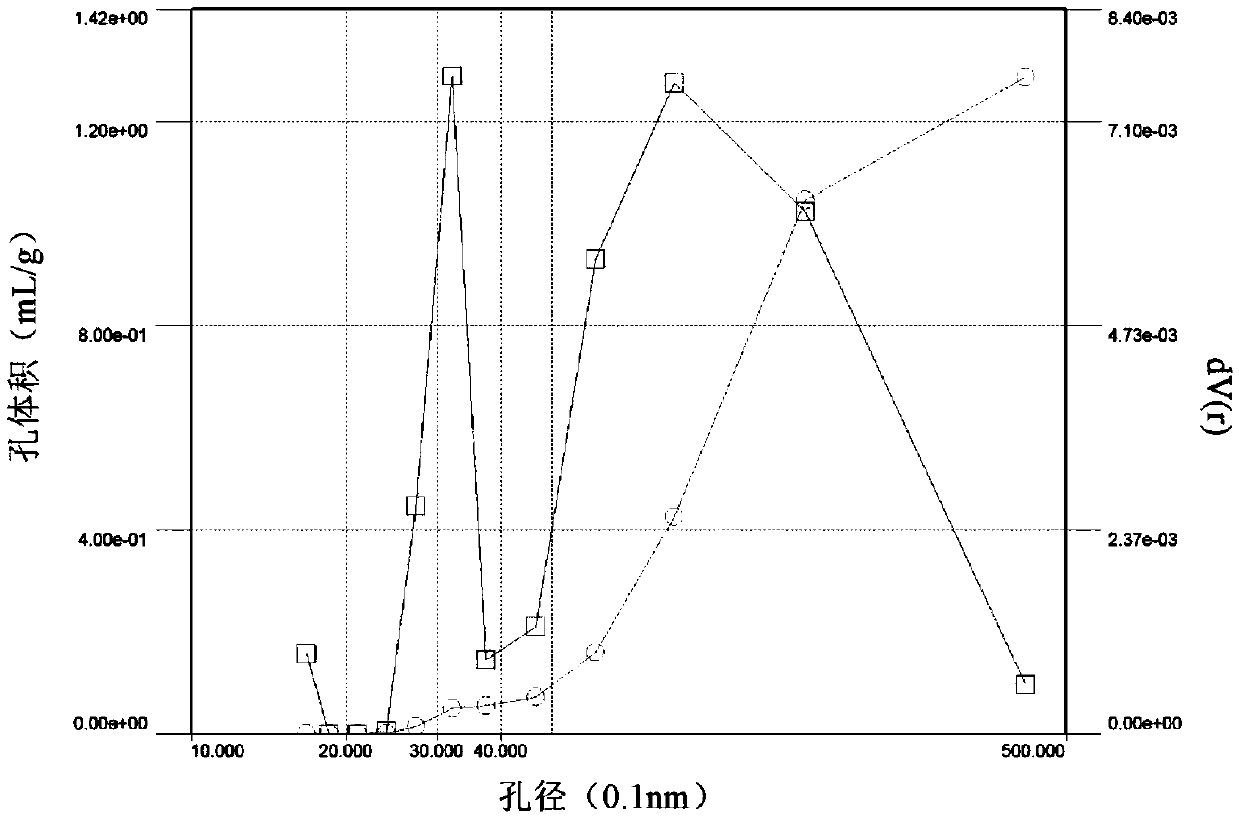

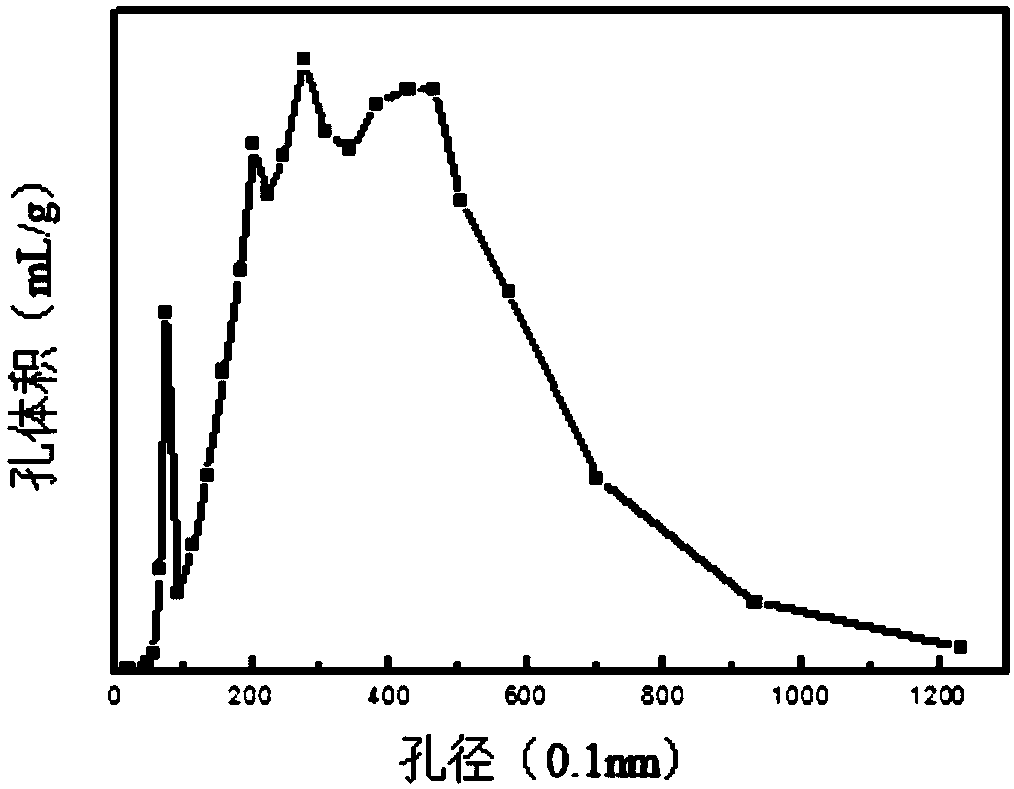

Isobutane dehydrogenation catalyst and preparation method thereof and method for preparing isobutene from isobutane dehydrogenation

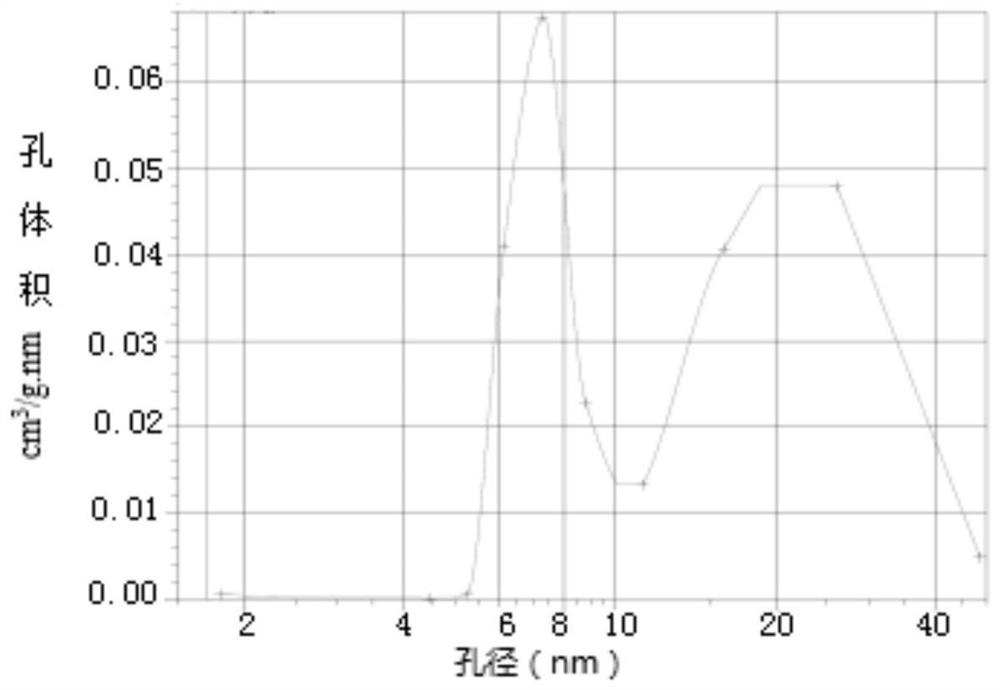

ActiveCN110496634BReduce manufacturing costHigh selectivityMolecular sieve catalystsMolecular sieve catalystPtru catalystDehydrogenation

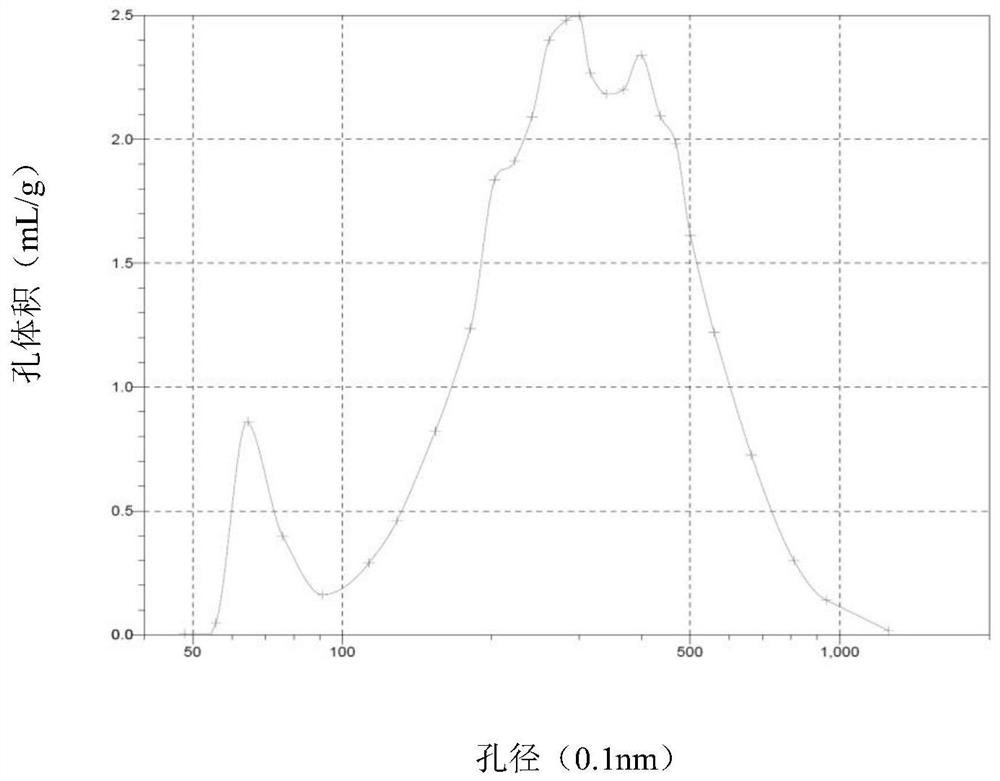

The invention relates to the technical field of catalyst preparation, and discloses an isobutane dehydrogenation catalyst, a preparation method thereof, and a method for preparing isobutene from isobutane dehydrogenation; wherein, the isobutane dehydrogenation catalyst includes a carrier and Pt loaded on the carrier Component and Zn component, the carrier is a one-dimensional straight-through channel double-hole spherical mesoporous composite carrier, the average particle diameter of the carrier is 30-70μm, and the specific surface area is 200-300m 2 / g, the pore volume is 0.5-2.3mL / g, the pore size distribution is bimodal, and the bimodal corresponds to the first most probable pore diameter of 5-20nm and the second most probable pore diameter of 10-40nm respectively , the first most probable pore diameter is smaller than the second most probable pore diameter; the dehydrogenation catalyst of the present invention can achieve better dehydrogenation activity, selectivity, stability and carbon deposition resistance under the condition of very low noble metal loading sex.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com