Non-noble metal propane dehydrogenation catalyst taking modified spherical doughnut mesoporous material silica gel composite material as carrier, preparation method and application thereof

A dehydrogenation catalyst and non-precious metal technology, applied in metal/metal oxide/metal hydroxide catalyst, carbon compound catalyst, catalyst activation/preparation, etc., can solve the problems of environmental pollution, high preparation cost, etc., and achieve high selectivity , Reduce preparation cost, good catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

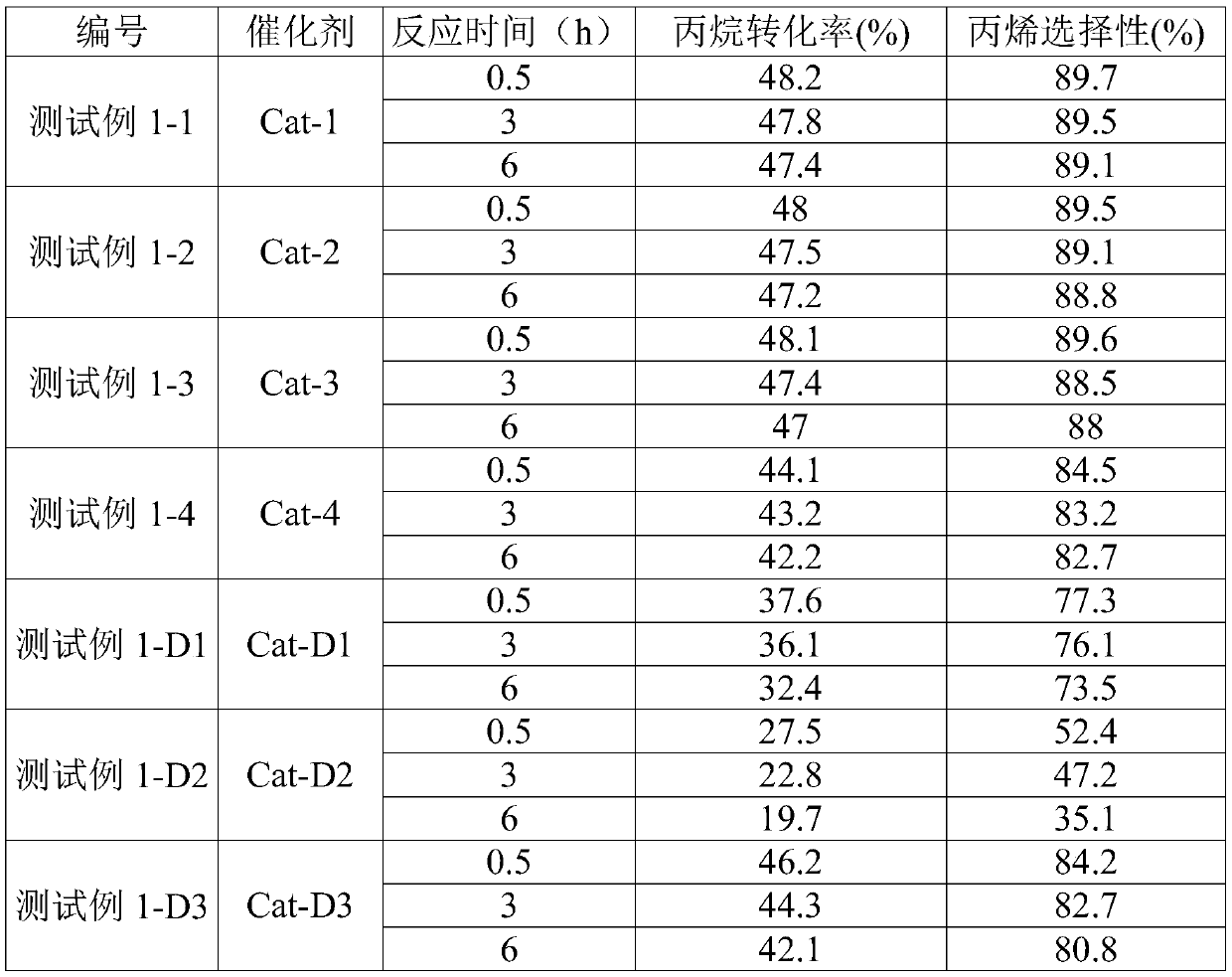

Examples

Embodiment 1

[0080] This example is used to illustrate the non-noble metal-based propane dehydrogenation catalyst and its preparation method.

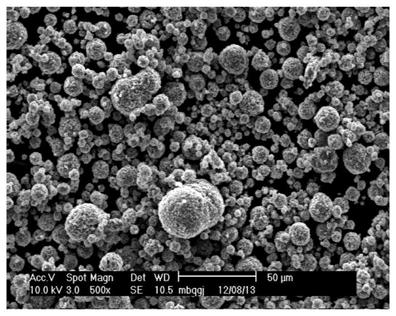

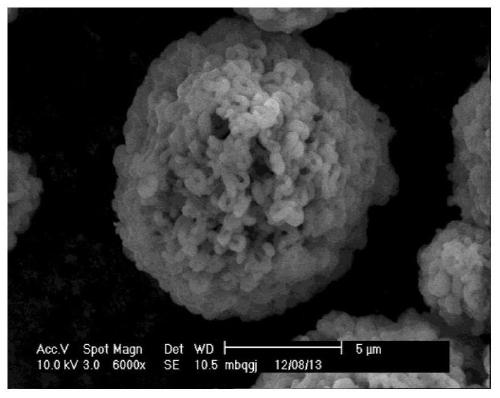

[0081] (1) Preparation of spherical donut mesoporous silica gel composites

[0082] Add 2g of triblock copolymer template agent P123 and 15g of N,N-dimethylformamide (DMF) into a solution of 11.2g of 37% hydrochloric acid and 64mL of water, mix and stir until P123 is completely dissolved; then add 4.45g Ethyl orthosilicate was slowly added dropwise to the above solution at a rate of 1 g / min, stirred for 24 hours at a temperature of 40°C with a mechanical stirring rate of 350 r / min, and then the obtained solution was transferred to a polytetrafluoroethylene lining crystallize at 90°C for 24 hours, then filter and wash with deionized water for 4 times until the pH of the donut mesoporous material filter cake is 7, and then suction filter to obtain a two-dimensional hexagonal pore distribution structure Donut mesoporous material filter cake A1;

[0...

Embodiment 2

[0099] This example is used to illustrate the non-noble metal-based propane dehydrogenation catalyst and its preparation method.

[0100] (1) Preparation of spherical donut mesoporous silica gel composites

[0101] Add 2g of triblock copolymer template agent P123 and 17.6g of N,N-dimethylformamide (DMF) to a solution of 11.2g of 37% hydrochloric acid and 64mL of water, mix and stir until P123 is completely dissolved; then add 6.68 Add 1 g of tetraethyl orthosilicate slowly to the above solution dropwise at a rate of 1 g / min, stir for 24 h at a temperature of 40°C with a mechanical stirring rate of 350 r / min, and then transfer the obtained solution into polytetrafluoroethylene In a lined reactor, crystallize at 120°C for 20h, then filter and wash with deionized water 4 times until the pH of the donut mesoporous material filter cake is 7, and then suction filter to obtain a two-dimensional hexagonal pore distribution Structured donut mesoporous material filter cake A2;

[0102...

Embodiment 3

[0115] This example is used to illustrate the non-noble metal-based propane dehydrogenation catalyst and its preparation method.

[0116] (1) Preparation of spherical donut mesoporous silica gel composites

[0117] Add 2g of triblock copolymer template agent P123 and 7.56g of N,N-dimethylformamide (DMF) into a solution of 11.2g of 37% hydrochloric acid and 64mL of water, mix and stir until P123 is completely dissolved; then add 3.6 Add 1 g of tetraethyl orthosilicate slowly to the above solution dropwise at a rate of 1 g / min, stir for 24 h at a temperature of 40°C with a mechanical stirring rate of 350 r / min, and then transfer the obtained solution into polytetrafluoroethylene In a lined reactor, crystallize at 100°C for 22h, then filter and wash with deionized water 4 times until the pH of the bagel mesoporous material filter cake is 7, and then suction filter to obtain a two-dimensional hexagonal pore distribution Structured donut mesoporous material filter cake A3;

[011...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com