KL molecular sieve loaded monatomic Pt and PtxFe cluster structure catalyst and preparation method and application thereof

A structural catalyst, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as reducing the effect of additives added, and insufficient contact between additives and Pt, and reducing the product. The generation of carbon, the simple and easy synthesis process, and the effect of uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

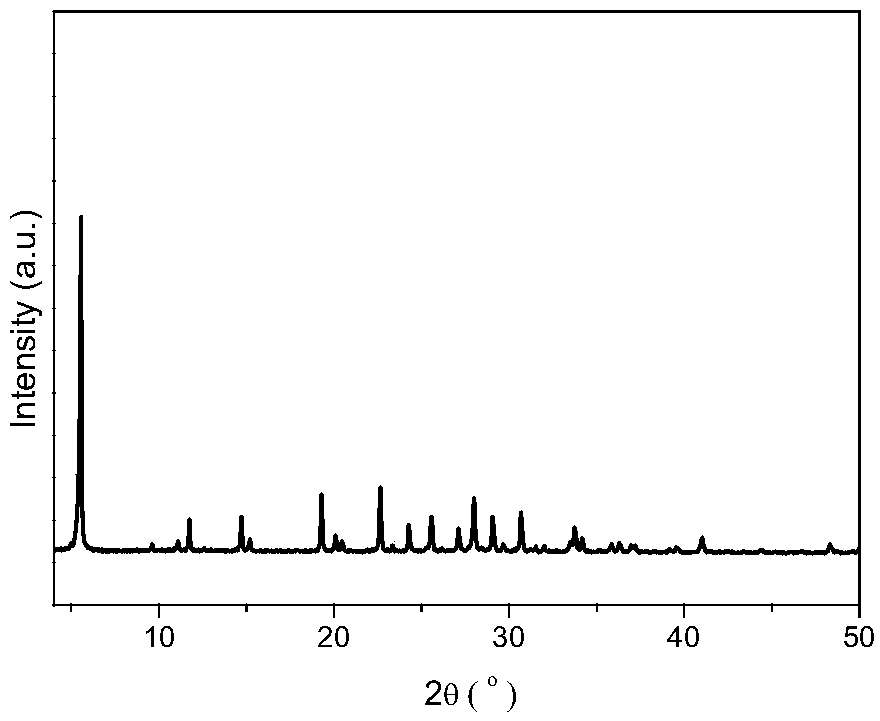

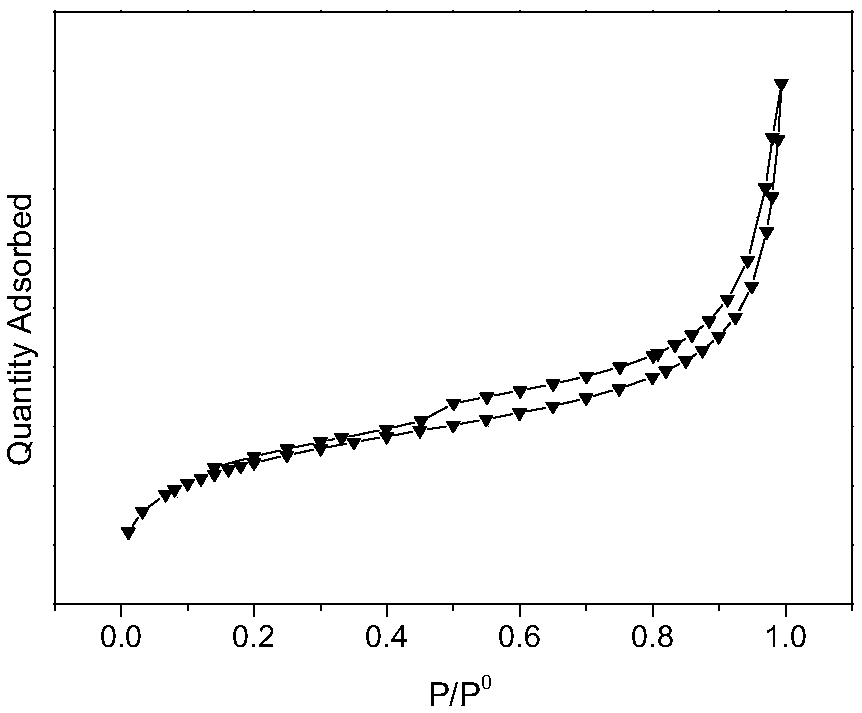

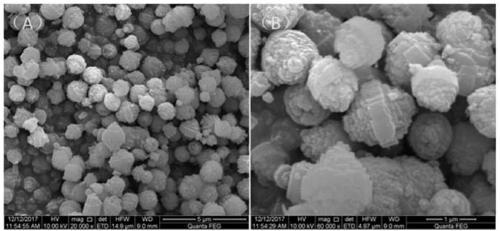

Embodiment 1

[0054] Take 3g of KL molecular sieve and disperse it in 50ml of absolute ethanol, mix it evenly and disperse it evenly on a quartz plate, dry it in the air at room temperature for 2 hours, and then transfer it to the reaction chamber of the atomic layer deposition equipment. The ALD deposition parameters set are: reaction Temperature 300°C; Reaction source: Iron source adopts ferrocene (Fe(Cp) 2 ) as the precursor, and the platinum source uses trimethyl-methylcyclopentadiene platinum (MeCpPtMe 3 ) is the precursor, and the oxidizing agent is O 3 . (Fe(Cp) 2 Temperature 90°C, MeCpPtMe 3 The temperature is 60°C, O 3 for room temperature. Carrier gas: 50sccm high-purity nitrogen; single cycle pulse, deposition and purge time: first (Fe(Cp) 2 The pulse time is 1s, the deposition time is 20s, and the purge time is 40s; then O 3 The pulse time is 1s, the response time is 20s, and the purge time is 40s. MeCpPtMe after Fe single cycle 3 The pulse time is 0.5s, the deposition ...

Embodiment 2

[0061] Take 3g of KL molecular sieve and disperse it in 50ml of absolute ethanol, mix it evenly and disperse it evenly on a quartz plate, dry it in the air at room temperature for 2 hours, and then transfer it to the reaction chamber of the atomic layer deposition equipment. The ALD deposition parameters set are: reaction Temperature 300°C; Reaction source: Iron source adopts ferrocene (Fe(Cp) 2 ) as the precursor, and the platinum source uses trimethyl-methylcyclopentadiene platinum (MeCpPtMe 3 ) is the precursor, and the oxidizing agent is O 3 . (Fe(Cp) 2 Temperature 90°C, MeCpPtMe 3 The temperature is 60°C, O 3 for room temperature. Carrier gas: 50sccm high-purity nitrogen; single-cycle pulse, deposition and purge time: first (Fe(Cp) 2 The pulse time is 1s, the deposition time is 20s, and the purge time is 40s; then O 3 The pulse time is 1s, the response time is 20s, and the purge time is 40s. MeCpPtMe after two cycles of Fe 3 The pulse time is 0.5s, the deposition...

Embodiment 3

[0063] Take 3g of KL molecular sieve and disperse it in 50ml of absolute ethanol, mix it evenly and disperse it evenly on a quartz plate, dry it in the air at room temperature for 2 hours, and then transfer it to the reaction chamber of the atomic layer deposition equipment. The ALD deposition parameters set are: reaction Temperature 300°C; Reaction source: Iron source adopts ferrocene (Fe(Cp) 2) as the precursor, and the platinum source uses trimethyl-methylcyclopentadiene platinum (MeCpPtMe 3 ) is the precursor, and the oxidizing agent is O 3 . (Fe(Cp) 2 Temperature 90°C, MeCpPtMe 3 The temperature is 60°C, O 3 for room temperature. Carrier gas: 50sccm high-purity nitrogen; single-cycle pulse, deposition and purge time: first (Fe(Cp) 2 The pulse time is 1s, the deposition time is 20s, and the purge time is 40s; then O 3 The pulse time is 1s, the response time is 20s, and the purge time is 40s. MeCpPtMe after three cycles of Fe 3 The pulse time is 0.5s, the depositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com