Non-noble metal isobutane dehydrogenation catalyst taking rod-like mesoporous molecular sieve as carrier, preparation method and applications thereof

A technology of dehydrogenation catalyst and mesoporous molecular sieve, which is applied in the direction of molecular sieve catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc. It can solve the problems of high preparation cost and environmental pollution, and achieve high selectivity and high alkane conversion rate , the effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] Preferably, in step (a), the mixing and contacting conditions include: a temperature of 25-60° C., a time of more than 25 minutes, and a pH of 1-6. In order to be more conducive to the uniform mixing of various substances, according to a preferred embodiment of the present invention, the mixing and contacting is carried out under stirring conditions.

[0039] In the present invention, the amount of the template agent and the silicon source can be changed within a wide range, for example, the molar ratio of the template agent and the amount of the silicon source can be 1:10-90; preferably 1: 50-75.

[0040] In the present invention, the silicon source can be various silicon sources conventionally used in the art, preferably the silicon source is ethyl orthosilicate, methyl orthosilicate, propyl orthosilicate, sodium orthosilicate and At least one of silica sol, more preferably tetraethyl orthosilicate.

[0041] According to a preferred embodiment of the present inventi...

Embodiment 1

[0083] This example is used to illustrate the non-noble metal-based isobutane dehydrogenation catalyst and its preparation method.

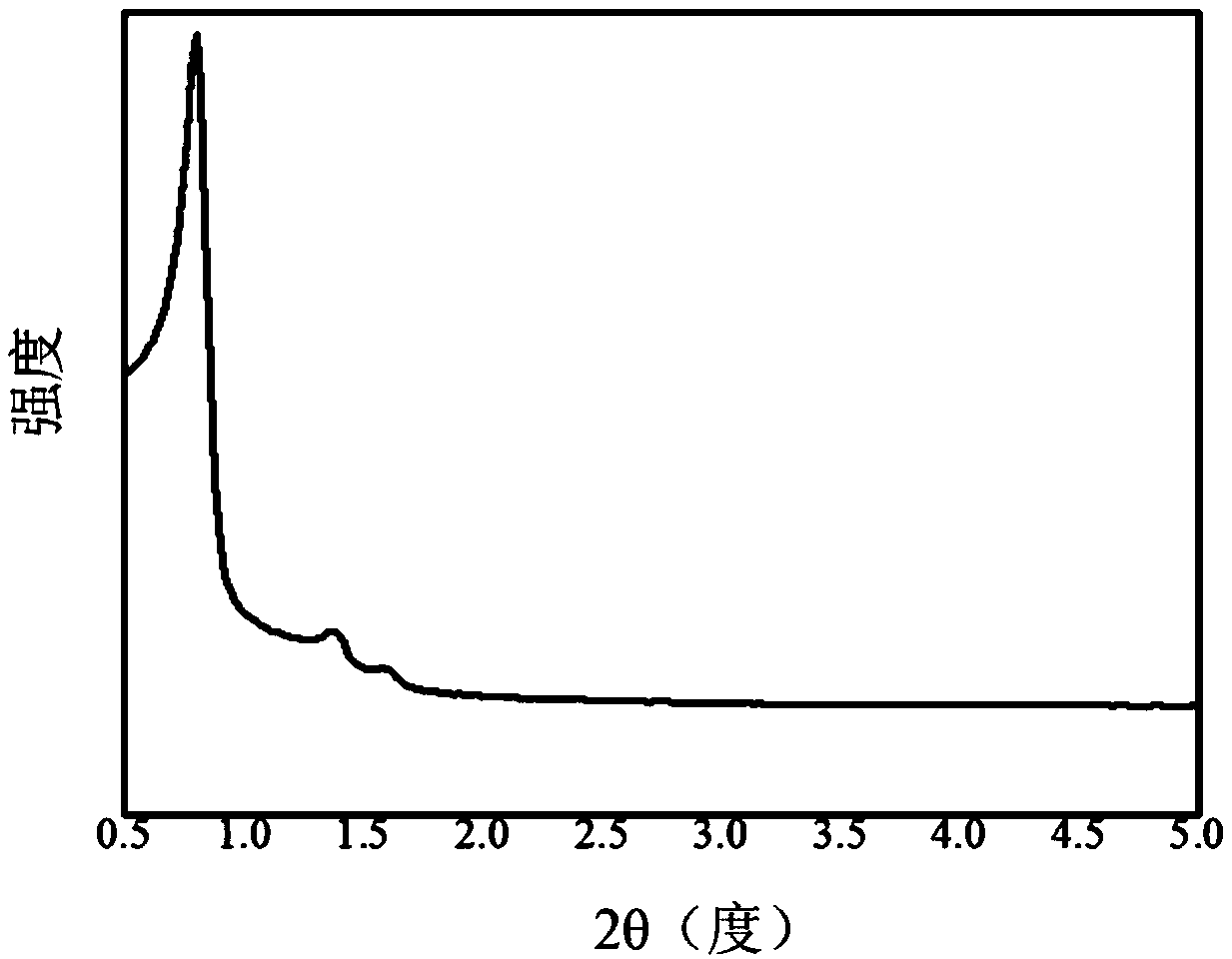

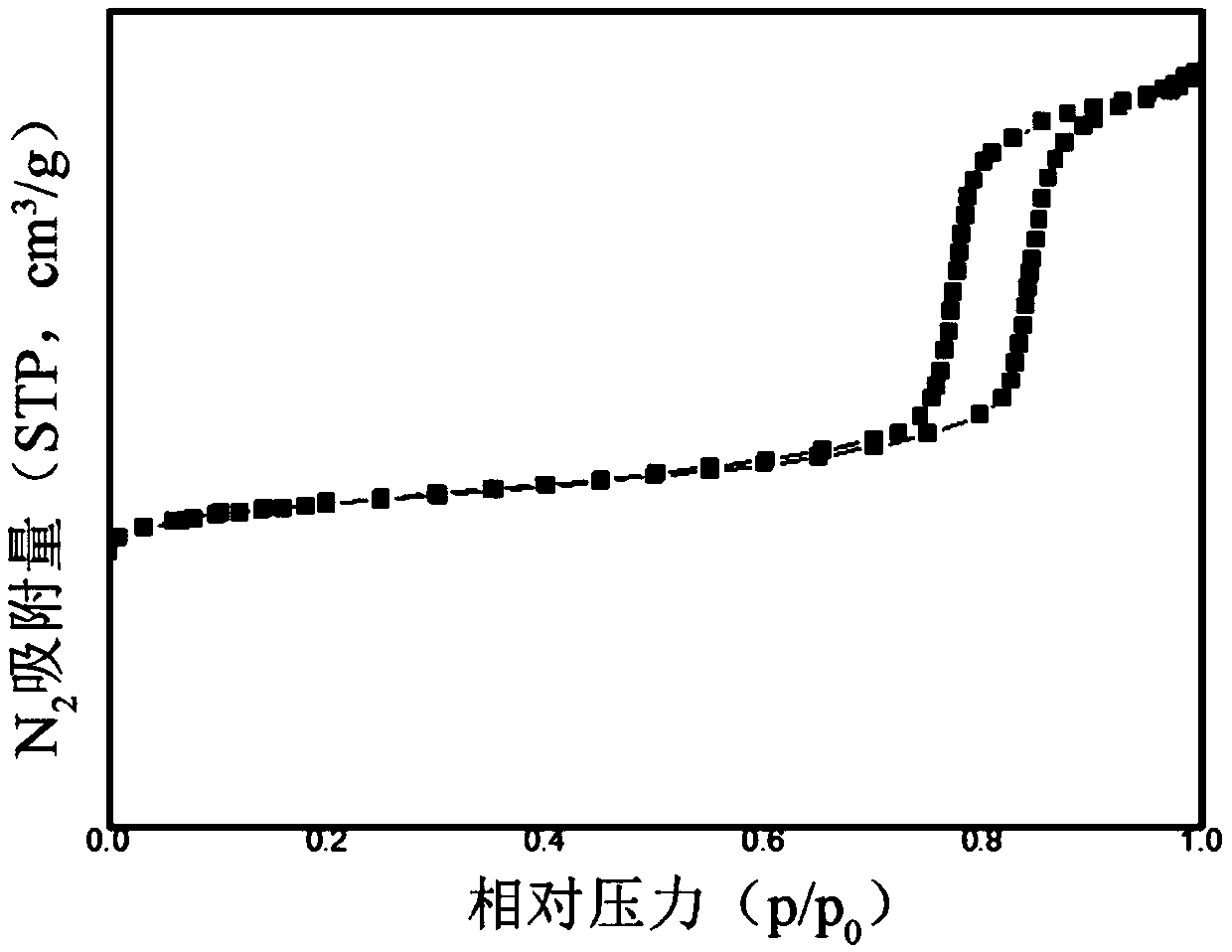

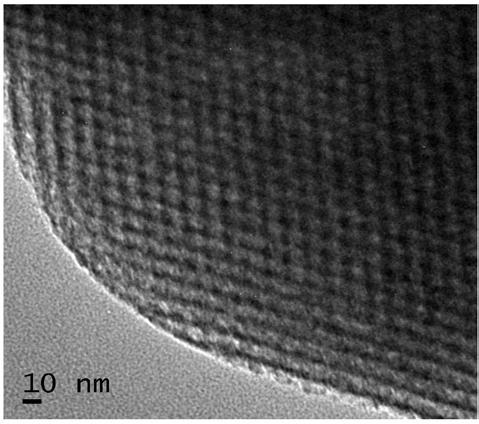

[0084] (1) Preparation of rod-shaped mesoporous molecular sieve carrier

[0085] Add 4g (0.0007mol) template agent P123 to a solution containing 37% by weight of hydrochloric acid (16.4mL) and water (128mL), and stir at 40°C until P123 is completely dissolved; then add 8.86g (0.042mol) orthosilicon Ethyl acetate was added to the above solution, stirred at 40°C for 24h, then the resulting solution was transferred to a Teflon-lined reactor, crystallized at 150°C for 24h, followed by filtration and deionized water Washing 4 times, then performing suction filtration and drying to obtain the raw powder of mesoporous material; washing the raw powder of mesoporous material with ethanol under reflux conditions for 24 hours, removing the template agent, and obtaining rod-shaped mesoporous molecular sieve carrier A1.

[0086] (2) Preparation of initial no...

Embodiment 2

[0100] This example is used to illustrate the non-noble metal-based isobutane dehydrogenation catalyst and its preparation method.

[0101] (1) Preparation of rod-shaped mesoporous molecular sieve carrier

[0102] Add 4g (0.0007mol) template agent P123 to a solution containing 37% by weight of hydrochloric acid (16.4mL) and water (128mL), stir at 40°C until P123 is completely dissolved; then add 10.9g (0.0525mol) orthosilicon Ethyl acetate was added to the above solution, stirred at 40°C for 24h, then the resulting solution was transferred to a polytetrafluoroethylene-lined reactor, crystallized at 180°C for 20h, followed by filtration and deionized water Washing 4 times, then performing suction filtration and drying to obtain the raw powder of mesoporous material; washing the raw powder of mesoporous material with ethanol under reflux conditions for 24 hours to remove the template agent to obtain rod-shaped mesoporous molecular sieve A2.

[0103] (2) Preparation of non-preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com