Isobutane dehydrogenation catalyst with spherical doughnut mesoporous material silica gel composite material as carrier, and preparation method and application of catalyst

A dehydrogenation catalyst and composite material technology, applied in the field of catalysts, can solve the problems of uneven dispersion of noble metal active components, poor catalytic activity and stability, and small average pore size, so as to reduce the risk of carbon deposition, improve catalytic performance, and improve selectivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] As mentioned above, the third aspect of the present invention provides the isobutane dehydrogenation catalyst prepared by the aforementioned preparation method and the application of the aforementioned isobutane dehydrogenation catalyst in the production of isobutene from isobutane dehydrogenation, wherein the The method for preparing isobutene from isobutane dehydrogenation comprises: dehydrogenating isobutane in the presence of a catalyst and hydrogen.

[0070] When the isobutane dehydrogenation catalyst prepared by the method provided by the invention is used to catalyze isobutane dehydrogenation to produce isobutene, both the conversion rate of isobutane and the selectivity of isobutene can be greatly improved.

[0071] According to the present invention, in order to increase the conversion rate of isobutane and prevent coking of the catalyst, preferably, the molar ratio of the amount of isobutane to the amount of hydrogen used is 0.5-1.5:1.

[0072] In the present ...

Embodiment 1

[0080] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

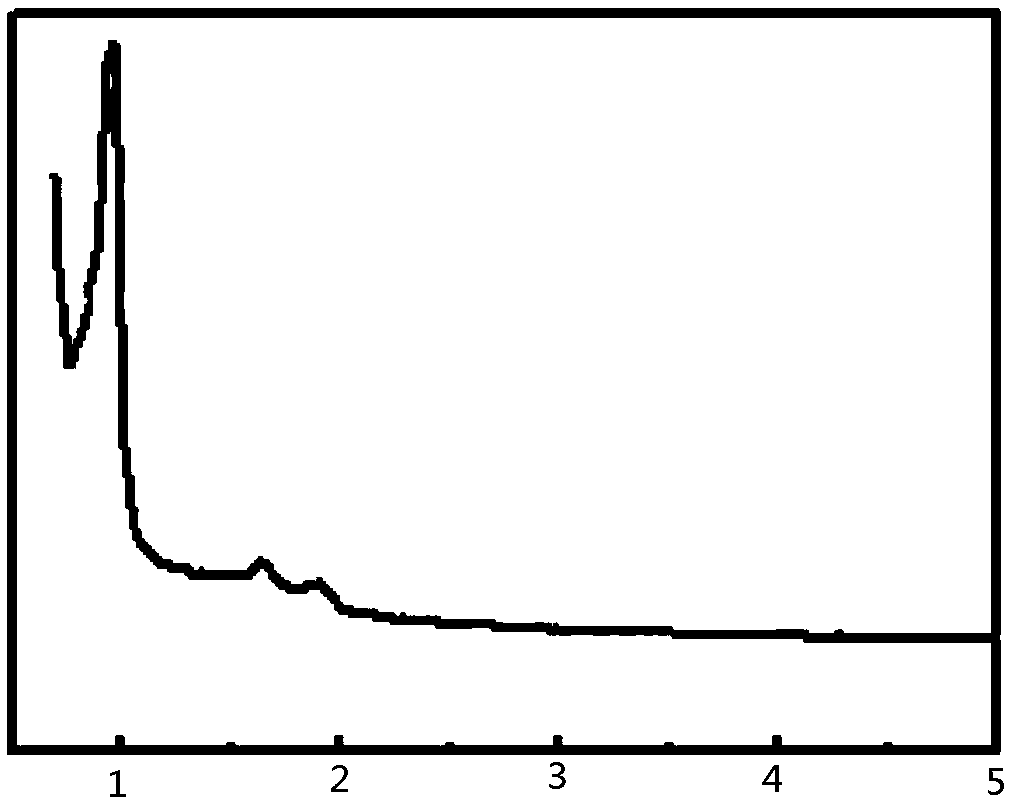

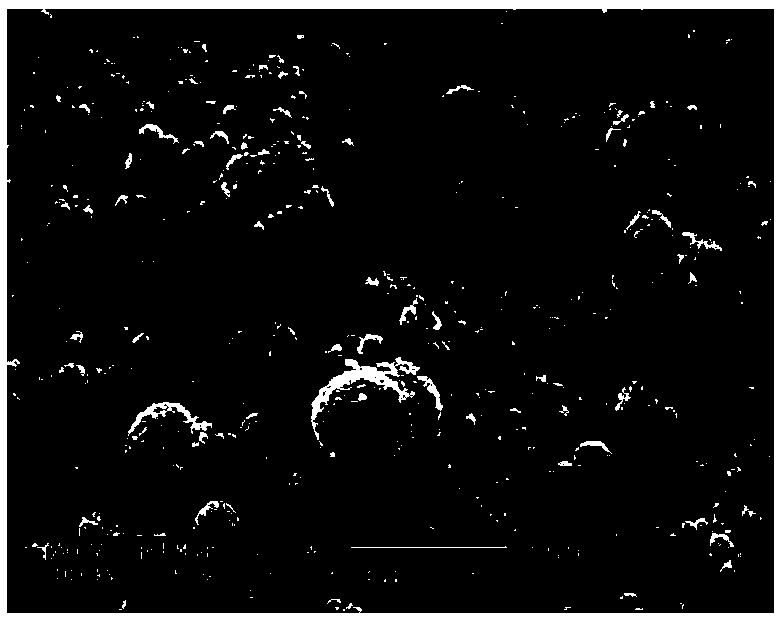

[0081] (1) Preparation of spherical donut mesoporous silica gel composite carrier

[0082] Add 2g of triblock copolymer template agent P123 and 15g of N,N-dimethylformamide (DMF) into a solution of 11.2g of 37% hydrochloric acid and 64mL of water, mix and stir until P123 is completely dissolved; then add 4.45g Ethyl orthosilicate was slowly added dropwise to the above solution at a rate of 1 g / min, stirred for 24 hours at a temperature of 40°C with a mechanical stirring rate of 350 r / min, and then the obtained solution was transferred to a polytetrafluoroethylene lining crystallize at 90°C for 24 hours, then filter and wash with deionized water for 4 times until the pH of the donut mesoporous material filter cake is 7, and then suction filter to obtain a two-dimensional hexagonal pore distribution structure Donut mesoporous material filter cake A1;

[0083] The wate...

Embodiment 2

[0102] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0103] (1) Preparation of spherical donut mesoporous silica gel composite carrier

[0104] Add 2g of triblock copolymer template agent P123 and 17.6g of N,N-dimethylformamide (DMF) to a solution of 11.2g of 37% hydrochloric acid and 64mL of water, mix and stir until P123 is completely dissolved; then add 6.68g Ethyl orthosilicate was slowly added dropwise to the above solution at a rate of 1 g / min, stirred for 24 hours at a temperature of 40°C with a mechanical stirring rate of 350 r / min, and then the obtained solution was transferred to a polytetrafluoroethylene lining crystallized at 120°C for 20 hours, then filtered and washed 4 times with deionized water until the pH of the donut mesoporous material filter cake was 7, and then suction filtered to obtain a two-dimensional hexagonal pore distribution structure Donut mesoporous material filter cake A2;

[0105] Con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com