Isobutane dehydrogenation catalyst and preparation method thereof and method for preparing isobutene from isobutane dehydrogenation

A dehydrogenation catalyst, isobutane technology, applied in catalyst activation/preparation, catalyst, molecular sieve catalyst and other directions, can solve the problems of uneven dispersion of precious metal active components, poor catalytic performance, etc., to achieve low cost, high selectivity, high Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

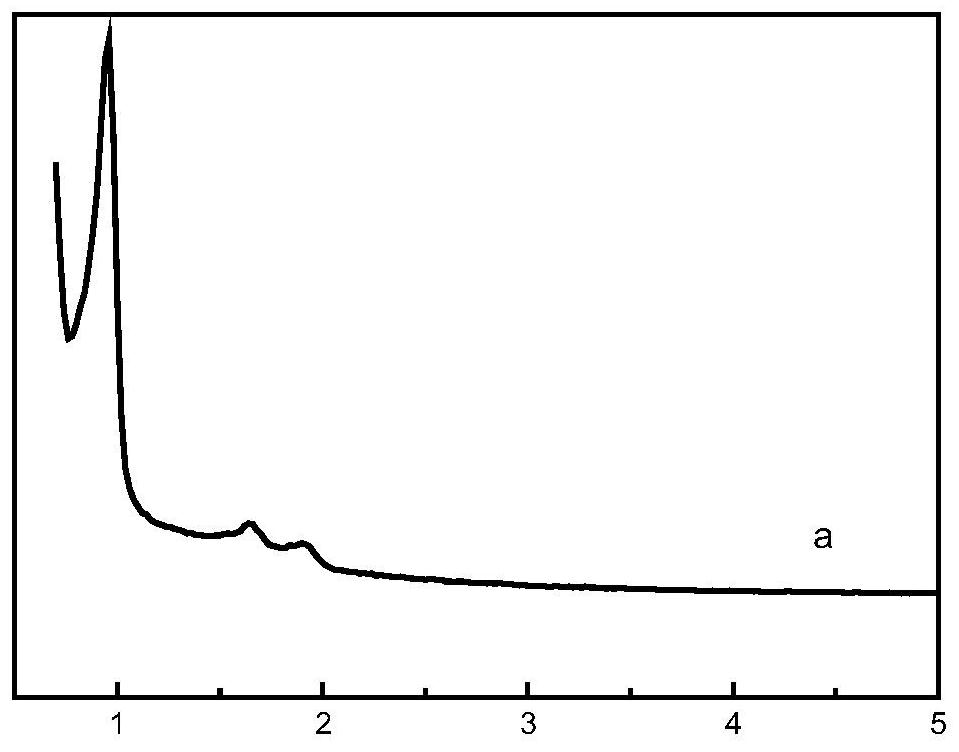

[0040] The present invention has no special limitation on the conditions of the first mixing contact, for example, the conditions of the first mixing contact include: the temperature can be 10-60°C, preferably 25-60°C; the time can be 10-72 hours , preferably 10-30 hours; the pH value can be 1-7, preferably 3-6. In order to be more conducive to uniform mixing among the various substances, according to a preferred embodiment of the present invention, the first mixing and contacting is performed under stirring conditions.

[0041] The present invention has no special limitation on the conditions of crystallization, and the conditions of crystallization can be conventional choices in this field. For example, the conditions of crystallization can include: the temperature is 30-150°C, and the time is 10- 72 hours. Preferably, the crystallization conditions include: a temperature of 40-100° C. and a time of 20-40 hours. The crystallization is carried out by a hydrothermal crystall...

Embodiment 1

[0086] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

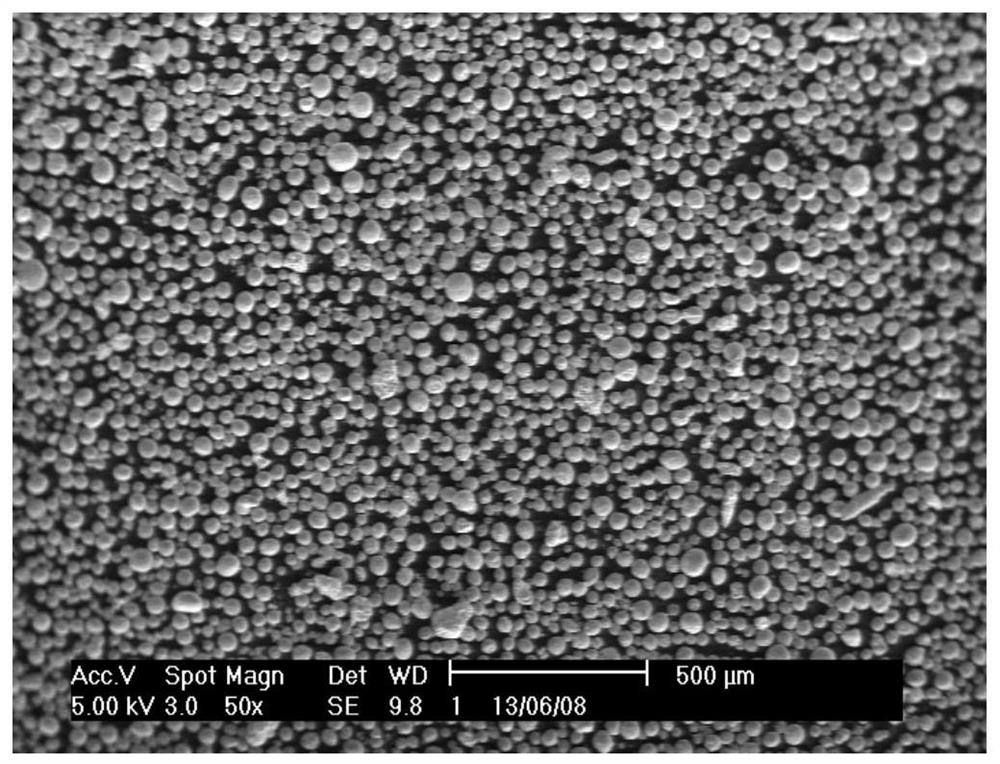

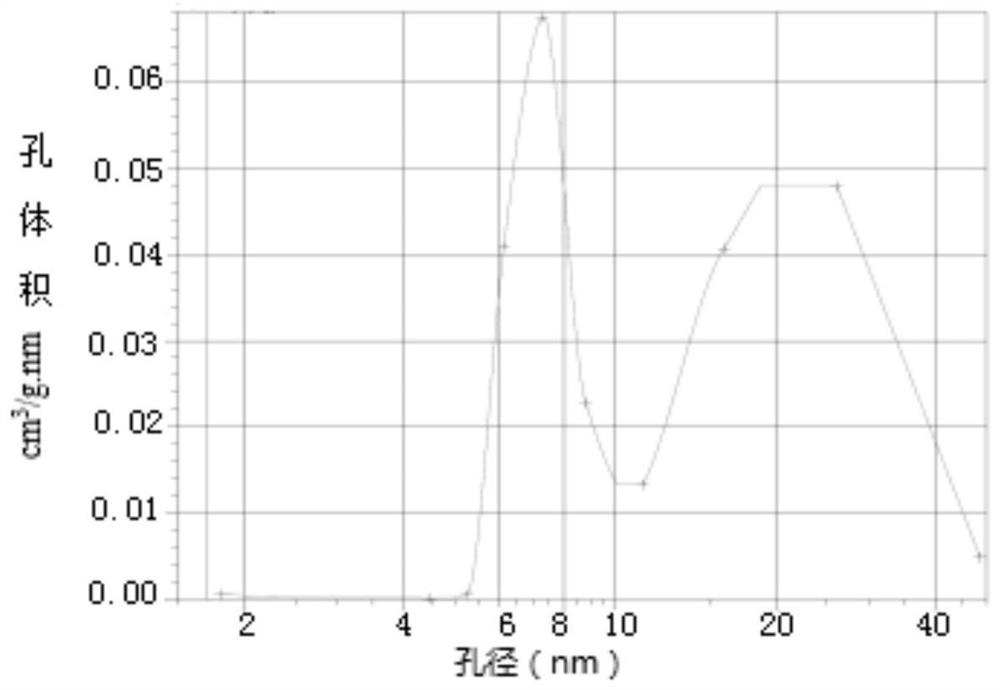

[0087] (1) Preparation of one-dimensional straight-through channel double-hole spherical mesoporous composite material (carrier)

[0088] 2.0 grams of P123 (the substance whose registration number is 9003-11-6 in the American Chemical Abstracts, its average molecular weight Mn=5800) and 15 grams of N,N-dimethylformamide (DMF) were added to 11.2 grams of 37% In a solution of hydrochloric acid and 64ml of water, stir at 40°C until P123 is completely dissolved; then add 4.45 grams of tetraethyl orthosilicate to the above solution and stir at 40°C for 24 hours, then transfer the solution to the reaction of the polytetrafluoroethylene lining In the kettle, crystallize in an oven at 60°C for 24 hours, then filter and wash to obtain the mesoporous material filter cake A1;

[0089] With the water glass of weight concentration 15% and the sulfuric acid solution of weight conc...

Embodiment 2

[0106] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0107] (1) Preparation of one-dimensional through-channel double-hole spherical mesoporous composites

[0108] 2.0 grams of P123 and 13.84 grams of N,N-dimethylformamide (DMF) were added to a solution of 16.5 grams of 37% by weight hydrochloric acid and 73ml of water, and stirred at 25°C until P123 was completely dissolved; then 6.75g (0.09 mol) ethyl orthosilicate was added to the above solution and stirred at 60° C. for 1 hour, and suction filtered to obtain the filter cake A2 of the mesoporous material.

[0109] Concentration is that the water glass of 15% by weight and the sulfuric acid solution of 12% by weight are mixed uniformly by water glass and sulfuric acid weight ratio after being 4:1, carry out stirring reaction at 40 ℃ for 1.5 hours, and the reaction product that obtains is used Sulfuric acid with a concentration of 98% by weight was used to adjust the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com