Isobutane dehydrogenation catalyst employing silica gel as support, preparation method for isobutane dehydrogenation catalyst and application of isobutane dehydrogenation catalyst

A dehydrogenation catalyst, isobutane technology, applied in catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of uneven dispersion of precious metal active components, poor catalytic activity and stability, and reduce the risk of carbon deposition. , Low preparation cost, good product repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

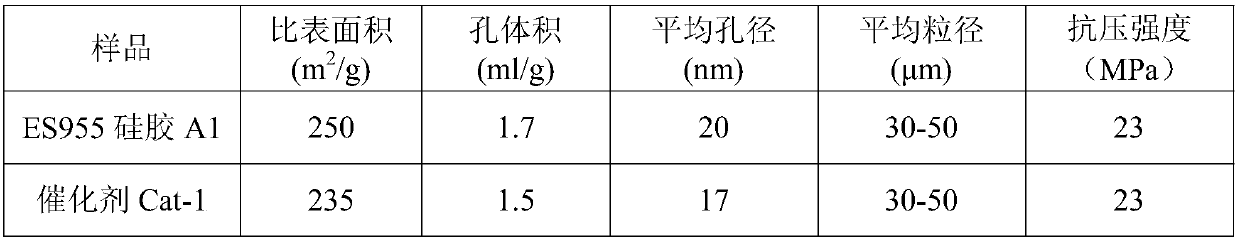

[0071] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0072] The ES955 silica gel A1 was calcined at 400° C. for 5 hours under the protection of nitrogen for thermal activation treatment to remove part of the hydroxyl groups and residual moisture of the ES955 silica gel A1 to obtain the thermally activated ES955 silica gel carrier B1.

[0073] 0.080g H 2 PtCl 6 ·6H 2 O and 0.457g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of deionized water to obtain a mixture solution, and 10 g of the heat-activated ES955 silica gel carrier B1 obtained after the aforementioned heat-activation treatment was immersed in the mixture solution, and after immersion at 25°C for 5 hours, evaporated with a rotary evaporator. The solvent water in the system was removed to obtain a solid product, which was placed in a drying oven at a temperature of 120° C. for 3 hours. Then in the muffle furnace, the temperature is 600 ℃ roasting 6h to obta...

Embodiment 2

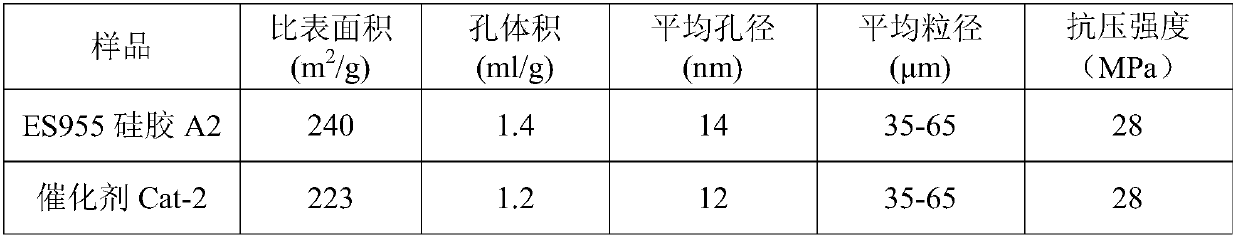

[0088] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0089] The ES955 silica gel A2 was calcined at 800° C. for 3 hours under the protection of nitrogen for thermal activation treatment to remove part of the hydroxyl groups and residual moisture of the ES955 silica gel A2 to obtain the thermally activated ES955 silica gel carrier B2.

[0090] 0.080g H 2 PtCl 6 ·6H 2 O and 0.457g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of deionized water to obtain a mixture solution, and 10 g of the heat-activated ES955 silica gel carrier B2 obtained after the aforementioned heat-activation treatment was immersed in the mixture solution, and after immersion at 25°C for 5 hours, evaporated with a rotary evaporator. The solvent water in the system was removed to obtain a solid product, which was placed in a drying oven at a temperature of 120° C. for 3 hours. Then in the muffle furnace, the temperature is 600 ℃ roasting 6h to obta...

Embodiment 3

[0096] The ES955 silica gel A3 was calcined at 600° C. for 4 hours under the protection of nitrogen for thermal activation treatment to remove part of the hydroxyl groups and residual moisture of the ES955 silica gel A3 to obtain the thermally activated ES955 silica gel carrier B3.

[0097] 0.080g H 2 PtCl 6 ·6H 2 O and 0.457g Zn(NO 3 ) 2 ·6H 2O was dissolved in 100ml of deionized water to obtain a mixture solution, and 10 g of the heat-activated ES955 silica gel carrier B3 obtained after the aforementioned heat-activation treatment was immersed in the mixture solution. The solvent water in the system was removed to obtain a solid product, which was placed in a drying oven at a temperature of 120° C. for 3 hours. Then in the muffle furnace, the temperature is 600 ℃ roasting 6h to obtain the isobutane dehydrogenation catalyst Cat-3 (based on the total weight of the isobutane dehydrogenation catalyst Cat-3, the content of the Pt component is based on the Pt element is 0.3%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com