Direct methane dry reforming power generation method based on symmetrical double-cathode structure solid oxide fuel cell

A dry reforming technology of solid oxide and methane, which is applied in the direction of fuel cells, battery electrodes, structural parts, etc., can solve the problems of reduced battery performance and life, difficulty in achieving internal reforming, loss of anode active area, etc., to increase flow speed, relieve internal thermal stress, and prevent battery rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

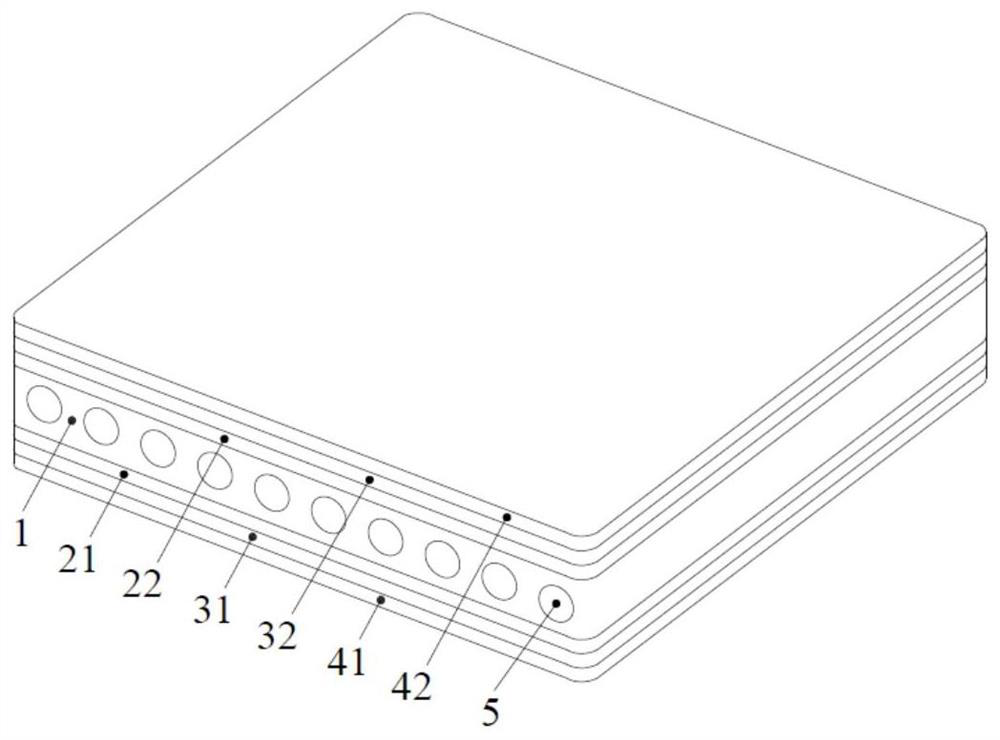

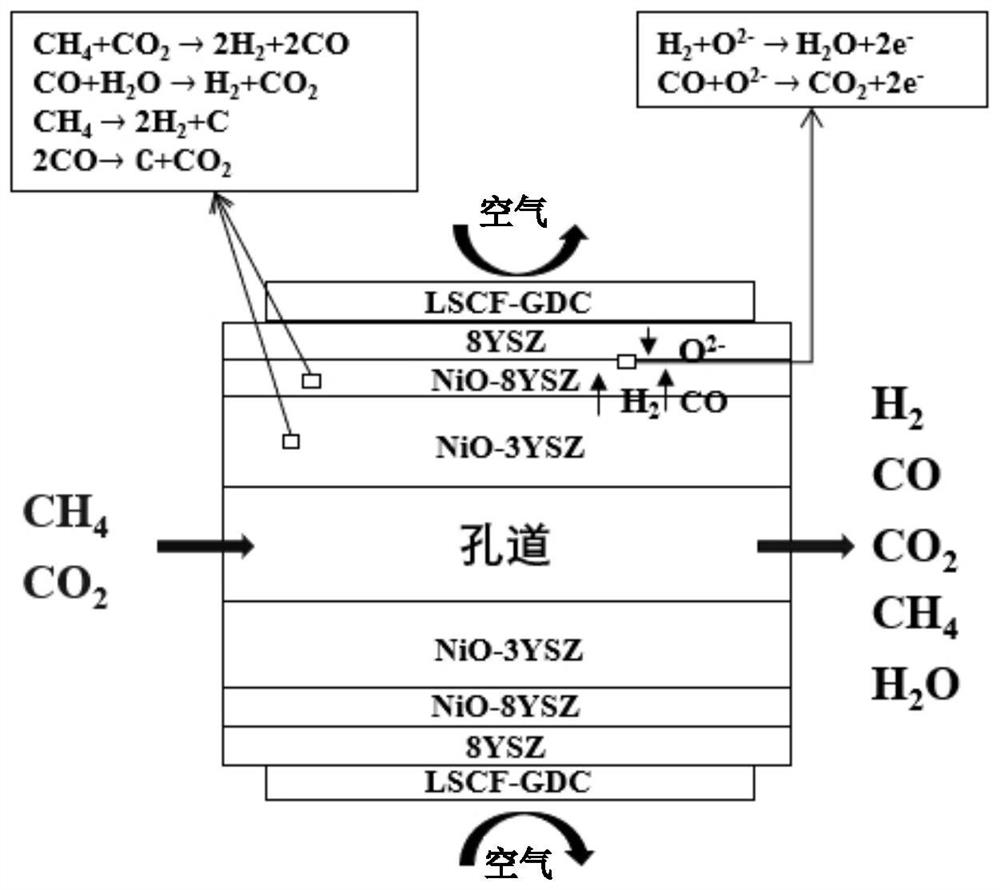

[0033] In this example, if figure 1 As shown, the solid oxide fuel cell uses the anode layer 1 as the supporting electrode layer, and the electrolyte layer and the cathode layer are stacked up and down along the thickness direction. The electrolyte layer includes a first electrolyte layer 21 and a second electrolyte layer 22, and the first electrolyte layer is located on the anode layer. The lower surface of the anode, the second electrolyte layer is located on the upper surface of the anode; the barrier layer includes a first barrier layer 31 and a second barrier layer 32, the first barrier layer is located on the lower surface of the first electrolyte layer, and the second barrier layer is located on the second electrolyte layer The upper surface of the layer; the cathode layer includes a first cathode layer 41 and a second cathode layer 42, the first cathode layer is located on the lower surface of the first barrier layer, and the second cathode layer is located on the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com