Aluminum oxide carrier and preparation method and application thereof

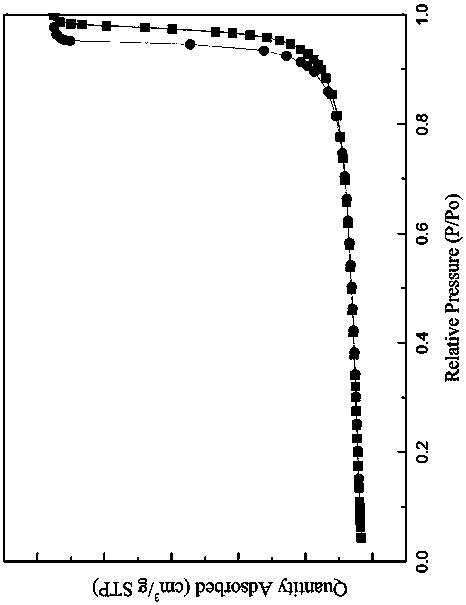

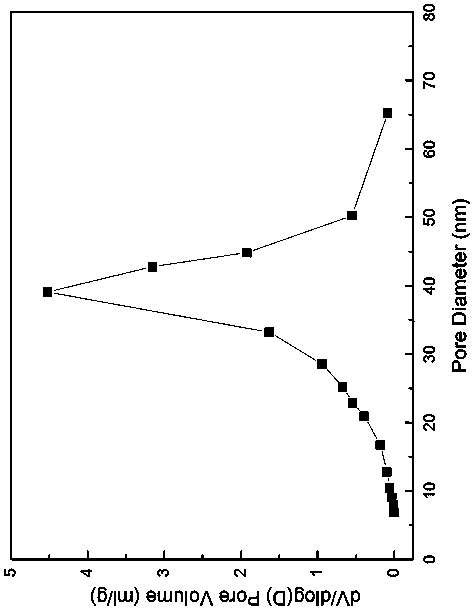

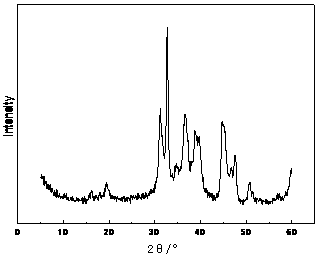

A technology of alumina carrier and alumina sol, which is applied in the direction of catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the uneven distribution of strength and non-concentrated pore size distribution of alumina carrier , Instable catalyst performance and other problems, to achieve the effect of concentrated pore distribution, not easy to porcelain, and avoid non-concentrated pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Aluminum sol preparation. Take 60 grams of pseudo-boehmite, 6 grams of methylcellulose, 4 grams of starch, 4 grams of hexamethylenetetramine, and 6 grams of urea, add an appropriate amount of deionized water and stir to form a suspension with a mass content of 25% alumina , continue to stir for 2 hours, slowly add 15.5 g of citric acid solution with a mass concentration of 25%, and stir at 35°C for 2 hours to form an alumina sol slurry;

[0058] (2) Aluminum sol molding. The oil phase of the hot oil column is liquid paraffin, the temperature of the oil bath is 85° C., the aperture of the drip nozzle is 1.5 mm, and the dripping speed is 2 drops / second. Drop the aluminum sol prepared in (1) into a hot oil column to form a ball, collect the formed pellets under the oil column, transfer to an aging kettle for aging at 120°C for 12 hours, then wash with water, and dry at 130°C for 8 hours;

[0059] (3) Thermal activation of the shaped carrier. Place the dried shaped c...

Embodiment 2

[0061] (1) Aluminum sol preparation. Take 45 grams of 10-mesh aluminum powder, slowly add 450ml of hydrochloric acid with a mass concentration of 30%, react at 85°C for 2.5 hours, add 6 grams of methylcellulose, 4 grams of starch, 4 grams of hexamethylenetetramine, and 6 grams of urea Stir after deionized water to form a suspension with a mass content of 35% alumina, and continue stirring for 2 hours to form alumina sol slurry;

[0062] (2) Aluminum sol molding. The oil phase of the hot oil column is liquid paraffin, the temperature of the oil bath is 95° C., the aperture of the drip nozzle is 2.0 mm, and the dripping speed is 3 drops / second. Drop the aluminum sol prepared in (1) into a hot oil column to form a ball, collect the formed pellets under the oil column, transfer to an aging kettle for aging at 150°C for 12 hours, then wash with water, and dry at 130°C for 8 hours;

[0063] (3) Thermal activation of the shaped carrier. Place the dried molded carrier in a high-tem...

Embodiment 3

[0065] (1) Take 70 grams of pseudoboehmite, 5 grams of polyacrylamide, 5 grams of methylcellulose, and 10 grams of urea, add an appropriate amount of deionized water and stir to form a suspension with a mass content of alumina of 35%, and continue Stir for 2 hours, slowly add 10 g of nitric acid solution with a mass concentration of 35%, and stir at 50°C for 10 hours to form an alumina sol slurry;

[0066] (2) Add 60 grams of boehmite and 20 grams of gibbsite to the aluminum sol prepared in (1), mix evenly, add 10 grams of asparagus powder, 2 grams of 35% nitric acid, mix and knead, and extrude , dried at 130°C for 8 hours;

[0067] (3) Place the dried shaped carrier in a high-temperature furnace, raise the temperature to 1050°C at a heating rate of 2°C / min and keep the temperature constant for 4 hours. ℃ respectively constant temperature 6h. The physical properties of the carrier are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com