Isobutane dehydrogenation catalyst using spherical double-mesoporous zeolite composite material as carrier, preparation method and applications thereof

A dehydrogenation catalyst and composite material technology, applied in the field of catalysts, can solve the problems of uneven dispersion of noble metal active components, poor catalytic activity and stability, etc., and achieve the effects of reducing the risk of carbon deposition, good catalytic performance and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

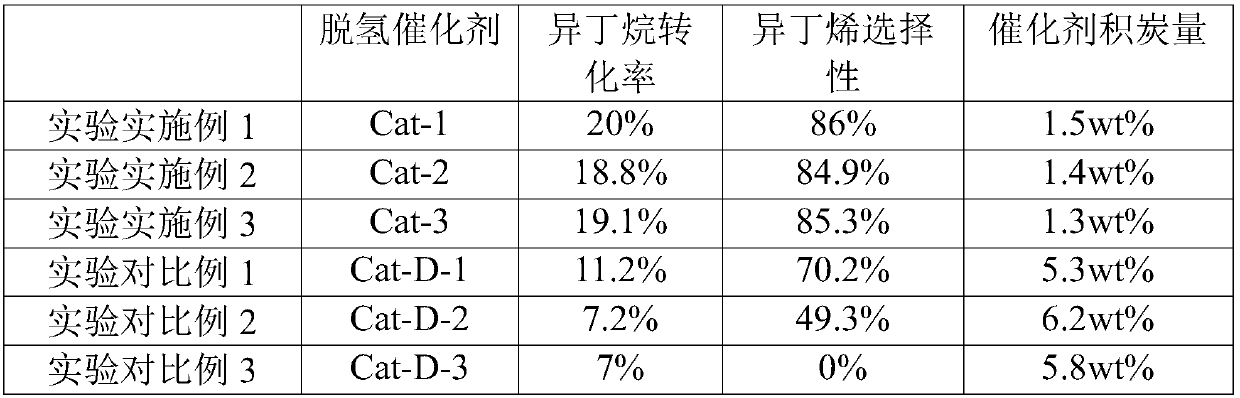

Embodiment 1

[0083] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

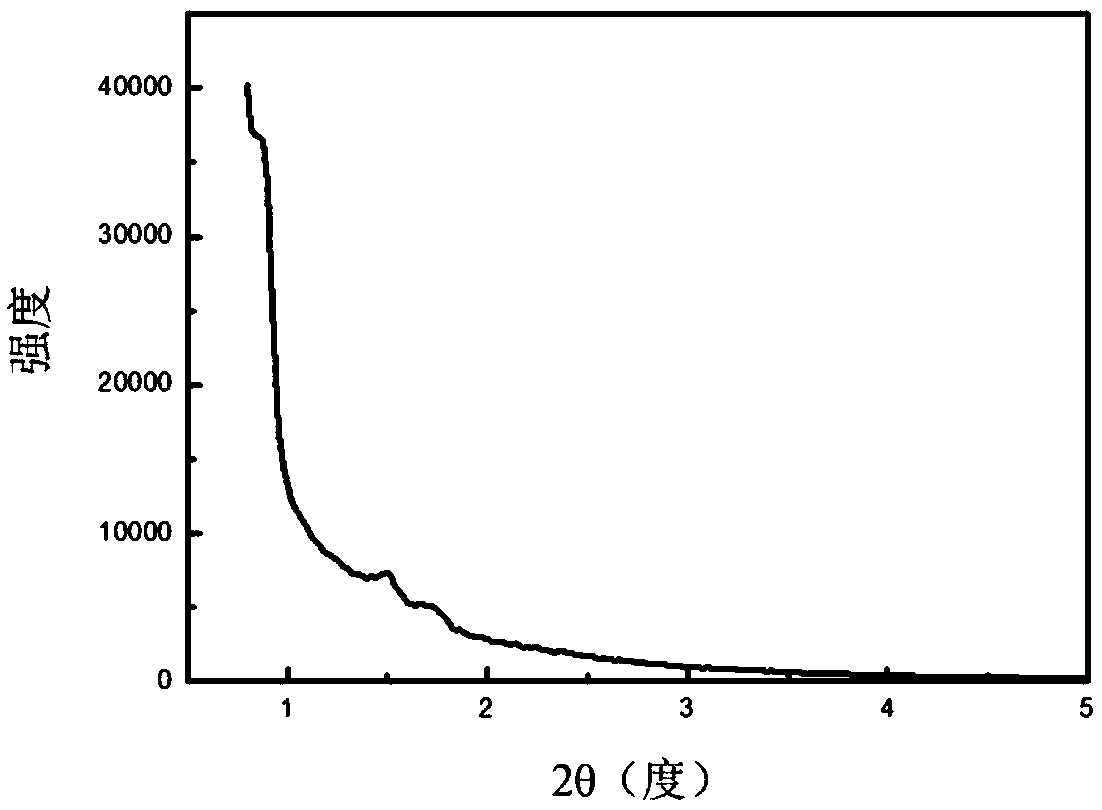

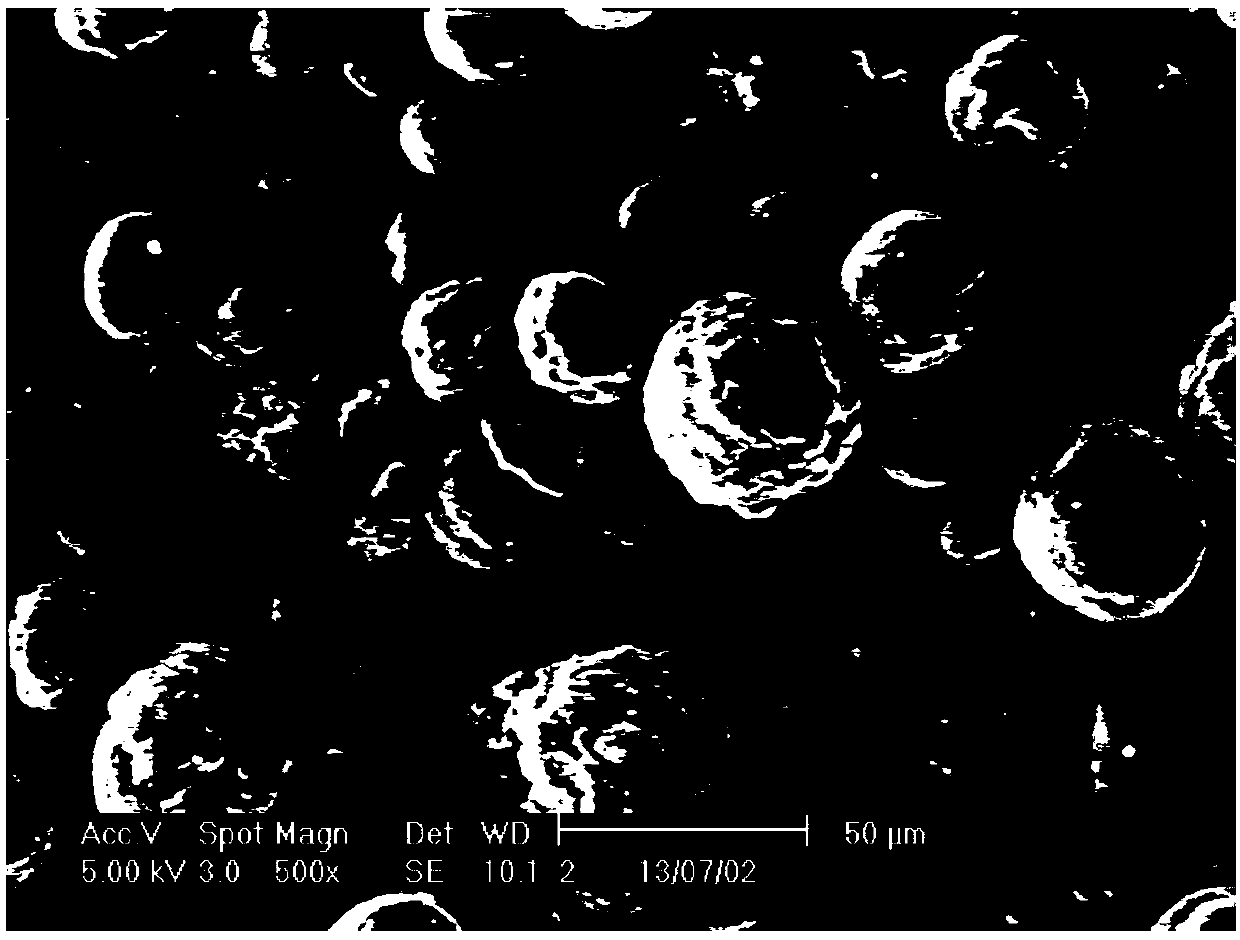

[0084] (1) Preparation of carrier

[0085]Add 1g (0.0002mol) of triblock copolymer surfactant P123 and 1.69g (0.037mol) of ethanol to 28ml of acetic acid and sodium acetate buffer solution with a pH value of 4, and stir at 15°C until P123 is completely dissolved. Add 6g (0.053mol) trimethylpentane to the obtained solution afterwards, stir at 15°C for 8h, then add 2.13g (0.014mol) tetramethoxysilane to it, at 15°C, the pH value is 4.5 Stirred under conditions for 20h, then transferred the obtained solution to a polytetrafluoroethylene-lined reactor, crystallized at 60°C for 24h, then filtered and washed 4 times with deionized water, and then suction filtered to obtain a one-dimensional Mesoporous molecular sieve material filter cake A1 with hexagonal single-pore distribution structure;

[0086] Concentration is that the water glass of 15% by weight and the sulfuric a...

Embodiment 2

[0108] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0109] (1) Preparation of carrier

[0110] Add 1g (0.0002mol) of triblock copolymer surfactant P123 and 1.84g (0.04mol) of ethanol to 28ml of acetic acid and sodium acetate buffer solution with a pH value of 5, and stir at 15°C until P123 is completely dissolved. Then add 9.12g (0.08mol) trimethylpentane to the resulting solution, stir at 15°C for 8h, then add 3.04g (0.02mol) tetramethoxysilane to it, at 25°C, pH value is 5.5 Stirring for 15h under the condition of , then transferring the obtained solution to a polytetrafluoroethylene-lined reactor, crystallizing at 100°C for 10h, then filtering and washing with deionized water for 4 times, and then suction filtering to obtain a Mesoporous molecular sieve material filter cake A2 with single-dimensional hexagonal channel distribution structure;

[0111] Concentration is that the water glass of 15% by weight and the s...

Embodiment 3

[0121] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0122] (1) Preparation of carrier

[0123] Add 1g (0.0002mol) of triblock copolymer surfactant P123 and 2.76g (0.06mol) of ethanol to 28ml of acetic acid and sodium acetate buffer solution with a pH value of 3, and stir at 15°C until P123 is completely dissolved. Then add 5.7g (0.05mol) trimethylpentane to the resulting solution, stir at 15°C for 8h, then add 2.13g (0.014mol) tetramethoxysilane, at 40°C, pH value is 3.5 Stirring for 10 h under the condition of , then transferring the obtained solution to a polytetrafluoroethylene-lined reactor, crystallizing at 40 ° C for 40 h, then filtering and washing with deionized water for 4 times, and then suction filtering to obtain a Mesoporous molecular sieve material filter cake A3 with a single-pore distribution structure of six-dimensional hexagonal channels;

[0124]The concentration is that the water glass of 15% by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com