A method and device for producing natural gas from low-hydrogen carbon bilan coke tail gas

A technology of semi-coke tail gas and low hydrogen carbon, which is applied in the field of natural gas production from semi-coke tail gas, can solve problems such as difficulty in ensuring stability, difficult temperature control, and no industrialized cases of semi-coke preparation of natural gas, so as to avoid equipment and operation and improve utilization Efficiency and the effect of reducing the risk of carbon accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

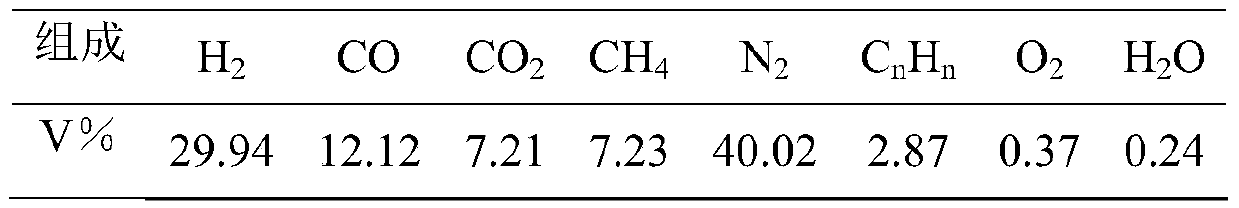

[0056] The hydrogen-to-carbon ratio of the blue-coke tail gas in the table below is 0.9891:

[0057]

[0058] Note: The semi-coke tail gas also contains impurities such as tar, benzene, naphthalene, phenol, dust, sulfide, ammonia, and heavy metals.

[0059] The semi-coke tail gas with a molar flow rate of 2000kmol / h is first pressurized to 3.0MPa, heat exchanged to 160°C, and desulfurized after entering the purification system, so that the sulfur content of the purified semi-coke tail gas is ≤20ppb.

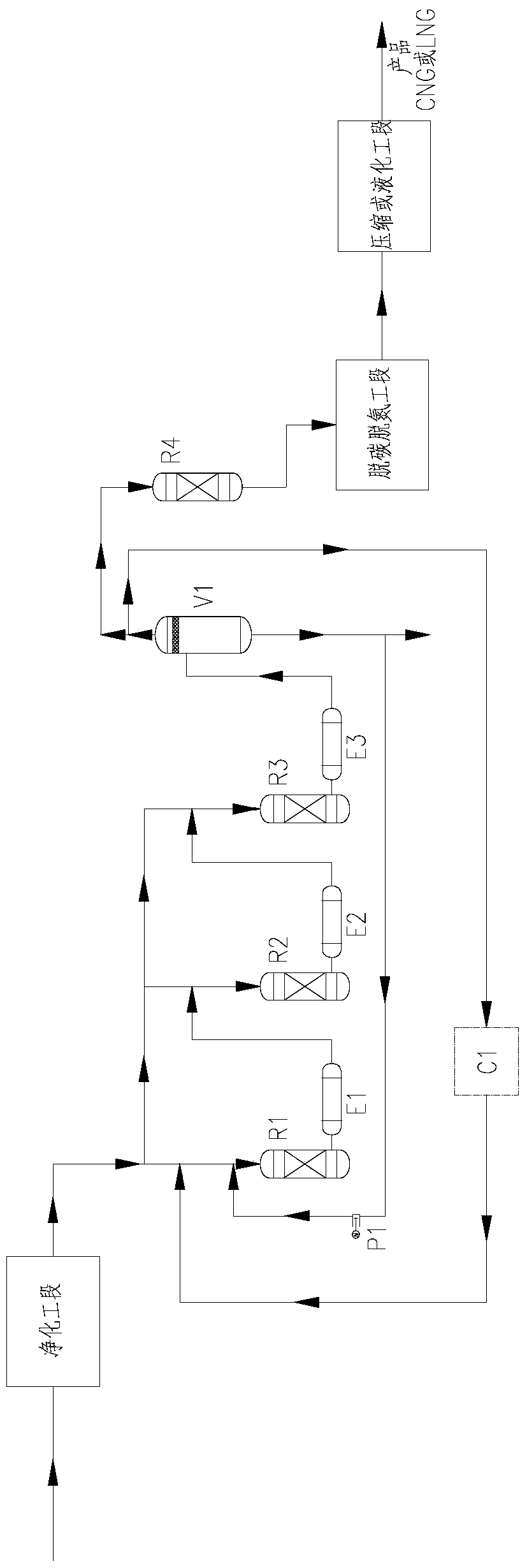

[0060] Then the purified semi-coke tail gas is divided into three shares according to the volume ratio of 8:5:7, the first 797kmol / h gas and 170°C, 530kmol / h cycle gas (as shown in the figure, the cycle gas comes from R3 After the outlet gas) is mixed, it is mixed with 203kmol / h of circulating water (as shown in the figure, the circulating water comes from the reaction production water, after V1 is separated, a part is used for circulation), and the water content of...

Embodiment 2

[0063] The hydrogen-to-carbon ratio of the blue-coke tail gas in the table below is 0.7595:

[0064]

[0065] Note: The semi-coke tail gas also contains impurities such as tar, benzene, naphthalene, phenol, dust, sulfide, ammonia, and heavy metals.

[0066] The semi-coke tail gas with a molar flow rate of 2000kmol / h is first pressurized to 3.0MPa, heat exchanged to 160°C, and desulfurized after entering the purification system, so that the sulfur content of the purified semi-coke tail gas is ≤20ppb.

[0067] Then the purified semi-coke tail gas is divided into three shares according to the volume ratio of 18:14:18, the first 718kmol / h gas and the 170°C, 396kmol / h cycle gas (as shown in the figure, the cycle gas comes from R3 After the outlet gas) is mixed, it is mixed with 196kmol / h of circulating water (as shown in the figure, the circulating water comes from the reaction production water, after V1 is separated, a part is used for circulation), and the water con...

Embodiment 3

[0070] The hydrogen-to-carbon ratio of the blue-coke tail gas in the table below is 0.6027:

[0071]

[0072] Note: The semi-coke tail gas also contains impurities such as tar, benzene, naphthalene, phenol, dust, sulfide, ammonia, and heavy metals.

[0073] The semi-coke tail gas with a molar flow rate of 2000kmol / h is first pressurized to 3.0MPa, heat exchanged to 160°C, and desulfurized after entering the purification system, so that the sulfur content of the purified semi-coke tail gas is ≤20ppb.

[0074] Then the purified semi-coke tail gas is divided into three shares according to the volume ratio of 4:3:3, the first 799kmol / h gas and 170°C, 208kmol / h cycle gas (as shown in the figure, the cycle gas comes from R3 After the outlet gas) is mixed, it is mixed with 210kmol / h circulating water (as shown in the figure, the circulating water comes from the reaction production water, after V1 is separated, a part is used for circulation), and the water content of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com