Isobutane dehydrogenation catalyst and preparation method thereof, and method for producing isobutene from isobutane dehydrogenation

A dehydrogenation catalyst and isobutane technology, which is applied in the field of isobutane dehydrogenation catalyst and isobutane dehydrogenation to isobutene, can solve the problems of poor catalytic activity and stability, uneven dispersion of precious metal active components, etc., and achieve stability Good performance, reduce the risk of carbon deposition, and the effect of easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

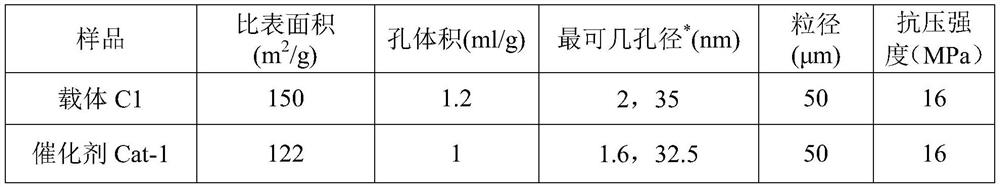

[0075] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0076] (1) Preparation of carrier

[0077] Hexadecyltrimethylammonium bromide and tetraethyl orthosilicate are added into the ammonia solution with a concentration of 25% by weight, wherein the addition of ethyl orthosilicate is 1g, and according to the molar feed ratio, ethyl orthosilicate Ester: cetyltrimethylammonium bromide: ammonia water (25%): deionized water = 1: 0.37: 2.8: 142, stirred at 80°C until dissolved, suction filtered the solution and obtained mesoporous material Cake, washing the filter cake to a pH of 7 to obtain a mesoporous molecular sieve filter cake A1 with a two-dimensional hexagonal pore structure;

[0078] Concentration is 15% by weight of water glass and concentration of 12% by weight of sulfuric acid solution and n-butanol, and according to water glass: sulfuric acid: n-butanol weight ratio = 5: 1: 1 fully reacted at 30 ℃ for 1.5h, The pH...

Embodiment 2

[0105] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0106] (1) Preparation of carrier

[0107] Hexadecyltrimethylammonium bromide and tetraethyl orthosilicate are added into the ammonia solution with a concentration of 25% by weight, wherein the addition of ethyl orthosilicate is 1g, and according to the molar feed ratio, ethyl orthosilicate Ester: cetyltrimethylammonium bromide: ammonia water (25%): deionized water = 1: 0.5: 3.5: 150, stirred at 80°C until dissolved, suction filtered the solution to obtain a mesoporous material filter Cake, washing the filter cake to a pH of 7 to obtain a mesoporous molecular sieve filter cake A2 with a two-dimensional hexagonal pore structure;

[0108] Concentration is 15% by weight of water glass and concentration of 12% by weight of sulfuric acid solution and n-butanol, and according to water glass: sulfuric acid: n-butanol weight ratio = 6: 1: 1 to fully react at 60 ℃ for 1h, use...

Embodiment 3

[0118] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0119] (1) Preparation of carrier

[0120] Hexadecyltrimethylammonium bromide and tetraethyl orthosilicate are added into the ammonia solution with a concentration of 25% by weight, wherein the addition of ethyl orthosilicate is 1g, and according to the molar feed ratio, ethyl orthosilicate Ester: Hexadecyltrimethylammonium bromide: Ammonia water (25%): Deionized water = 1:0.4:3:130, stirred at 60°C until dissolved, suction filtered the solution and obtained mesoporous material filter Cake, washing the filter cake to a pH of 7 to obtain a mesoporous molecular sieve filter cake A3 with a two-dimensional hexagonal pore structure;

[0121] Concentration is that the water glass of 15% by weight and the concentration of 12% by weight of sulfuric acid solution and n-butanol, and by water glass: sulfuric acid: n-butanol weight ratio=3:1:1 fully react at 10 ℃ for 5h, use Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com