Chemical Looping Partial Oxidation Reforming Conversion Directly Coupled Fuel Cell Power Generation System

A fuel cell and chemical chain technology, applied in the field of chemical chain partial oxidation reforming transformation direct coupling fuel cell power generation system, can solve the problems of poor adaptability of carbon-containing fuels, achieve reduced carbon capture energy consumption, reduced exergy loss, and equipment The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

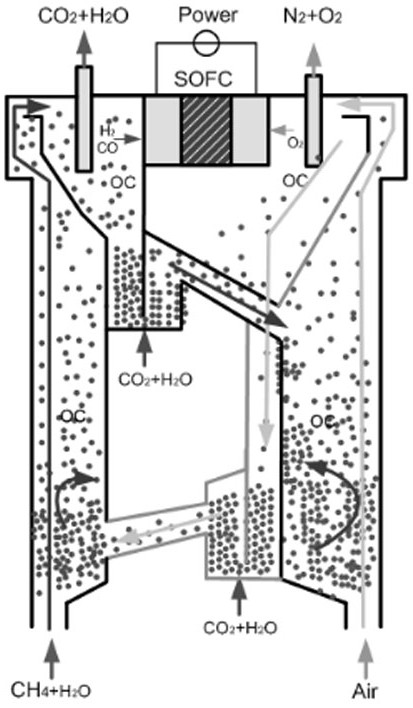

[0021] Such as figure 1 As shown, the present invention proposes to establish a coupling system of methane chemical chain reforming and solid oxide fuel cell, so that the hydrogen-rich gas generated by chemical chain reforming can be directly supplied to the fuel cell for power generation, and the direct heat and mass transfer between the two units can be realized. , waste heat recovery, reduce process exergy loss, significantly reduce electrode carbon deposition tendency, and realize carbon dioxide enrichment after electrochemical reaction.

[0022] The methane chemical chain partial oxidation reforming conversion process proposed by the implementation of the present invention makes the partial oxidation reforming conversion process be divided into two steps and carried out in two reactors. In the reduction reactor, methane reacts with the solid oxygen carrier to be partially oxidized, Reforming into hydrogen and carbon monoxide, and further reacting with water vapor to gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com