A dual fuel nozzle with dual oil passages and single nozzle

A single-nozzle, dual-fuel technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problem of easy carbon deposition at the nozzle of the main oil circuit, achieve good atomization effect, improve combustion efficiency, and increase fuel injection flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail below in conjunction with accompanying drawing example:

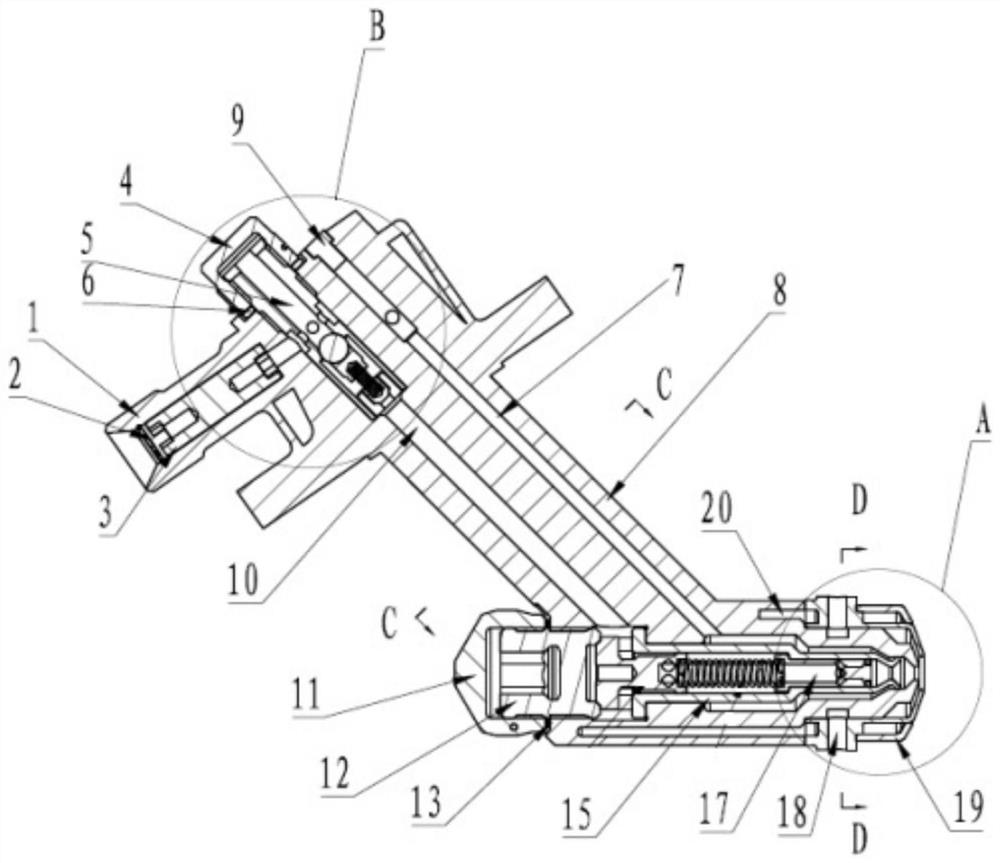

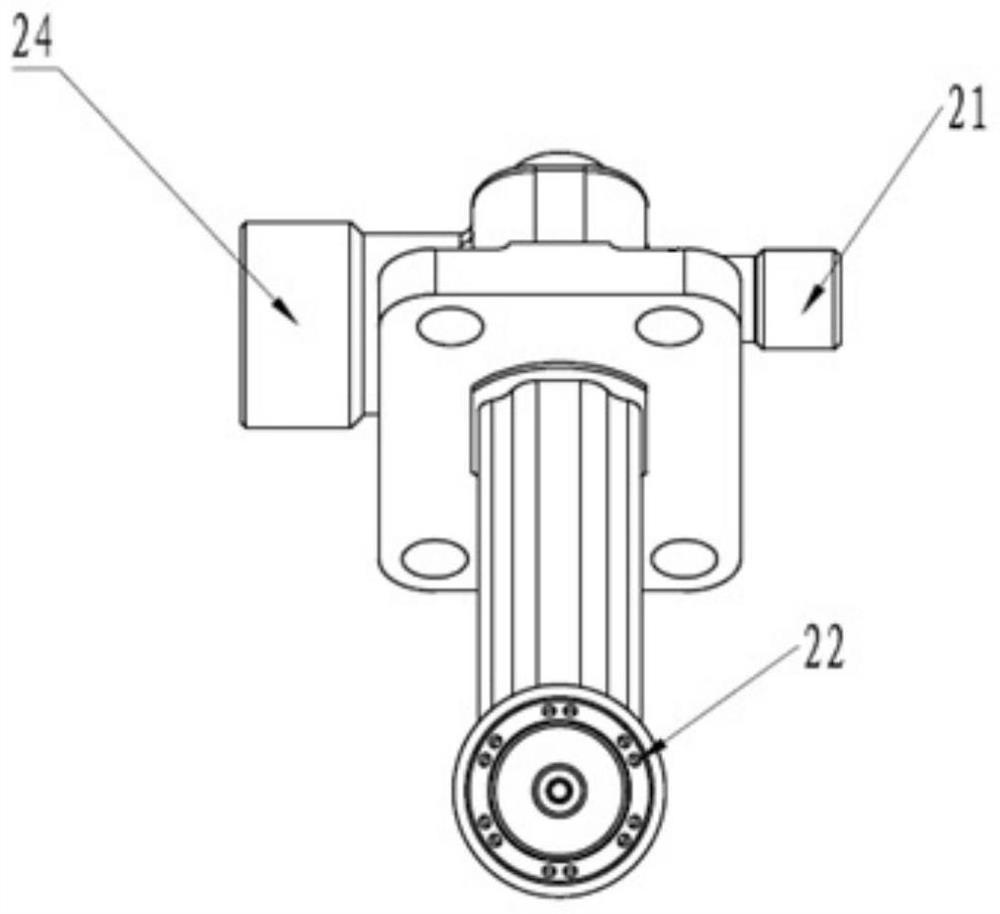

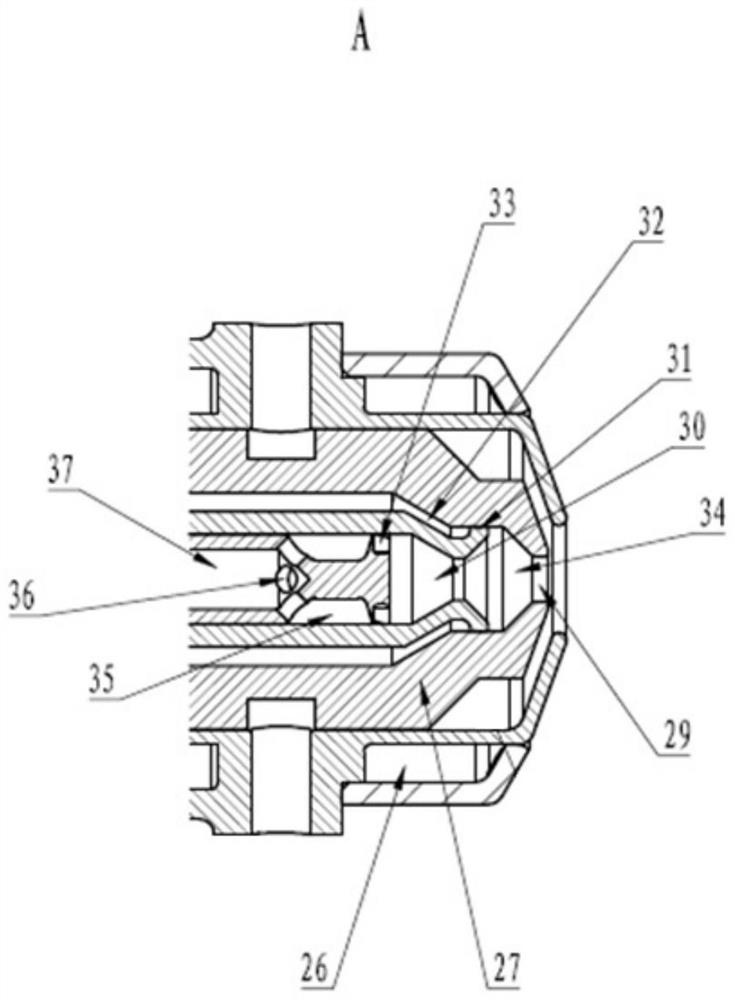

[0029] combine Figure 1-7 , the present invention is a dual fuel nozzle with dual oil circuit and single nozzle, which mainly includes main oil circuit connector 1, auxiliary oil circuit connector 21, gaseous fuel connector 24, nozzle housing 8, check valve 5, main oil circuit swirl Atomization assembly, auxiliary oil circuit swirl atomization assembly, carbon deposition prevention air cooling assembly 27, gaseous fuel nozzle 19, detachable compression and fixing assembly; said main oil circuit joint 1 and auxiliary oil circuit joint 21 are installed with fuel oil The filter 3 and the stop ring 2; the check valve 5 structurally includes a plug cover 4, a gasket 6, a valve body 43, a ball seat 40, a check valve spring 41, and a check valve block 42; the main The oil circuit swirl atomization assembly includes the main oil circuit swirler 17, the main fuel flow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com